Heat dissipation device, semiconductor production system and fault monitoring method of heat dissipation fan

A heat dissipation device and heat dissipation fan technology, which is applied in semiconductor/solid-state device manufacturing, pump control, non-variable pumps, etc., can solve the problems that the failure of the heat dissipation fan cannot be found in time, the production accident monitoring circuit is complex, and the lack of real-time monitoring of the heat dissipation fan, etc. problem, to achieve the effect of simple fault monitoring method, simple structure, and avoiding production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

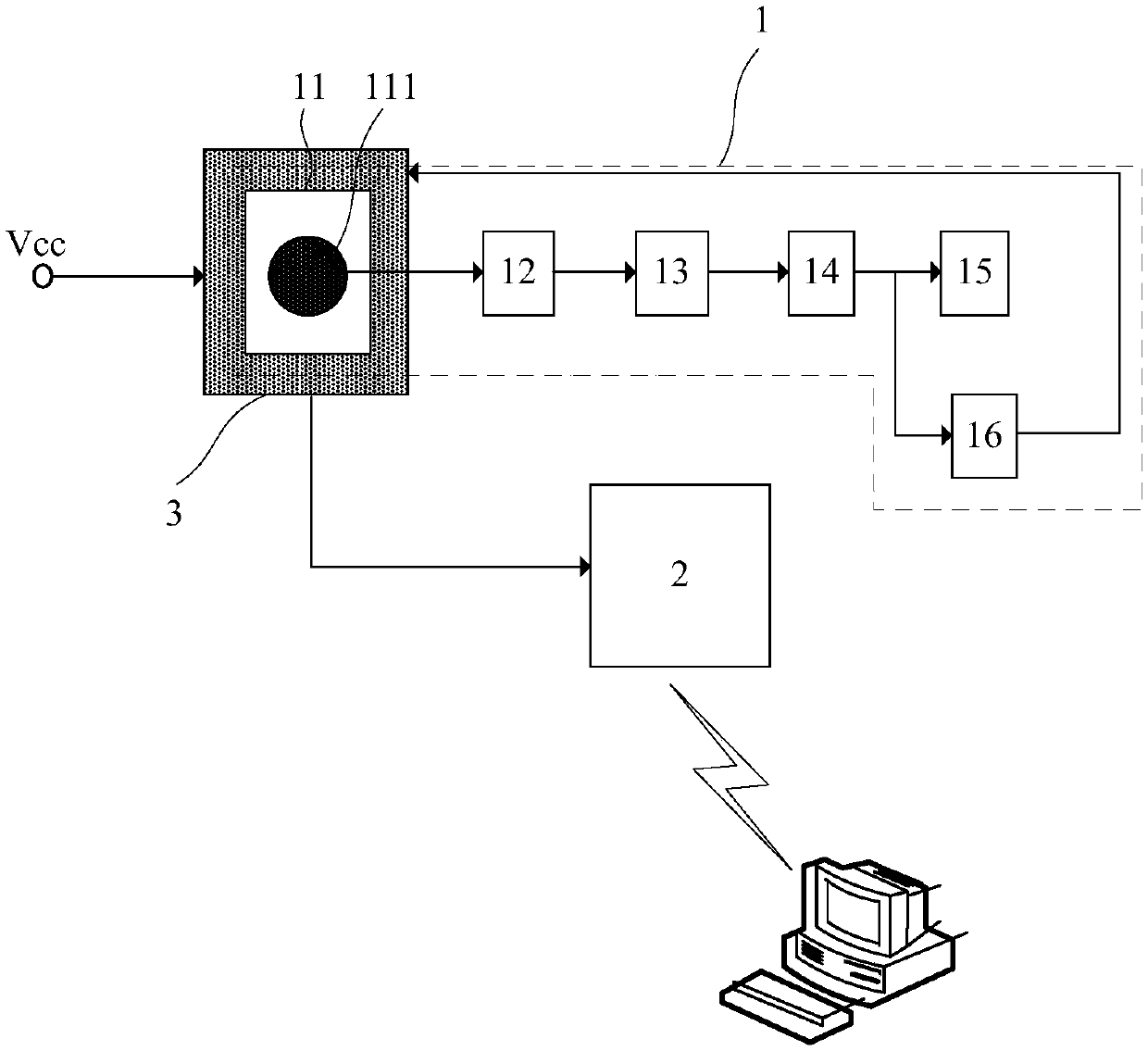

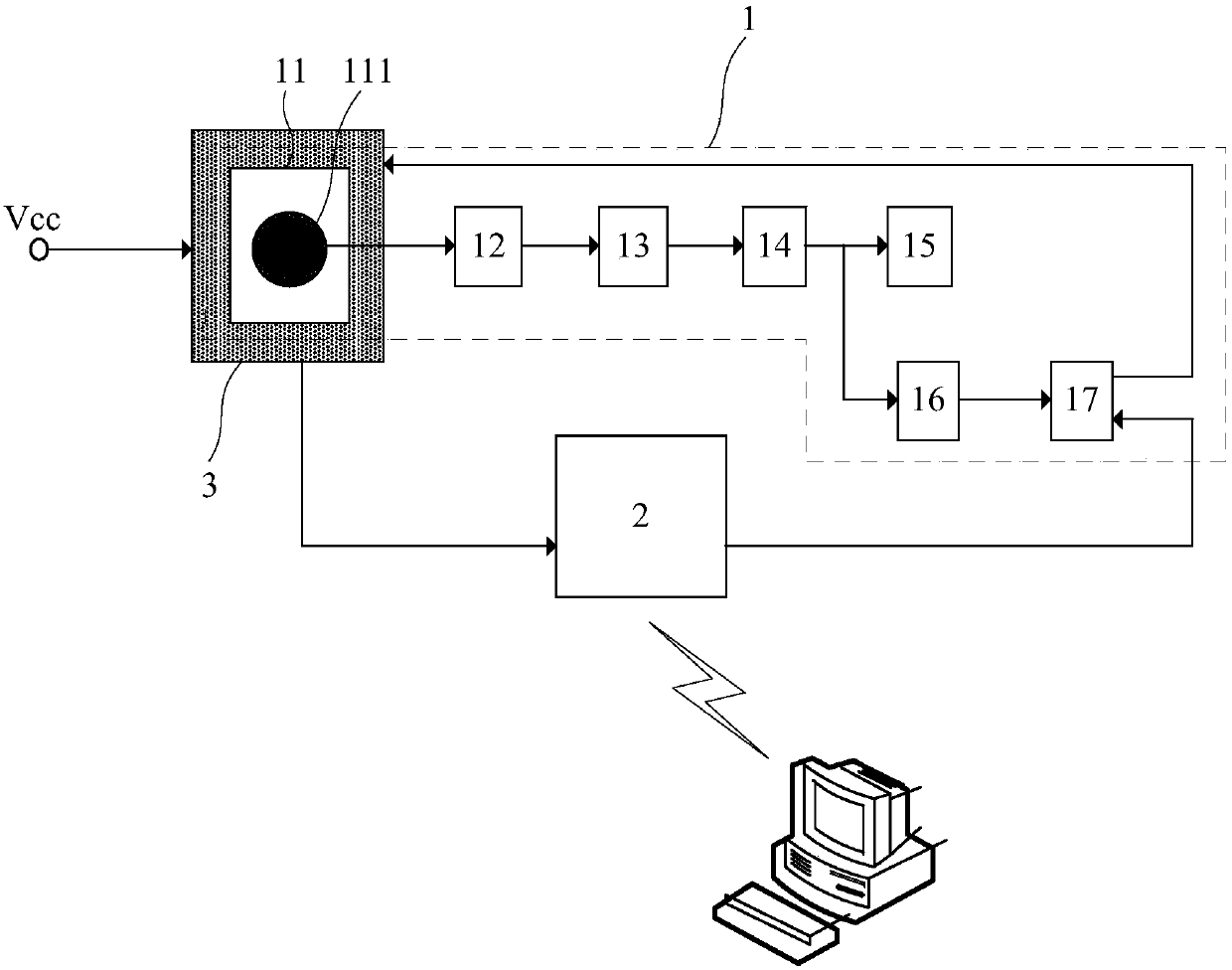

[0044] Such as figure 1 and figure 2 As shown, the present invention provides a heat dissipation device 1, the heat dissipation device 1 includes a cooling fan 11 and a current monitoring module 12; the cooling fan 11 includes a motor 111; the current monitoring module 12 has an input terminal and an output terminal, wherein The input terminal of the current monitoring module 12 is connected to the motor 111 for monitoring the induced current of the motor 111, and the output terminal of the current monitoring module 12 is used for outputting the detected induced current. The cooling fan 11 needs to be connected to a power supply Vcc during operation, and the power supply is generally a converted DC power supply.

[0045] The heat dissipation fan 11 can be a fan with blades or a fan without blades. Although the working principles are slightly different, they all take heat away by accelerating the flow of air. For example, the bladeless fan uses the motor 111 to suck air into...

Embodiment 2

[0056] Such as figure 1 and figure 2As shown, the present invention also provides a semiconductor production system, the semiconductor production system includes semiconductor production equipment 2, a power supply device 3 and a heat dissipation device 1, wherein the power supply device 3 is connected to the semiconductor production equipment 2; The heat dissipation device 1 includes a heat dissipation fan 11 and a current monitoring module 12, and the heat dissipation fan 11 is located in the power supply device 3 for dissipating heat to the power supply device 3, and the heat dissipation fan 11 includes a motor 111; the current The monitoring module 12 has an input terminal and an output terminal. The input terminal of the current monitoring module 12 is connected to the motor 111 to monitor the induced current of the motor 111. The output terminal of the current monitoring module 12 is used for outputting The sensed current is monitored. The heat dissipation device 1 is...

Embodiment 3

[0059] The present invention also provides a method for monitoring the failure of the cooling fan. When the cooling fan 11 is working, the induced current of the motor 111 located in the cooling fan 11 is monitored in real time, and the cooling fan is judged according to the detected induced current. Whether fan 11 is faulty.

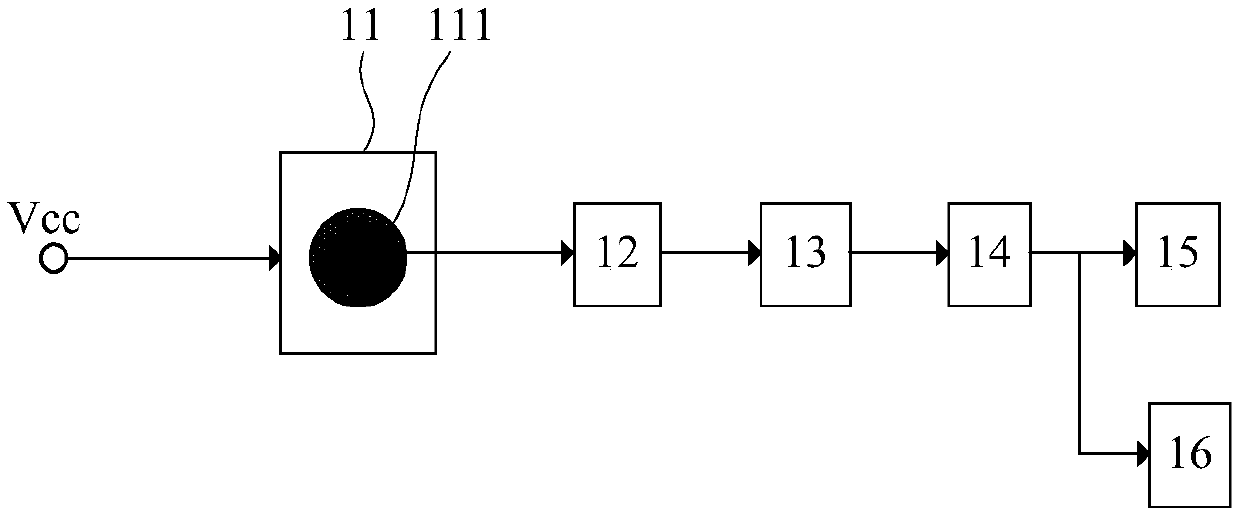

[0060] Such as image 3 As shown, in order to achieve the purpose of the present invention, a monitoring circuit is constructed in this embodiment, and the monitoring circuit is connected to the motor 111 in a heat dissipation fan 11, and is used to monitor in real time when the heat dissipation fan 11 is working. The induced current of the motor 111 in the cooling fan 11 is used to determine whether the cooling fan 11 is faulty according to the detected induced current.

[0061] As an example, the monitoring circuit includes a current monitoring module 12, the current monitoring module 12 has an input terminal and an output terminal, wherein the input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com