Multi-path output controlling valve

A multi-channel output control and spool technology, applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problems that cannot meet the high-precision control temperature of the refrigeration system, the internal leakage index is not easy to control, and the processing difficulty is high. Reduced requirements for valve port surface finish and concentricity, easy product processing, and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

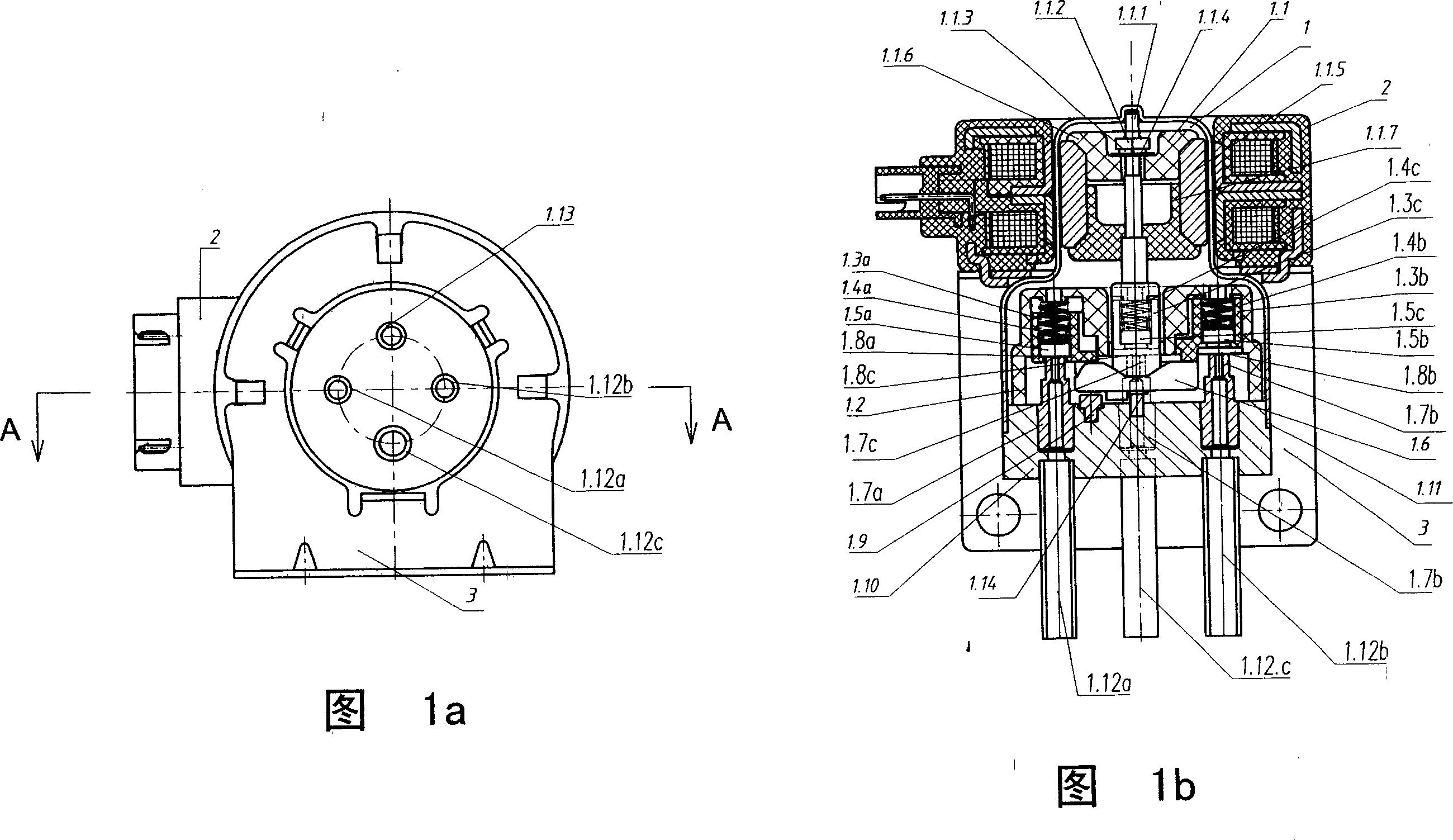

[0038] The main structure of the multi-output control valve of the present invention is shown in Figures 1a and 1b, which can be divided into three parts from the external structure, including: a valve body part 1, a motor stator part 2, and a mounting frame 3. A stator part 2 is provided at one end close to the rotor magnetic steel 1.1.5, the valve body part 1 is placed in the shaft hole 2.12 of the stator part 2 as shown in Figure 8, and the installation frame 3 is fixed on the valve body part 1 and The stator parts 2 are sleeved on the valve sleeve 1.11 of the valve body part 1 .

[0039] The above-mentioned valve body part 1 comprises: rotor part 1.1, spool seat 1.2, spool 1.3a, 1.3b, 1.3c, spring 1.4a, 1.4b, 1.4c, gasket 1.5a, 1.5b, 1.5c, cam 1.6, valve nozzle 1.7a, 1.7b, 1.7c, positioning column 1.9, valve seat 1.10, valve sleeve 1.11, outflow pipe (also called outlet pipe) 1.12a, 1.12b, 1.12c, inflow pipe (also called inlet pipe) Tube) 1.13, circlip 1.14.

[0040] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com