Rapid and effective brushing machine for knitwear

A technology for knitwear and brushing machine, which is applied in the field of high-efficiency brushing machine and fast knitwear and clothing, can solve problems such as few types, and achieve the effects of high work efficiency, easy promotion and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

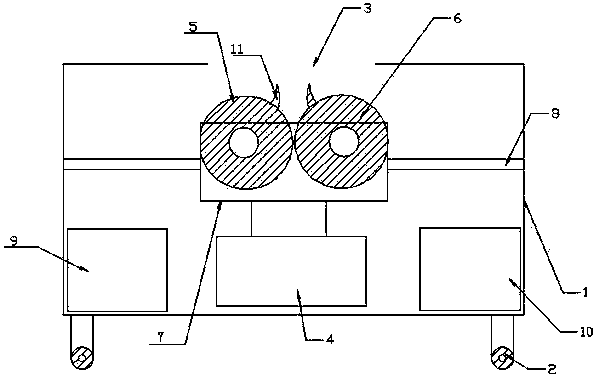

[0020] further as figure 1 As shown, the clothing to be brushed is placed at the material inlet 3 on the frame 1 (wherein the material inlet 3 is a mesh structure), and the driving motor 4 is driven through the gear transmission box 7 to drive the first rotating brush shaft 5, The second rotating brush shaft 6 does the occlusal action, then the bristle teeth 11 shave the debris on the clothing and drive the debris to the bottom of the baffle plate 8, and the first centrifugal hair suction machine 9 and the second centrifugal hair suction machine 10 will be broken. The scraps are absorbed and collected, and the baffle plate 8 can prevent the scraps from returning to the production workshop due to the air flow; this brush bristle function can quickly remove the residues (short hair, Fly hair, fluff and other residues), thus solving the problem of low efficiency and poor effect of driving single-axis bristles and the traditional manual operation with viscose, which greatly reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com