Anode mud cleaning device for electrolytic lead anode plates

A technology for cleaning device and anode plate, applied in the direction of electrolysis process, electrolysis components, and process efficiency improvement, etc., can solve the problems of easy damage of roller brushes, great harm to workers' health, low work efficiency, etc., and achieves broad market prospects and good Scraping effect, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

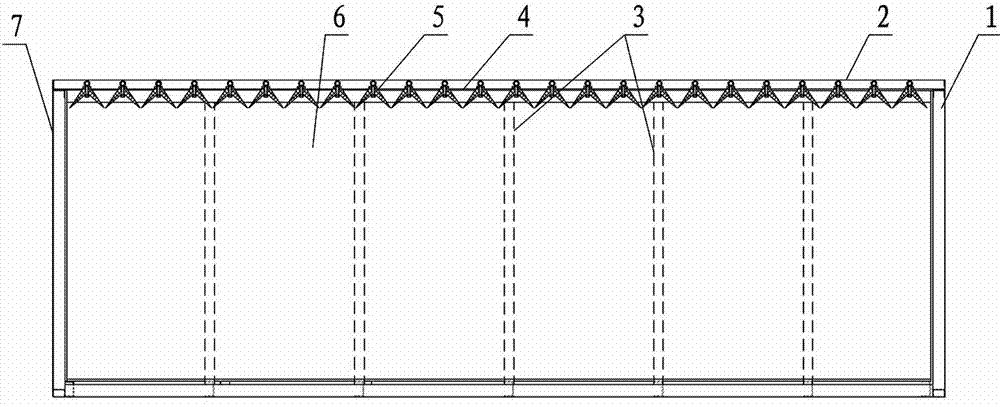

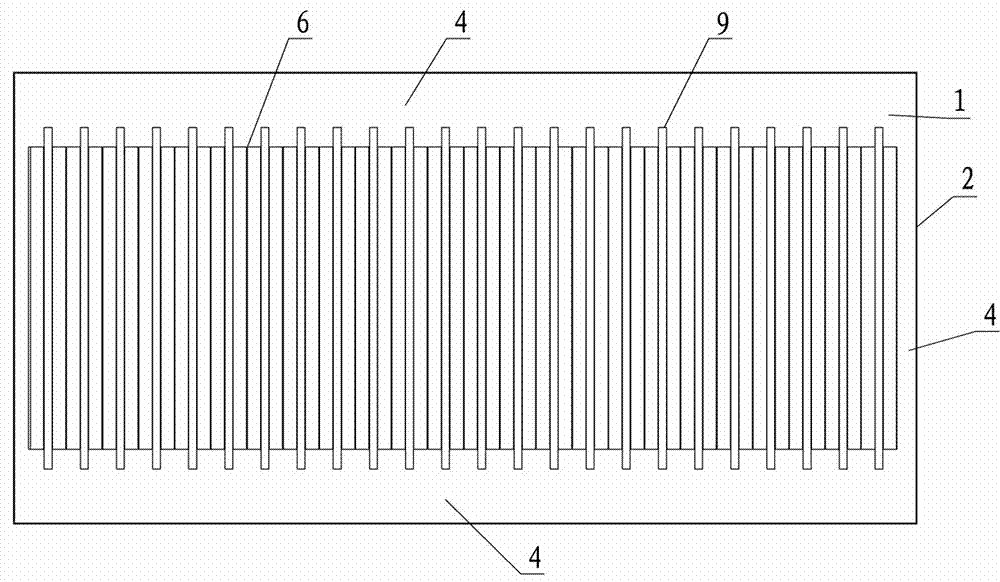

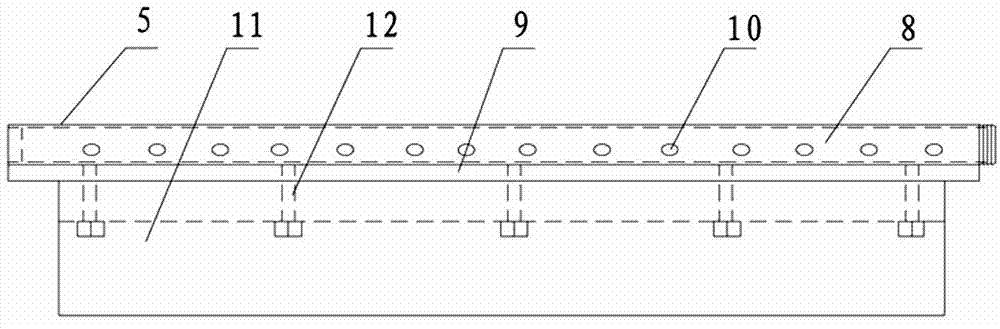

[0021] Embodiment 1, the present invention mainly comprises box body 1, support 3 and mud scraper 5; Said box body 1 suits more than 2 support 3 of rectangular frame shape, and described support 3 is made up of the crossbeam of bottom, the straight beam of side Connect with two or more steel plates to form a built-in rectangular frame-shaped cleaning tank 6, and the upper part of the cleaning tank 6 is horizontally connected with the connecting plate 4 arranged on the upper part of the box body 1; the mud scraper 5 includes a support plate 9 and a herringbone The scraper body 11, the support plate 9 and the scraper body 11 are fixedly connected to each other, and the support plate 9 and the scraper body 11 can be fixedly connected to each other by using screws 12 or screw rods; the two ends of the support plate 9 are connected to The plates 4 are connected, and a liquid spray device is arranged on the support plate 9; more than two mud scrapers 5 are installed across the cleani...

Embodiment 2

[0024] Embodiment 2, the present invention can also be provided with a rectangular fence 2 on the periphery of the connecting plate 4 to enhance the protective effect. refer to Figure 1 to Figure 3 , all the other are with embodiment 1.

Embodiment 3

[0025] Embodiment 3, the present invention can also be provided with a rectangular exterior decoration surface 7 on the outside of the box body 1, and the upper part of the cleaning tank 6 is horizontally connected with the upper part of the exterior decoration surface 7 via the connecting plate 4. By arranging the outer decorative surface 7, the appearance can be enhanced, and the effect of protection can also be enhanced. refer to Figures 1 to 3 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com