Intelligent new energy vehicle whole vehicle heat management system

A new energy vehicle and management system technology, applied in the field of intelligent new energy vehicle thermal management system, can solve the problems of high cost, unreasonable design, large space occupation, etc., to reduce working time, save installation space, and save energy Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

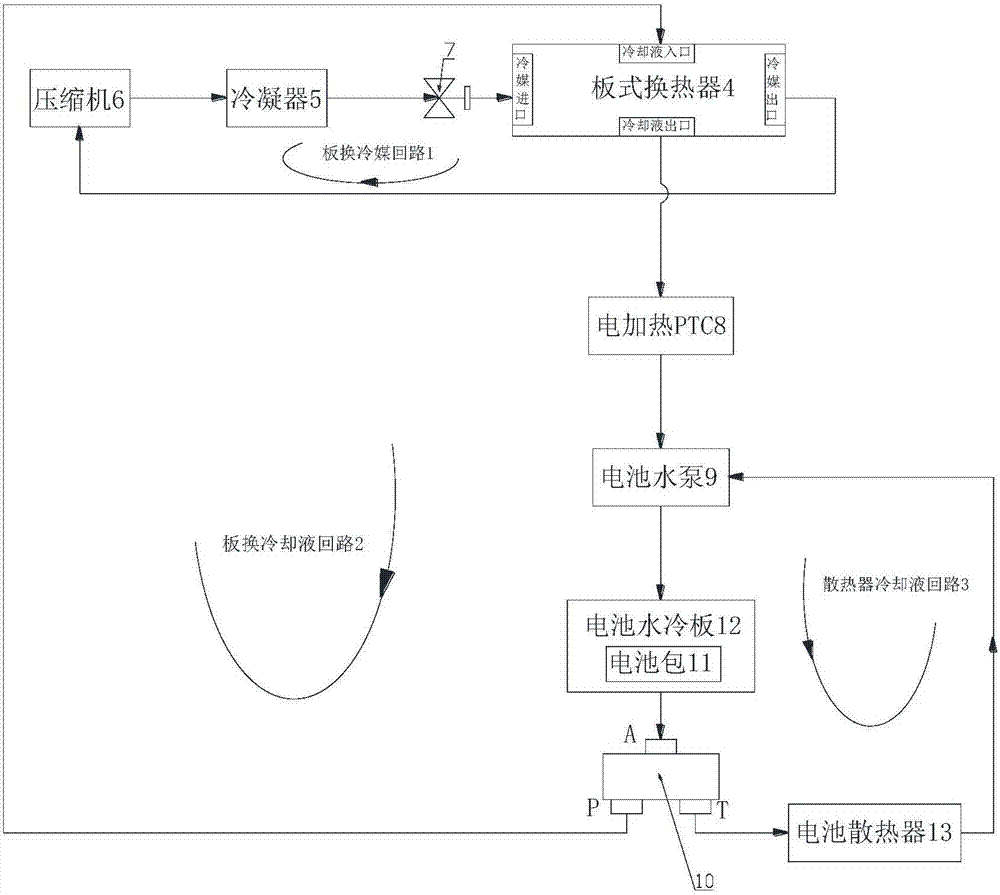

[0047] When the temperature reaches the set high temperature, for example, during the fast charging process, the battery pack 11 generates a large amount of heat, and the coolant near the battery water cooling plate 12 is in a high temperature state, and the coolant water temperature sensor transmits the sensed temperature signal to the ECU controller . The plate exchange refrigerant circuit 1 composed of the compressor 6, the condenser 5, and the plate heat exchanger 4 refrigerant channels starts to work under the control of the ECU controller to complete the refrigeration cycle. At this time, the P port of the two-position three-way solenoid valve 10 is turned on, and the T port is closed. The coolant inlet of the heat exchanger 4 flows out from the coolant outlet of the plate heat exchanger 4, and through the action of the plate heat exchanger 4, the high-temperature coolant and the low-temperature refrigerant realize heat conversion, so the cooling from the plate heat exch...

Embodiment 2

[0049] When the calorific value of the battery is small, such as during the normal driving of the vehicle, the plate replacement refrigerant circuit 1 and the plate replacement coolant circuit 2 do not work, and the ECU controller only activates the radiator coolant circuit 3. At this time, the P port of the two-position three-way solenoid valve 10 is closed, and the T port is turned on. The battery water pump 9 flows the relatively high-temperature coolant in the battery water-cooling plate 12 into the battery radiator 13 through the T port of the two-position three-way solenoid valve 10, and the battery radiator 13 is arranged along the axis of the cooling fan. The natural wind conducts heat exchange to realize cooling, and the cooled coolant flows into the battery water pump 9 and the battery water cooling plate 12 through the water pipe, and cools the battery pack 11 attached to the battery water cooling plate 12, so that the cycle is repeated continuously , until the temp...

Embodiment 3

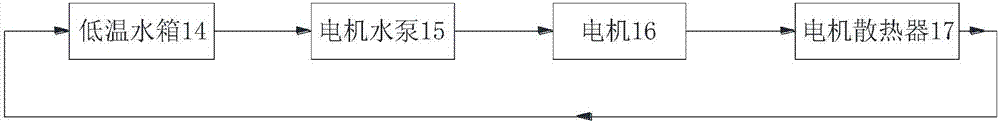

[0051] In cold winter or when the ambient temperature is relatively low, the battery pack 11 cannot be discharged to drive the motor, the ECU controller connects the electric heating PTC8, opens the P port of the two-position three-way solenoid valve 10, and closes the two-position three-way solenoid valve 10 T mouth. Under the action of the battery water pump 9, the low-temperature coolant in the battery water-cooled plate 12 flows back to the The battery water pump 9 and the battery water-cooled plate 12 heat the battery pack 11 with the battery water-cooled plate 12, and this loop constitutes a battery heating loop, and this loop continues until the temperature of the battery pack 11 reaches the discharge working temperature. Of course, since the present invention integrates the motor thermal management subsystem and the battery thermal management subsystem into one box, the present invention can use the heat generated by the motor to heat up the battery, reduce the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com