Automobile air-knife window wiper

A wiper and air knife technology, applied in the field of automotive air knife wipers, can solve the problems of accelerated scraper wear, large frictional resistance between the scraper and the windshield, affecting the driver's sight, etc., and achieves the effect of increasing the speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

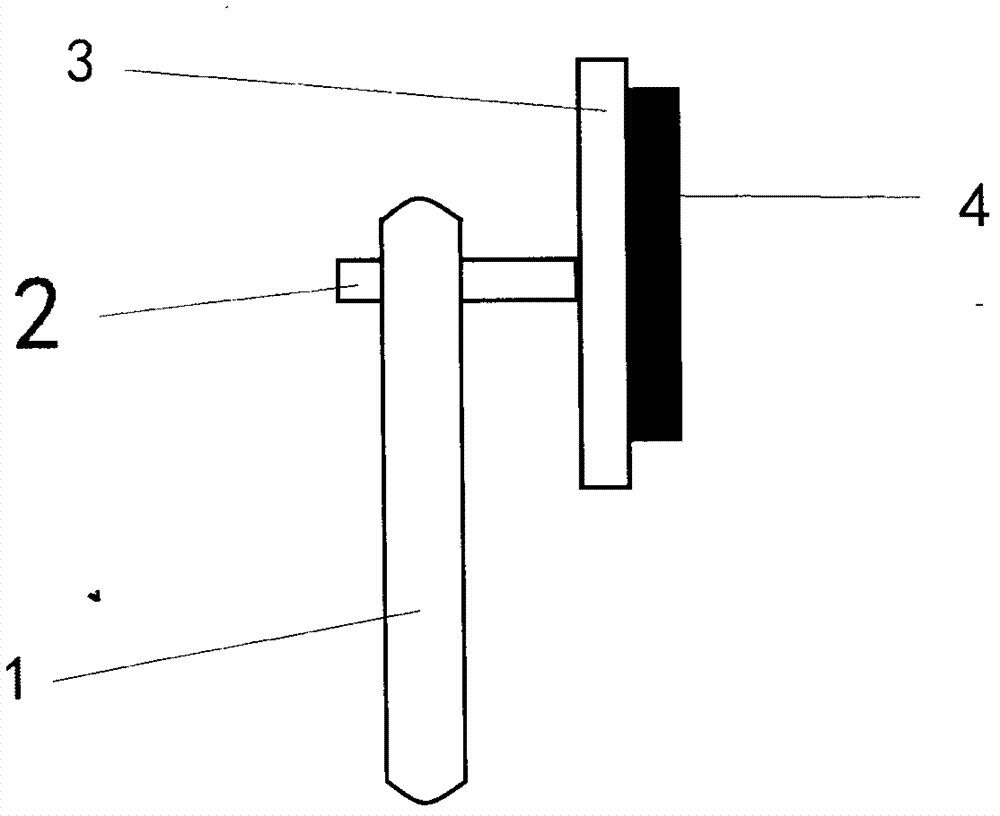

[0012] Such as figure 1 As shown, this is a traditional rubber wiper. The rubber strip 4 is clamped by a clamping plate 3, and the clamping plate 3 is connected to the rocker arm 1 through a rotating shaft 2. Under the action of the transmission mechanism, the rocker arm 1 drives the splint 3 to swing left and right, and the rubber strip 4 scrapes the rain and dust on the windshield.

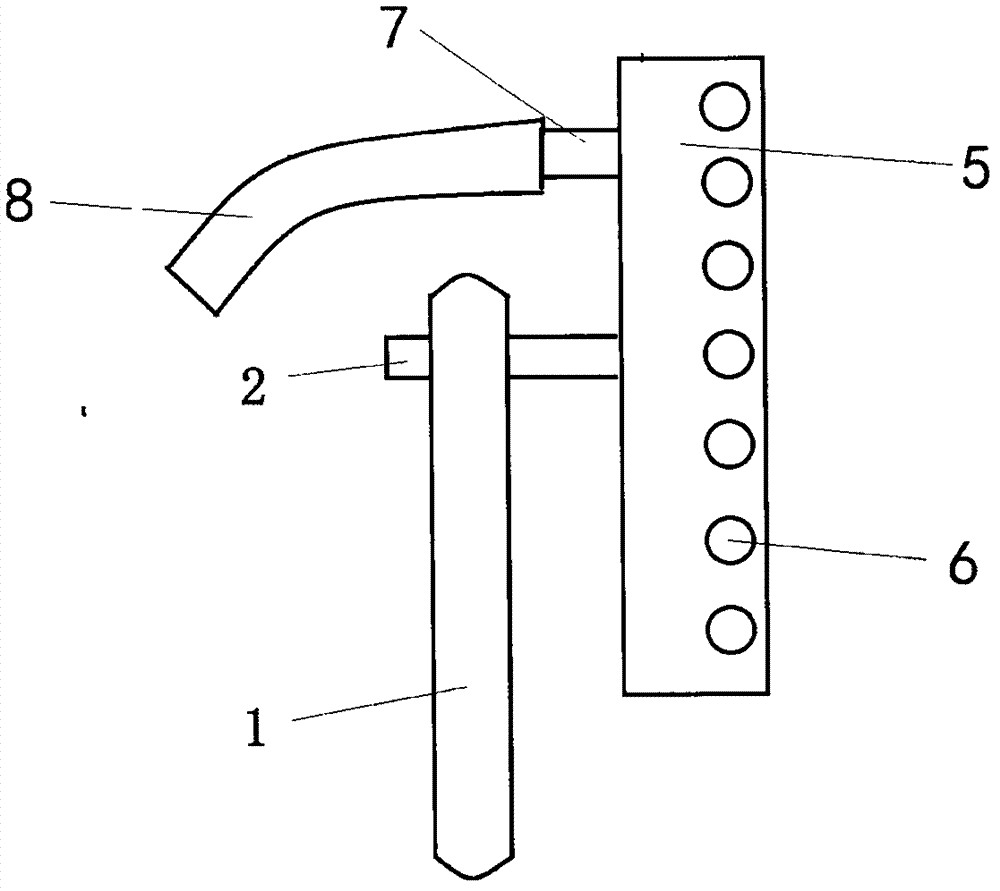

[0013] Such as figure 2 As shown, this is an air knife wiper. The air knife 5 is a tube with a discharge hole. The air knife 5 has an air outlet 6 and an air inlet 7, and the air inlet 7 is connected with the connecting pipe 8. When rain and dust on the windshield need to be wiped off, the air compressor is started, high-pressure air flows into the air knife 5 through the connecting pipe 8, and the high-pressure air is blown toward the windshield through the air outlet 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com