Balanced type single-pipe suction dredge

A dredger, balanced technology, applied in the settlement tank and other directions, can solve the problems of variable diameter suction pipe and truss self-weight, counterweight deviation, center turret deflection, etc., to reduce installation and debugging workload, installation Easy to debug and reduce the effect of mud scraping resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

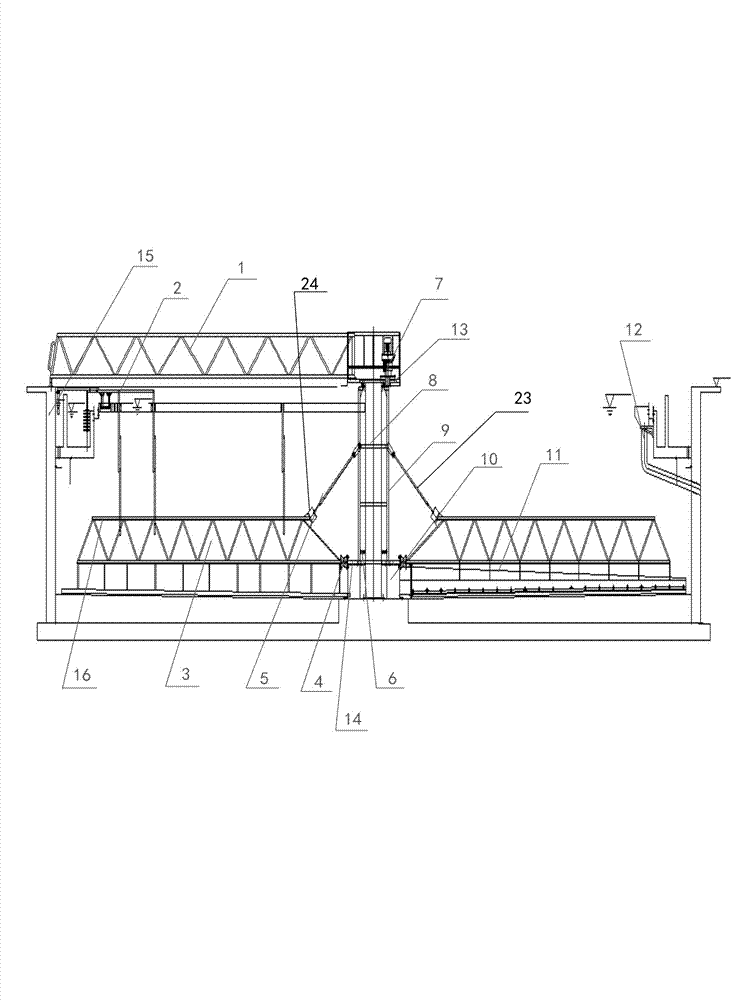

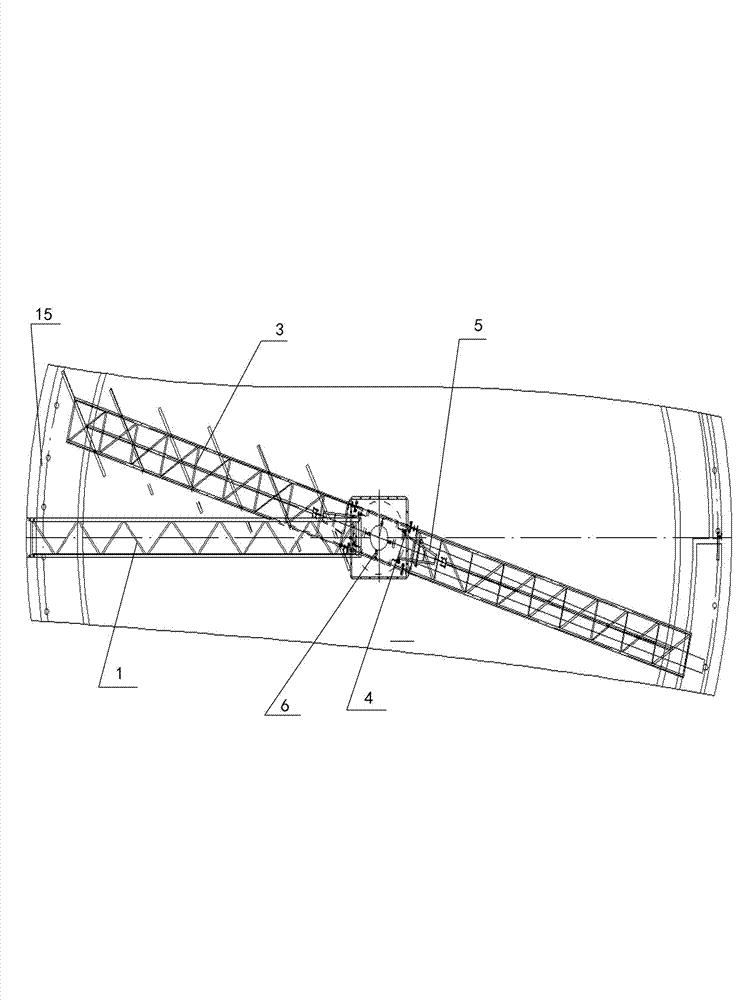

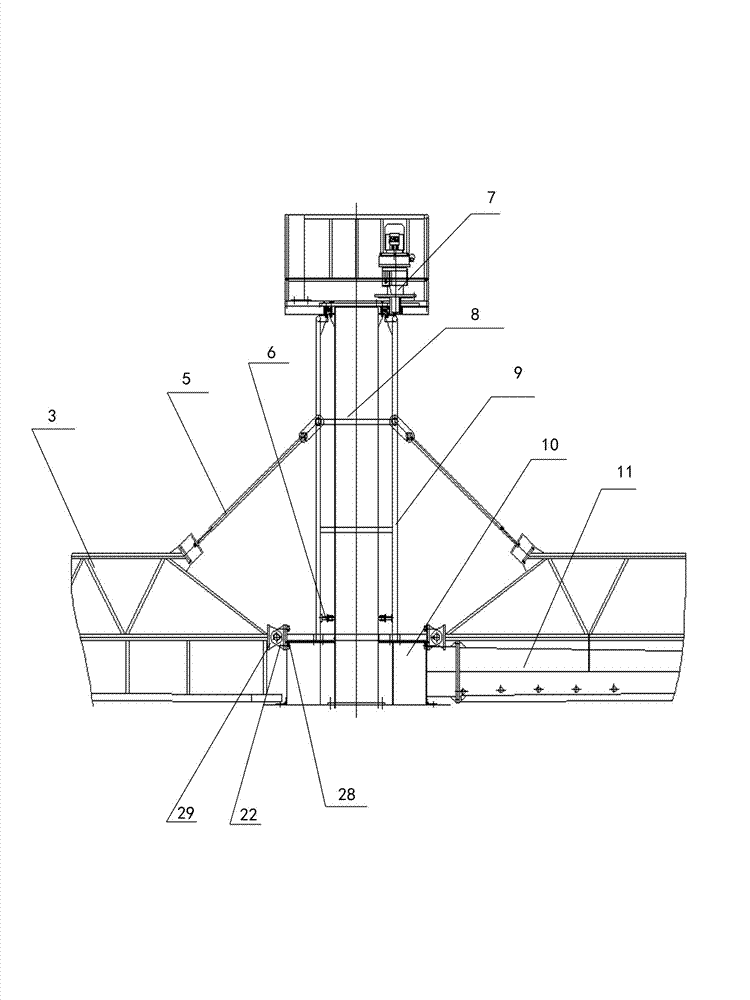

[0016] exist figure 1 , figure 2 with image 3 Among them, the present invention provides a balanced single-pipe dredger, which mainly includes a frame 15, one side of the frame 15 is provided with a slagging device 12, and the frame 15 is provided with a working bridge 1, a scraper Mud truss 3, mud scraping truss adjustment hinge device 4, mud scraping truss adjustment device 5, balance device 6, central driving device 7, central column 8, central tumbler 9, central mud collection tube 10 and variable diameter suction pipe 11 , the bottom surface of the working bridge 1 is provided with a skimming part 2, the top of the central column 8 is connected with the working bridge 1, and the end where the working bridge 1 is connected with the central column 8 is provided with a central driving device 7, and at the center column 8 There is a central tumbler 9 hanging around, and the central tumbler 9 is connected to the connection platform 13 on the upper part of the central colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com