Multipurpose three-phase test device

A test device and multi-purpose technology, applied in the direction of phase sequence/synchronous indication, etc., can solve the problems of affecting the progress of the test work, increasing the preparation time, and the small size of the three-phase clamp, so as to avoid poor contact and low-voltage electric shock accidents , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

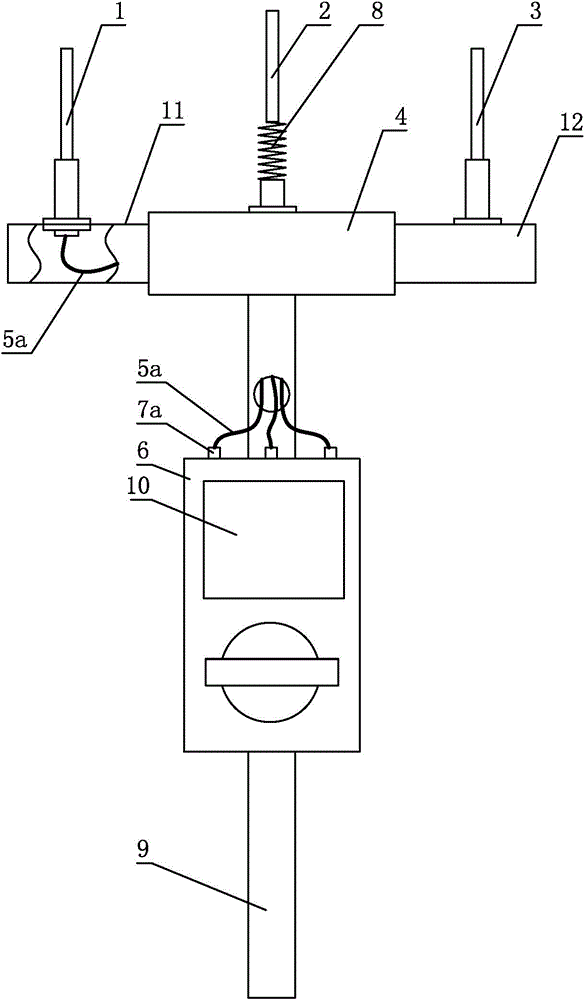

[0031] figure 1 Among them, the technical solution of the present invention provides a kind of multi-purpose three-phase test device, comprises three-phase tester, and it is provided with a test rod with left, middle and right phase contact probes 1, 2, 3 at the front end; The left, middle and right phase contact probes are arranged on the cross bar 4 at the front end of the test rod; The three signal input terminals (7a is taken as an example in the figure, the same below) are connected correspondingly; the contact probes of the left and right phases are fixed on the crossbar at the front end of the test rod, and the contact probes of the middle phase pass through the spring 8 is fixed on the crossbar at the front end of the test rod; the three-phase tester is fixed on the hand-held rod 9 of the test rod; a retractable sleeve 11 and 12 are respectively arranged on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com