Full-automatic film laminating machine

A laminating machine, fully automatic technology, applied in the direction of container manufacturing machinery, paper/cardboard containers, box production operations, etc., can solve the problems of high consumption cost of oil-based lamination, poor quality of laminating products, not enough environmental protection, etc., to achieve reduction Collection and sorting, labor reduction, and the effect of convenient horizontal position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

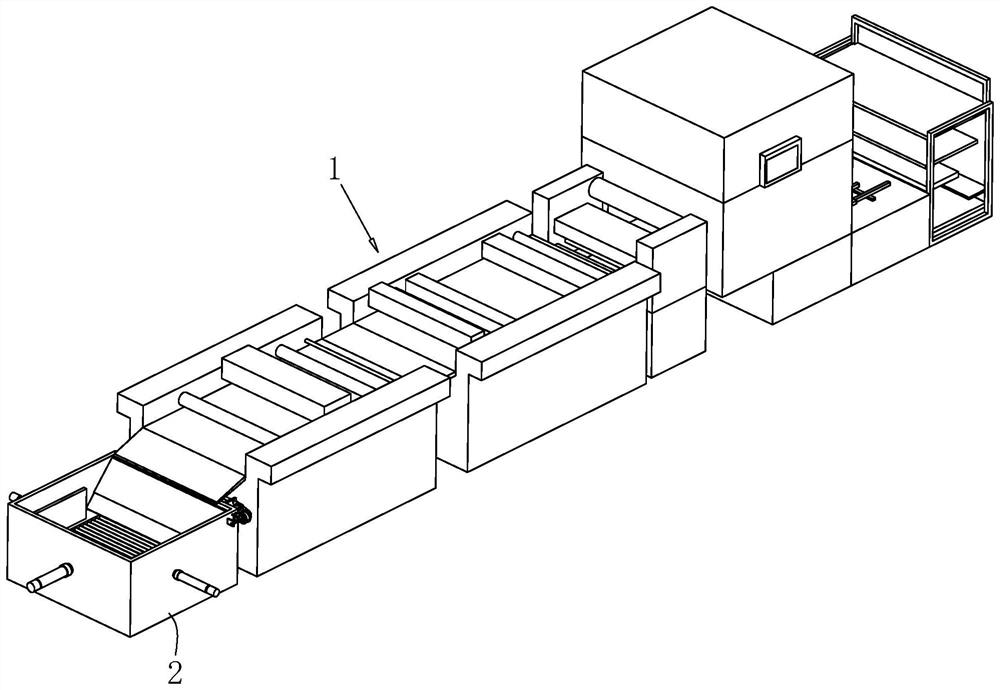

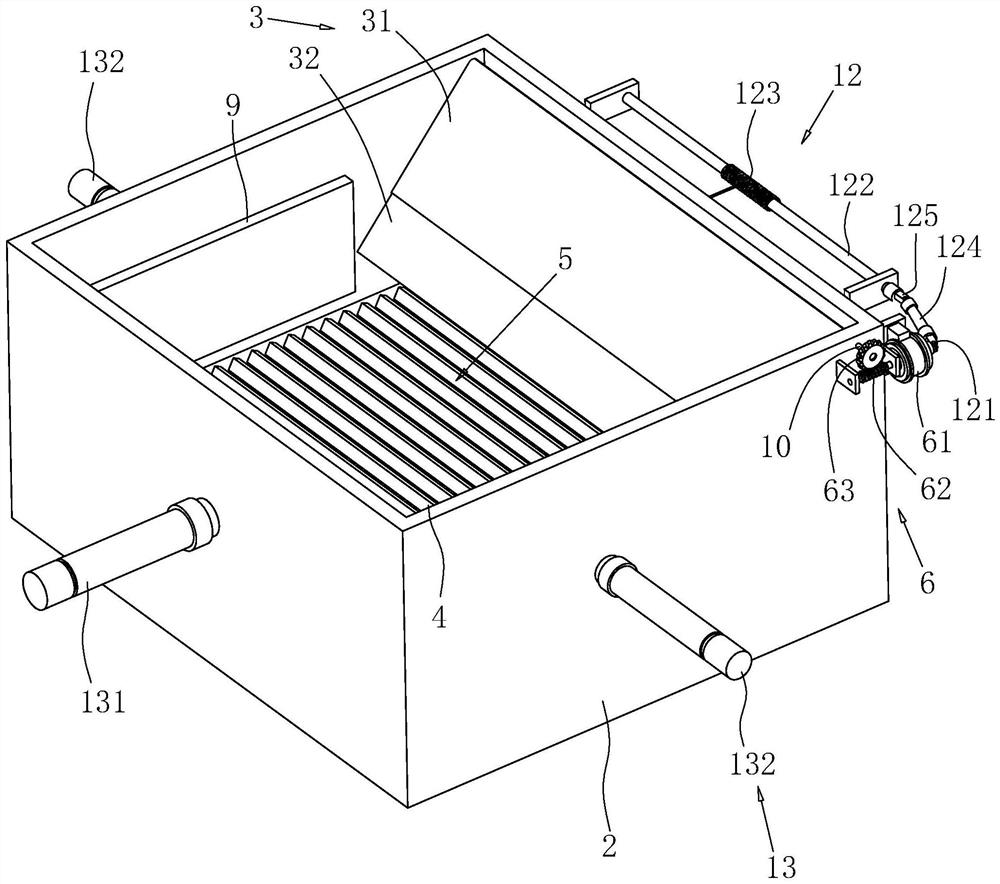

[0042] Attached to the following Figure 1-3 This application will be described in further detail.

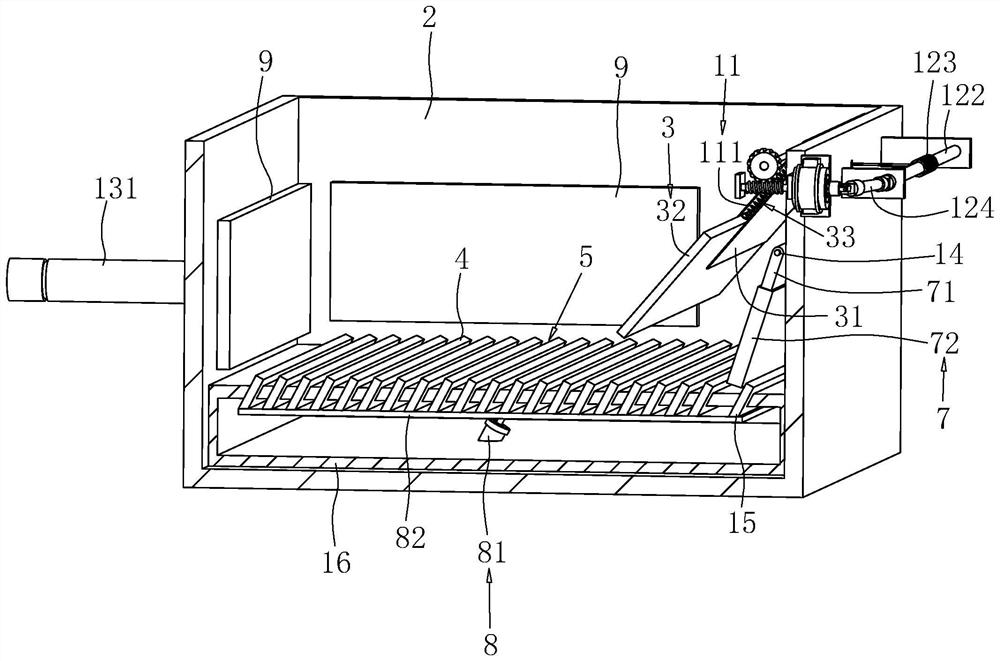

[0043] The embodiment of the present application discloses a fully automatic laminating machine. refer to figure 1 and figure 2 , The automatic laminating machine includes a laminating machine mechanism 1. The paper output end of the laminating machine mechanism 1 is provided with a receiving box 2. The receiving box 2 and the paper output end of the laminator mechanism 1 are connected to each other, and the receiving box 2 is close to the laminating machine. The inner wall of the film machine mechanism 1 is rotatably provided with a deflector 3, and the rotation axis of the deflector 3 is perpendicular to the conveying direction of the paper;

[0044] refer to figure 2 and image 3 , the bottom wall of the receiving box 2 is provided with a receiving plate 16, the receiving plate 16 is hollow, and a plurality of limit blocks 4 are arranged on the receiving plate 16. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com