Quick foreign matter remover

A fast, miscellaneous knife technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of equipment not working properly, labor-intensive, labor-intensive, low production efficiency, etc. Simple and easy, long service life, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

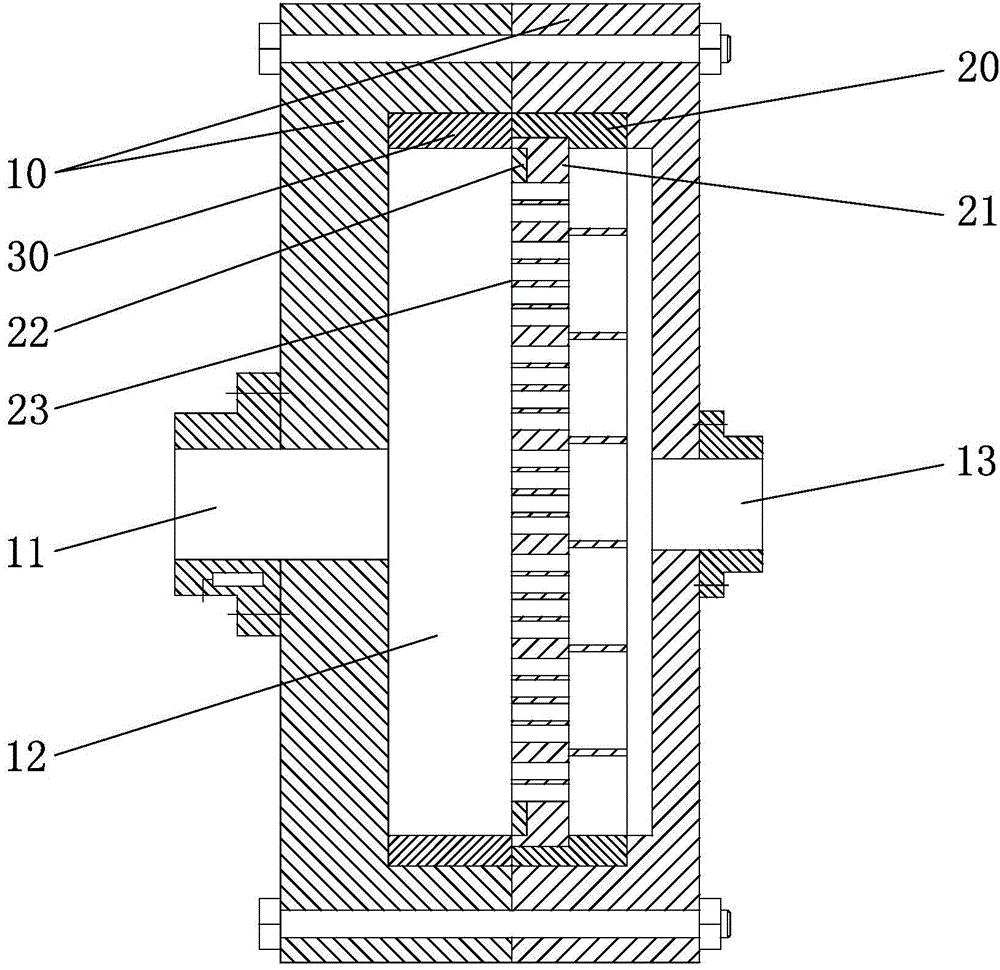

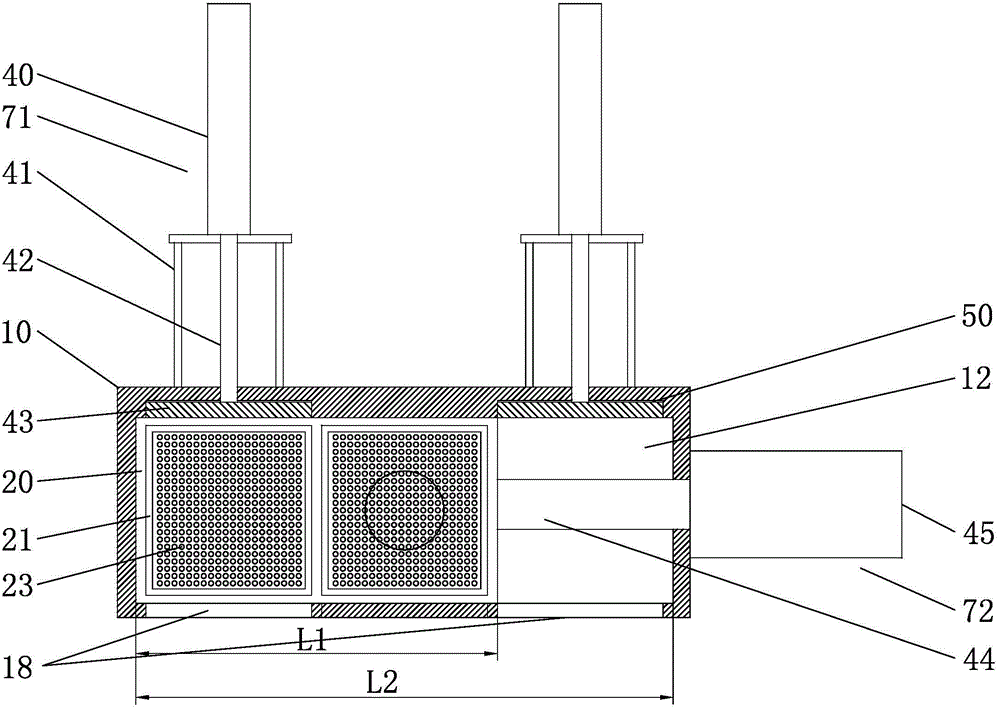

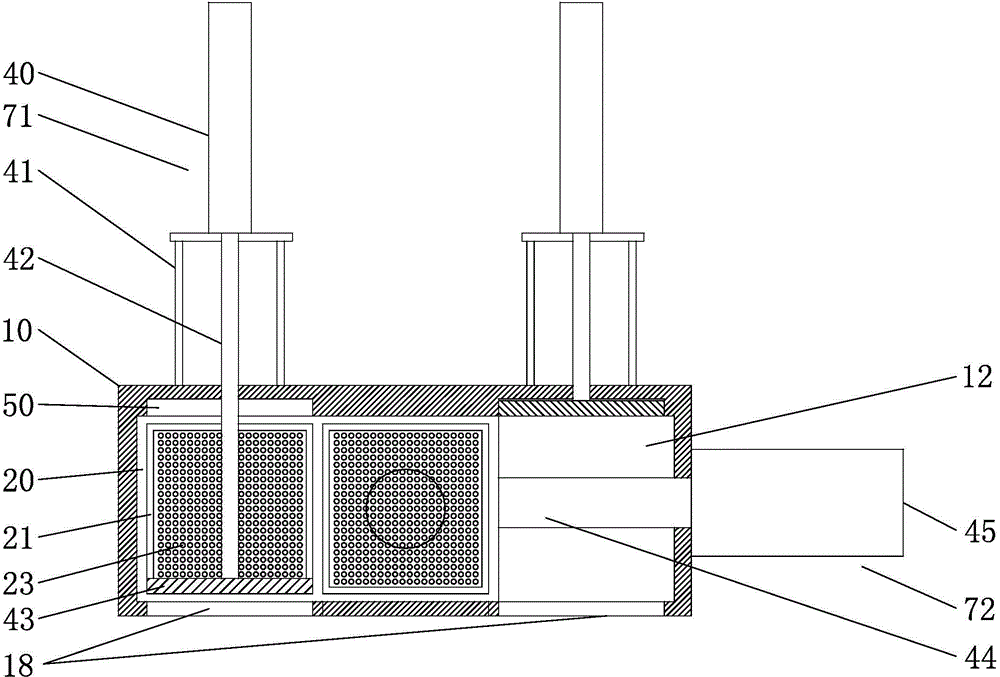

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Image 6 :

[0025] For the fast impurity remover, the middle part of the housing 10 is provided with a transverse collection chamber 12, the side wall of the housing 10 on the front side of the middle part of the housing 10 is provided with a feed port 11 communicating with the collection chamber 12, and the rear side is provided with an outlet. The feed port 13, the filter screen frame 20 driven by the power device to slide horizontally is arranged in the material collecting chamber 12, and more than one filter screen 23 with a filter screen frame 21 is arranged side by side in the described filter screen frame 20. When the net 23 is set in the center of the collection chamber 12, the surroundings of the filter screen frame 21 in the collection chamber 12 are sealed with the housing 10, and the front side of the filter screen 23 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com