Single-hole single-pushing glost firing kiln utilizing residual heat of cooling area of high-temperature electrical kiln

A cooling zone, single hole single technology, applied in the kiln field, can solve the problems of large loss of sagger, large investment, high energy consumption, etc., and achieve the effect of convenient operation, reduced energy waste, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

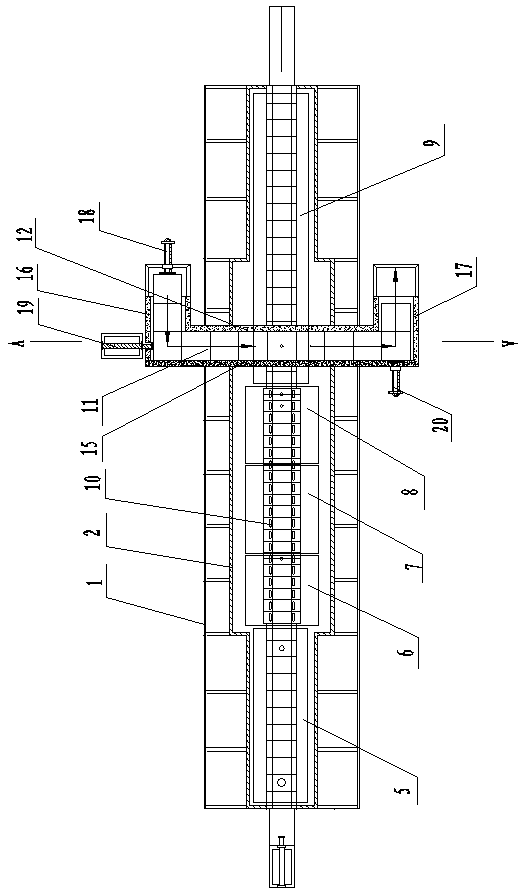

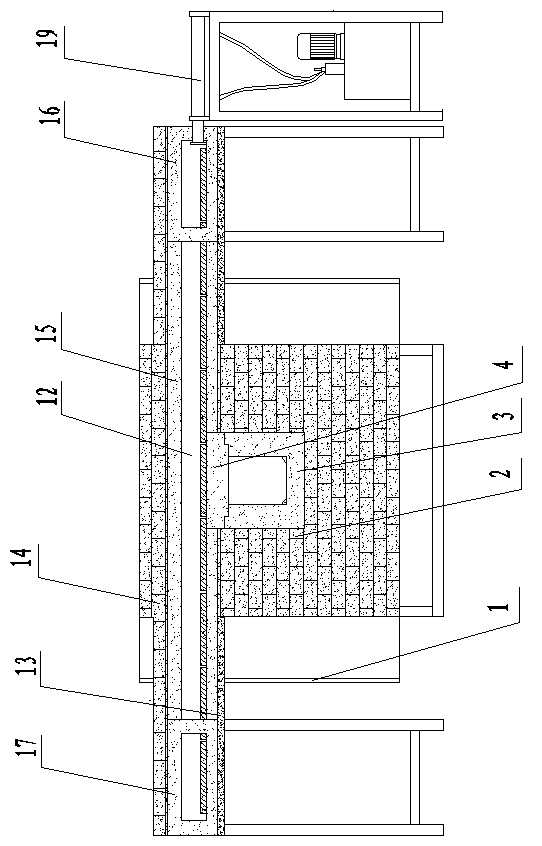

[0011] Such as figure 1 As shown, the kiln includes 1700℃ high temperature pusher electric kiln shell 1, 1700℃ high temperature pusher electric kiln body 2, 1700℃ high temperature pusher electric kiln body 2 is set at 1700℃ high temperature pusher electric kiln shell 1. Inside, 1700℃ high temperature push plate electric kiln body 2. Inside the kiln body 2 is equipped with inner liner 3, top brick 4, the top brick 4 is matched with the upper top of the inner liner 3, the inner liner 3, top brick 4 push the plate electric kiln from 1700℃ high temperature The inlet end of the kiln body 2 to the outlet end of the 1700℃ high-temperature push-plate electric kiln body 2 is filled in rows one by one. The 1700℃ high-temperature push-plate electric kiln body 2 is located in preheating zone 5 and low temperature zone from front to back. 6. The high temperature zone 7, the constant temperature zone 8, the cooling zone 9, the low temperature zone 6, the high temperature zone 7, and the const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com