Full-automatic glue sprayer and glue spraying method

A glue spraying machine, fully automatic technology, applied in the direction of coating, liquid coating on the surface, etc., can solve the problem of inability to adjust the position and re-plan the route, the contact area between the spiral heating wire and the glue is small, and the heating is uneven And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

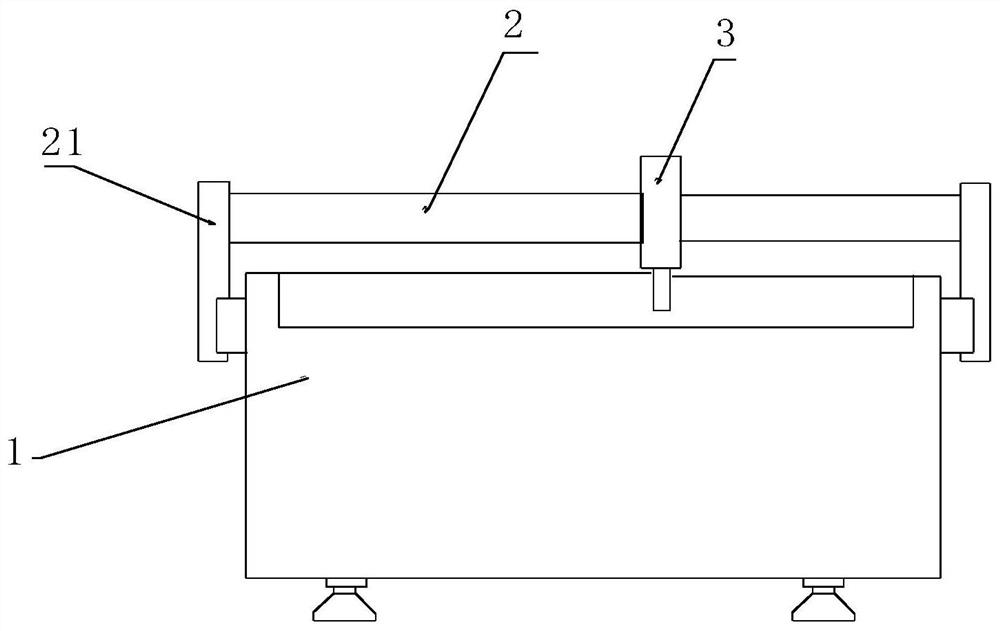

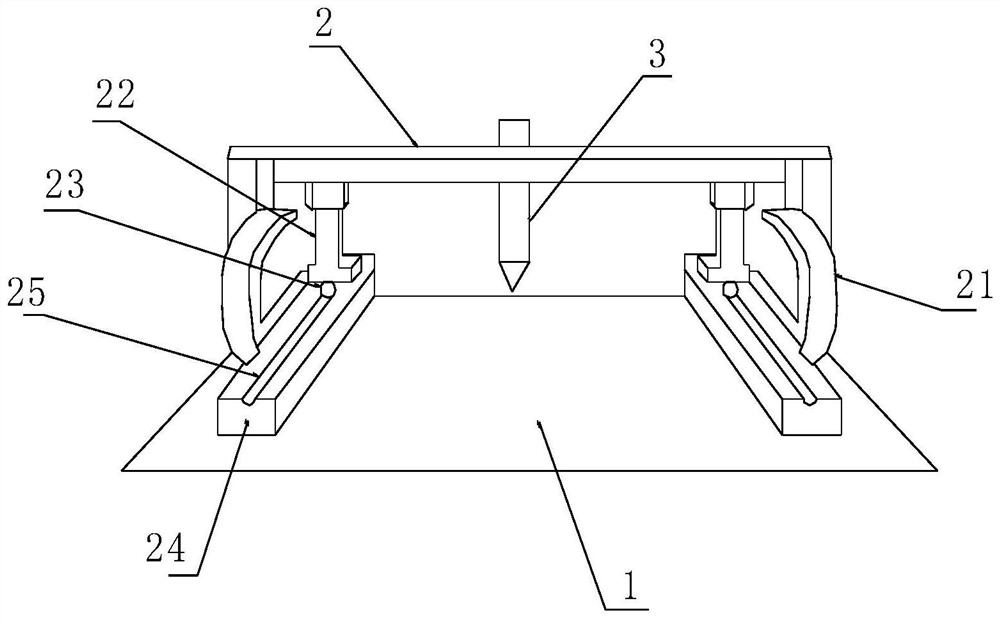

[0032] Such as Figure 1-4 As shown, a fully automatic glue spraying machine in this embodiment includes a glue spraying machine base 1 , a beam 2 , a glue injection cylinder 3 , a sliding mechanism, a heating mechanism 4 , a detector 33 , and a slider controller 32 .

[0033] Glue spraying machine base 1 is the supporting platform for the whole glue spraying work. The two ends of the beam 2 are respectively connected with the two sides of the base 1 of the glue spraying machine through the crawler belt 21 .

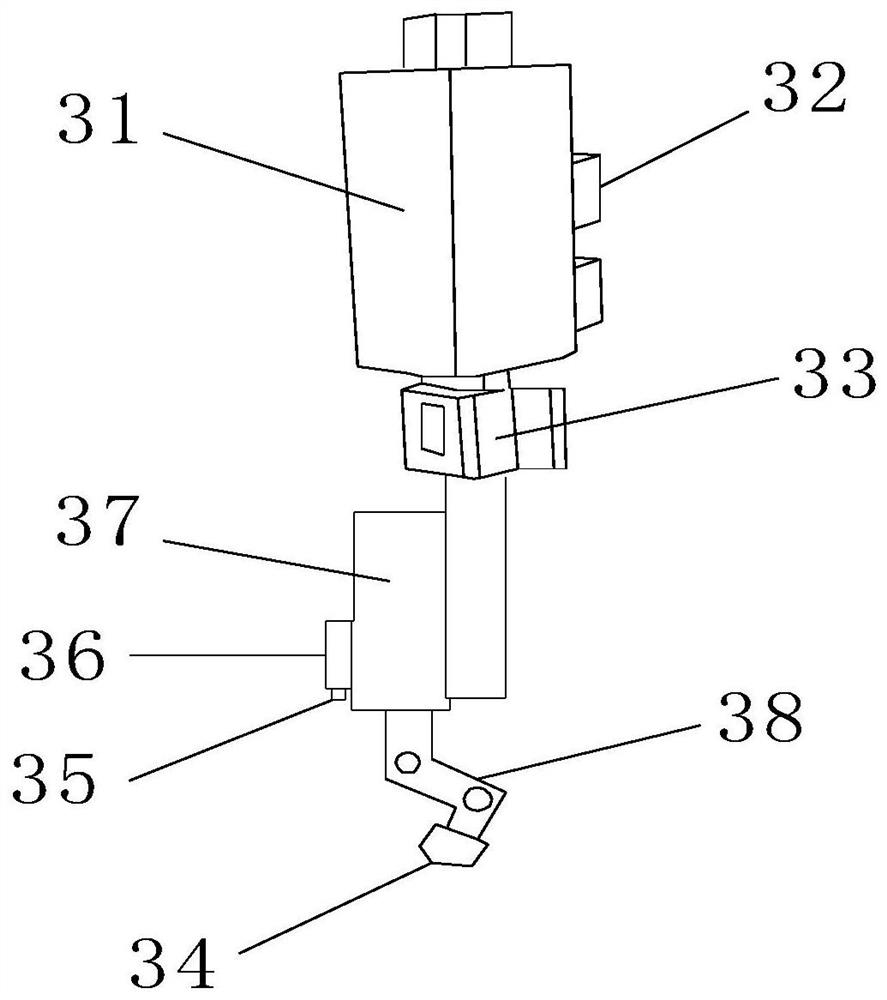

[0034] The glue injection cylinder 3 includes a mounting plate 31 installed on the crossbeam 2, a rotating drive device 37 is pierced in the mounting plate 31, and an angle adjusting member 38 is provided at the end of the output shaft of the rotating drive device 37, so that A glue spray head 34 is provided at the end of the angle adjusting member 38 , and a laser 35 is installed on one side of the rotary driving device 37 through a laser mounting plate 36 . The rotar...

Embodiment 2

[0041] A method for spraying glue, applied to the automatic glue spraying machine of the above-mentioned embodiment, comprising the following steps:

[0042] Detect the horizontal projection distance between the glue spray head 34 and the slider 22;

[0043] judging whether the horizontal projection distance is equal to a predetermined horizontal projection distance;

[0044] When the horizontal projection distance is equal to the predetermined horizontal projection distance, the slider controller 32 drives the slider 22 to move linearly on the guide rail 24 to spray glue; when the horizontal projection distance is not equal to the predetermined horizontal projection distance, the slider The block controller 32 drives the laser 35 to scan, and feeds back the position information of the glue spraying machine base 1 that needs to be sprayed to the external host for readjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com