Separation device for removing sludge in oily wastewater

A separation device and sludge technology, applied in the direction of flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of large dosage of chemicals, low degree of automation, inability to recycle resources, etc., and achieve effective Separation, high degree of automation, avoiding the effect of sludge clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

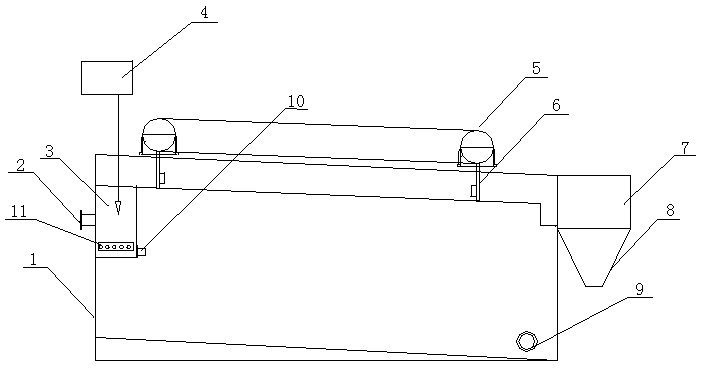

[0017] Such as figure 1 As shown, this embodiment includes a separation chamber 1 and a reaction chamber 3 and a mud scraping device arranged on the separation chamber 1 .

[0018] The separation chamber 1 of this embodiment is a tank body with a sealing cover, and the mud scraping device is located on the sealing cover.

[0019] The separation chamber 1 of this embodiment is provided with a water inlet 2 and a water outlet 9 , the water inlet 2 communicates with the reaction chamber 3 , and a dosing device 4 is arranged above the reaction chamber 3 .

[0020] The separation chamber 1 of this embodiment is also provided with a collection tank 7 , and a mud bucket 8 is provided below the collection tank 7 .

[0021] The mud scraping device in this embodiment includes a conveying device 5 and at least one scraper 6 arranged on the conveying device 5 , and one end of the conveying device 5 close to the water inlet 2 is higher than the other end.

[0022] The reaction chamber 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com