Inflatable greenhouse film

A technology of shed film and edge film, which is applied in climate change adaptation, greenhouse cultivation, gardening, etc., can solve the problems of occupying too many frame materials, occupying greenhouses, and labor, so as to avoid collapse accidents, increase use efficiency, and iron and weld forming easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

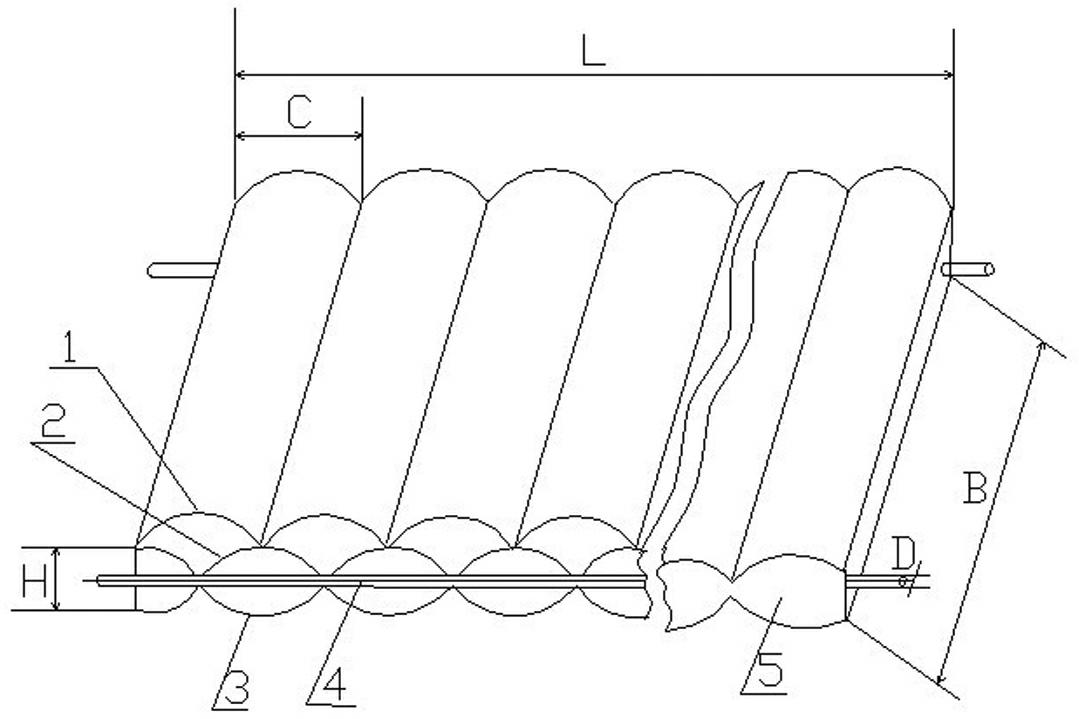

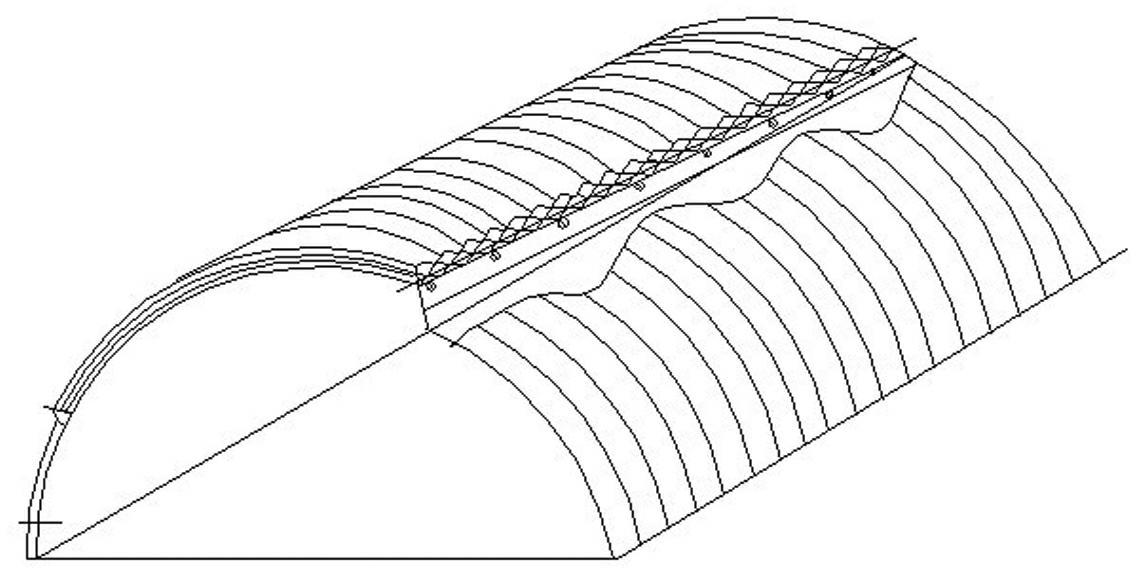

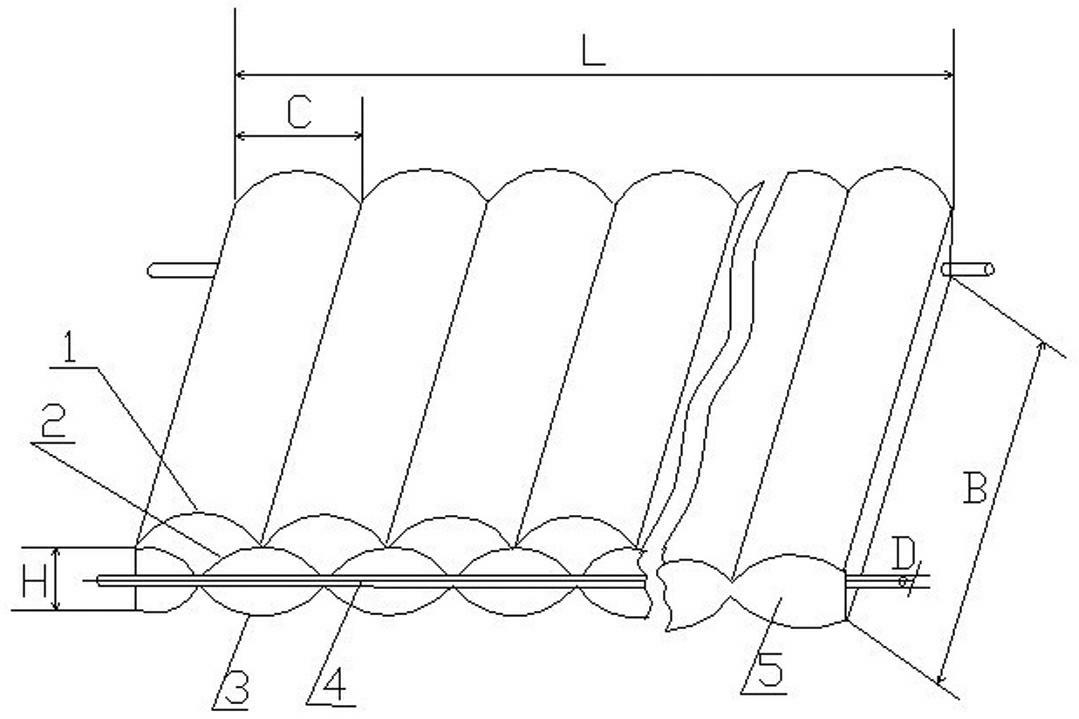

[0016] figure 1 The shown inflatable shed film is composed of an upper film 1 , a middle film 2 , a bottom film 3 , and supporting air ducts and edge-sealing films 5 of equal length and width and stacked in the same direction. The upper film 1, the middle film 2, the bottom film 3 and the sealing edge film 5 are all commercially available agricultural shed films. In this embodiment, the inflatable shed film has a length of L=6000mm, a width of B=1800mm, a thickness of H=100mm, and a ridge width of c=150mm. During production, the middle film 2 is laid flat on the bottom film 3, and the four sides are flush. The two ends of the stacked two-layer film length are respectively connected to the upper and lower sides of the edge sealing film 5 by iron welding and sealing, and a horizontal iron welding straight seam is made at a distance of 75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com