Lithium-ion battery slurrying and mixing plate

A lithium electronic battery and slurry technology, which is applied in mixers, mixers with rotary stirring devices, dissolution and other directions, can solve the problems of easy adsorption on the side wall, high viscosity of the slurry, and difficulty in cleaning the mixing tray. Achieve the effect of reducing the workload, mixing evenly and fully, and avoiding the degradation of battery quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

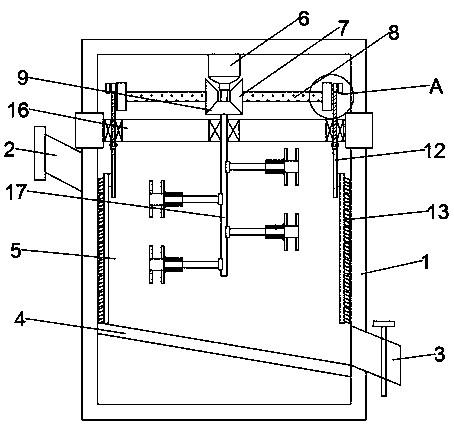

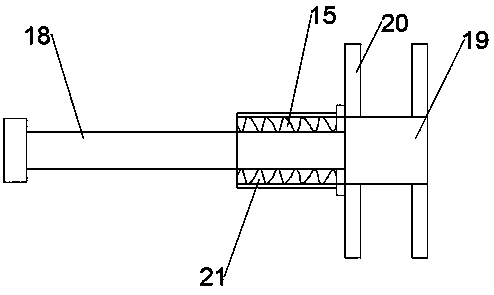

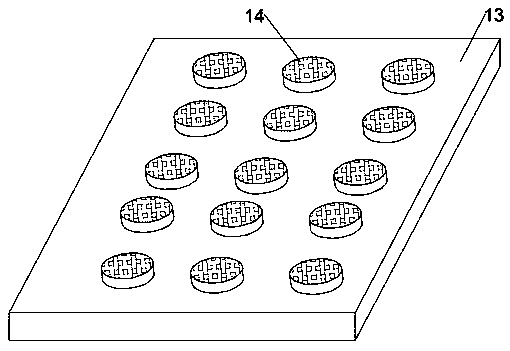

[0020] see Figure 1~4 In an embodiment of the present invention, a battery slurry stirring structure includes a first stirring paddle 18, a sleeve 19, a second stirring paddle 20 and a chute 21, the outer surface of the first stirring paddle 18 is polished and polished, A sleeve 19 is sheathed on the outside of the first stirring paddle 18, and the first stirring paddle 18 is slidably connected to the sleeve 19. A section of the first stirring paddle 18 and the first stirring paddle 18 is in contact with a chute 21, so that A buffer spring 15 is installed in the chute 21, and the first stirring paddle 18 and the sleeve 19 are respectively fixedly welded at the two ends of the buffer spring 15. The setting of the buffer spring 15 can realize the adjustment of the first stirring blade 18 and the sleeve. 19 buffer protection, the sleeve 19 is evenly arranged with a plurality of second stirring paddles 20 up and down;

[0021] The connection between the sleeve 19 and the second ...

Embodiment 2

[0027] see Figure 1~2 In the embodiment of the present invention, the connection mode between the second stirring paddle 20 and the sleeve 19 is hinged, which expands the stirring range and is beneficial to realize sufficient mixing of the slurry. Other structures in this embodiment are the same as in Embodiment 1 same.

[0028] The working principle of the present invention is: the slurry enters the stirring chamber 5 through the feeding port 2, starts the working motor 6, and the working motor 6 drives the second rotating shaft 17 to rotate, and the second rotating shaft 17 drives the battery slurry stirring structure to rotate, realizing the mixing and stirring of the slurry, and at the same time, the sleeve 19 slides along the first stirring paddle 18, driving the second stirring paddle 20 to fully mix and stir the slurry , to avoid the degradation of battery quality caused by uneven slurry mixing, and at the same time, when the slurry in the center of the stirring chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com