Washing machine

A washing machine and drain valve technology, applied in the field of washing machines, can solve the problems of water waste and ineffective washing, and achieve the effects of preventing bacterial growth, saving water resources, and reducing washing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

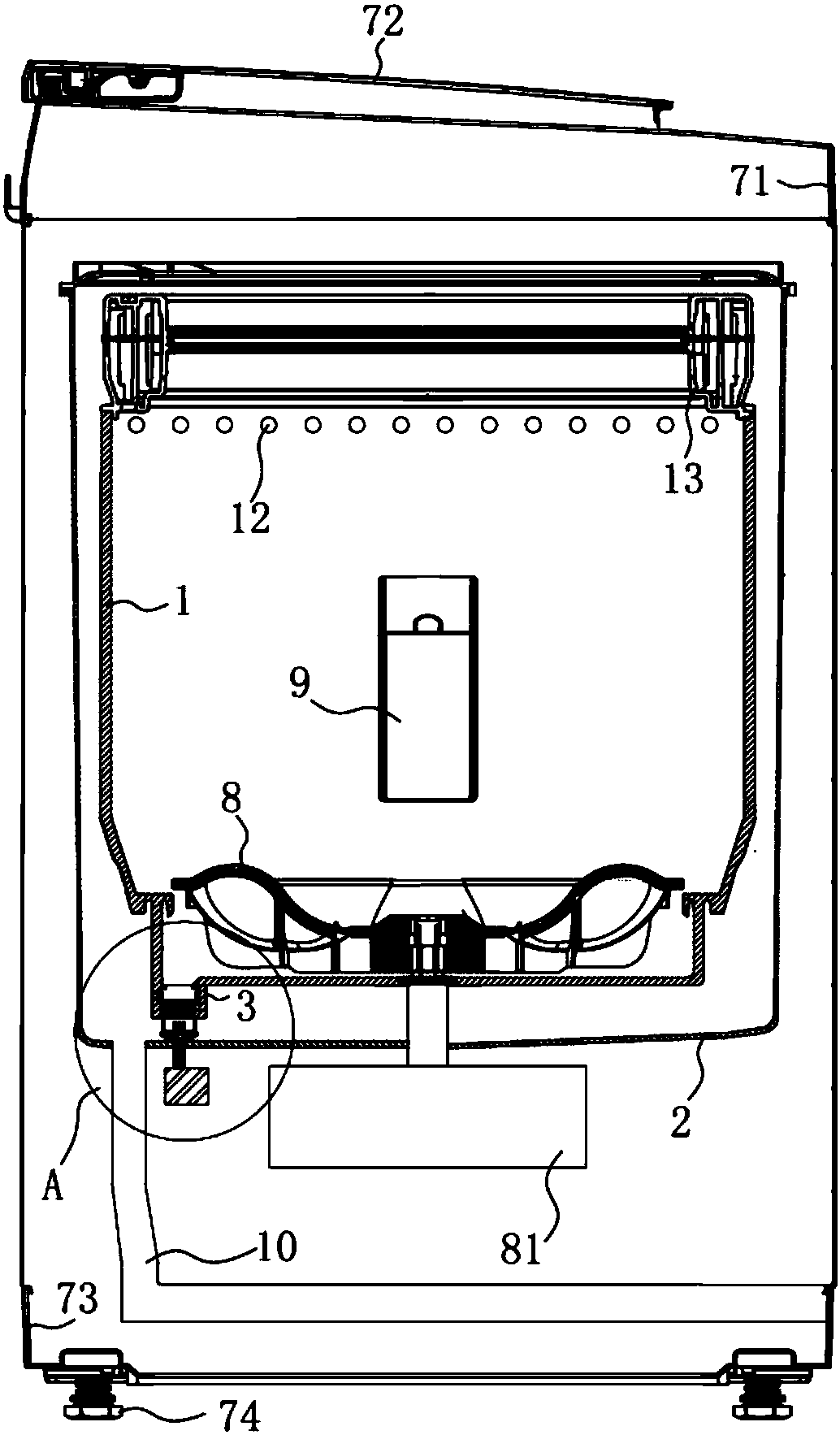

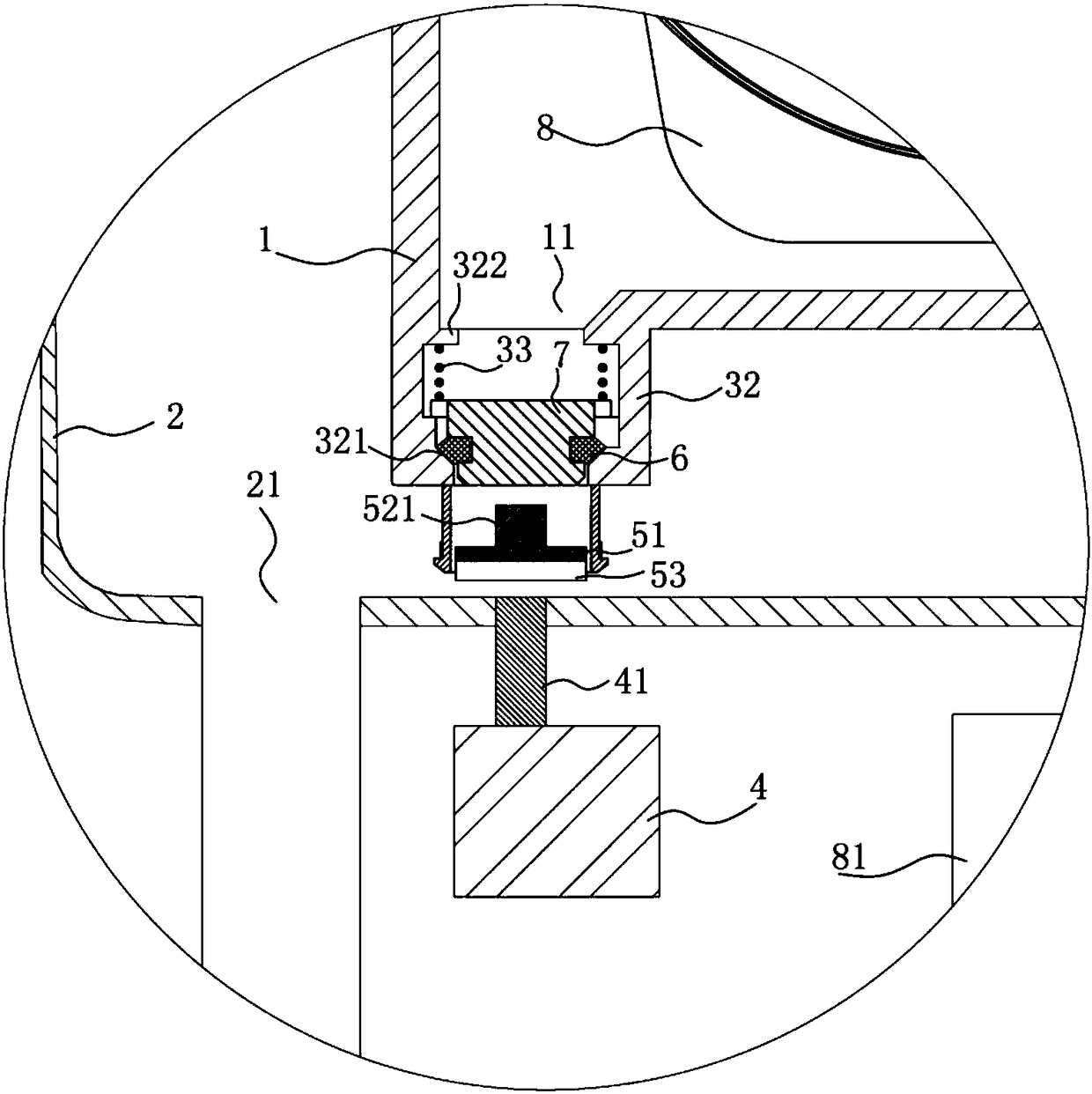

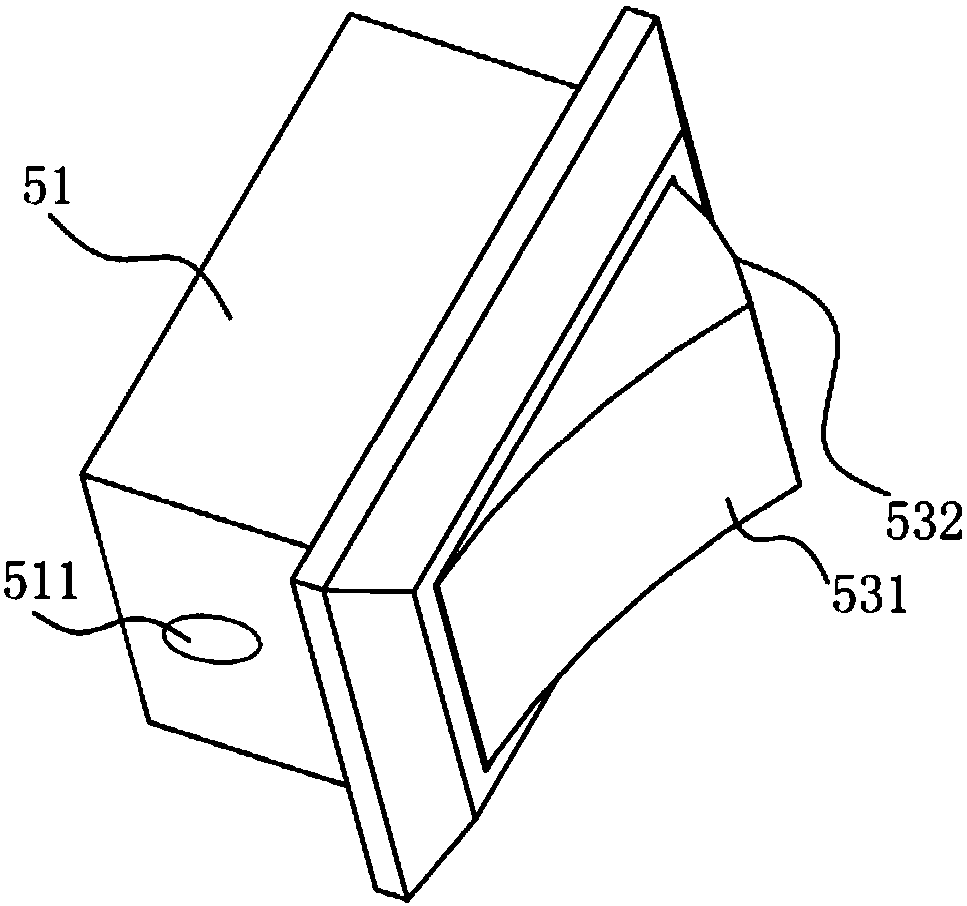

[0037] A washing machine is provided in this embodiment, comprising an inner tub 1 and an outer tub 2, such as figure 1 As shown, an inner barrel drain hole 11 is provided at the bottom of the inner barrel 1, and the inner barrel drain hole 11 is provided with a drain valve 3, and the outer barrel 2 is provided with a power device 4 that pushes a spool 31 of the drain valve 3, and the outer barrel drain hole 21, and the drain hole 21 communicates with the drain pipe 10 for draining water out of the shell 7 of the washing machine, wherein the drain hole 21 of the outer tub is located at the bottom of the outer tub 1 to discharge sewage, and the end of the drain valve 3 near the outer tub 2 is provided with a drain switch 5 and a power unit 4 The extension shaft 41 stretches out and touches the drain switch 5 to open or close the drain valve 3. Wherein the power unit 4 is a push rod motor. This structure can convert circular rotation into linear motion.

[0038] Of course, the...

Embodiment 2

[0058] In this embodiment, the difference from Embodiment 1 is:

[0059] Such as Figure 8-9 As shown, in this embodiment, the drain valve 3 is arranged on the side wall of the inner tub 1, while the power unit is arranged on the side wall of the outer tub 2, but the inner tub drainage hole 21 that needs to be noted is still arranged at the bottom of the outer tub 2, and at the same time The bottom of the spool of the drain valve 3 is coplanar with the bottom of the inner tub 1, which can ensure that all the water in the inner tub is discharged and prevent residual washing water from remaining in the inner tub 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com