Battery pack temperature control system and method

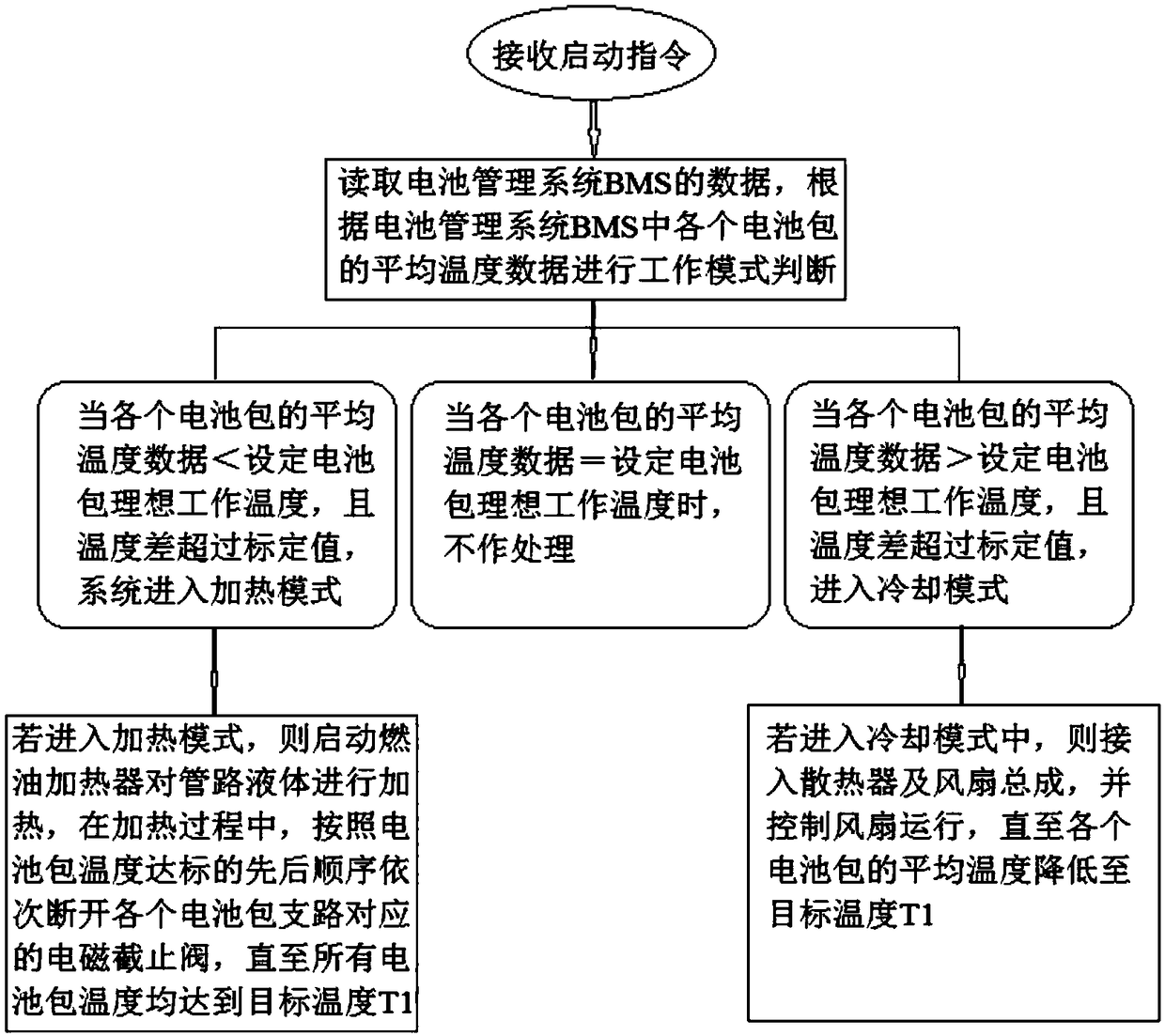

A temperature control system and battery pack technology, applied in the field of electric vehicles, can solve the problems that the temperature cannot be guaranteed to reach the target temperature at the same time, affect the service life of the battery pack, and the calculation of the target temperature is inaccurate, so as to improve the measurement accuracy, reduce the temperature difference, Efficiency improvement effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

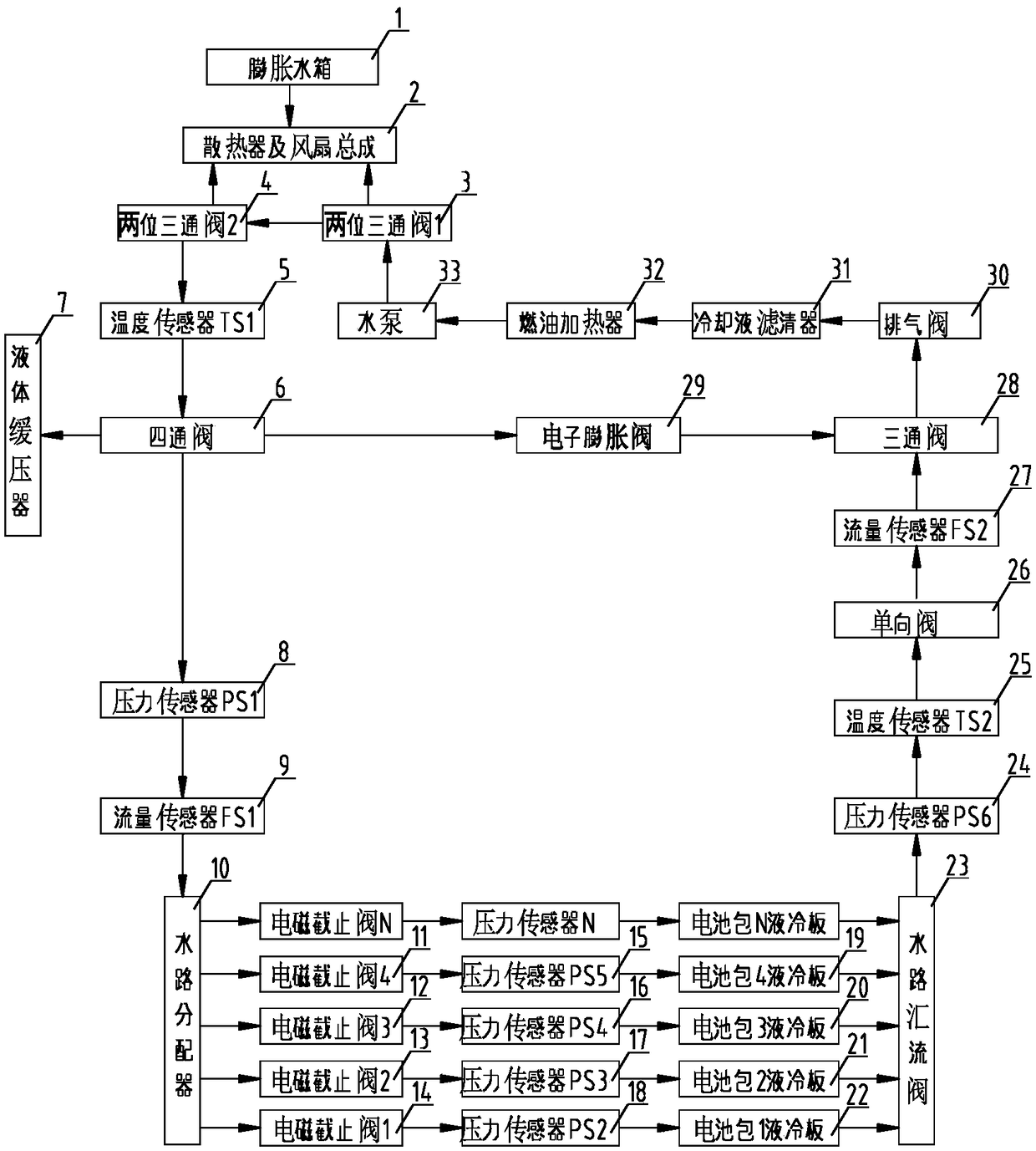

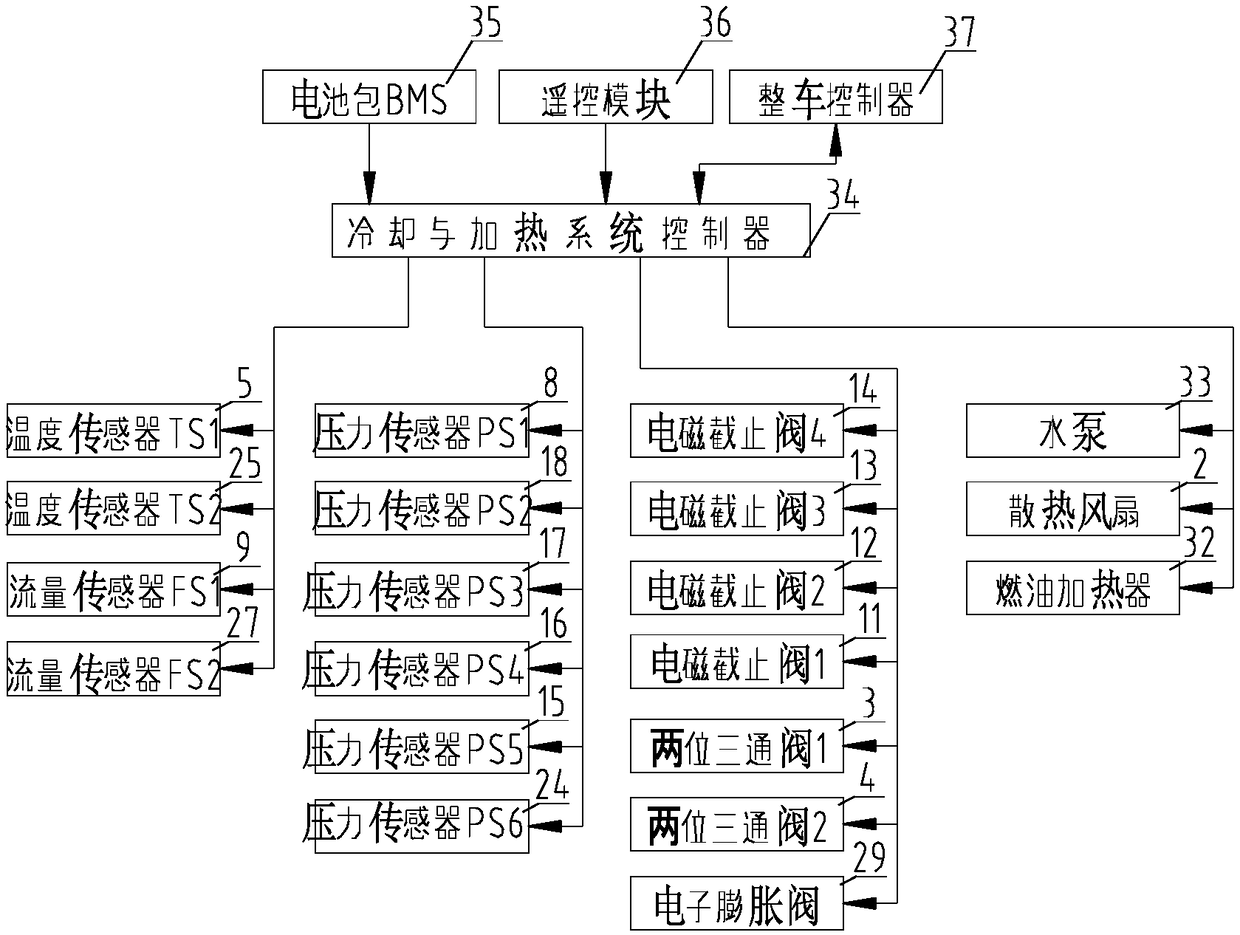

[0052] Such as figure 1 As shown, it includes an expansion tank 1, a radiator and a fan assembly 2, and a main pipe for connecting a water pump 33, a fuel heater 32, a temperature sensor, and several battery pack liquid cold plates. The expansion tank 1 communicates with the water inlet of the radiator and the fan assembly 2, and also includes a waterway distributor 10 and a waterway confluence valve 23. The main pipe is divided into several branch pipes through the waterway distributor 10, and the branch pipes flow through the waterway. The valve 23 is collected to the main pipe, and the several battery pack liquid cooling plates, including 1 battery pack 4 liquid cold plate 9, battery pack 3 liquid cold plate 20, battery pack 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com