Pulsed power supply for electric spark machine tool

A technology for processing machine tools and pulse power supplies, which is applied in electric processing equipment, metal processing equipment, circuits, etc., and can solve problems such as affecting processing efficiency and processing quality, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

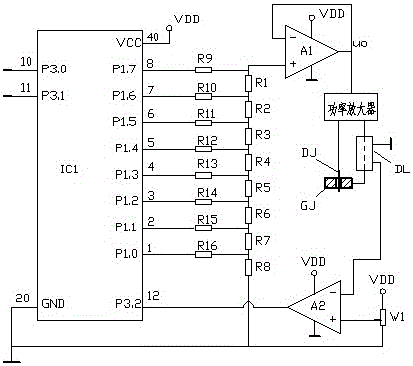

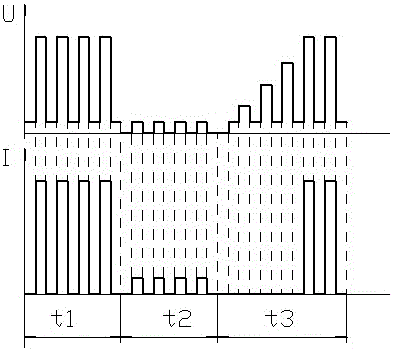

Method used

Image

Examples

no. 2 example

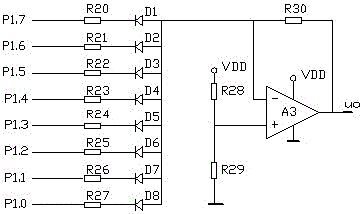

[0022] The second embodiment: the difference between the second embodiment and the first embodiment is that the D / A converter described in the second embodiment includes resistors R20-R30, diodes D1-D8, operational amplifier A3, and the P1 port Pin P1.7 is connected to the cathode of diode D1 through resistor R20, pin P1.6 of port P1 is connected to the cathode of diode D2 through resistor R21, pin P1.5 of port P1 is connected to the cathode of diode D3 through resistor R22, port P1 The pin P1.4 of the P1 port is connected to the cathode of the diode D4 through the resistor R23, the pin P1.3 of the P1 port is connected to the cathode of the diode D5 through the resistor R24, and the pin P1.2 of the P1 port is connected to the cathode of the diode D6 through the resistor R25, P1 The pin P1.1 of the port is connected to the cathode of the diode D7 through the resistor R26, the pin P1.0 of the P1 port is connected to the cathode of the diode D8 through the resistor R27, and the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com