Wastewater treatment device for unsaturated polyester resin production and processing

A polyester resin and wastewater treatment technology, which is applied in heating water/sewage treatment, natural water treatment, water/sewage treatment, etc. It can solve the problem that the through holes of the leaking board are easily blocked, the heat transfer effect is reduced, and the heat is not fully utilized. problem, to avoid heat transfer to the side motor, good mud scraping effect, and avoid blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

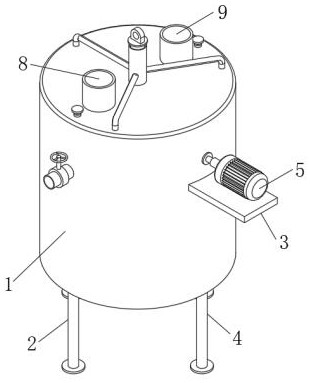

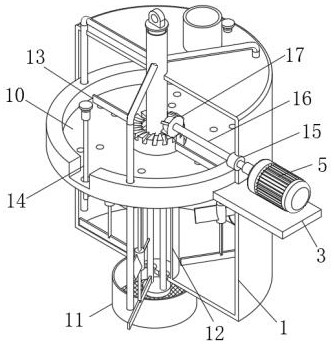

[0029] Such as Figure 1-Figure 4As shown, a heat conduction structure of a waste water treatment device for unsaturated polyester resin production and processing, including a distillation barrel 1, a built-in installation pipe 4 is arranged on the bottom surface of the distillation barrel 1, and a liquid inlet pipe is arranged on the top of the distillation barrel 1 8. A steam outlet pipe 9 is arranged on the side of the liquid inlet pipe 8 on the distillation barrel 1, an upper outlet valve 6 is arranged on the upper side of the distillation barrel 1, and a lower outlet valve 7 is arranged on the lower side of the distillation barrel 1. The barrel 1 is provided with a middle filter plate 10, which is characterized in that: the built-in installation pipe 4 is provided with a heat conduction structure 12, the heat conduction structure 12 includes a middle air guide tube 21 and a side air guide tube 20, and the middle air guide tube 21 and the side air guide tube 20 Fixed insta...

Embodiment 2

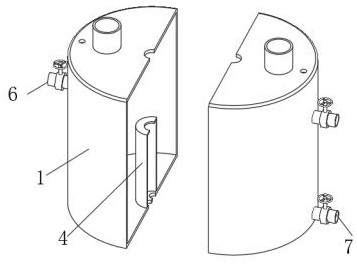

[0031] Such as Figure 1-Figure 4 As shown, the parts that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to those in the first embodiment, and only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as Figure 5 As shown, a mud scraping structure of a waste water treatment device for unsaturated polyester resin production and processing, the middle part of the middle filter plate 10 is provided with a middle rotating hole 33, and the middle part of the filter plate 10 is provided at the outer position of the middle rotating hole 33 There are several side filter holes 34, side movable grooves 35 are arranged on both sides of the middle filter plate 10, the upper outlet valve 6 on the distillation barrel 1 is located on the side of the side movable groove 35, and the middle bearing 22 is located on the side of the middle filter plate 10...

Embodiment 3

[0033] Such as Figure 1-Figure 4 As shown, the parts that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to those in the first embodiment, and only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as Image 6 with Figure 8 As shown, a through-plug structure of a waste water treatment device for unsaturated polyester resin production and processing, the two ends of the bottom ring support 31 are provided with side pull rods 30, and the side pull rods 30 are movably installed with the middle filter plate 10 through the through holes. , and the side pull rod 30 is located in the side movable groove 35, the upper annular gasket 36 is arranged on the side pull rod 30, the side pull rod 30 is also movably installed with the upper position of the distillation barrel 1 through the through hole, and the upper annular gasket 36 Located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com