Electroplating-sludge cement curing process

A technology of electroplating sludge and cement solidification, applied in water/sludge/sewage treatment, sludge treatment, fixed/solidified sludge treatment, etc., can solve the ecological environment and human health damage, lack of treatment and disposal of hazardous waste technology Means and economic capacity, global environmental hazards and other issues, to achieve the effect of meeting the use requirements and smooth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

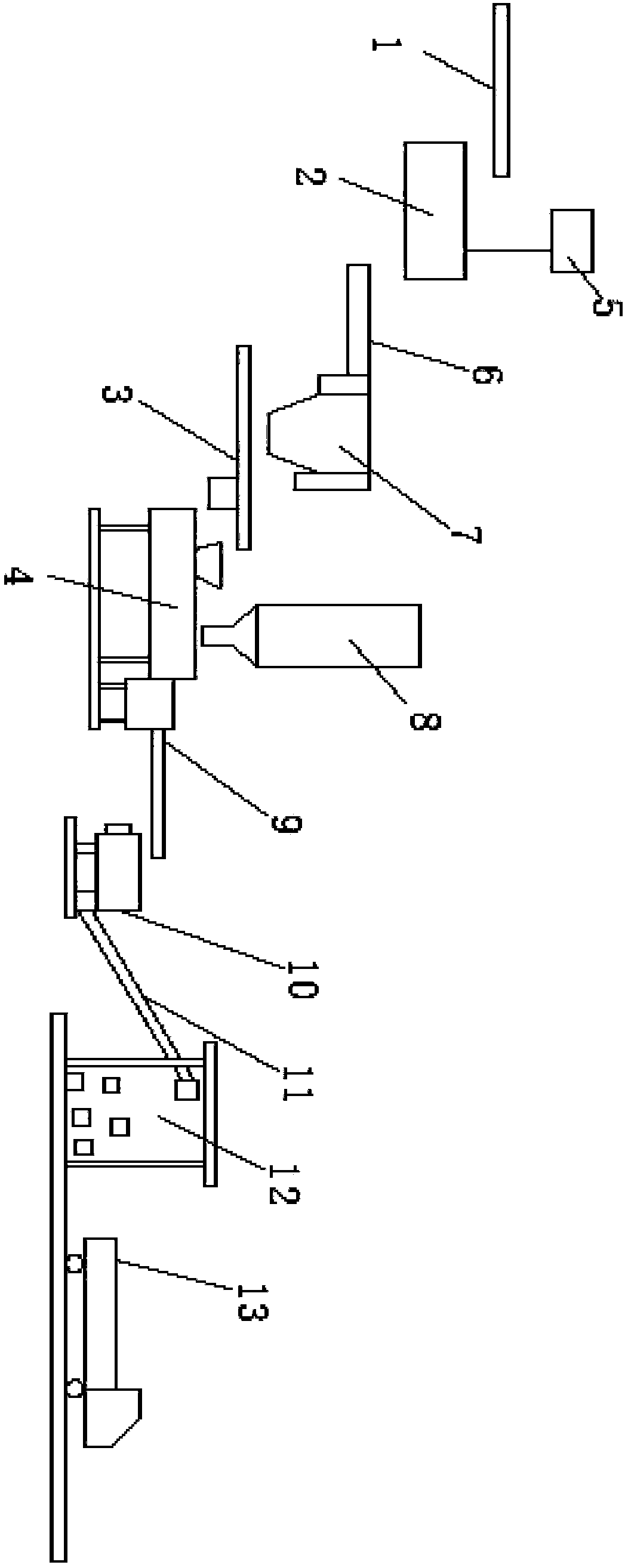

[0038] The following steps are involved in the treatment of dry electroplating sludge:

[0039] Step 1: First, the electroplating sludge is transported into the dry crushing box 2 through the conveyor belt device 1, and then dried and crushed;

[0040] Step 2: transfer the dried and pulverized electroplating sludge to the storage tank 7 through the feeding mechanism 6;

[0041] Step 3: discharge the electroplating sludge in the storage tank 7 into the mixer 4 through the metering device 3;

[0042] Step 4: Add cement, water and additives to the mixing mixer 4 through the feeding device 8, and start the mixing mixer for mixing;

[0043] Step 5: Transfer the mixed mixture to the molding machine 10 through the material transfer device 9, and the molding machine 10 performs molding processing on the mixture, and the mixture forms a cement block;

[0044] Step 6: The cement blocks formed by the molding machine 10 are transported to the curing room by the belt conveyor 11, and are...

Embodiment 2

[0049] Treatment of wet electroplating sludge involves the following steps:

[0050] Step 1: First, the electroplating sludge is transported into the dry crushing box 2 through the conveyor belt device 1, and then dried and crushed;

[0051] Step 2: transfer the dried and pulverized electroplating sludge to the storage tank 7 through the feeding mechanism 6;

[0052] Step 3: discharge the electroplating sludge in the storage tank 7 into the mixer 4 through the metering device 3;

[0053] Step 4: Add cement, water and additives to the mixing mixer 4 through the feeding device 8, and start the mixing mixer for mixing;

[0054] Step 5: Transfer the mixed mixture to the molding machine 10 through the material transfer device 9, and the molding machine 10 performs molding processing on the mixture, and the mixture forms a cement block;

[0055] Step 6: The cement blocks formed by the molding machine 10 are transported to the curing room by the belt conveyor 11, and are left to st...

Embodiment 3

[0060] The following steps are included in the treatment of powdered electroplating sludge:

[0061] Step 1: transfer the powdered electroplating sludge to the storage tank 7 through the material lifting mechanism 6;

[0062] Step 2: discharge the electroplating sludge in the storage tank 7 into the mixer 4 through the metering device 3;

[0063] Step 3: Add cement, water and additives to the mixing mixer 4 through the feeding device 8, and start the mixing mixer for mixing;

[0064] Step 4: Transfer the mixed mixture to the molding machine 10 through the transfer device 9, and the molding machine 10 performs molding processing on the mixture, and the mixture forms a cement block;

[0065] Step 5: The cement blocks formed by the molding machine 10 are transported to the curing room by the belt conveyor 11, and are left to stand and solidified for storage;

[0066] Step 6: The cement block after standing still and solidified is transported to the transport vehicle 13, and tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com