Aluminum alloy glass energy-saving door

An aluminum alloy and aluminum alloy profile technology, which is applied in the installation of window glass, door leaf, window/door, etc., can solve the problems of low wind pressure resistance and unsatisfactory performance of aluminum alloy doors, and achieve good thermal insulation performance and improved Contact strength, tilt prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

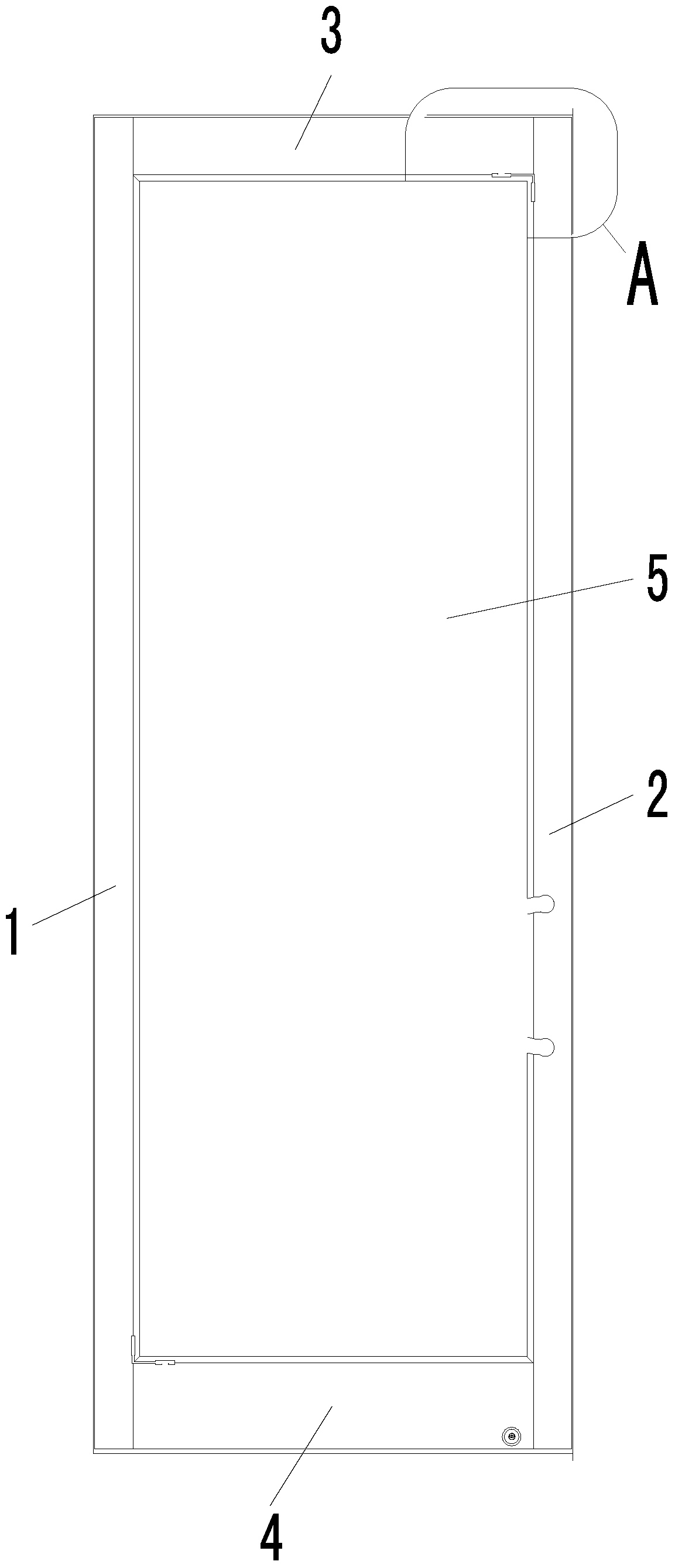

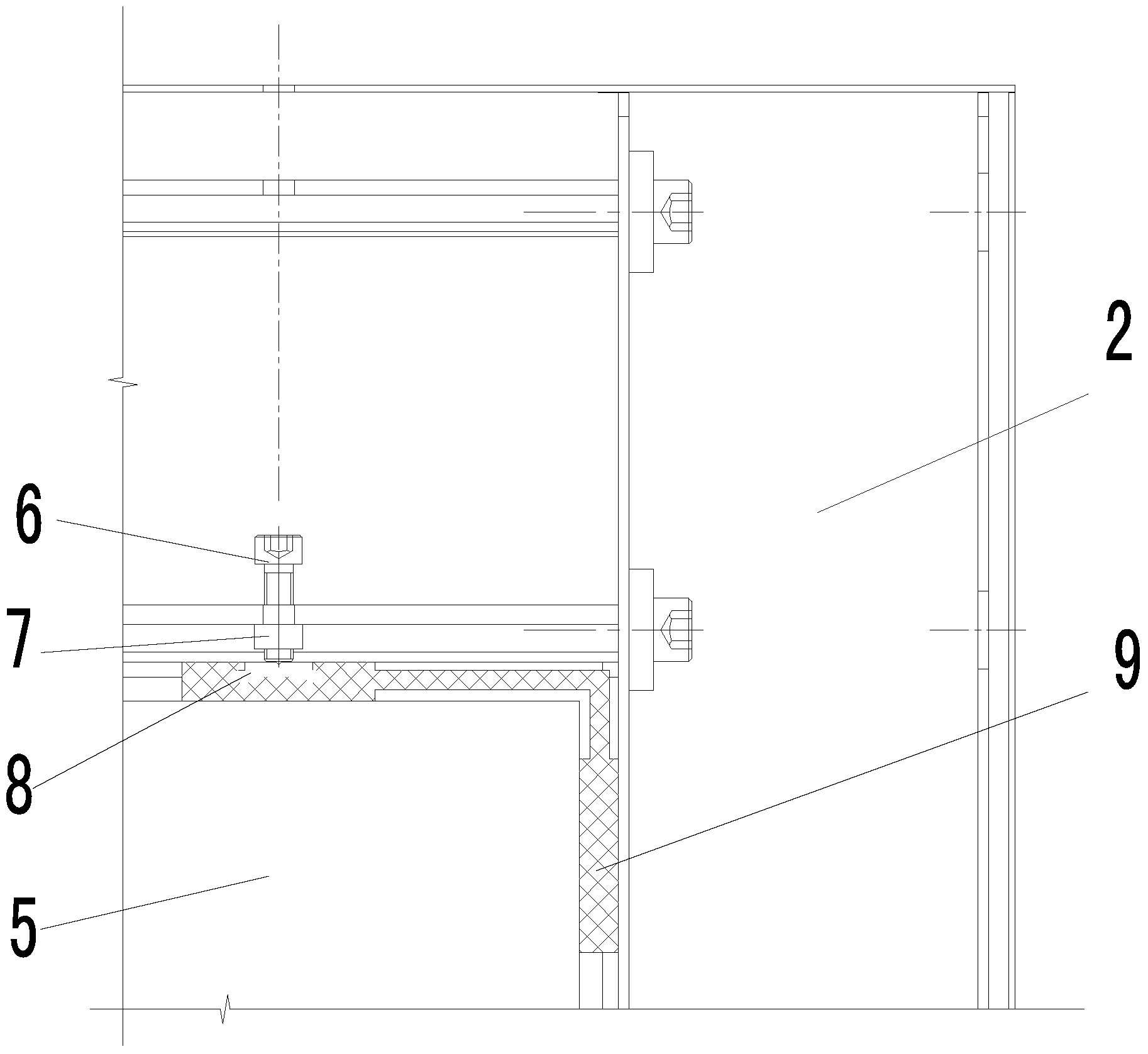

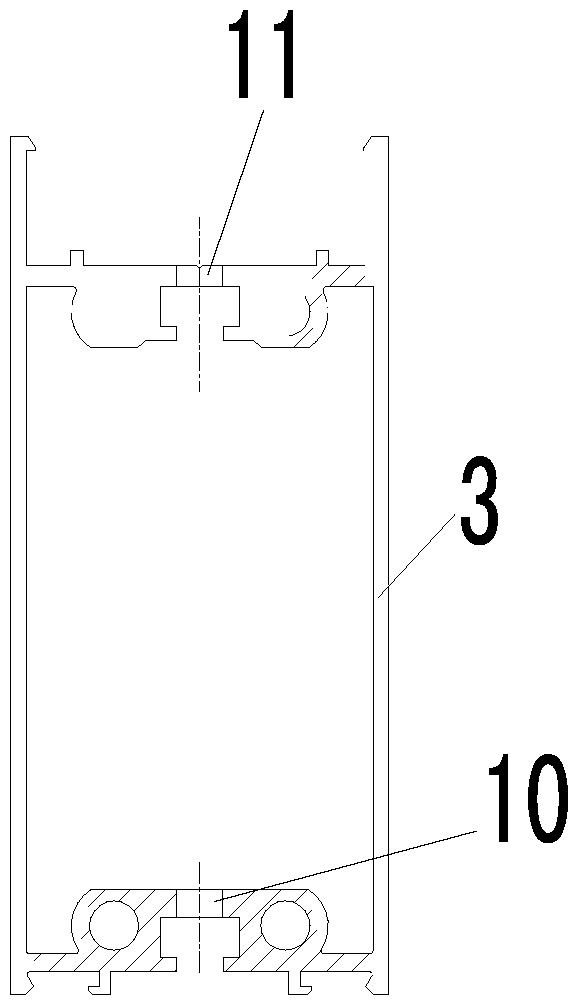

[0032] attached Figure 1-11The aluminum alloy glass energy-saving door according to the present invention includes a door frame, a glass plate assembly 5, and a corner lifter; the glass plate assembly 5 is a hollow glass formed by two or more glass plates; the door frame includes The left aluminum alloy door stile 1, the upper door stile 3, the right aluminum alloy door stile 2, and the lower door 4; the left aluminum alloy door stile 1, the upper door stile 3, the right aluminum alloy door stile 2, and the lower door 4 are encircled in turn to form Frame; the glass panel assembly 5 is arranged in the door frame; the drop-off angle lifter is arranged on one side of the door upper rail 3; the door upper rail 3 is a hollow aluminum alloy profile; the lower surface of the hollow aluminum alloy profile A first through hole 10 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com