Novel anti-blocking reverse feeding device

A reverse feeding, anti-blocking technology, applied in packaging, conveyor, transportation and packaging, etc., can solve problems such as outlet blockage, uneven size, affecting normal production, etc., to avoid blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

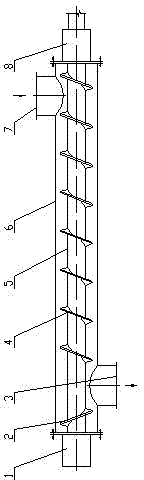

[0011] attached by figure 1 It can be seen that the appearance of the present invention is a horizontal long cylinder, which is composed of a rear shaft head 1, a reverse shaft 2, a discharge port 3, a forward shaft 4, a screw shaft 5, a cylinder body 6, an inlet 7, a front shaft head 8, etc. The main components are composed. A discharge port 3 is opened at the lower left end of the cylinder body 6 , and an inlet 7 is opened at the upper right end of the cylinder body 6 . The rear axle head 1 is connected with the cylinder body 6 with bolts through the connection flange, and the front axle head 8 is connected with the cylinder body 6 with bolts through the connection flange. The left end of the screw shaft 5 is equipped with a reverse shaft leaf 2, and the right end of the screw shaft 5 to the right end of the discharge port 3 is equipped with a forward shaft leaf 4. The reverse shaft 2 is opposite to the rotation angle of the forward shaft 4 with a difference of 180°, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com