Indoor concentrated and combustion system of VOCs with catalytic poison oxidation device

An oxidation device and combustion system technology, applied in the direction of combustion methods, chemical instruments and methods, combustion types, etc., can solve problems such as temperature above 500°C, performance degradation, etc., to reduce emissions, improve activity, and solve harmful gases and residues The effect of odor problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

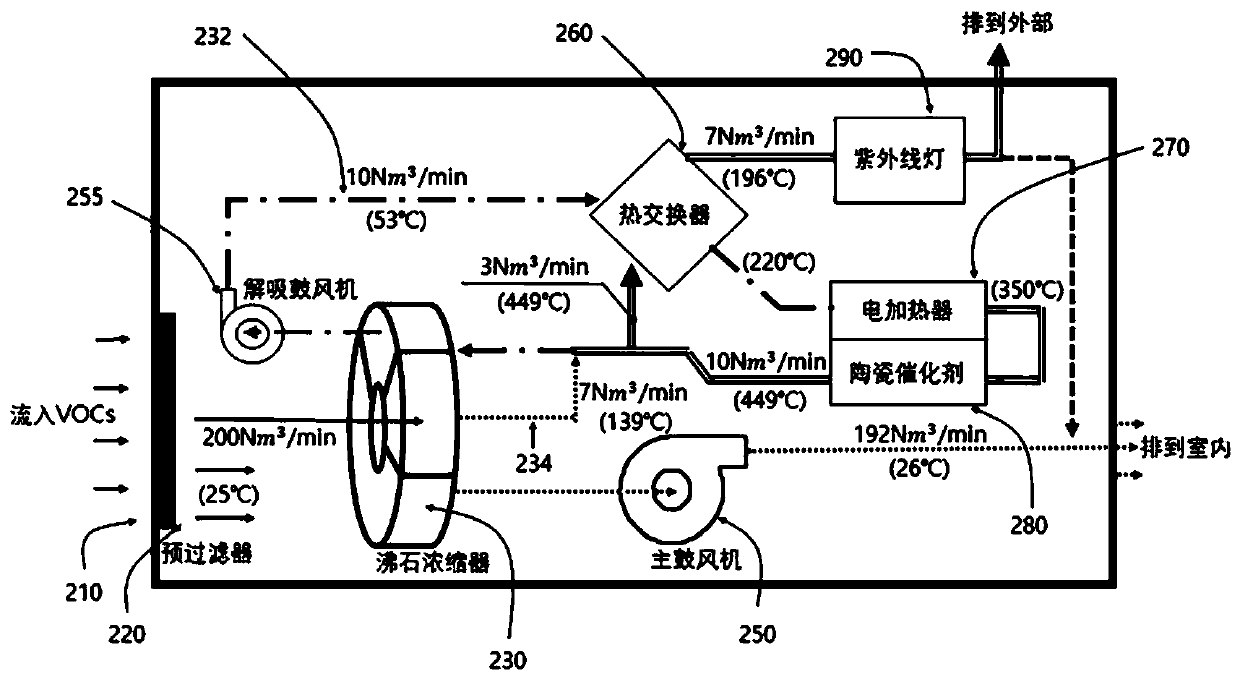

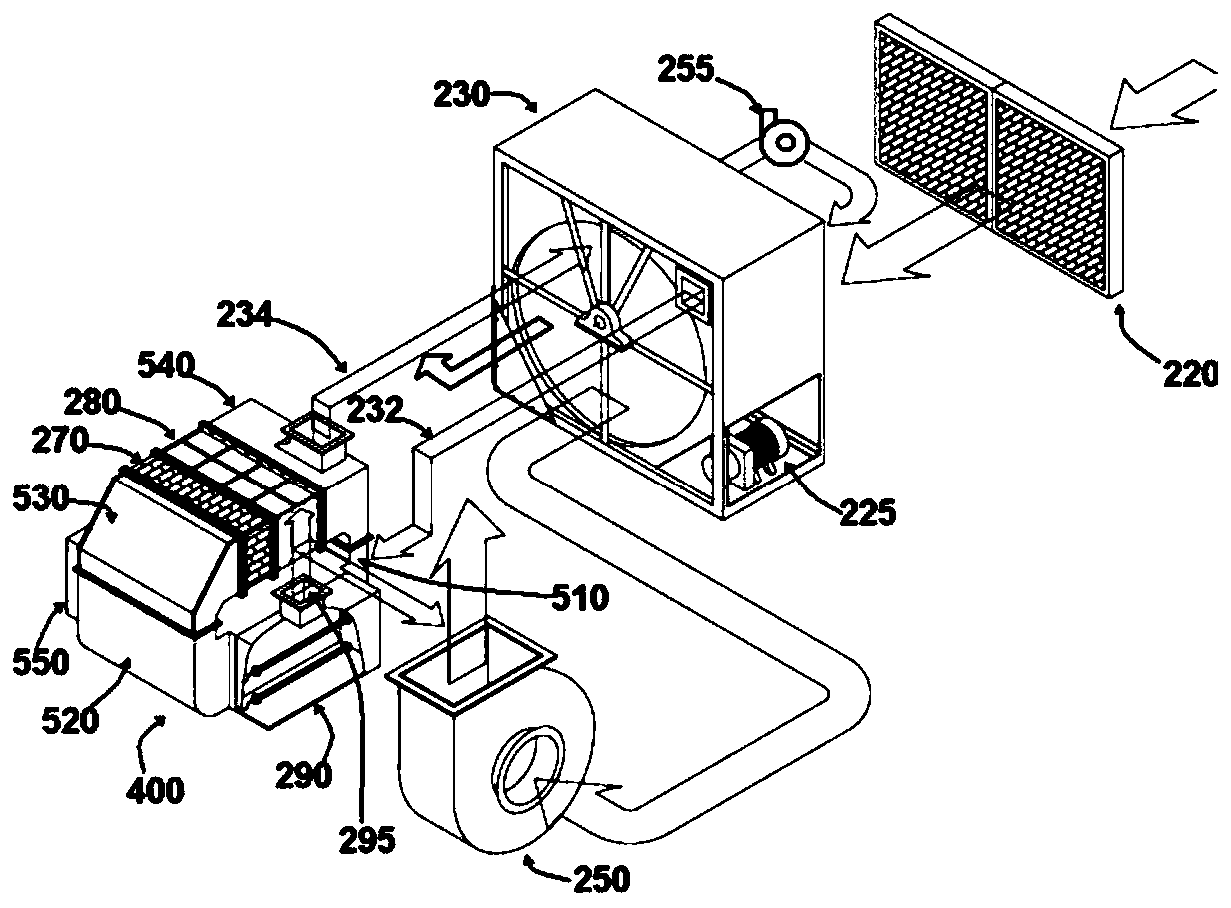

[0044] The following will refer to Figure 2 to Figure 5 A preferred embodiment of the indoor concentrated combustion system equipped with a catalytic poison oxidation device used in the present invention will be described in detail.

[0045] The present invention provides an indoor concentrated combustion system equipped with a catalyst poison oxidation device, comprising: a VOCs gas collection unit 210 installed on the front of a square box-shaped zeolite concentrator to collect volatile gases at normal temperature; a pre-filter 220 , installed on the back of the VOCs gas trapping part to filter out particulate matter such as dust in the VOCs gas trapped in the VOCs gas trapping part; the zeolite concentrator part 230 is used to adsorb benzene, thinner, odor, etc. The VOCs gas passing through the pre-filter 220 is filtered by means of volatile substances, and then the main blower is used to discharge it into the room. The discharge pipe 234 of the concentrator part is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com