Patents

Literature

46results about How to "Improve overheating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Control method and control device of air conditioning system and machine room air conditioning system

InactiveCN112539529AImprove overcooling and overheatingReduce operating costsMechanical apparatusSpace heating and ventilation safety systemsLoad schedulingProcess engineering

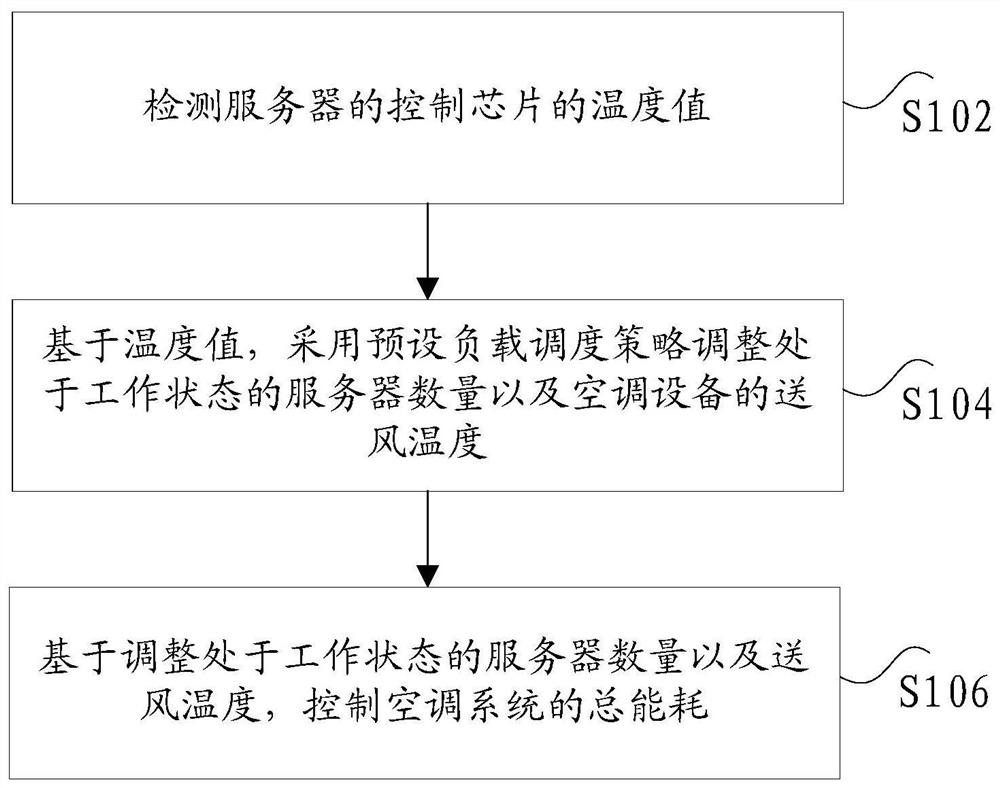

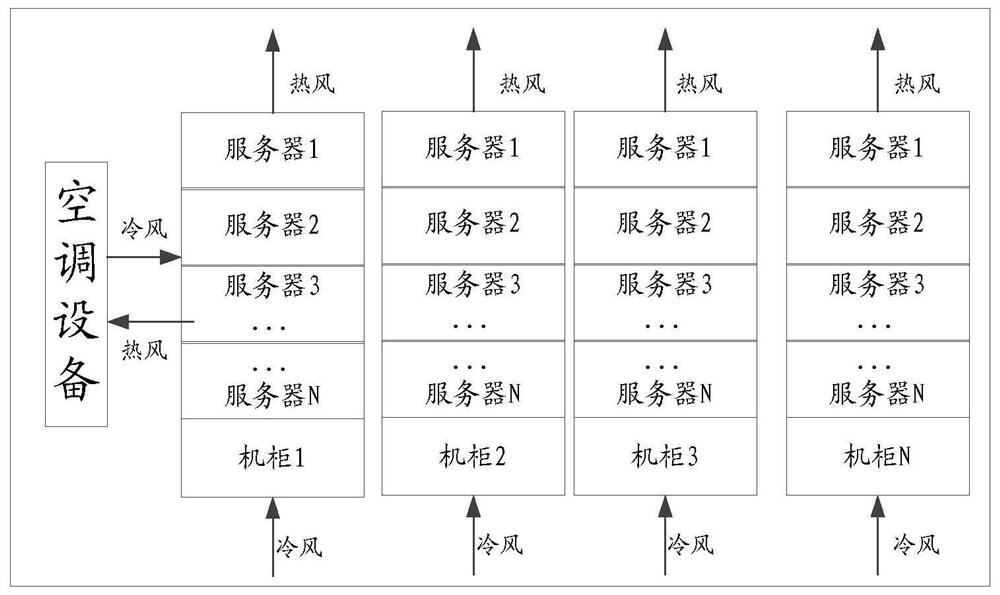

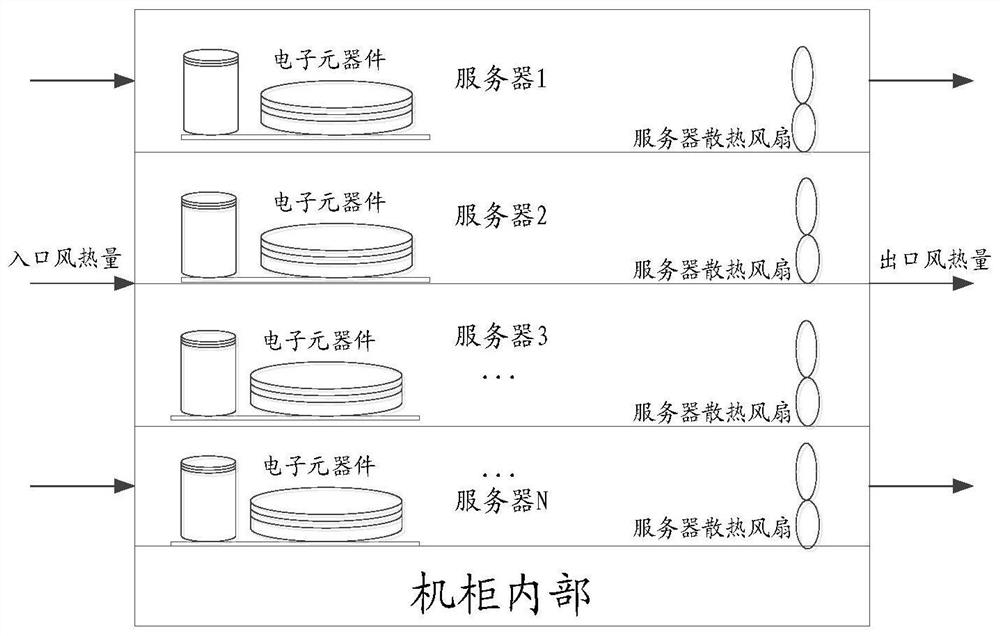

The invention discloses a control method and control device of an air conditioning system and a machine room air conditioning system. The air conditioning system comprises air conditioning equipment and cabinets, multiple servers are installed in the cabinets, and the air conditioning equipment is used for supplying air to the cabinets and dissipating heat for the servers in the cabinets. The control method comprises the steps that the temperature values of control chips of the servers are detected; based on the temperature values, a preset load scheduling strategy is adopted to adjust the number of the servers in a working state and the air supply temperature of the air conditioning equipment; and the total energy consumption of the air conditioning system is controlled based on adjustment of the number of the servers in the working state and the air supply temperature. The technical problems that in the prior art, IT equipment power consumption in a machine room is not matched with cooling capacity supply of an air conditioning system, and the local overheating or supercooling phenomenon is likely to happen are solved.

Owner:GREE ELECTRIC APPLIANCES INC

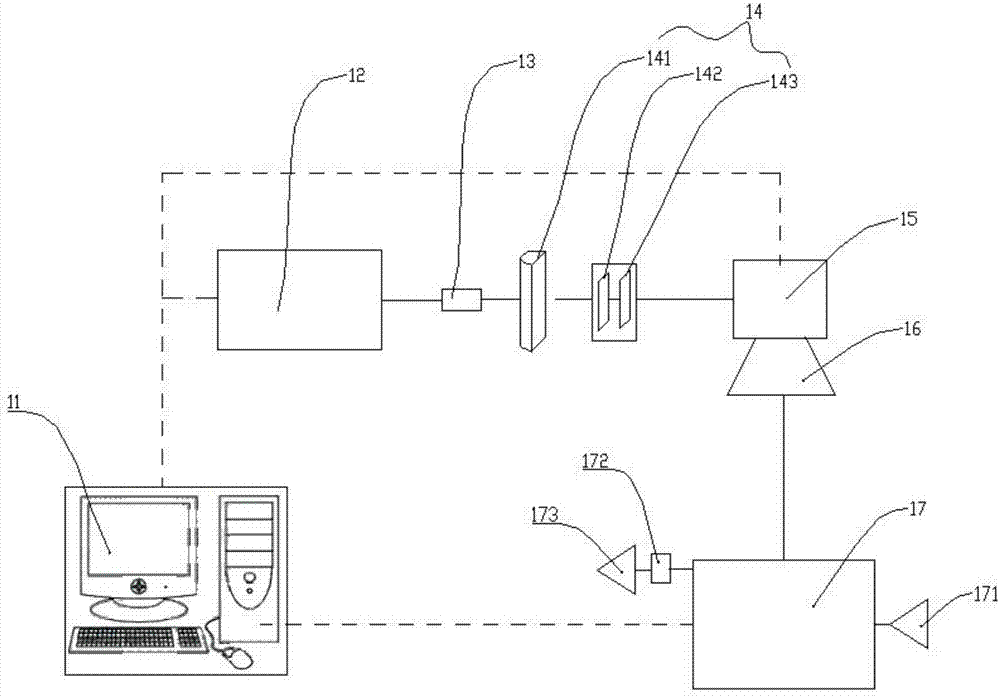

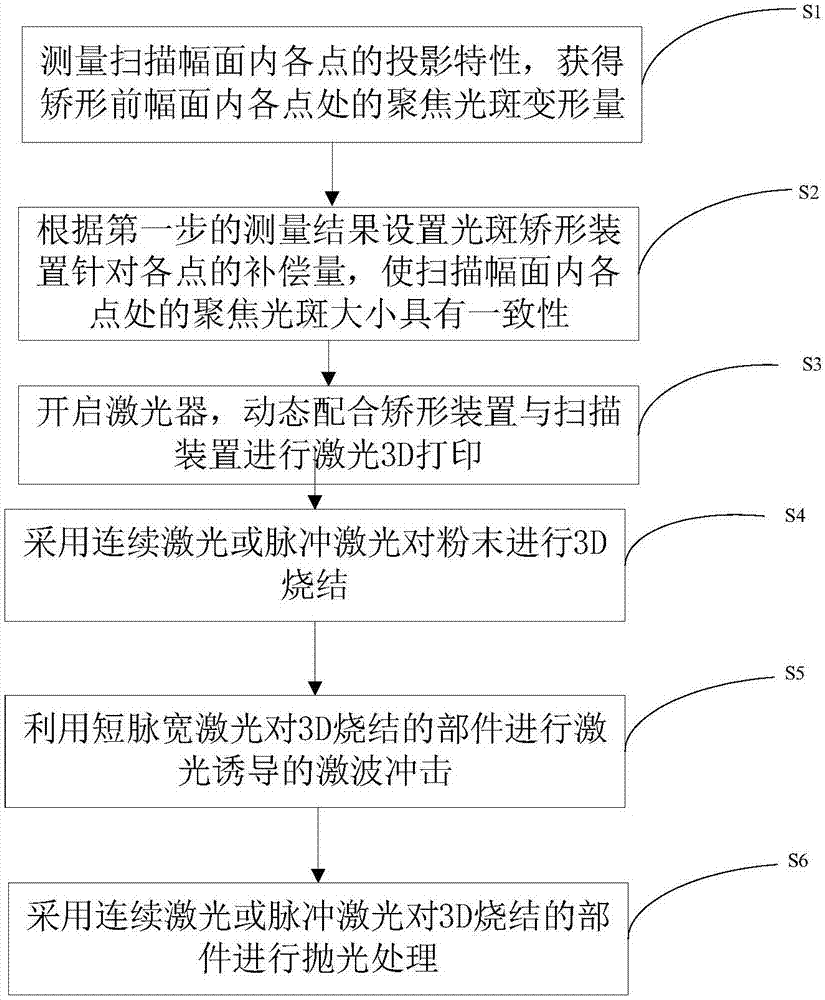

Laser 3D printing method and system with shape correction function

InactiveCN107336440AEnsure consistencyQuality improvementAdditive manufacturing apparatus3D object support structuresOptoelectronicsLaser pulse width

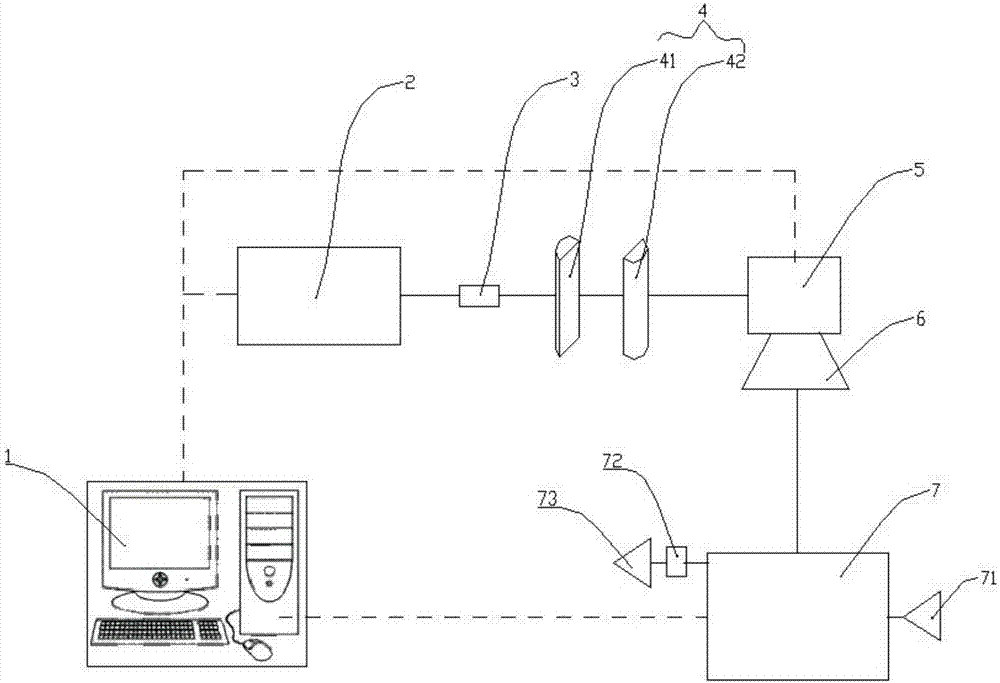

The invention discloses a laser 3D printing method with a shape correction function. The method comprises the following steps that (1), projection characteristics of all points in scanning breadth are measured, and the focusing light spot deformation amount of all the points in the scanning breadth before shape correction is obtained; (2), the compensation dosage of a light spot shape correction device to all the points is set according to the measurement result in the first step, and the sizes of focusing light spots at all the points in the scanning breadth can have consistency; (3), a laser is stated, and the laser is dynamically matched with the shape correction device and a scanning device for laser 3D printing. According to the laser 3D printing method and system with the shape correction function, the laser sintering degree is controlled by changing the laser pulse width in the 3D printing process, the situation that holes, superburning and nodulizing are generated in the printing process is improved, and density is improved; and besides, the shape correction device is added, it can be guaranteed that the sizes of the focusing light spots in the scanning breadth have consistency by precisely controlling the compensation amount of the light spot shape correction device, and thus 3D printing quality is guaranteed.

Owner:INNO LASER TECH CORP LTD +1

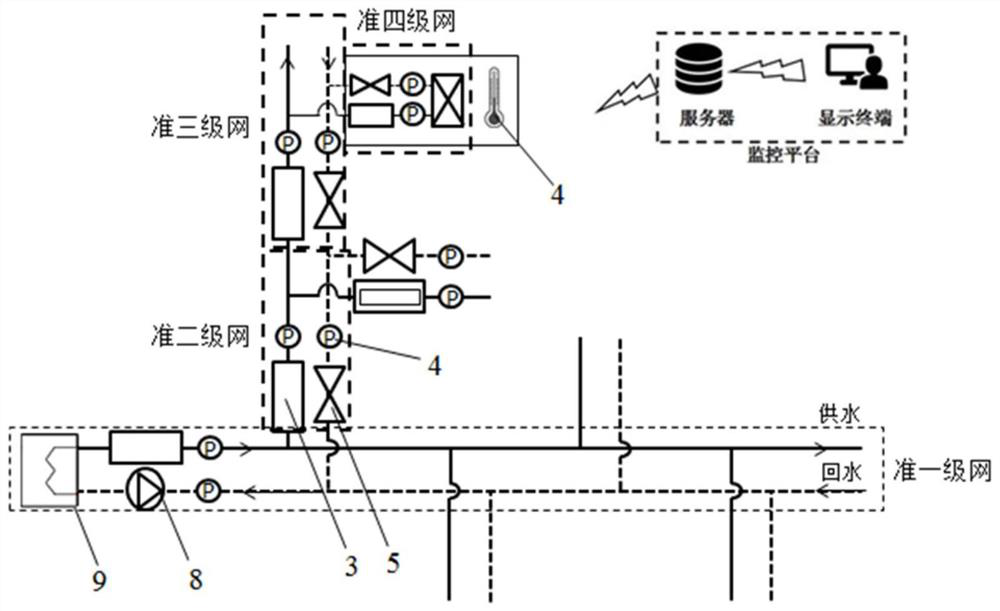

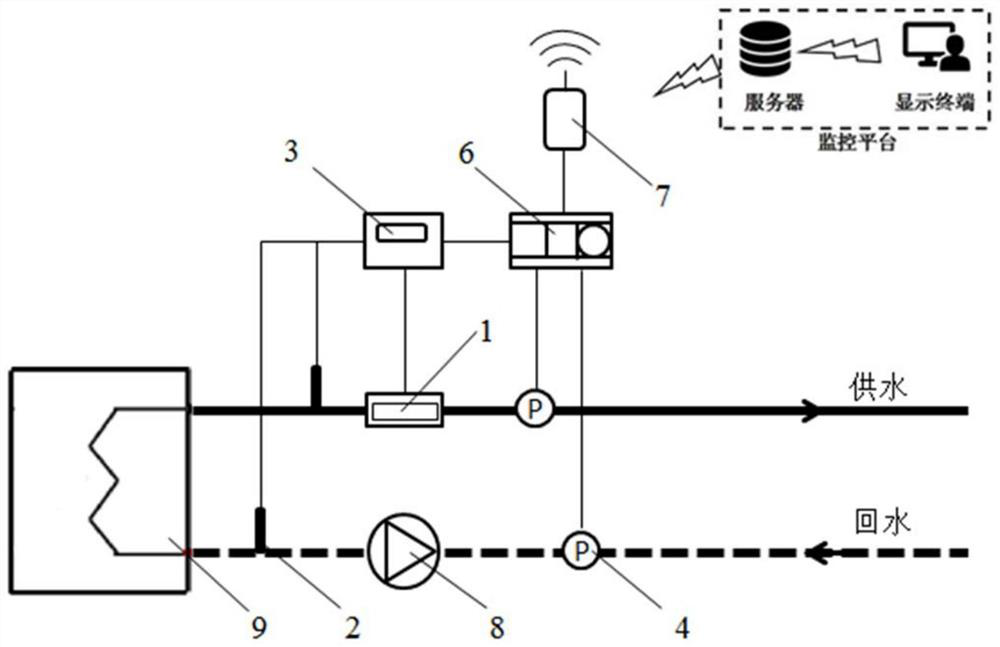

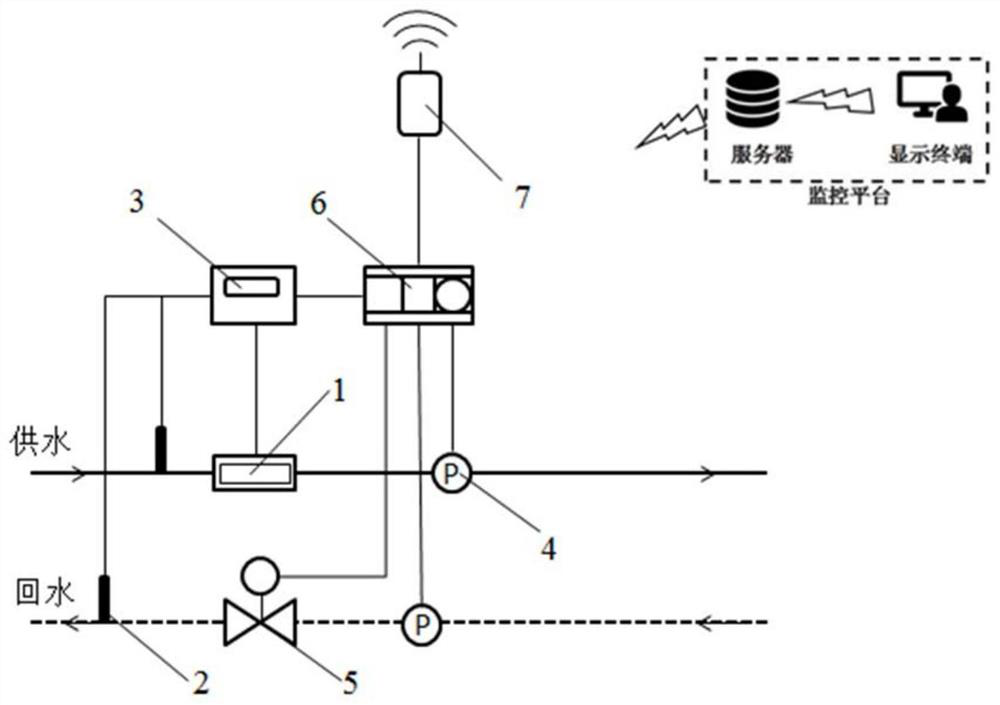

Regional heat supply system integrating pipe network grading and intelligent control, and transformation method

PendingCN112013453AImplement flow controlRealize regulationLighting and heating apparatusSpace heating and ventilation detailsThermodynamicsEngineering

The invention discloses a regional heat supply system integrating pipe network grading and intelligent control, and a transformation method. An energy station is used as a quasi-primary network, transformation is carried out based on a heat inlet, and the heat inlet originally used as a primary network is transformed into a quasi-secondary network; a heat branch and a heat tail end are transformedinto a quasi-tertiary network and a quasi-quaternary network correspondingly so as to realize flow control and load regulation irrelevant to the pressure in a control unit ring; a water pump and a pressure gauge are mounted on a water return pipeline of the quasi-primary network; and dynamic differential pressure balance valves and pressure gauges are mounted on water return pipelines of the quasi-secondary network and the quasi-tertiary network, a dynamic differential pressure balance valve and a water distributing and collecting device are mounted on a water return pipeline of the quasi-quaternary network, and communication modules connected with a monitoring platform are mounted in the quasi-primary network, the quasi-secondary network, the quasi-tertiary network and the quasi-quaternary network correspondingly.

Owner:TIANJIN UNIV +1

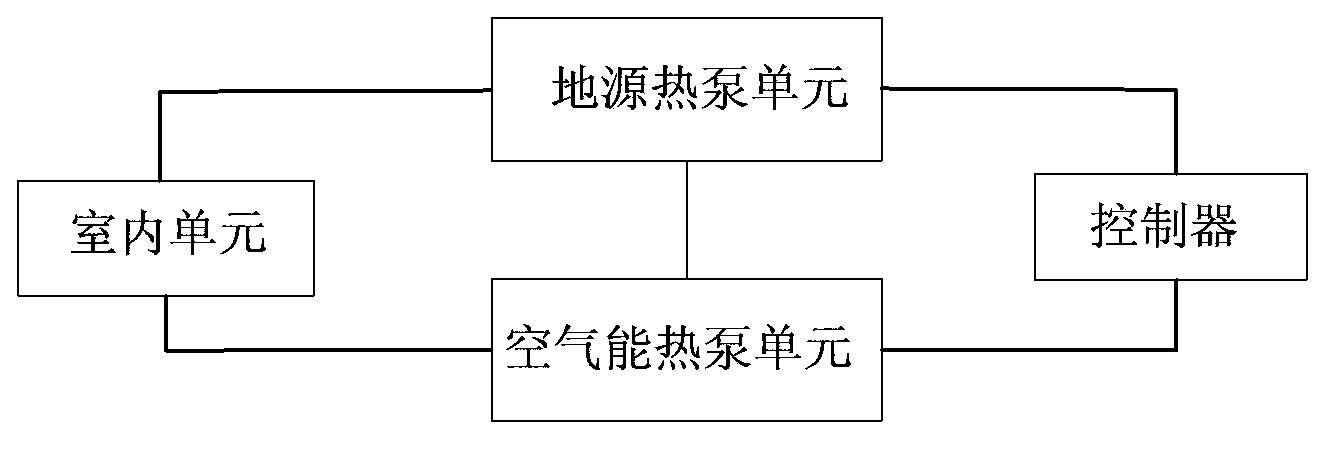

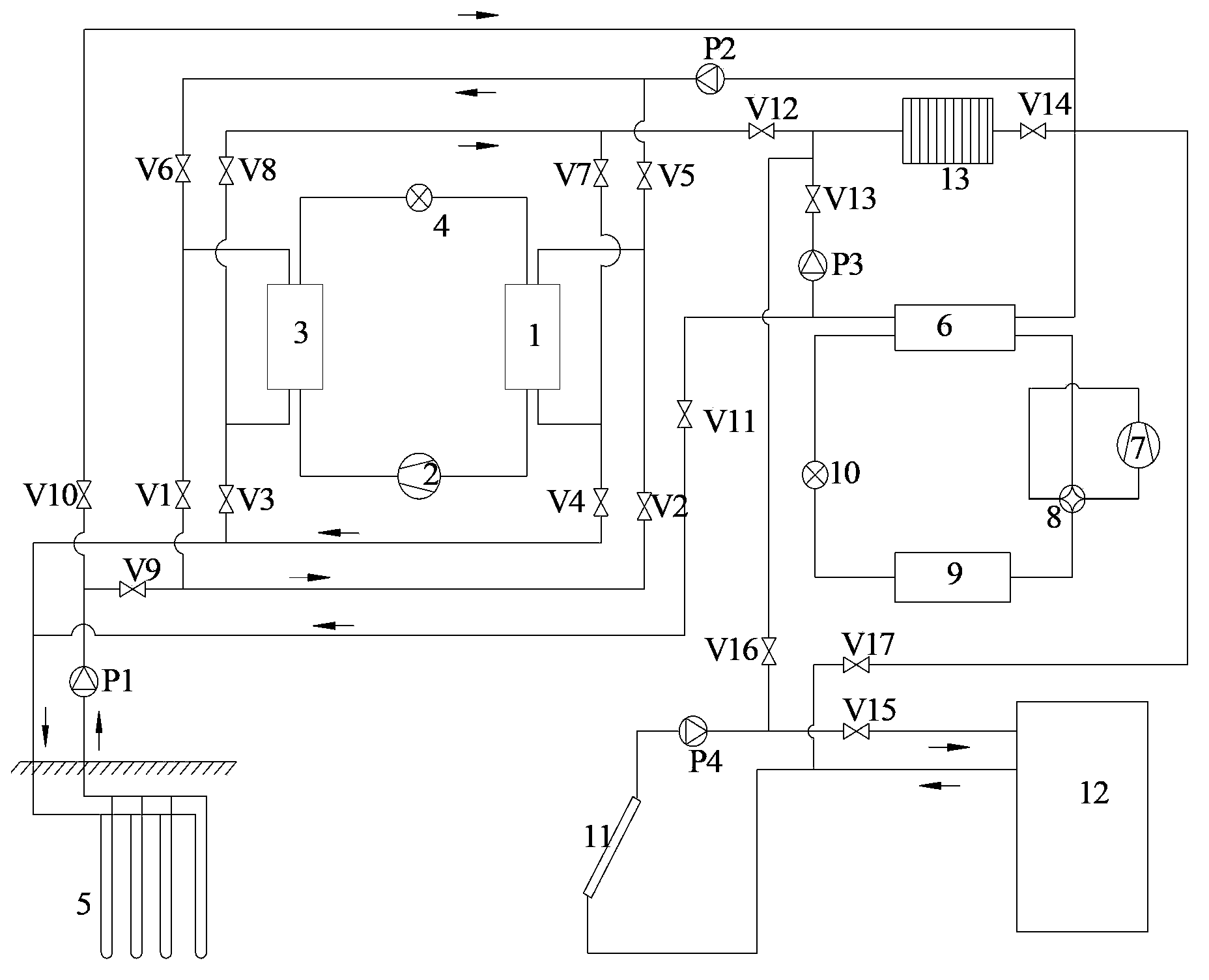

Air-conditioning system

InactiveCN103912938AImprove overheatingSave energyHeat pumpsSpace heating and ventilation safety systemsElectricity priceAir conditioning

The invention provides an air-conditioning system. The air-conditioning system comprises an indoor unit, a ground source heat pump unit, an air source heat pump unit and a controller, wherein the ground source heat pump unit is communicated with the indoor unit, the air source heat pump unit is communicated with the indoor unit, the ground source heat pump unit comprises a buried pipe heat exchanger, and the air source heat pump unit is communicated with the buried pipe heat exchanger. The controller is connected with the indoor unit, the ground source heat pump unit and the air source heat pump unit, and the air source heat pump unit is started within a low electricity price time period to store energy to the soil through the buried pipe heat exchanger. The low electricity price at night is utilized to perform soil cold accumulation or heat accumulation, system peak value cooling and heating loads can be effectively adjusted, energy is stored during the low electricity price period, electricity is used when the electricity price is high, running efficiency is improved, and the running cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

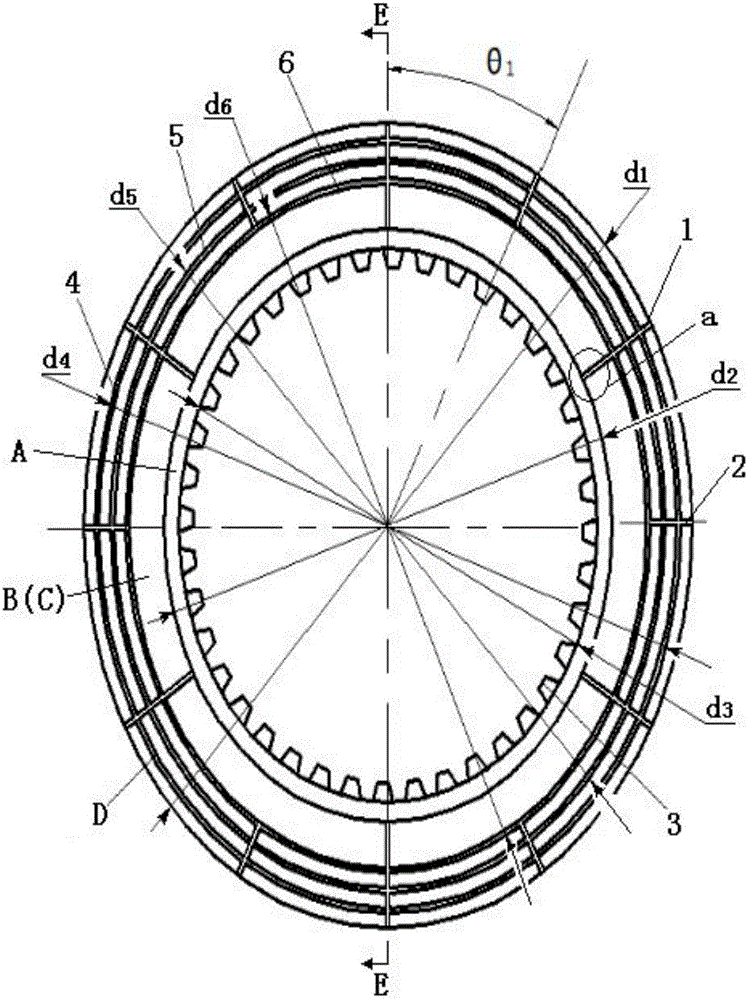

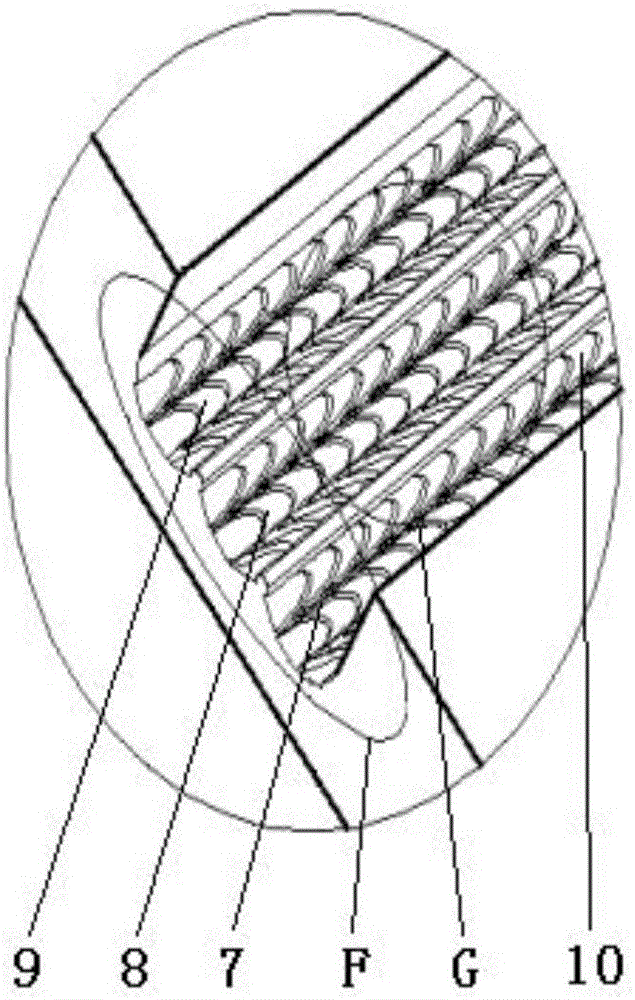

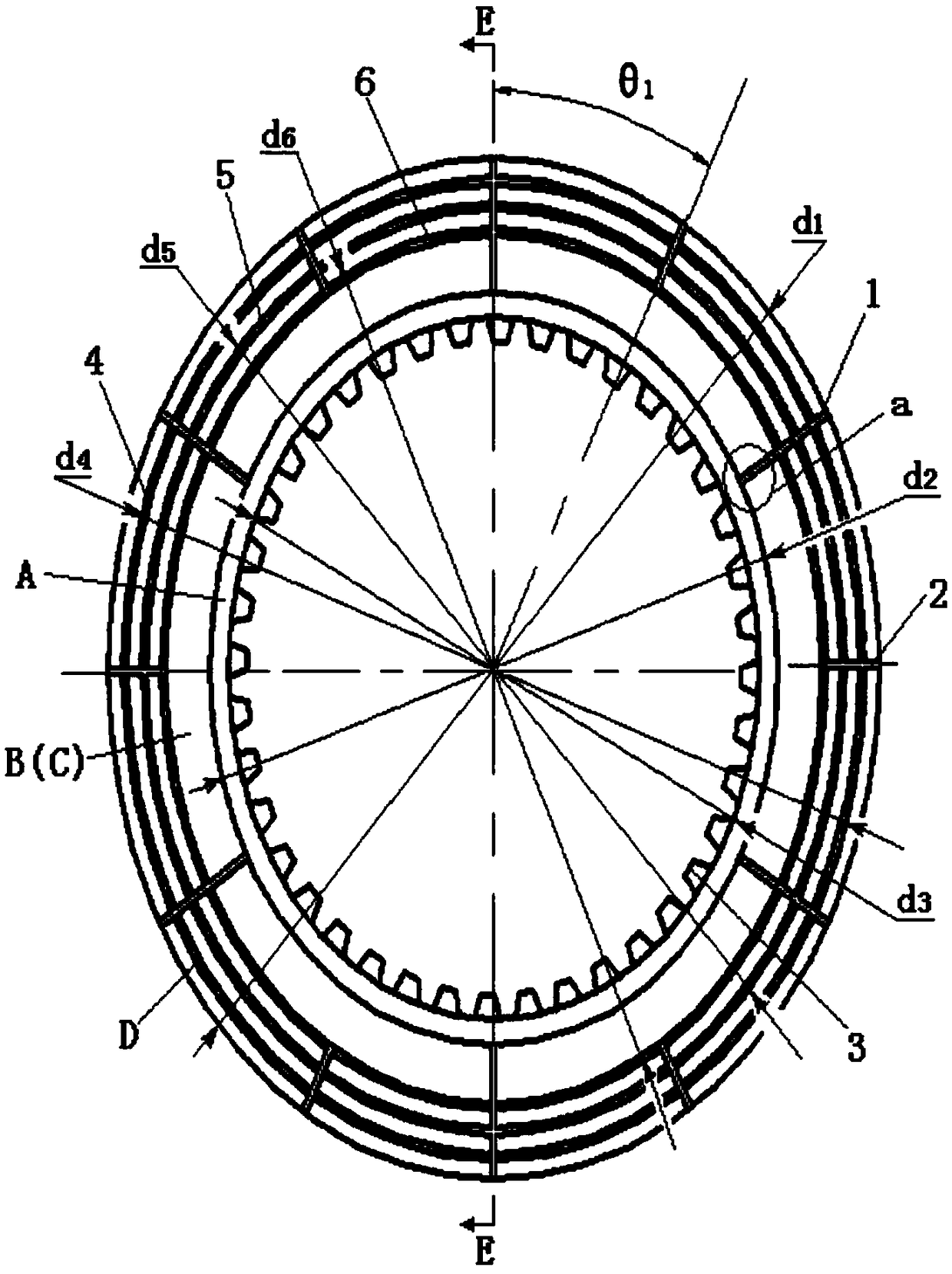

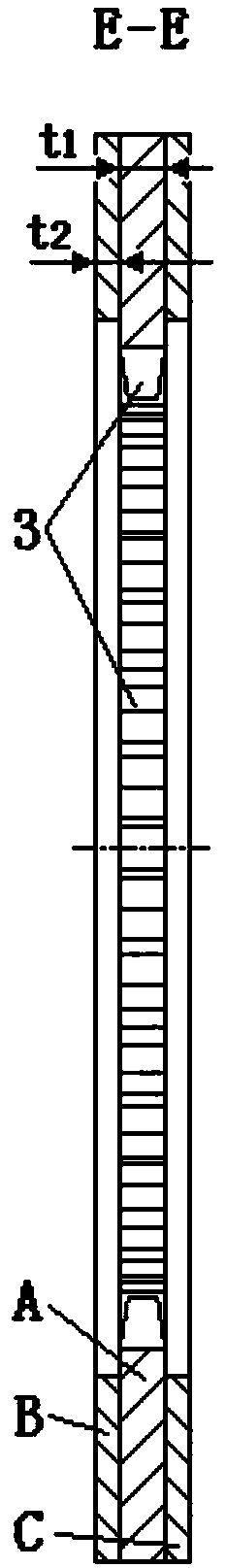

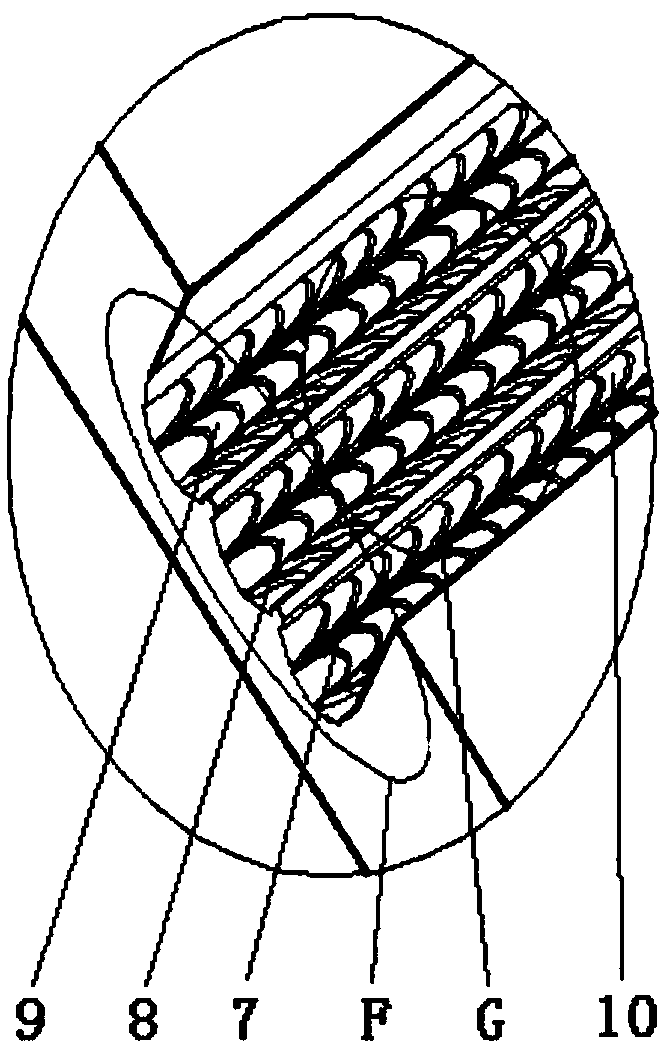

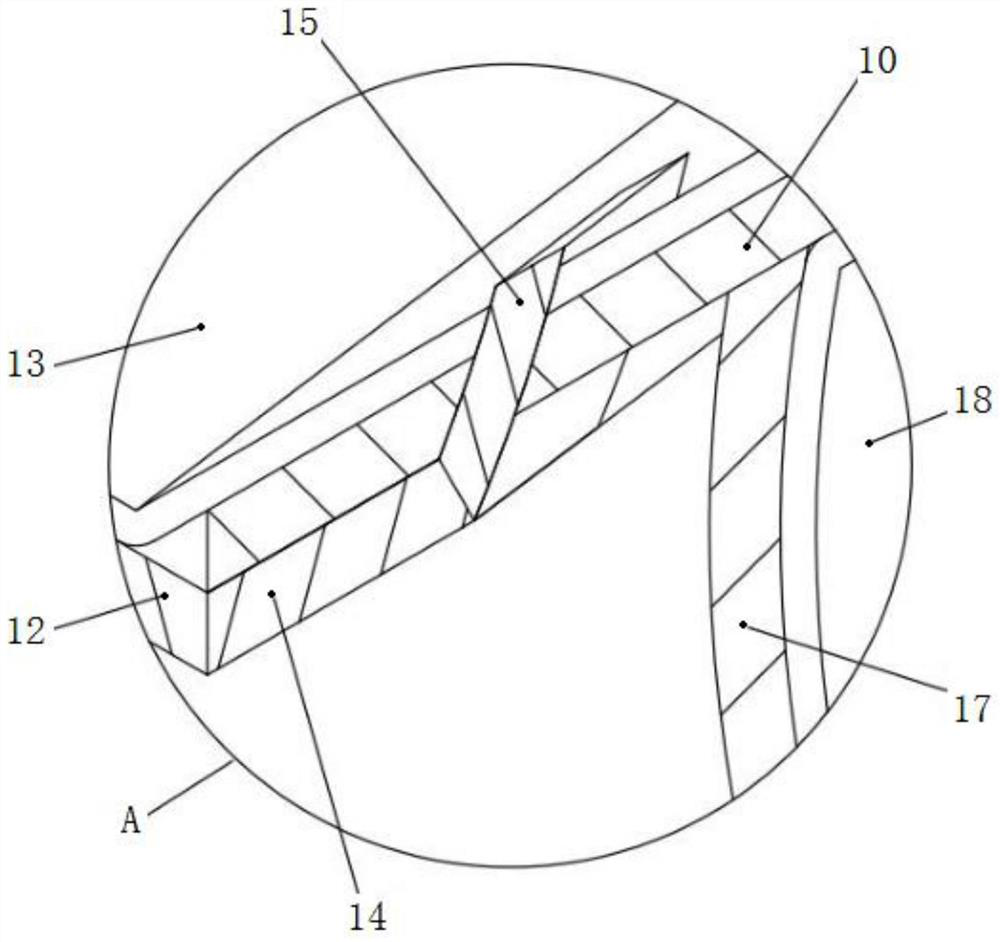

Wet clutch friction plate with bionic oil groove structure

InactiveCN106438746AIncrease profitFull heat exchangeFriction clutchesFriction liningClutchFriction reduction

The invention discloses a wet clutch friction plate with a bionic oil groove structure, and belongs to the technical field of automobile clutch friction plates. The wet clutch friction plate consists of a core plate and friction liners, wherein the two friction liners are symmetrically and fixedly connected with the front side and the back side of the core plate; radial oil grooves and annular oil grooves are formed in surfaces of both two friction liners; bionic micro structures consisting of guide grooves and bionic unit grooves are arranged at the bottoms of the oil grooves. Therefore, by adopting the wet clutch friction plate, an excellent one-way conveying guide function on cooled lubricating oil can be achieved, the flowing speed of the lubricating oil in the oil grooves can be effectively increased, heat convection between the lubricating oil and the friction plate can be improved, and surface temperature increase of the friction plate can be remarkably reduced; due to the combination of the radial oil grooves and the annular oil grooves, a unique composite oil groove mode can be achieved, failure situations such as over heat and deformation caused by concentrated heat stress on the surface of the friction plate can be alleviated, the performance of the friction plate can be comprehensively improved, and the service life of the friction plate can be prolonged.

Owner:JILIN UNIV

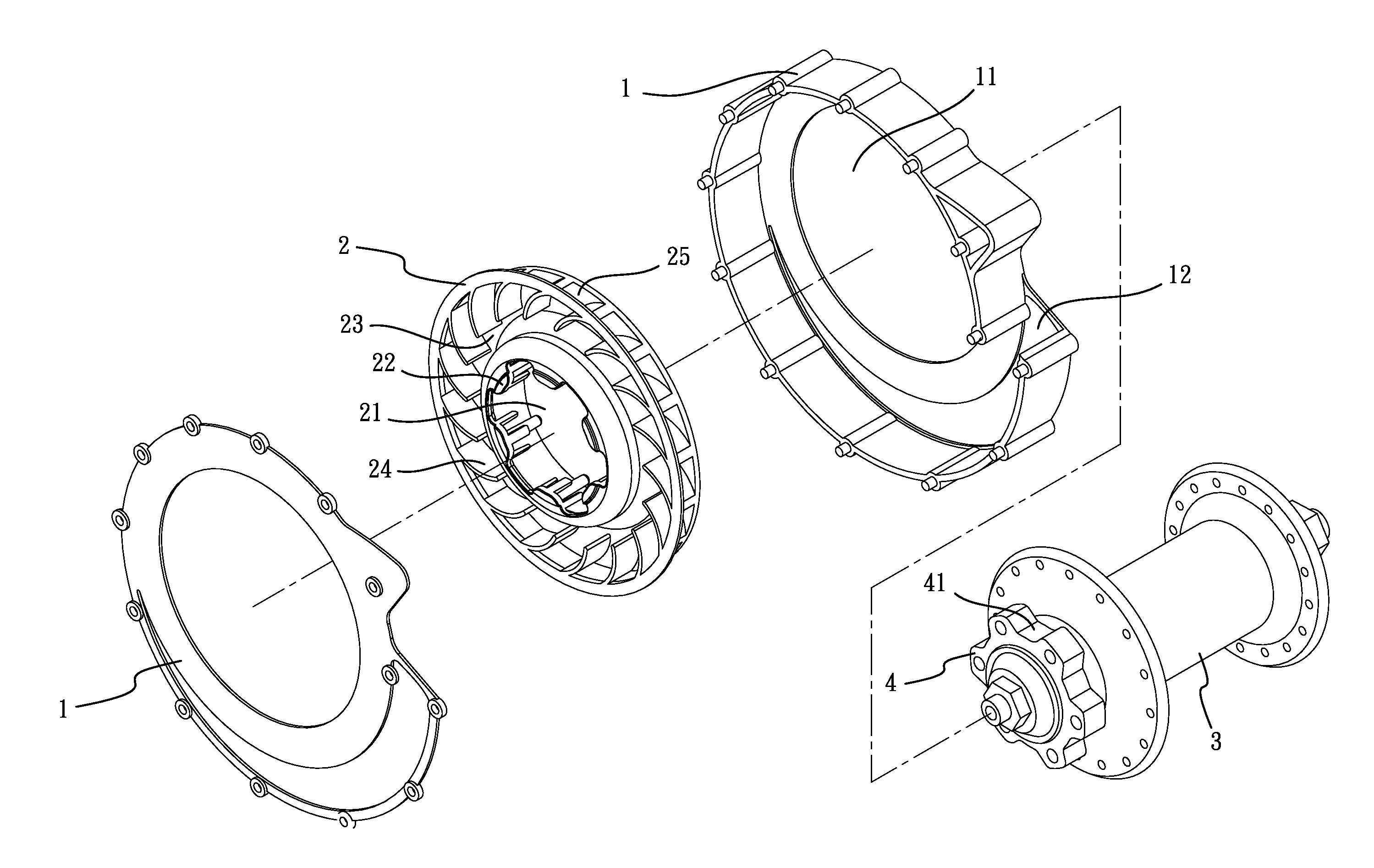

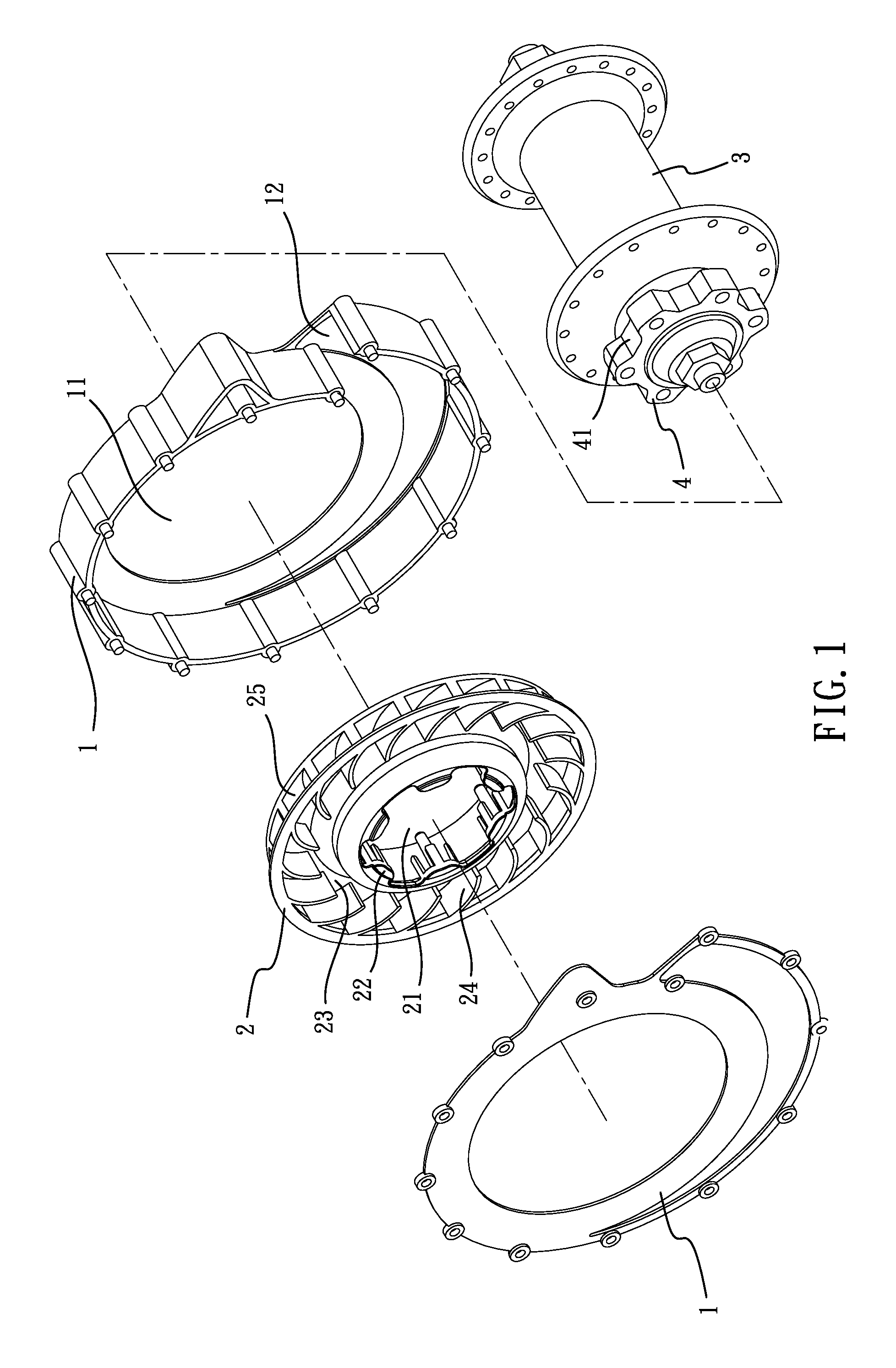

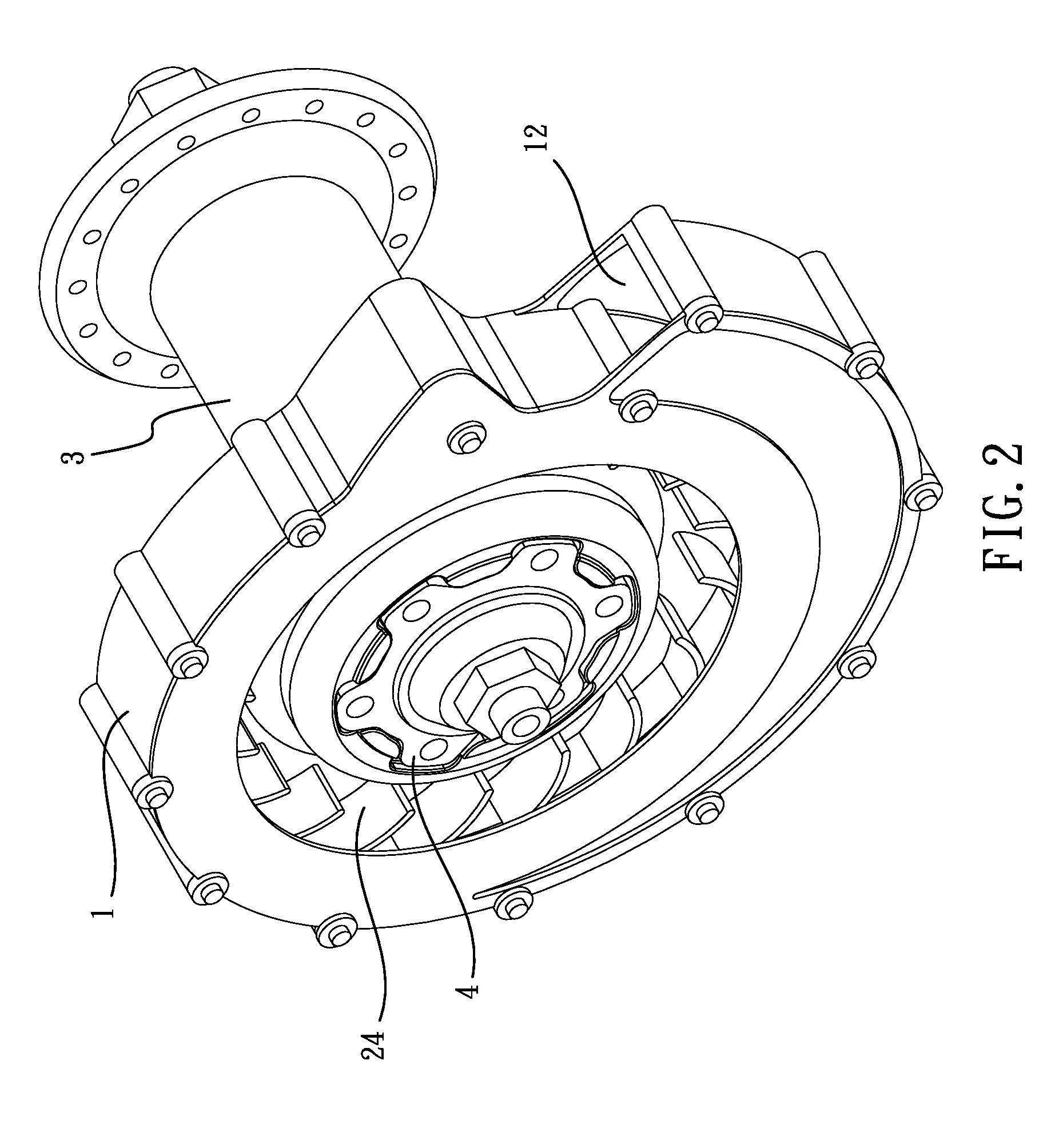

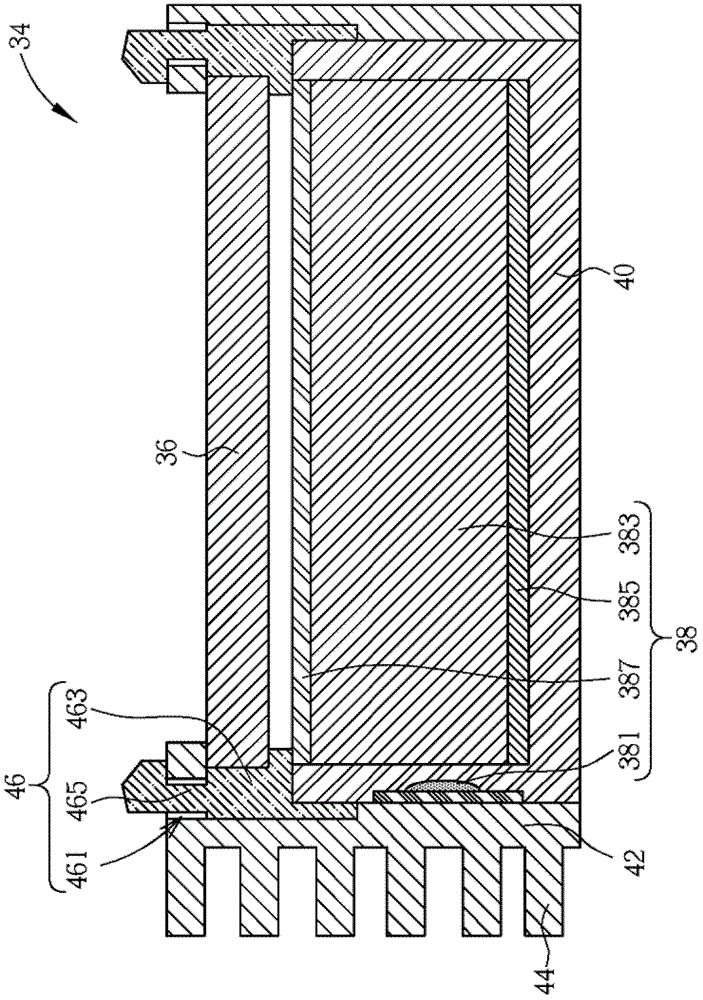

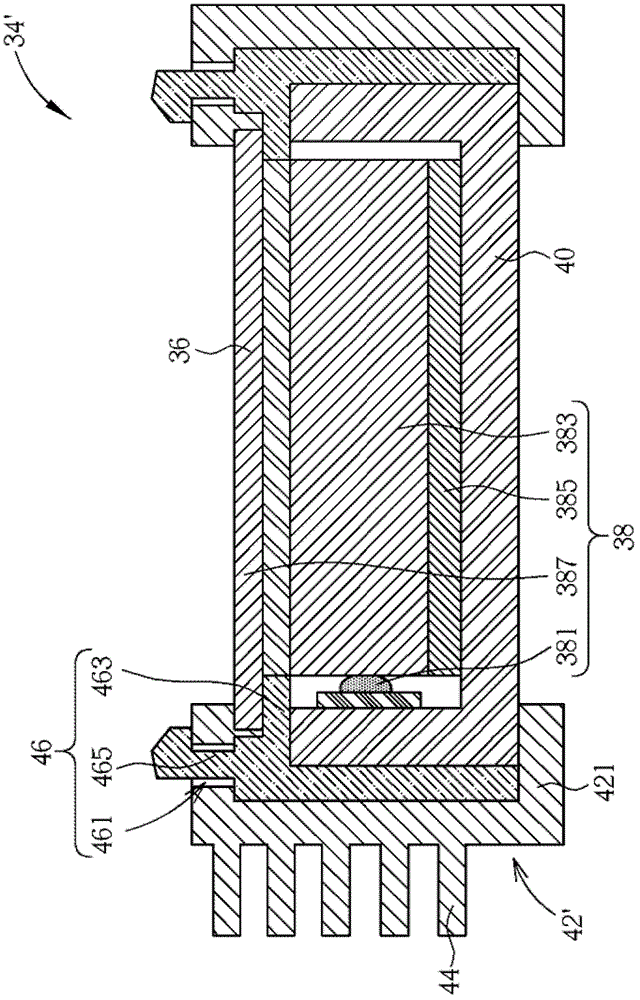

Cooling device for hydraulic braking systems

InactiveUS20130052002A1Improve overheatingPump componentsAxially engaging brakesTurbineBraking system

A cooling device for hydraulic braking systems includes a case, a turbine unit, and a ring which is connected to an end of a hub. The case has a thorough hole and a ventilation exit communicating inside and outside of the case is defined on the case. The turbine unit is located in the case and has a fixing hole which communicates with the through hole. The ring is connected to the fixing hole of the turbine unit. The ring drives the turbine unit which generates air flows in the case. The air flows flow to the outside of the case via the ventilation exit to remove the heat of the braking system.

Owner:ASHIMA LTD

Pressure detecting method for electric pressure cooker

InactiveCN102445335AImprove overheatingAccurate detectionMachine part testingInternal pressureWorking environment

The invention relates to a pressure detecting method for an electric pressure cooker. The method comprises the following steps of: regulating pressure in advance: regulating the breaking pressure of a pressure travel switch of the detected electric pressure cooker to a preset value P0; aerating for pressurizing: charging a gas medium into the detected electric pressure cooker to raise the pressure in the detected electric pressure cooker; detecting pressure: recording the product pressure value P of the pressure travel switch at a breaking moment, and comparing the product pressure value P with a detection standard pressure value P1; when the product pressure value P is accordant with the detection standard pressure value P1, entering a next step; when the product pressure value P is not accordant with the detection standard pressure value P1, stopping detection for maintaining; and releasing pressure: releasing the internal pressure of the detected electric pressure cooker. The detecting method can be widely applied to electric pressure cooker products, and is a simple, efficient and accurate detecting method for the working pressure of an electric pressure cooker; and due to the adoption of the detecting pressure, the production field can be saved, electric energy is saved, the production efficiency is increased, and the overheated working environment for workers is improved.

Owner:MIDEA GRP CO LTD

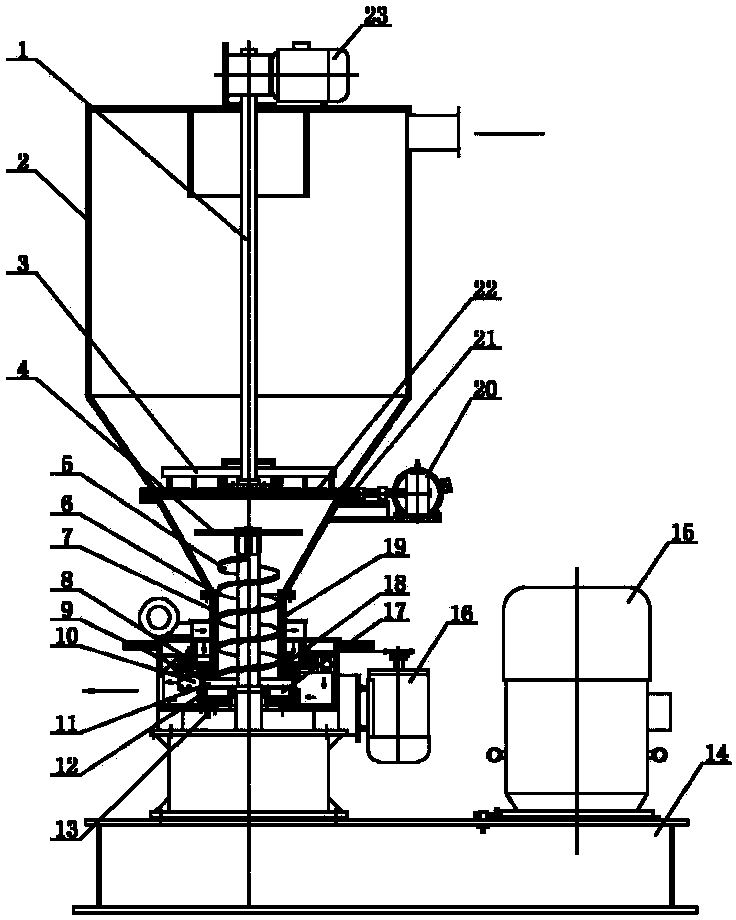

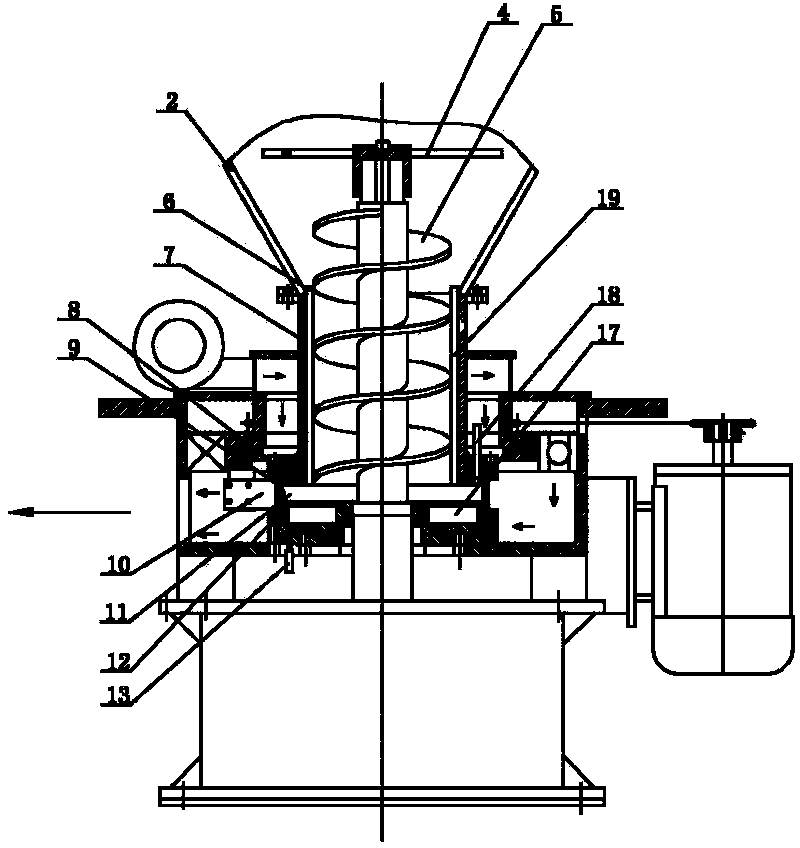

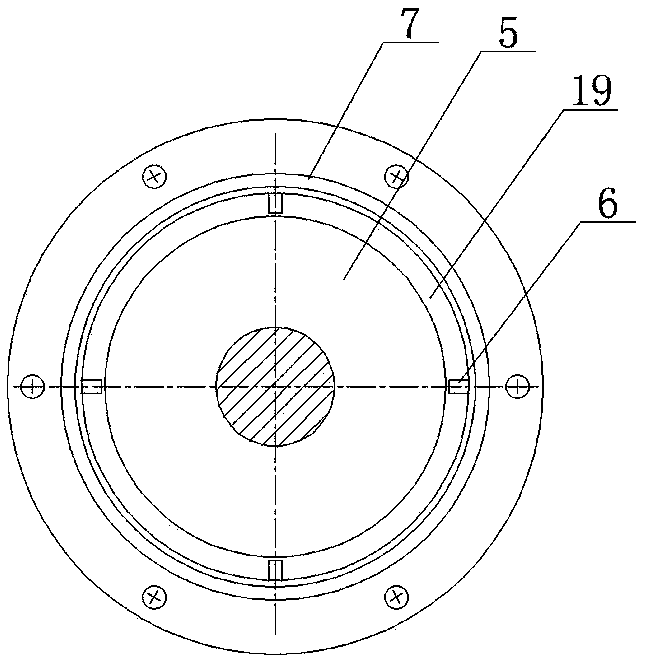

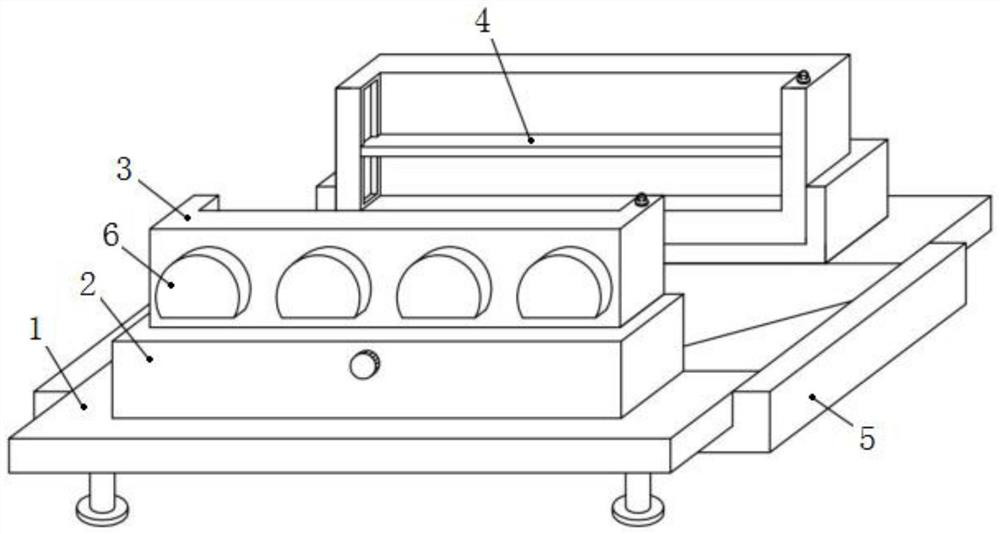

Energy-saving efficient plastic granulator

The invention discloses an energy-saving efficient plastic granulator, a feeding screw rod is rotationally arranged in a feed barrel, a scraper plate is rotationally arranged in a granulation extrusion cavity, a scraping block is arranged on the excircle of the scraper plate, the scraping block is closely attached to the inner cylinder wall of an extrusion die cylinder, the cylinder wall of the extrusion die cylinder is provided with extrusion holes, and a rotational cut-off tool is arranged on the outer cylinder wall of the extrusion die cylinder; the energy-saving efficient plastic granulator is characterized in that: the inner cylinder wall of the feed barrel is provided with a plurality of vertical ribs, the vertical ribs pass through, from up to down, the whole feed cylinder height, the top circle of the vertical ribs is matched with the excircle of the feeding screw rod, adjacent vertical ribs, and the inner cylinder wall of the feed barrel and the excircle of the feeding screw rod enclose a space to form an inner air circulation channel of the feed barrel. The energy-saving efficient plastic granulator uses the scraping block to grind a material to produce heat to melt the material for plastic granulation, the energy-saving efficient plastic granulator can always smoothly exhaust in the working process, and the unique scraper plate is designed to avoid local overheating of the material so as to avoid obstruction of heat transfer, so that automatic control of blanking and feeding can be achieved, and the entire normal high-speed granulation process and high granulation quality can be ensured.

Owner:RUIAN OULI MACHINE

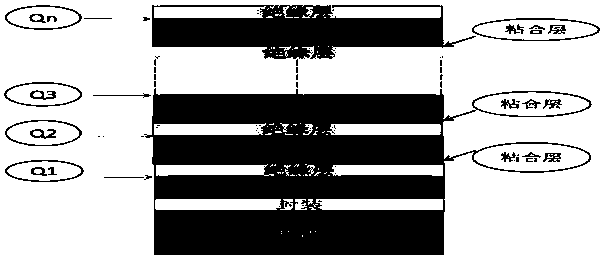

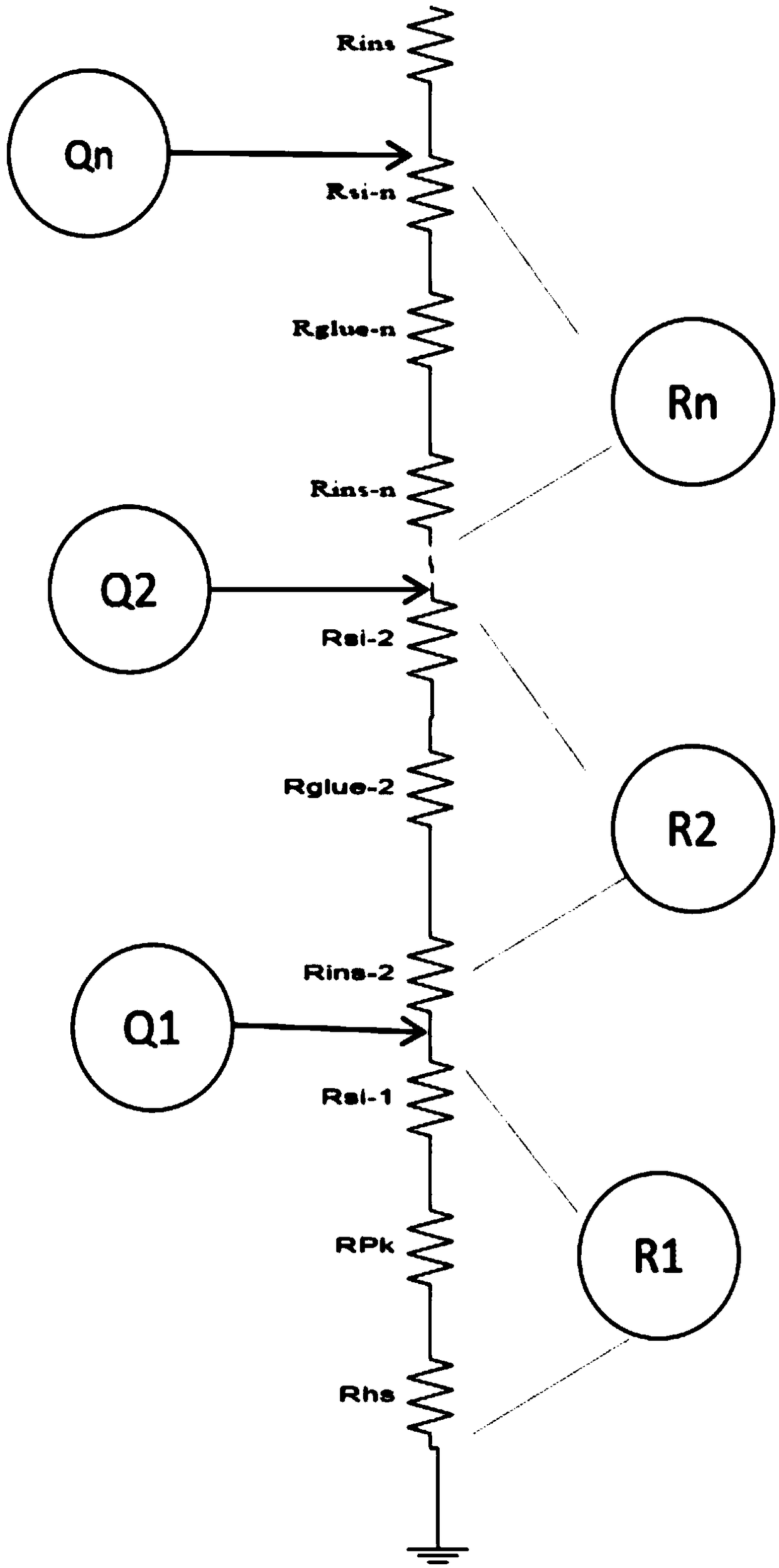

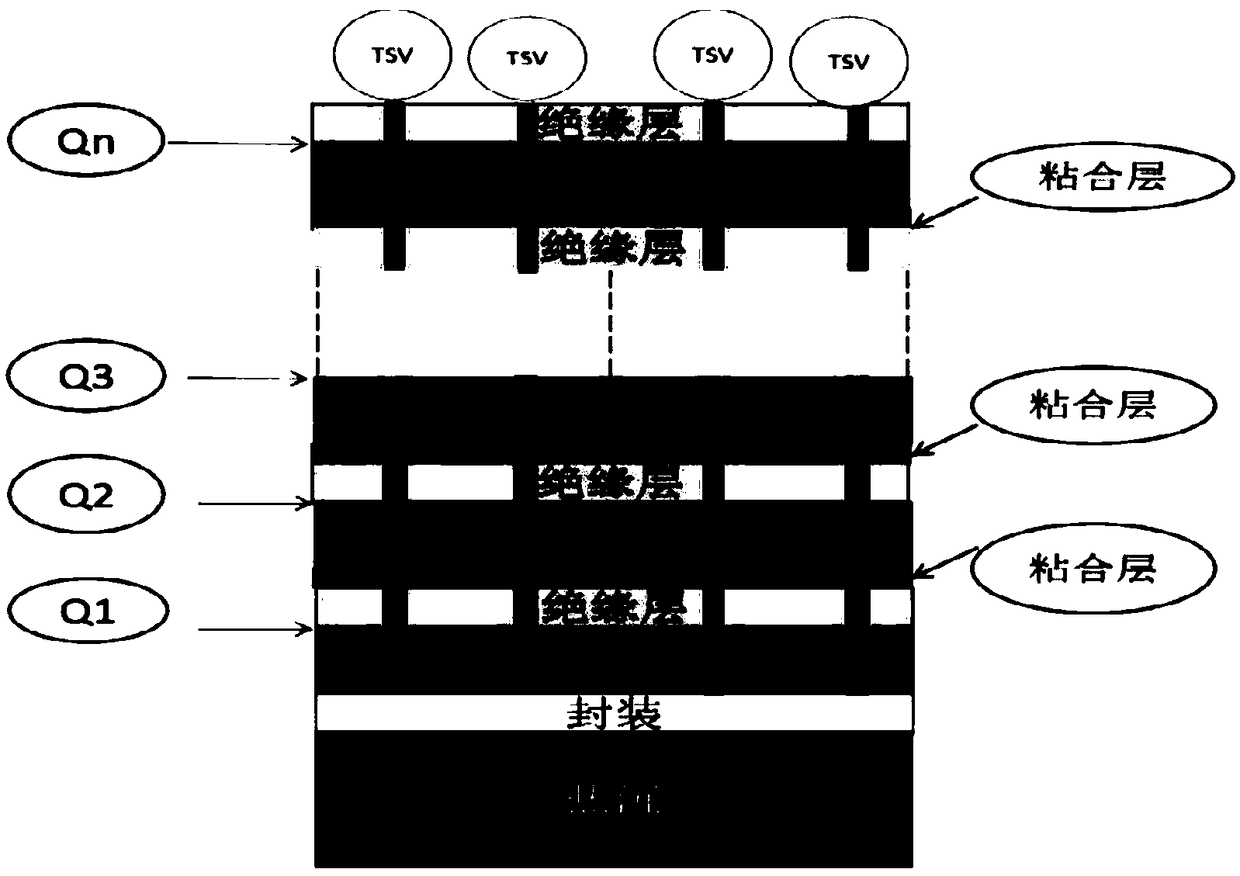

A method for heat management in SOP system integration

ActiveCN109446612AReduce the temperatureImprove overheatingDesign optimisation/simulationCAD circuit designSystem integrationHeat management

A method for heat management in SOP system integration is provided. A through-silicon via is provided in that multilayer stacked chip, and a heat conduction model of the multilayer stacked chip with silicon vias is established, the invention utilizes matlab and ansys icepeak to compare and verify the simulation results, and then determines the size and quantity of the through silicon holes. The invention solves the problem of overheating by using TSV in the SOP system integration, determines the number and size of TSV through simulation, and realizes the optimal thermal management scheme.

Owner:TAICANG T&W ELECTRONICS CO LTD

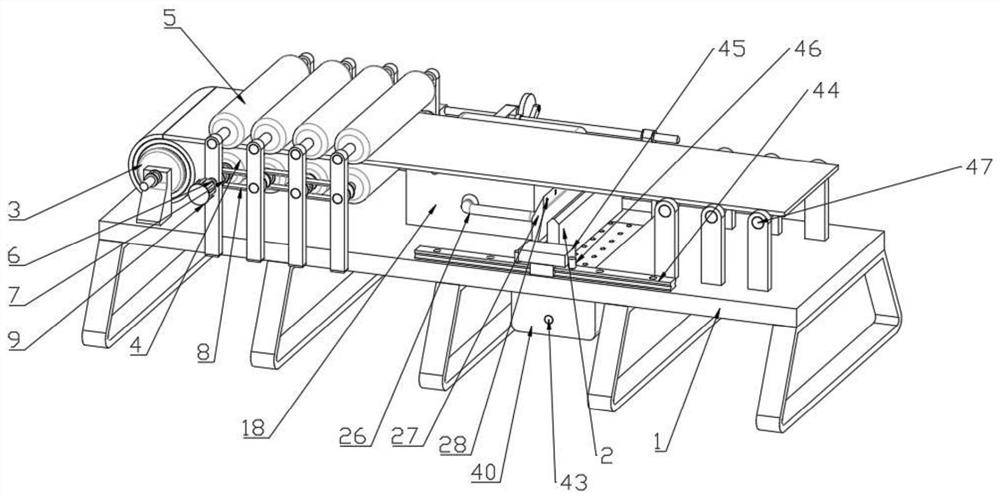

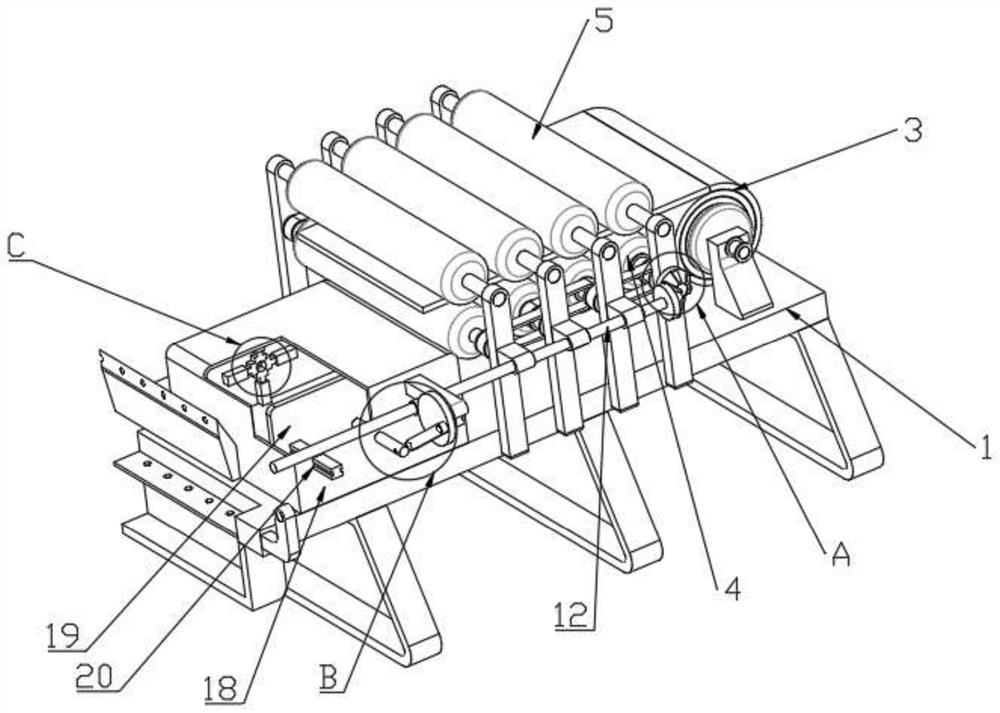

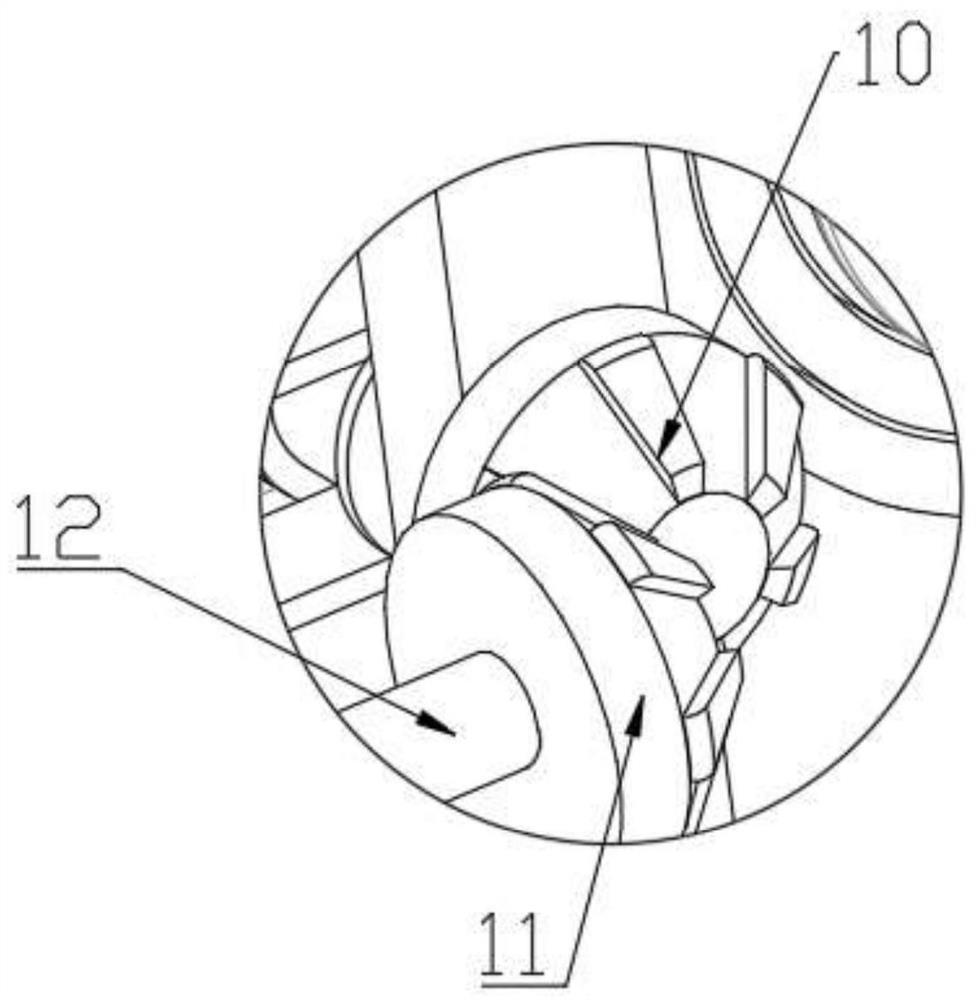

Unreeling machine convenient for cutting for hardware machining

InactiveCN111940809ASimple structureReduce capital investmentShearing machinesMaintainance and safety accessoriesElectric machineryRotational axis

The invention discloses an unreeling machine convenient for cutting for hardware machining. The unreeling machine comprises a workbench and a cutting device; a reeling drum is arranged on the left side of the workbench; a plurality of driving rollers distributed in parallel are arranged on the left side of the upper end of the workbench; a plurality of driven rollers are arranged on the upper sides of the driving rollers; each rotating shaft I penetrates through the inner side of the corresponding driving roller and is fixedly connected with the corresponding driving roller; transmission wheels I are arranged on the outer sides of a plurality of adjacent driving rollers in a sleeving mode; each transmission wheel I is internally provided with a transmission belt I in a clamping manner; andeach motor is installed on one side of the corresponding rotating shaft I. When the unreeling machine disclosed by the invention is used, the motor is used for driving the driving rollers and the rotating shaft I to rotate; each rotating shaft I penetrates through the corresponding transmission belt I; the transmission belts I are used for driving the plurality of driving rollers to move simultaneously; raw materials for hardware machining are straightened in a pressing way through extrusion of the driving rollers and the driven rollers; meanwhile the raw materials can be pulled to move; andthe raw materials drive the reeling drum to rotate to continuously straighten the raw materials wound on the outer side of the reeling drum.

Owner:尹梅存

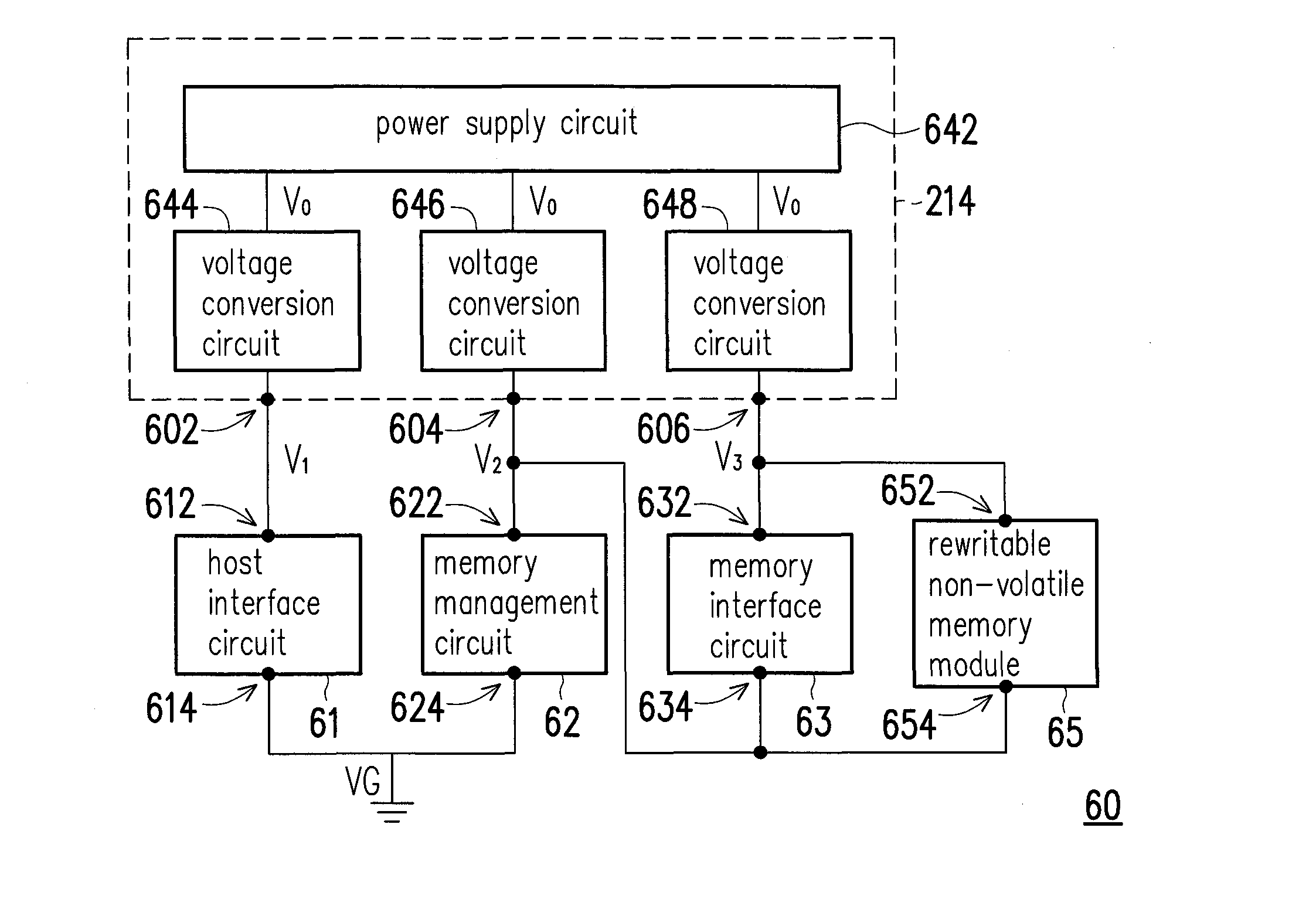

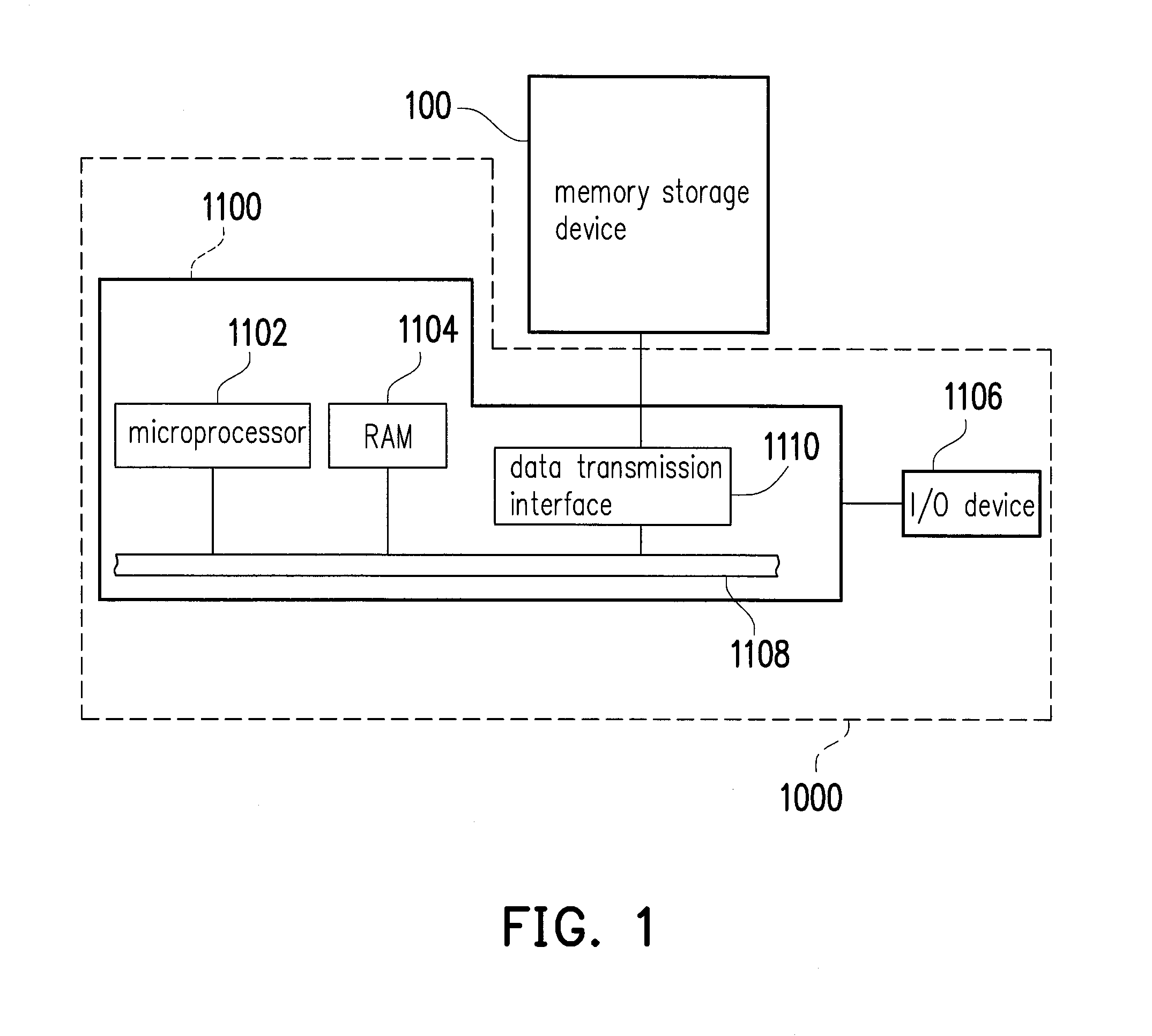

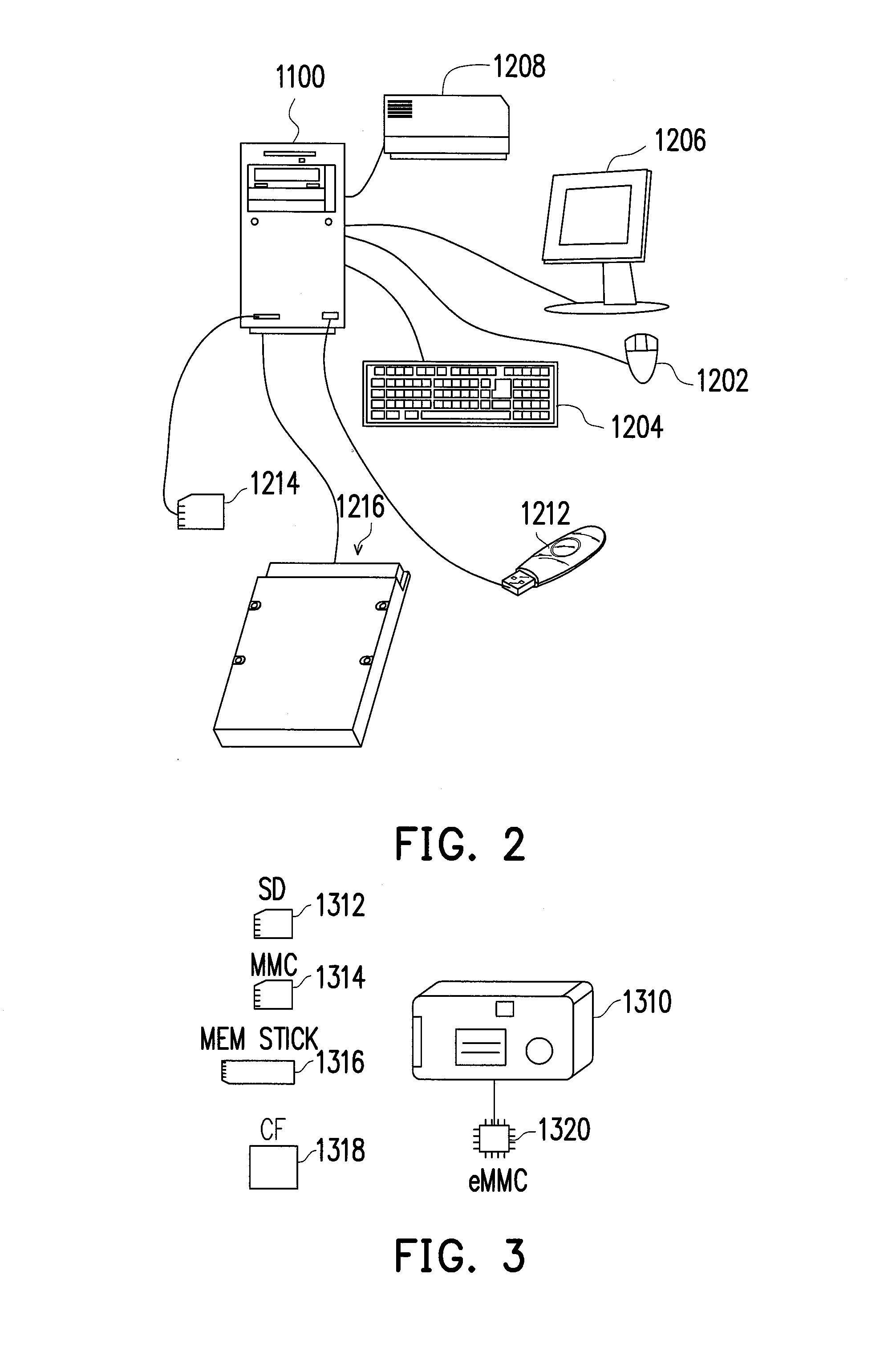

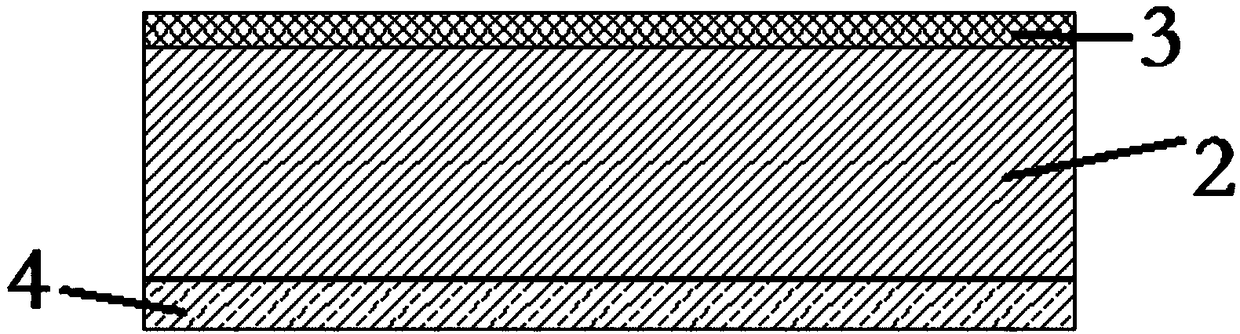

Memory storage device, memory control circuit unit and power supply method

ActiveUS20150323969A1Improve overheatingImprove the problemVolume/mass flow measurementRead-only memoriesLow voltageMemory interface

A memory storage device, a memory control circuit unit and a power supply method are provided. The power supply method includes: providing a first power voltage to a host interface circuit of the memory storage device; providing a second power voltage to a memory management circuit of the memory storage device; providing a third power voltage to a memory interface circuit of the memory storage device, wherein a reference voltage terminal of the memory interface circuit is coupled to a power input terminal of the memory management circuit. Thus, the overheat problem of the memory storage device due to the voltage conversion may be improved.

Owner:PHISON ELECTRONICS

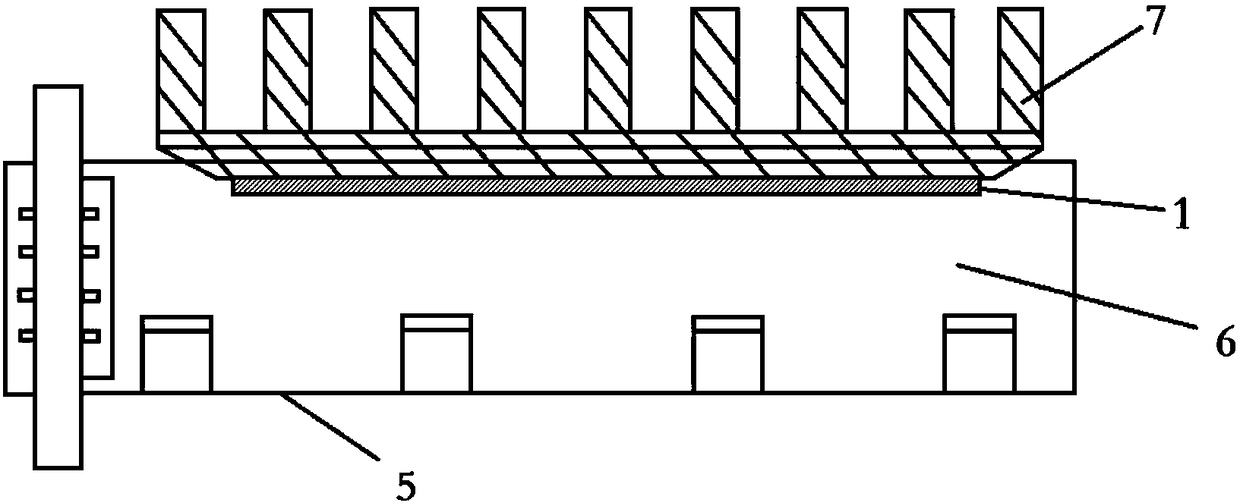

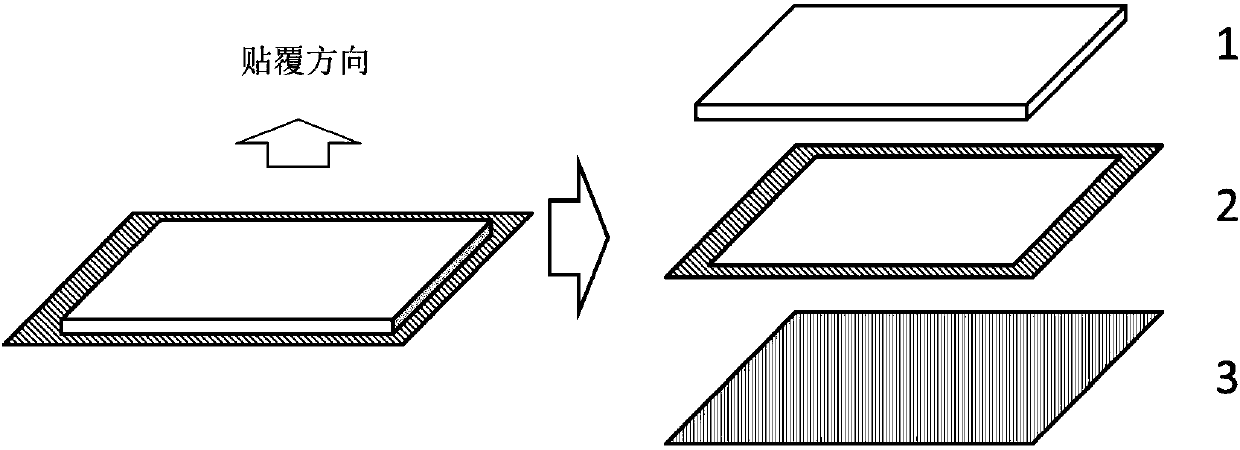

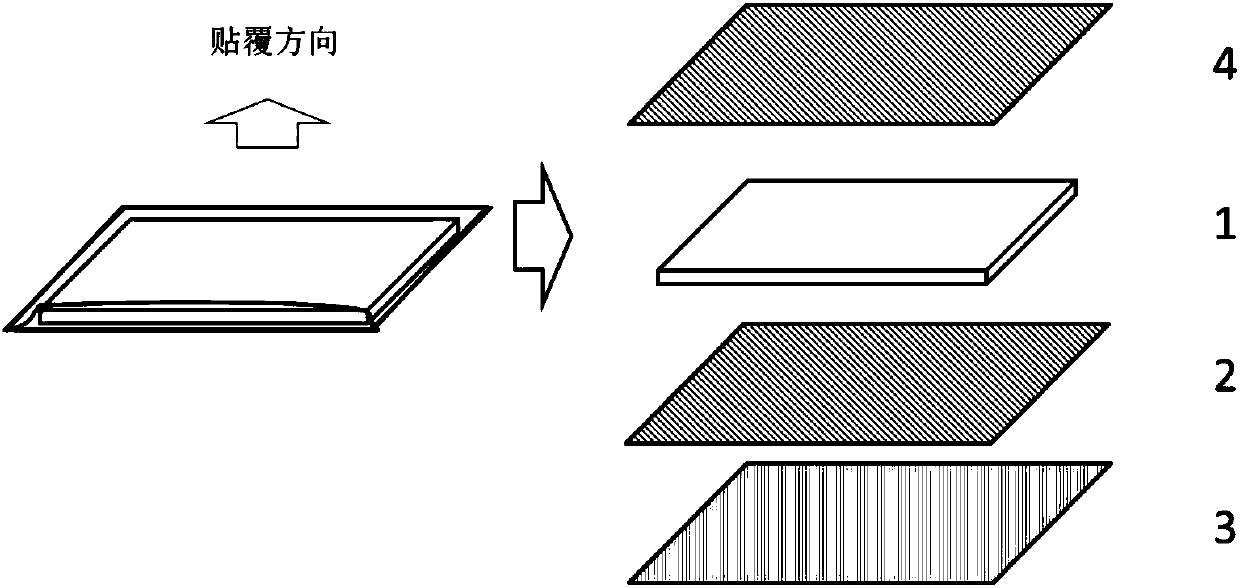

Wear-resistant highly heat-conducting sheet and application thereof

InactiveCN108184316AImprove wear resistanceImprove interface thermal resistanceFilm/foil adhesivesModifications by conduction heat transferWear resistantHeat conducting

The invention provides a wear-resistant highly heat-conducting sheet and application thereof and relates to a heat-conducting material. The wear-resistant highly heat-conducting sheet comprises a heat-conducting layer which is located above and is made of a heat-conducting material with a heat conductivity coefficient larger than 2 W / m-K, and a wear resistant layer which is located below and is made of a wear resistant material with a heat conductivity coefficient larger than 0.3 W / m-K, and the wear resistant layer is fixed under the heat-conducting layer. The wear resistance performance is improved by the wear resistant layer, and at the same time the heat-conducting layer protected by the wear resistant layer is used to improve interface thermal resistance. A plugging resistant connectorwith the wear-resistant highly heat-conducting sheet is the application of the wear-resistant highly heat-conducting sheet in the connector.

Owner:SHANGHAI ALLIED PLASTIC IND

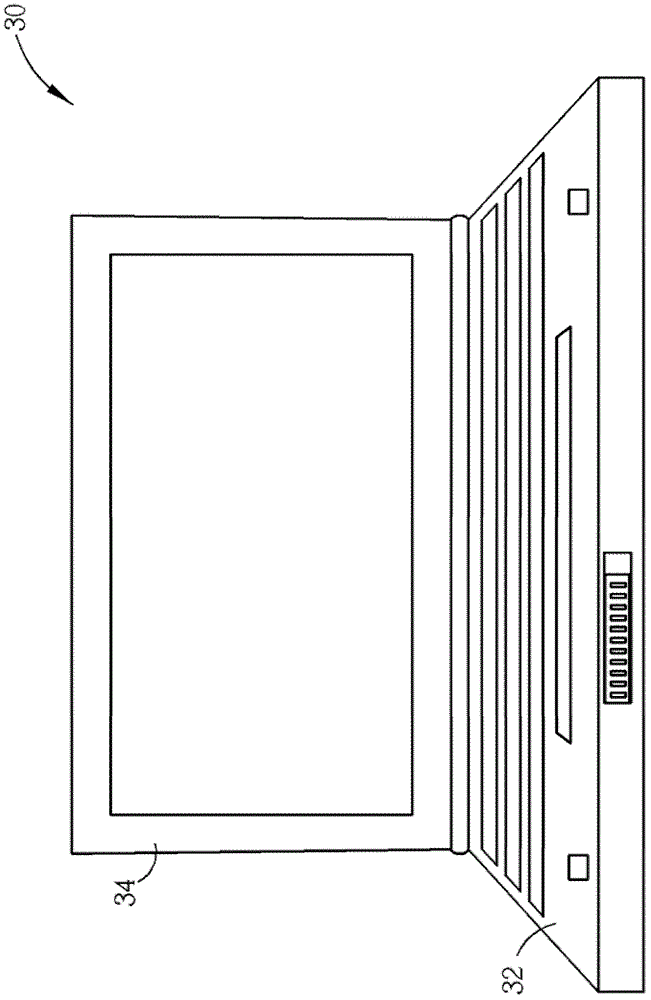

Display device with heat dissipating structures and electronic device using same

InactiveCN103064214AExtended service lifeImprove luminous efficiencyStatic indicating devicesLighting heating/cooling arrangementsLight guideDisplay device

The invention discloses a display device with heat dissipating structures and an electronic device using the same. The display device includes a panel, a backlight module, a back cover, a rim frame and a plurality of thermal fins. The backlight module provides the panel with a light source and includes a light emitting unit and a light guide plate. The light emitting unit emits light, and the light guide plate is disposed below the panel for guiding the light emitted by the light emitting unit to the panel. The back cover is installed on an outer side of the panel and the backlight module. The rim frame combines the back cover for covering the panel and the backlight module cooperatively with the back cover. The plurality of thermal fins is disposed on the rim frame for dissipating heat conducted from the rim frame and generated by the light emitting unit.

Owner:WISTRON CORP

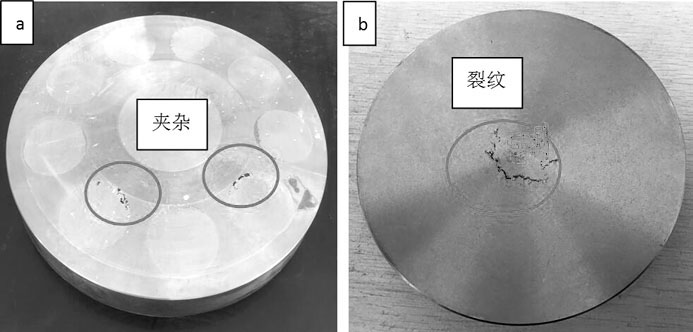

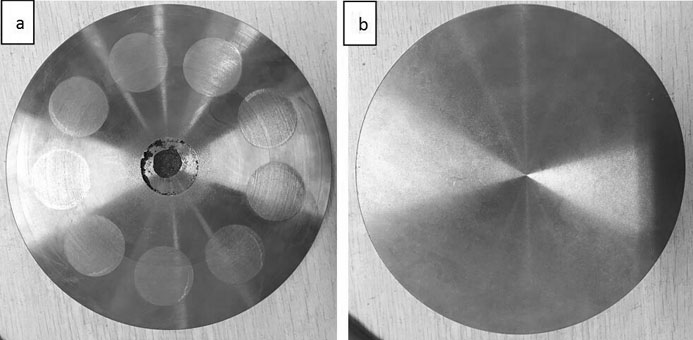

Bimetal plunger pump cylinder body extrusion casting forming method

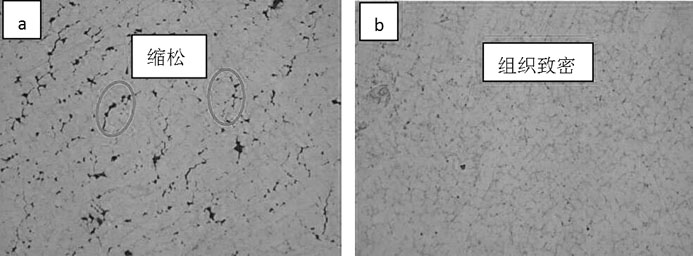

InactiveCN113070463AImprove performance uniformityImprove the density of different positionsCylinder blockPlunger pump

The invention discloses a bimetal plunger pump cylinder body extrusion casting forming method, and relates to the technical field of bimetal extrusion forming preparation. Firstly, in the preheating stage, a steel substrate is placed in an extrusion die, an induction coil heats the steel substrate to 1130-1170 DEG C, a liquid copper alloy with the temperature being 1150-1250 DEG C is injected into the steel substrate, standing and cooling are carried out at the room temperature to 750-900 DEG C, and then in the semi-solid extrusion stage, lower and upper timed and partitioned extrusion is conducted, and a lower punch upwards conducts semi-solid extrusion so that a copper alloy valve plate copper layer at the lower end of a plunger pump cylinder body can be extruded and formed. After a valve plate of a cylinder body is formed, an upper punch begins to downwards extrude a riser at the upper end of the cylinder body, and a plunger and a kidney-shaped hole of the cylinder body are formed. The bimetal cylinder body prepared through the bimetal plunger pump cylinder body extrusion casting forming method is free of interface cracking and high in bonding strength, and the copper alloy structure is compact, fine and uniform.

Owner:ZHONGBEI UNIV

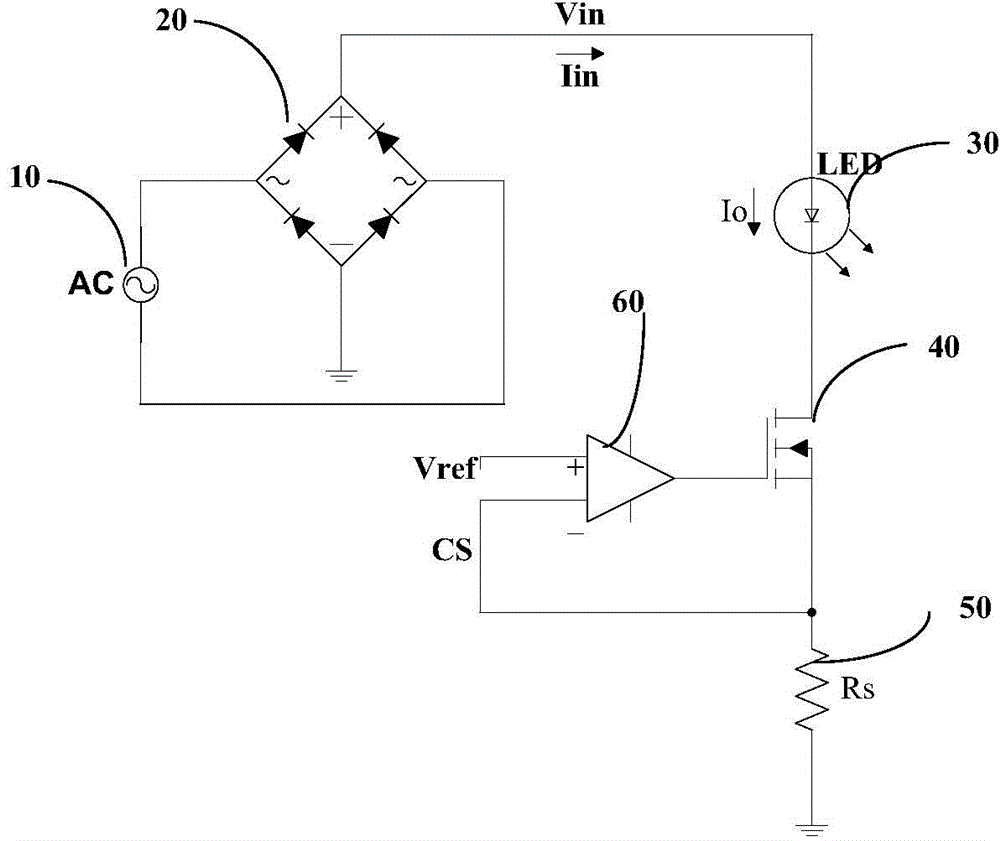

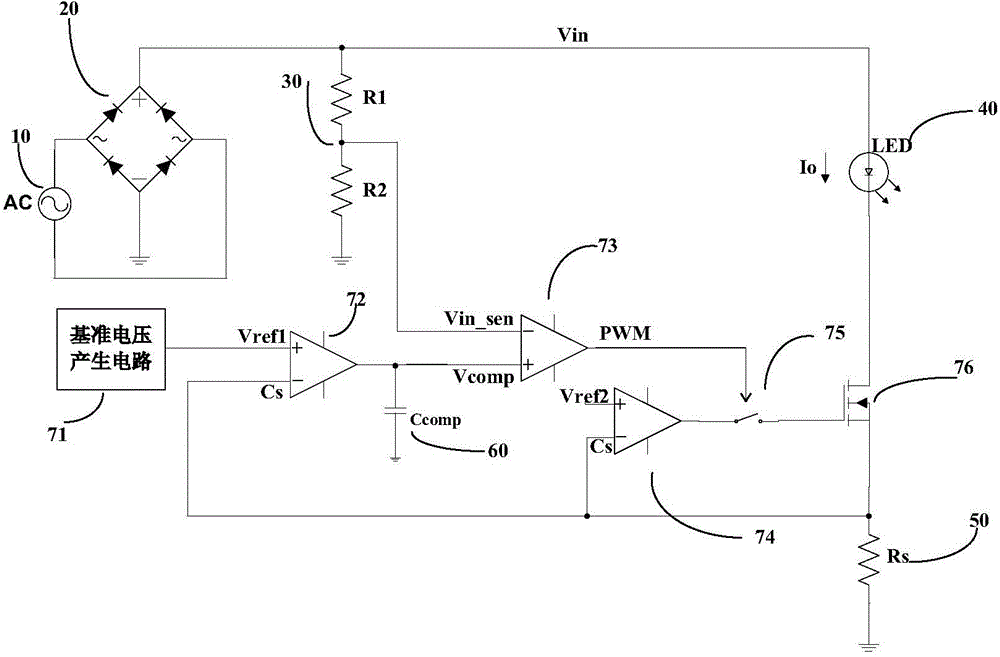

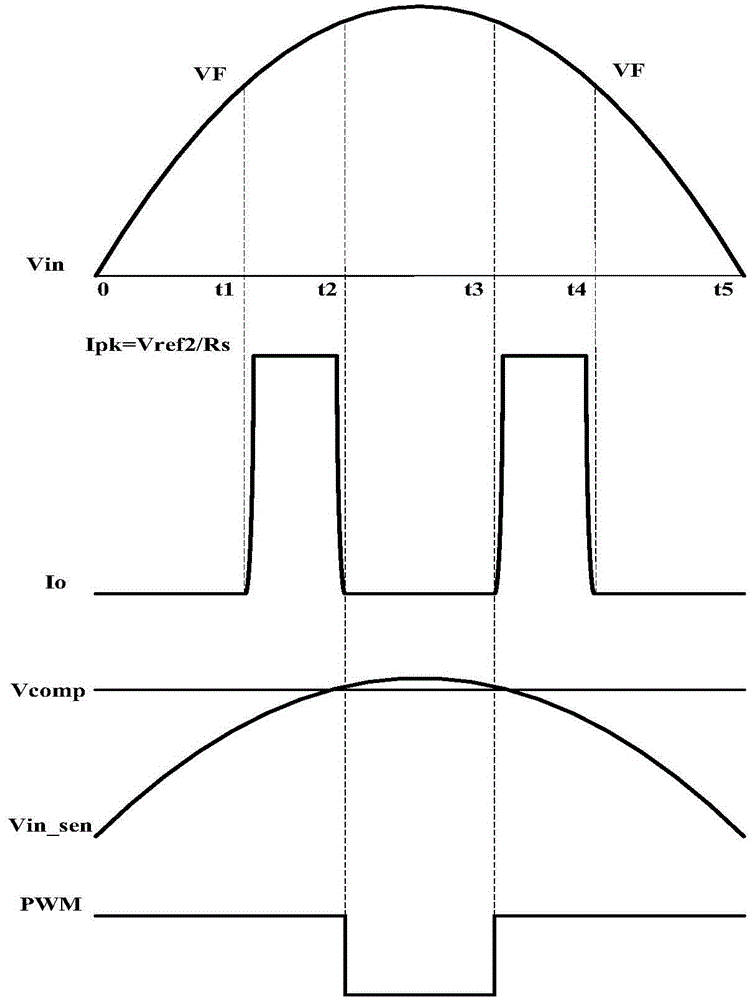

Linear switching constant-current LED drive circuit for control over peak current

ActiveCN103491682BBrightness unchangedImprove overheatingElectric light circuit arrangementAverage currentPeak value

The invention discloses a linear switching constant-current LED drive circuit for control over peak current, and relates to the field of power source drive circuits. Compared with an existing linear constant-current LED drive circuit, and according to the linear switching constant-current LED drive circuit for control over the peak current, an integrating capacitor is connected to a loop of a drive chip in parallel, and average current passing through an LED lamp bead can be kept to be constant through the integrating constant-current mode; in addition, due to the fact that a loop formed by an operational amplifier, a switching selector and a high-voltage power MOS is added to the loop of the drive chip to limit the peak current passing through the LED bead, useless power consumption of a system can be reduced, working efficiency of the system can be improved, heat produced in the working process of the drive chip is reduced, the required rated current of the LED bead can be effectively reduced, the luminous efficiency of the LED bead is improved, the luminous decay of the LED bead slows down, the service life of the LED bead is prolonged, and cost of the system is reduced.

Owner:FREMONT MICRO DEVICES SHENZHEN LTD

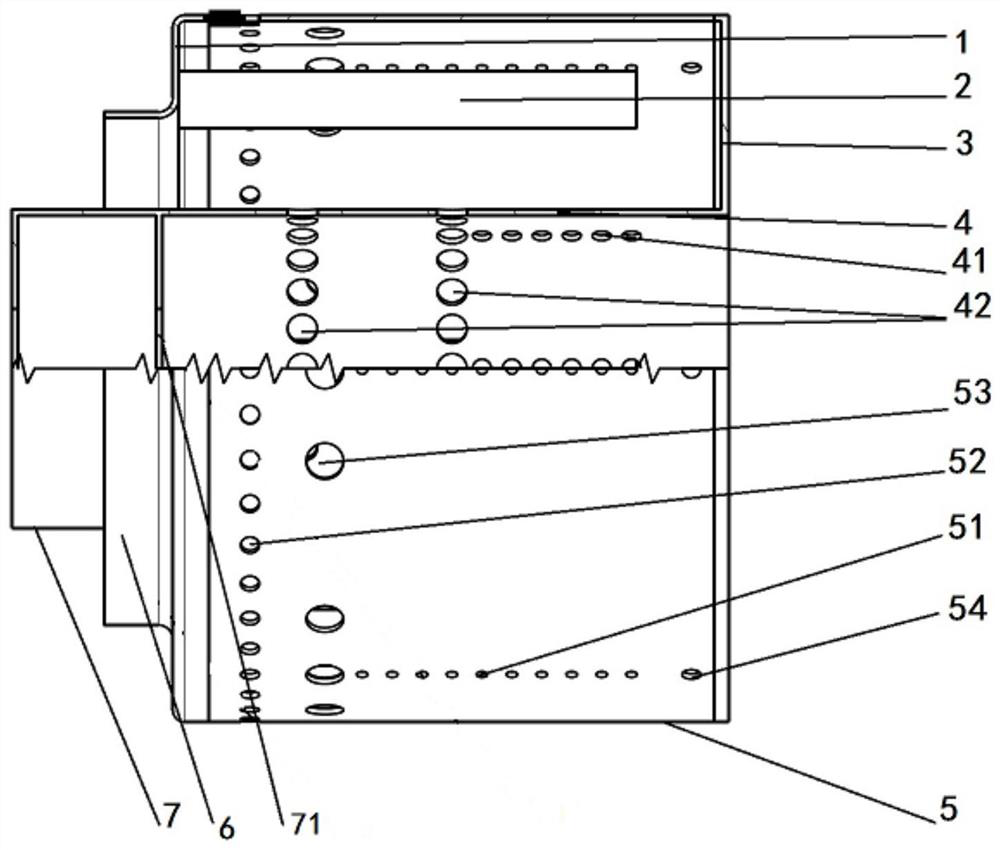

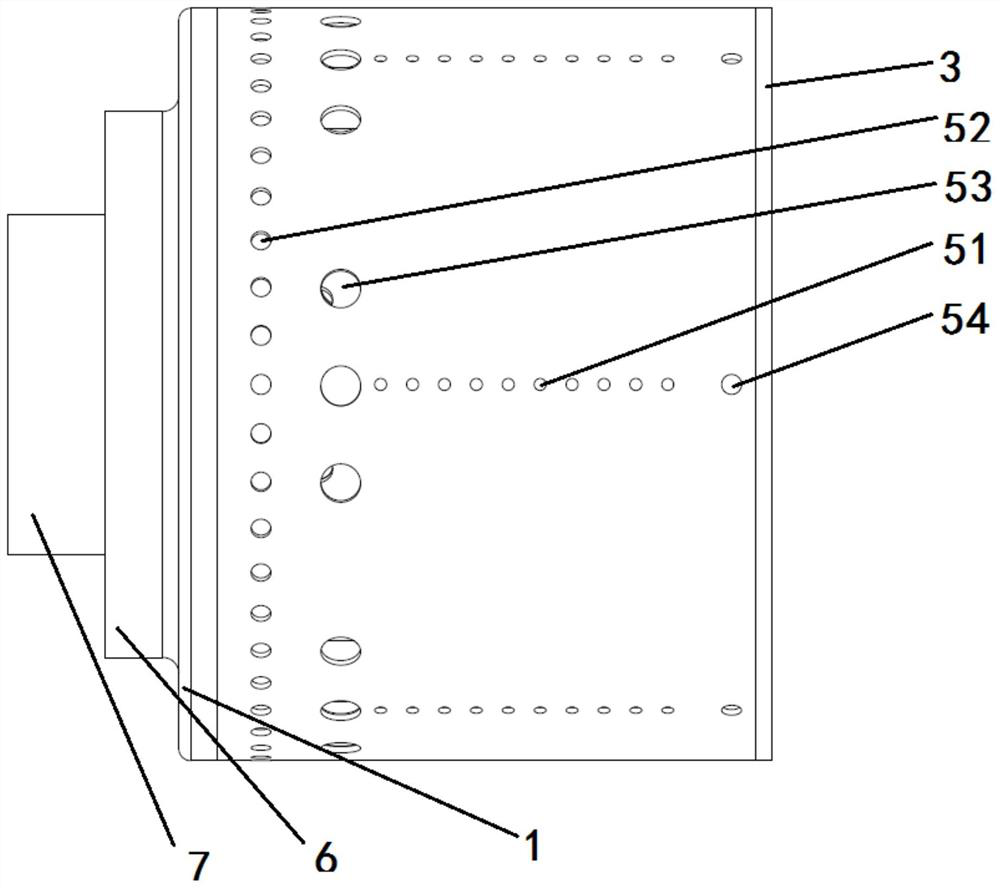

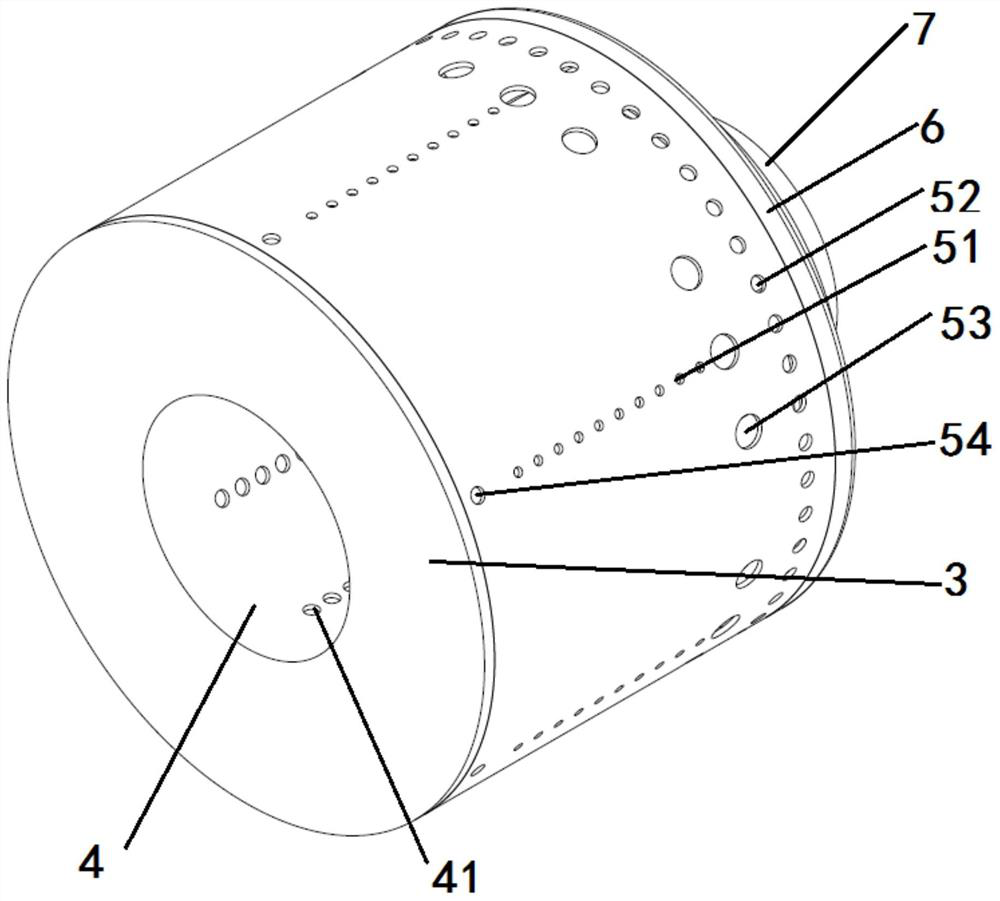

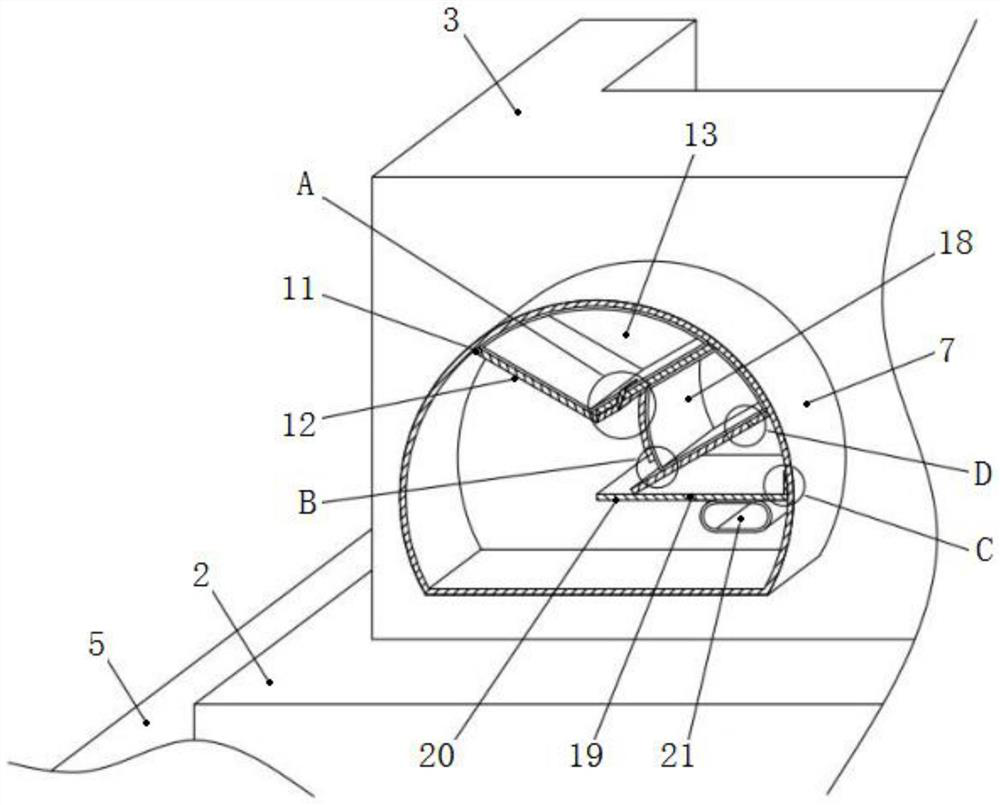

Micro turbojet engine combustion chamber structure

PendingCN112082176AEvenly distributedImprove overheatingContinuous combustion chamberCombustion chamberEngineering

The invention provides a micro turbojet engine combustion chamber structure. The micro turbojet engine combustion chamber structure comprises a flame tube outer cylinder and an evaporation pipe fixingplate, wherein the flame tube outer cylinder is arranged outside a flame tube inner cylinder in a sleeving mode, and a combustion chamber is formed between the flame tube inner cylinder and the flametube outer cylinder; air inlet hole sets are formed in the flame tube inner cylinder and the flame tube outer cylinder; the evaporation pipe fixing plate is connected to one end, far away from a first end cover, of the flame tube outer cylinder, an evaporation pipe is arranged inside the combustion chamber, and the evaporation pipe is close to the inner wall of the flame tube inner cylinder; andthe air inlet hole sets comprise a plurality of second through holes, the second through holes are formed in the flame tube outer cylinder which is located at the same angle as the evaporation pipe, and the straight line formed by connecting the multiple second through holes which are located at the same angle as the evaporation pipe is parallel to the axis of the evaporation pipe. The second through holes which are formed in the flame tube outer cylinder and directly face the evaporation pipe are formed, and when pressurized air enters the combustion chamber through the multiple second through holes, the air is blocked by the evaporation pipe to form airflow flowing along the wall surface, and therefore the inner wall of the flame tube outer cylinder is cooled and protected.

Owner:TSINGHUA UNIV

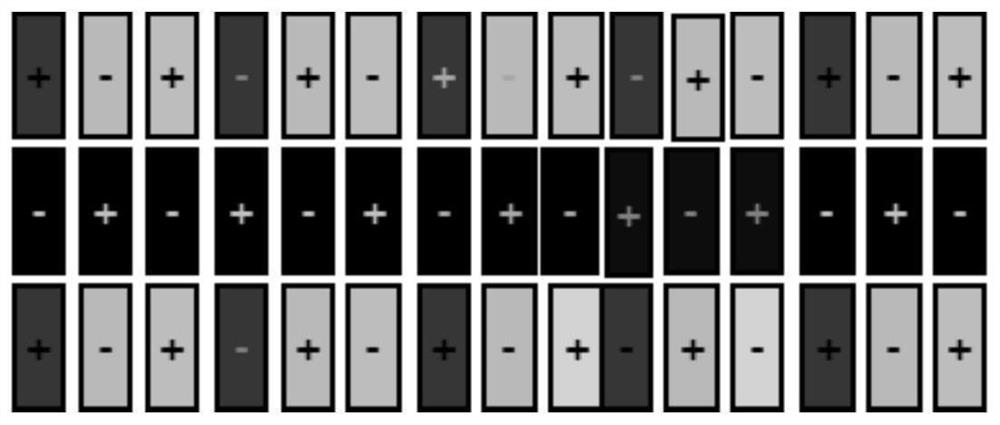

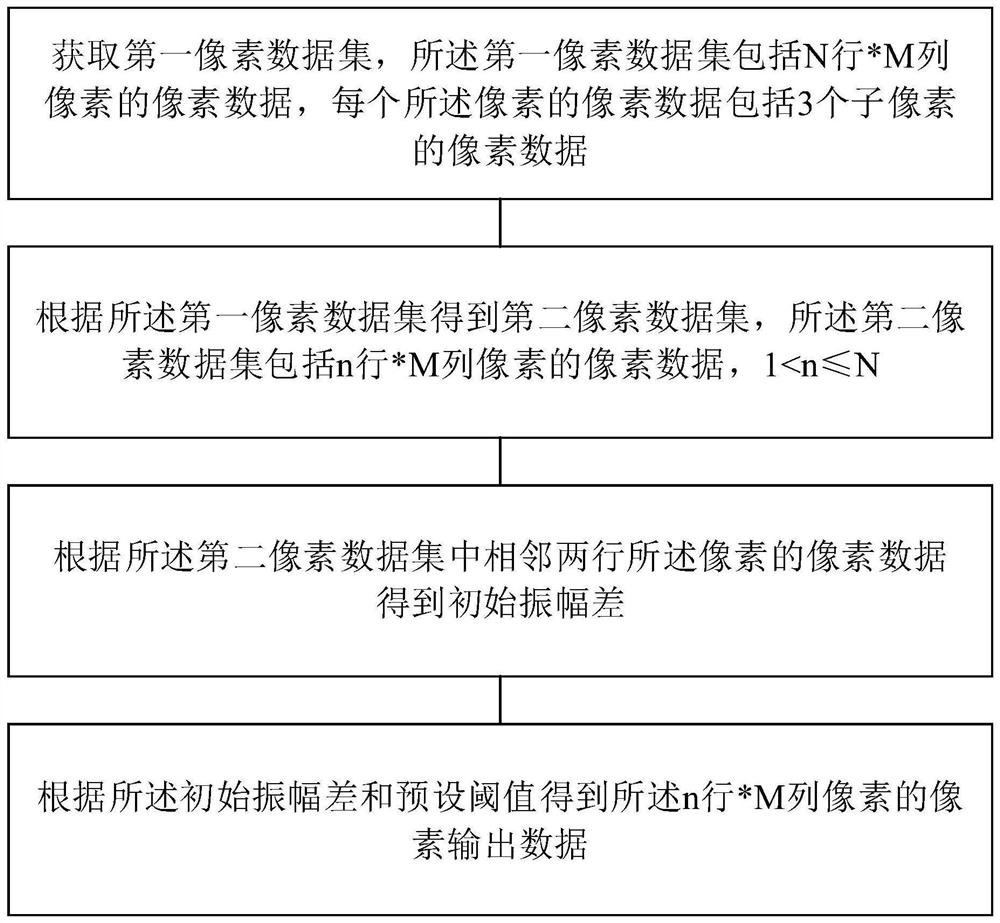

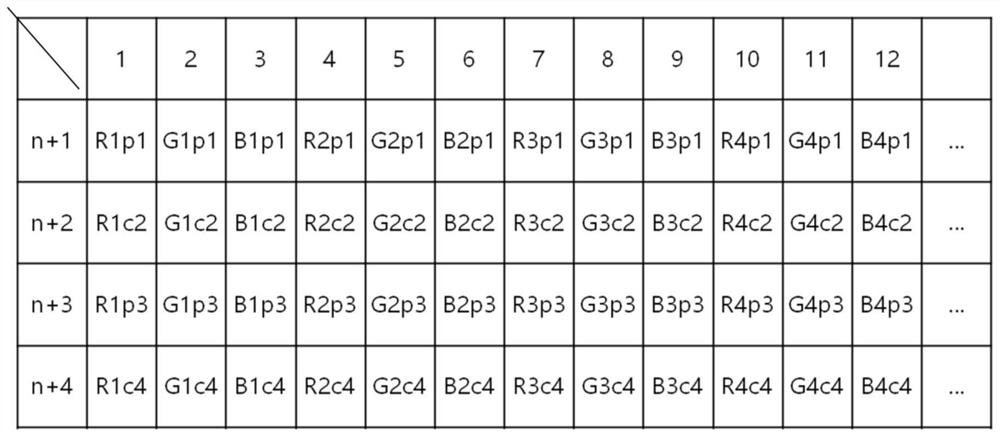

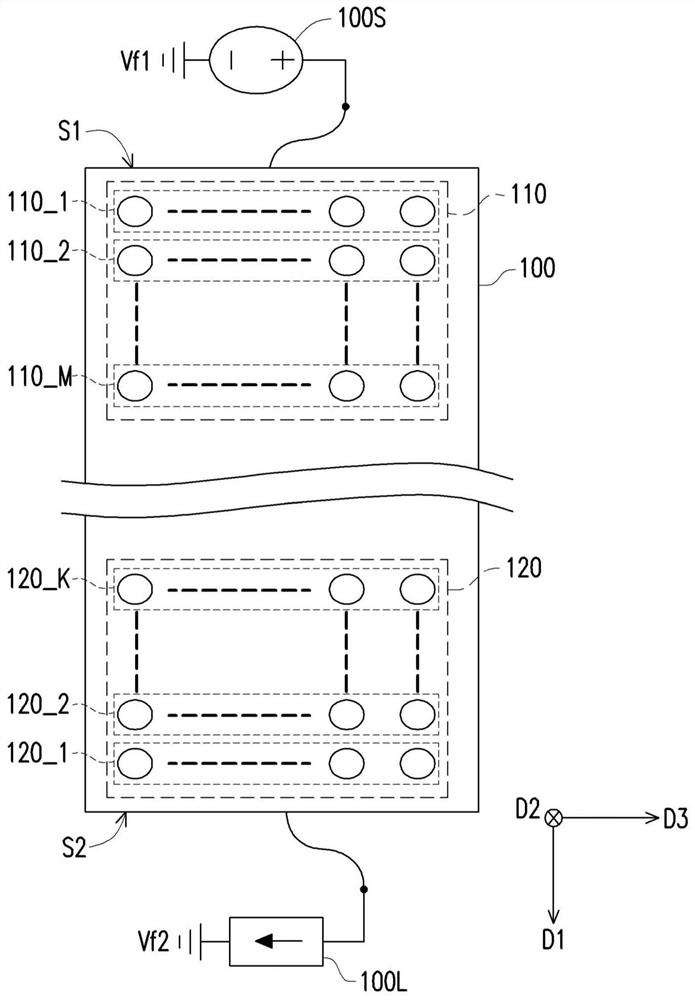

Pixel data optimization method, pixel matrix driving device and display

ActiveCN113496682AHigh energy consumptionImprove overheatingCathode-ray tube indicatorsAlgorithmDisplay device

The invention discloses a pixel data optimization method, a pixel matrix driving device and a display. The optimization method comprises the following steps: acquiring a first pixel data set; obtaining a second pixel data set according to the first pixel data set; obtaining an initial amplitude difference according to pixel data of two adjacent rows of pixels in the second pixel data set; and obtaining pixel output data of the n rows * M columns of pixels according to the initial amplitude difference and a preset threshold. According to the invention, the initial amplitude difference obtained by the pixel data of the two adjacent rows of pixels is compared with the preset threshold value, so that a final pixel gray-scale value to be displayed by each pixel can be adjusted according to a comparison result, and the energy consumption of the driving device can be improved. Therefore, the overheat phenomenon of the COF driving device is improved, and the visual effect can be improved.

Owner:XIANYANG CAIHONG OPTOELECTRONICS TECH CO LTD

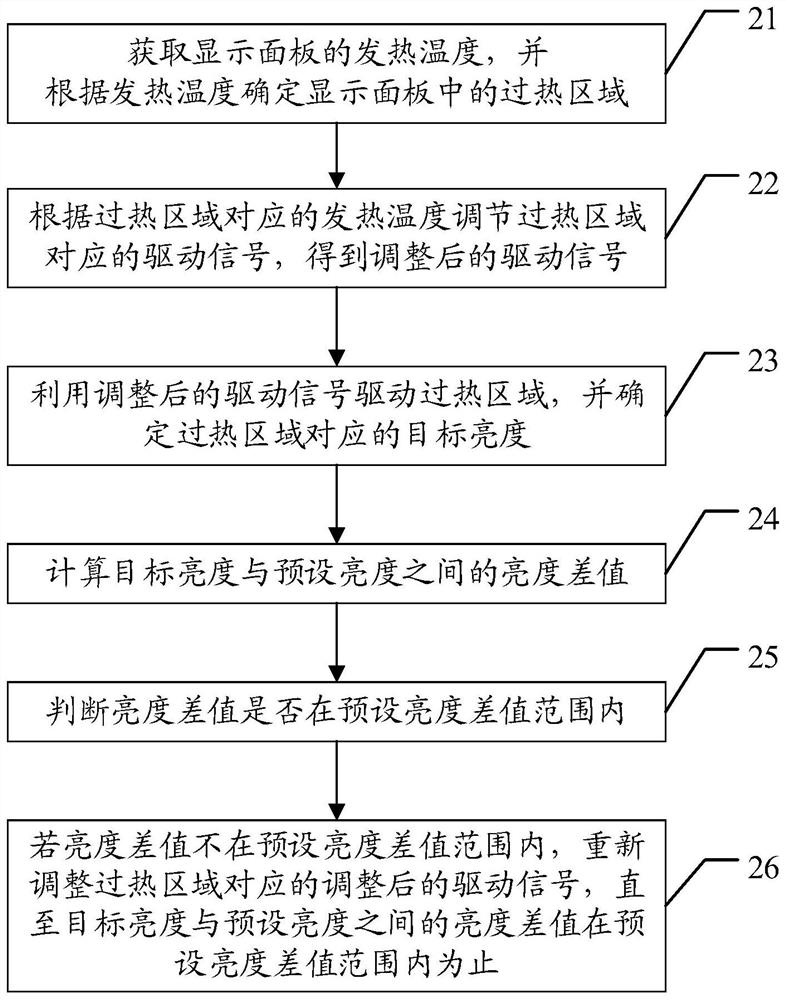

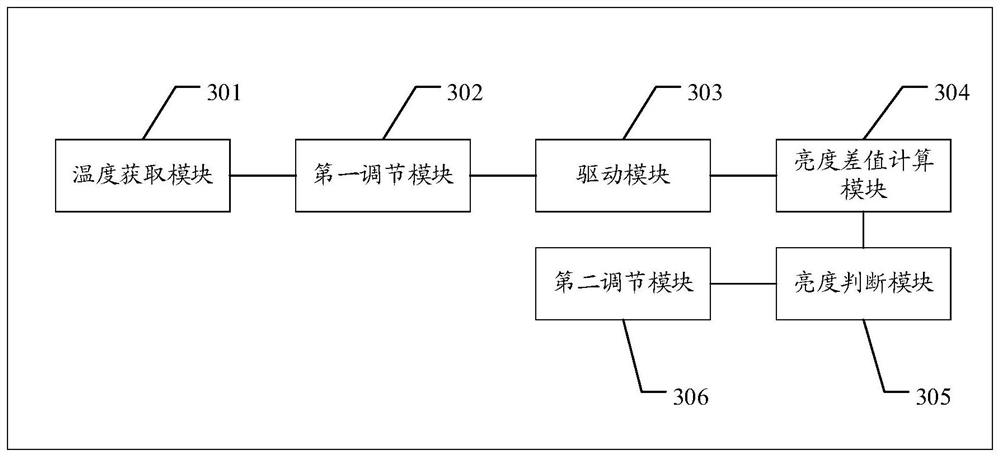

Method and device for improving uneven display of panel picture, server and storage medium

The invention provides a method and device for improving uneven display of a panel picture, a server and a storage medium. Firstly, the heating temperature corresponding to the display panel is obtained, and an overheating area in the display panel is determined according to the heating temperature; adjusting a driving signal corresponding to the overheat area according to the heating temperature corresponding to the overheat area to obtain an adjusted driving signal, and driving the overheat area by using the adjusted driving signal; and determining target brightness corresponding to the overheat area after the adjusted driving signal drives the overheat area so as to judge whether the overheat area is still overheated according to the target brightness, and if yes, continuing to adjust the adjusted driving signal corresponding to the overheat area until the overheat area is not overheated any more. According to the method, the overheat area is determined according to the temperature of the display panel, and then the driving signal corresponding to the overheat area is continuously adjusted according to the temperature until the overheat area is not overheated any more; according to the adjusting method, the problem of overheating of the panel can be effectively solved, and the problem of non-uniform picture display is avoided.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

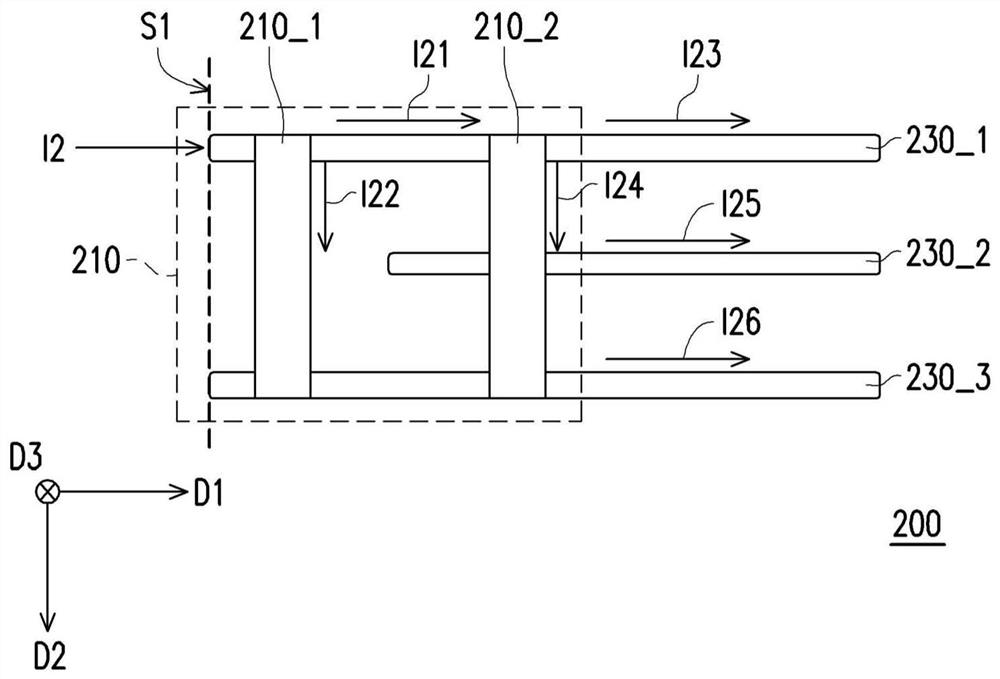

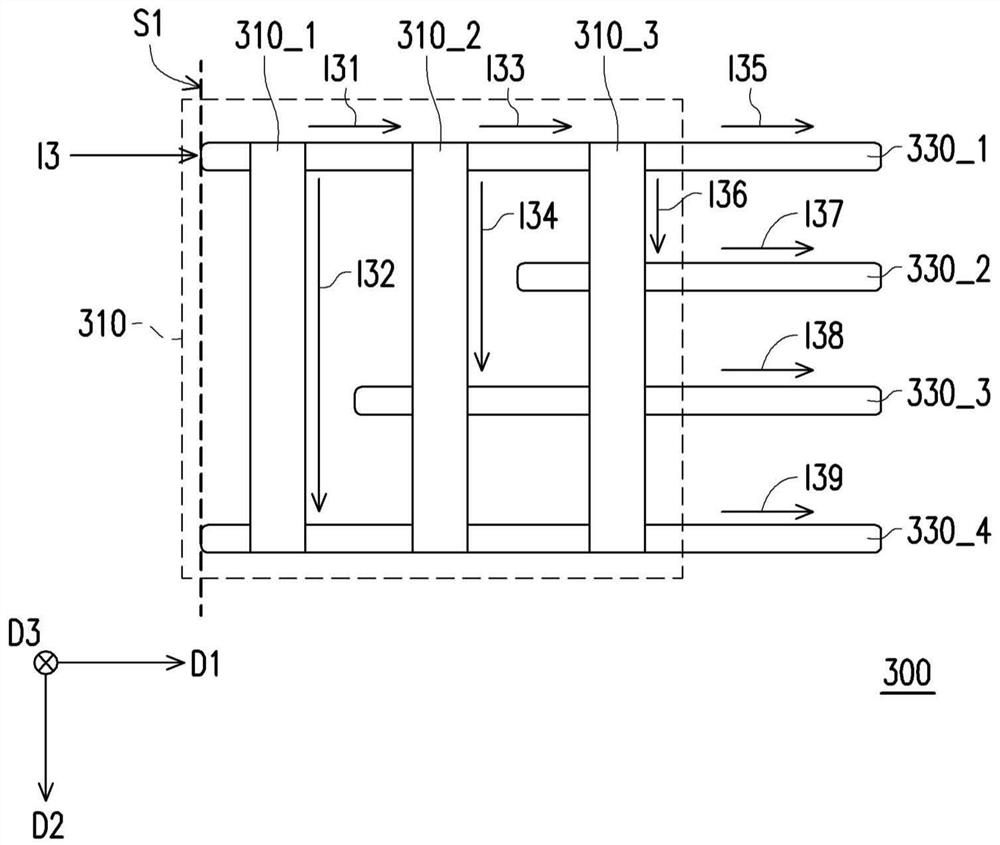

Printed circuit board

ActiveCN113411947AImprove overheatingPrinted circuit aspectsHigh current circuit adaptationsComputer sciencePrinted circuit board

A printed circuit board is provided. The printed circuit board includes N power layers and a first via group. The N power layers are arranged in parallel and spaced from each other. The first via group includes M rows of vias which are disposed through the N power layers, where N and M are positive integers greater than 0. Each row of the M rows of vias is electrically connected to the first layer of the N power layers. A Pth row of the M rows of vias is further electrically connected to Q power layers of the N power layers respectively, wherein Q is the smallest positive integer greater than or equal to P((N-1) / M), and P is a positive integer less than or equal to M.

Owner:WIWYNN CORP

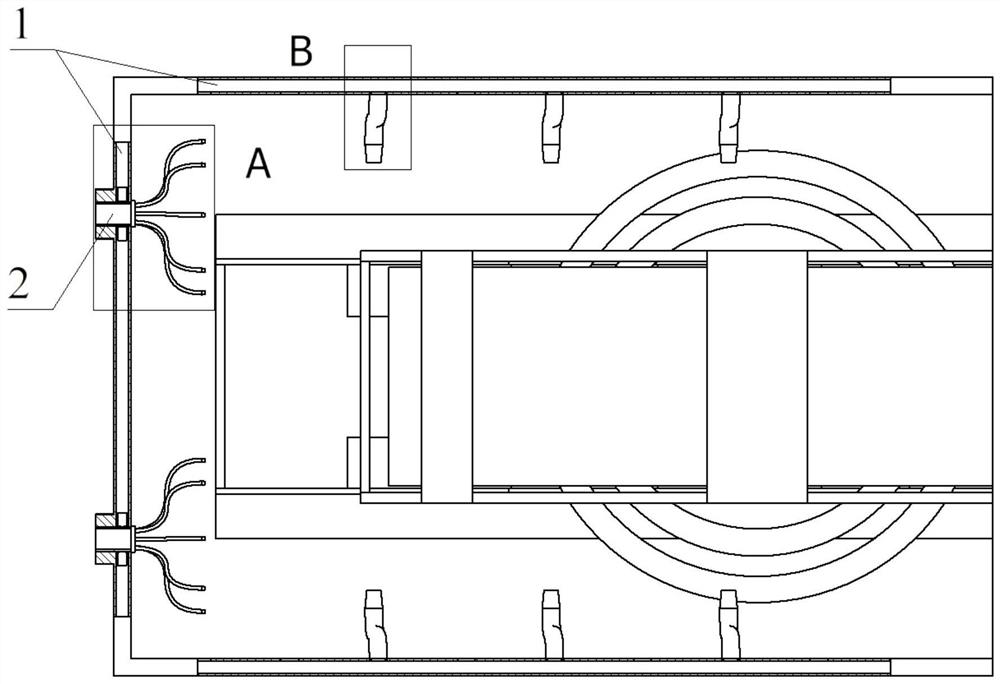

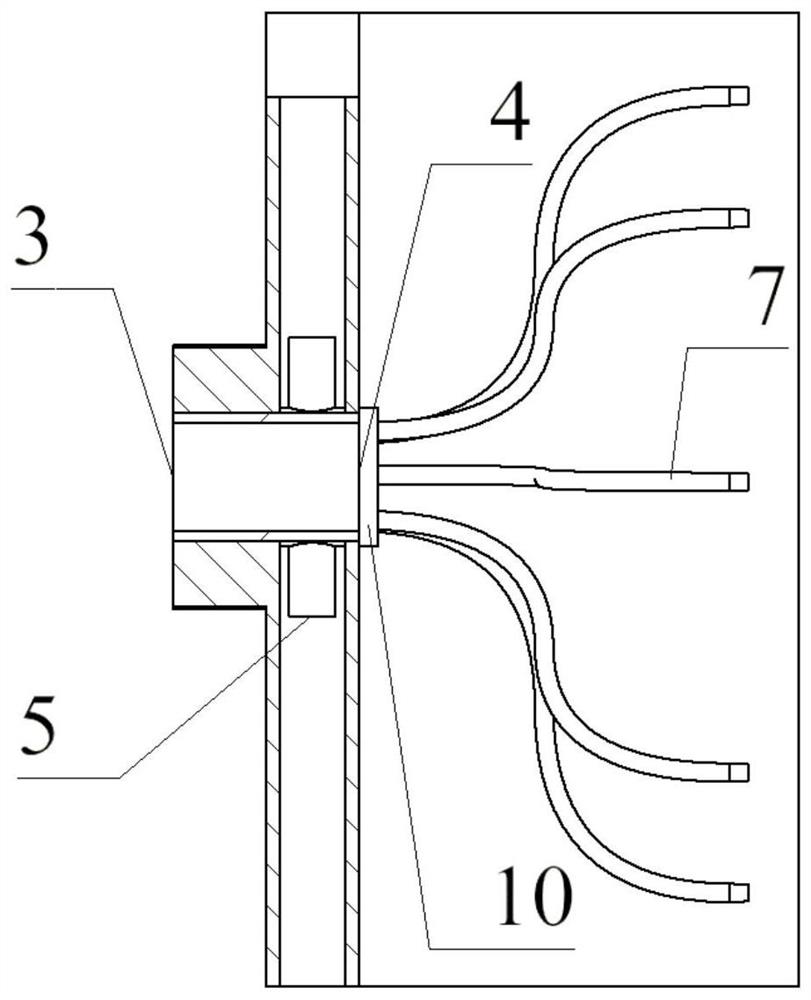

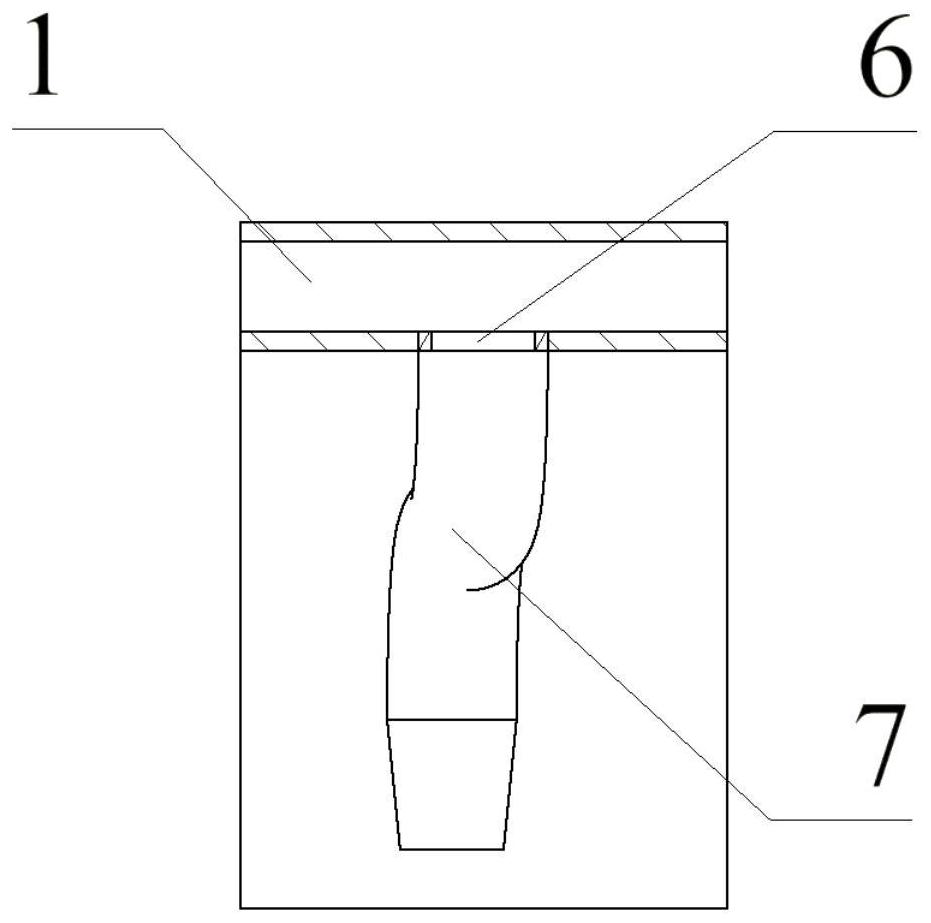

Device and method for improving local overheating phenomenon and temperature non-uniformity of converter transformer

ActiveCN111710501AReduce weightReduce manufacturing costTransformers/inductances coolingTransformers/inductances casingsEngineeringConvection heat

The invention discloses a device and method for improving the local overheating phenomenon and temperature non-uniformity of a converter transformer. By adopting a hollow box body, an oil guide structure, small holes and other structures, the internal flow field distribution of the converter transformer is more uniform, the convection heat exchange efficiency of transformer oil is improved, and the heat and mass transfer between the transformer oil is enhanced, so that the non-uniformity of the internal temperature distribution of the converter transformer is improved. Local enhanced heat exchange is carried out on a local overheating position by adopting a directional nozzle structure, so that the local overheating phenomenon of the converter transformer is improved.

Owner:XI AN JIAOTONG UNIV +2

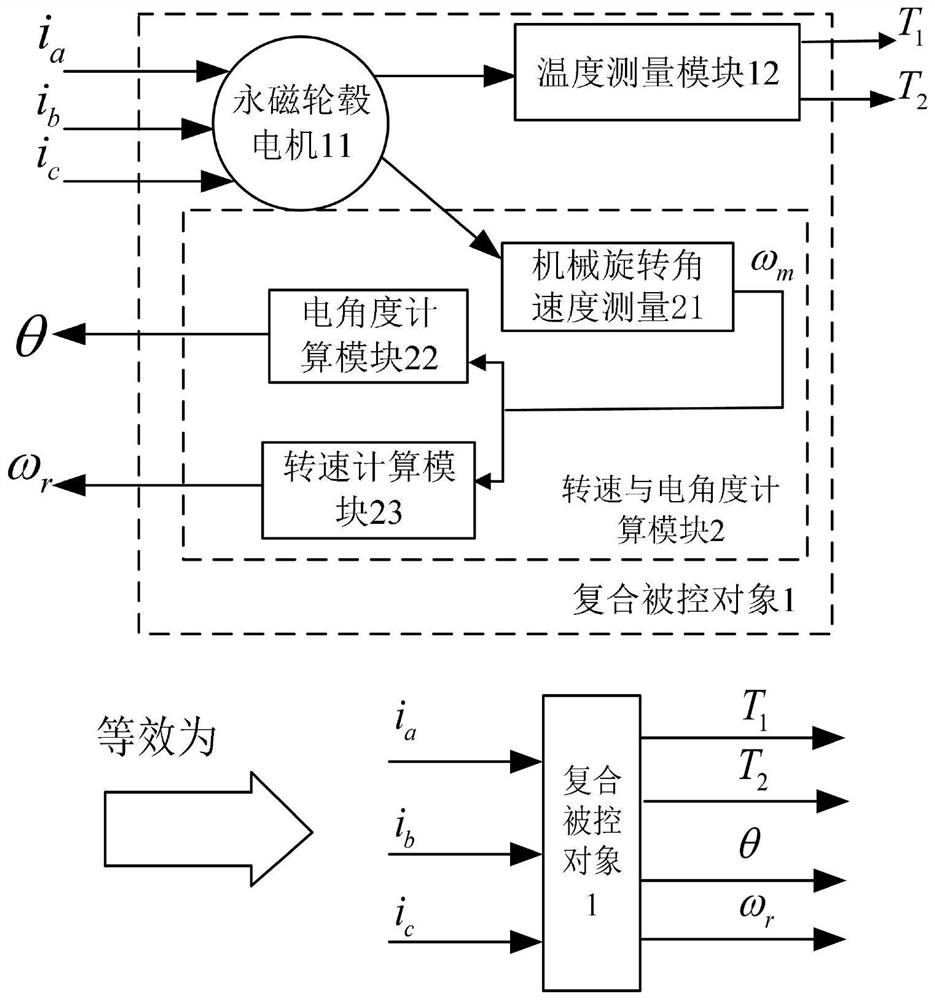

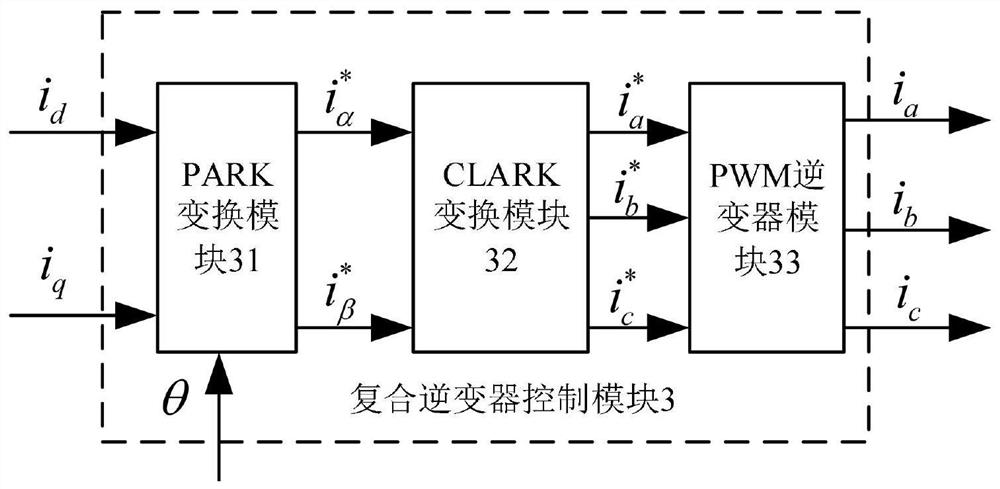

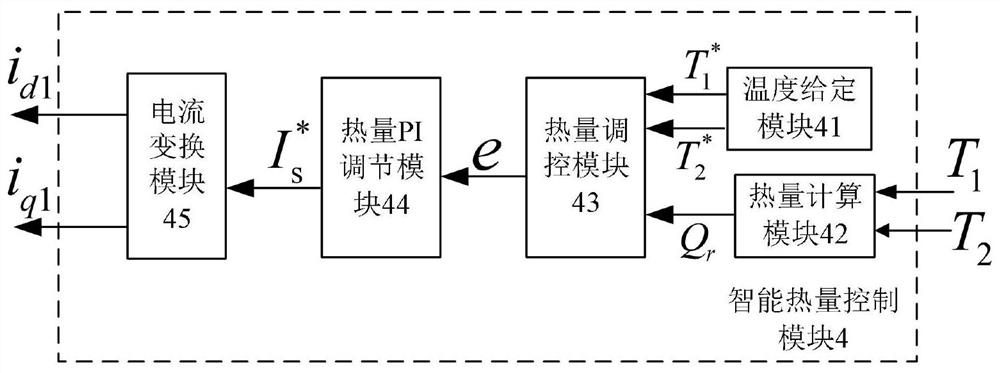

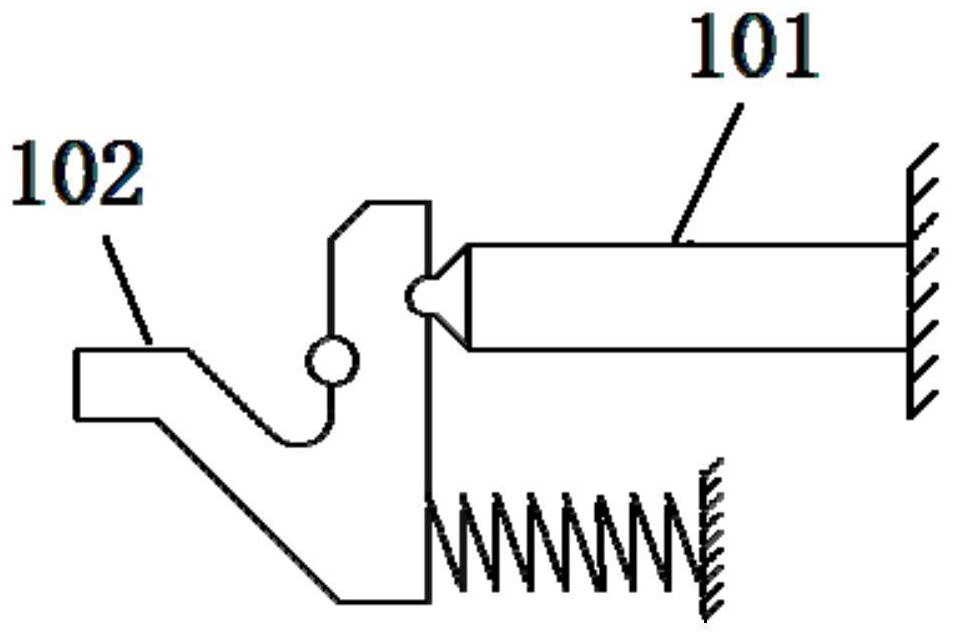

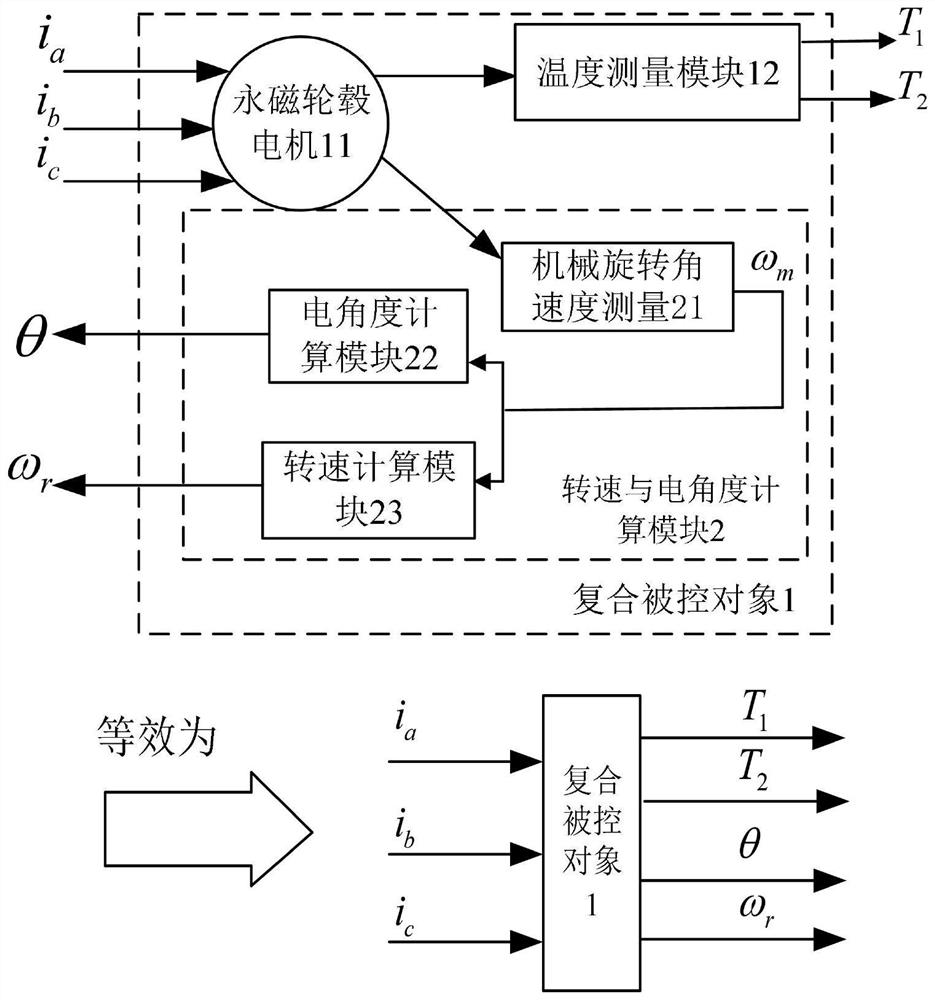

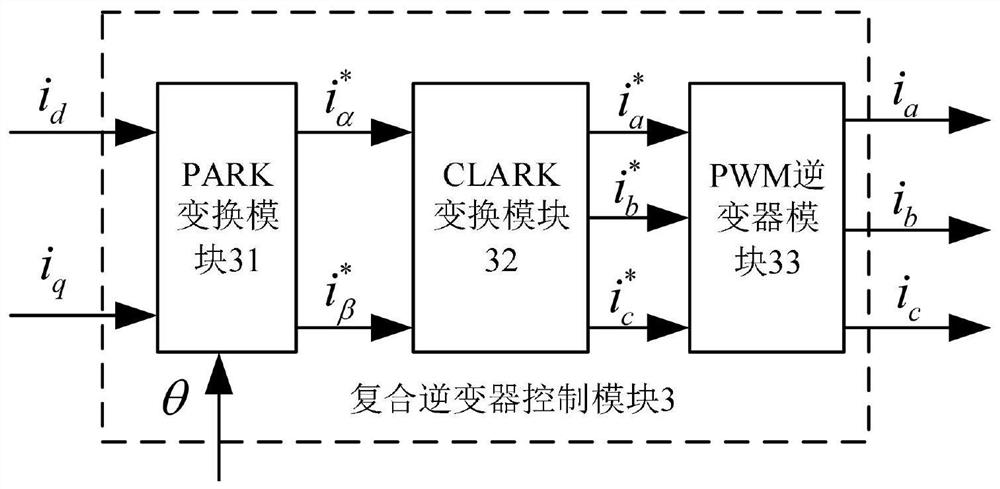

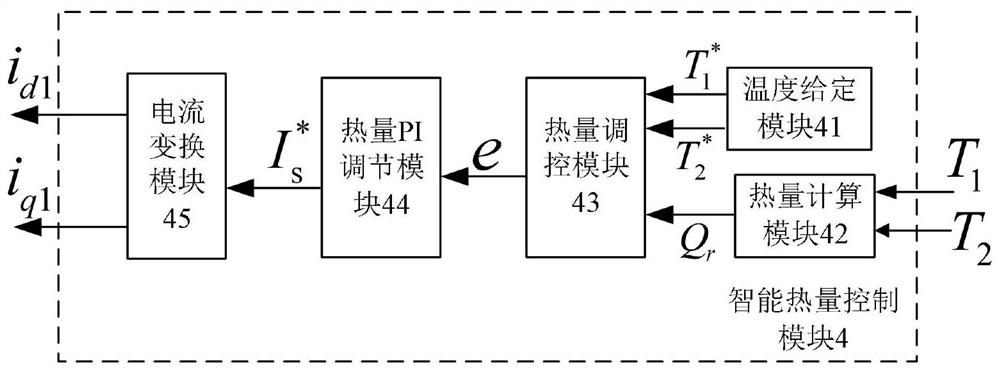

Construction method of electric vehicle permanent magnet hub motor energy composite controller

ActiveCN112701973AImprove overheatingHigh control precisionElectronic commutation motor controlSpeed controllerTemperature controlElectric machine

The invention discloses a construction method of an electric vehicle permanent magnet wheel hub motor energy composite controller.A composite controlled object is formed by a permanent magnet wheel hub motor, a temperature measurement module and a rotating speed and electric angle calculation module, and a PARK conversion module, a CLARK conversion module and a PWM inverter module are sequentially connected in series to form a composite inverter control module; an intelligent heat control module is composed of a temperature setting module, a heat calculation module, and a heat regulation and control module, a heat PI regulation module and a current conversion module which are sequentially connected in series; a flux linkage observation module, a coordinate transformation module, a torque error calculation module, a reference torque calculation module, a torque estimation module, a target torque giving module, a PI adjustment module, a phase angle updating module and a current transformation module jointly form a composite temperature control torque module, and the temperature of the hub motor is measured to feed back and adjust the running state of the motor; and the composite temperature control torque module and the heat control module are jointly regulated and controlled to realize temperature and torque control.

Owner:JIANGSU UNIV

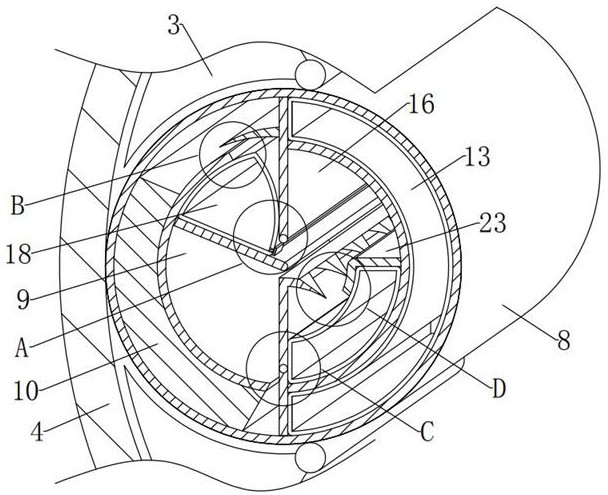

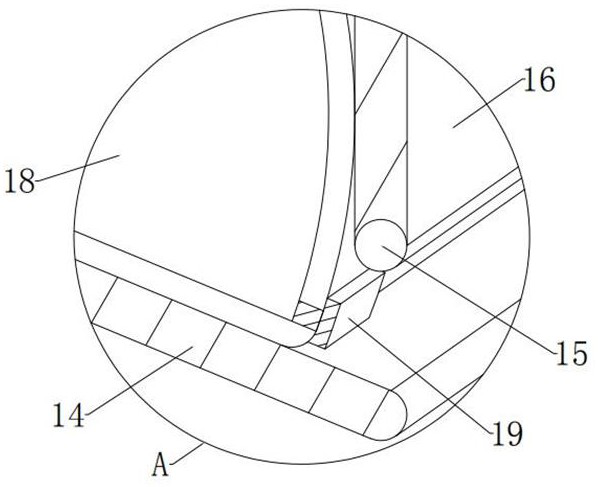

A wet clutch friction plate with bionic oil groove structure

InactiveCN106438746BExcellent one-way conductionSpeed up the flowFriction clutchesFriction liningMicro structureFriction reduction

The invention discloses a wet clutch friction plate with a bionic oil groove structure, and belongs to the technical field of automobile clutch friction plates. The wet clutch friction plate consists of a core plate and friction liners, wherein the two friction liners are symmetrically and fixedly connected with the front side and the back side of the core plate; radial oil grooves and annular oil grooves are formed in surfaces of both two friction liners; bionic micro structures consisting of guide grooves and bionic unit grooves are arranged at the bottoms of the oil grooves. Therefore, by adopting the wet clutch friction plate, an excellent one-way conveying guide function on cooled lubricating oil can be achieved, the flowing speed of the lubricating oil in the oil grooves can be effectively increased, heat convection between the lubricating oil and the friction plate can be improved, and surface temperature increase of the friction plate can be remarkably reduced; due to the combination of the radial oil grooves and the annular oil grooves, a unique composite oil groove mode can be achieved, failure situations such as over heat and deformation caused by concentrated heat stress on the surface of the friction plate can be alleviated, the performance of the friction plate can be comprehensively improved, and the service life of the friction plate can be prolonged.

Owner:JILIN UNIV

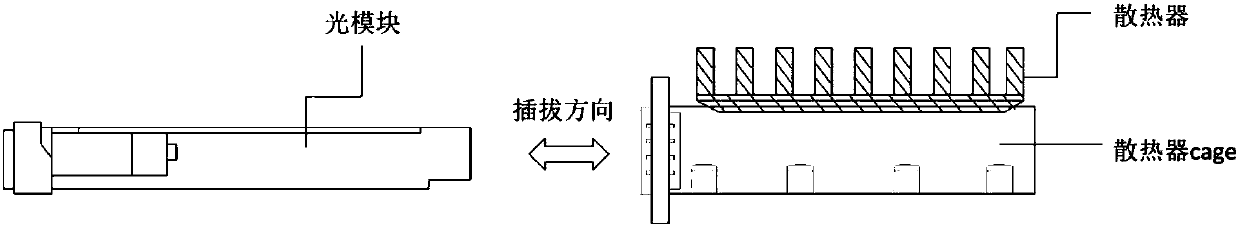

Compound thermal-conductive interface material and cooling structure in optical module plugging occasion

InactiveCN109866477AImprove thermal contact resistanceImprove thermal conductivitySemiconductor/solid-state device detailsSynthetic resin layered productsOptical ModuleWear resistant

The invention provides a compound thermal-conductive interface material suitable for a plugging occasion between an optical module and a shell cooler. The compound thermal-conductive interface material suitable for the plugging occasion between the optical module and the shell cooler comprises a thermal-conductive layer, an adhesive layer and a wear-resistant layer which are sequentially arranged;a material of the thermal-conductive layer is a thermal-conductive interface material which has a thermal conductivity coefficient higher than 2 W / m.K in a thickness direction and thickness in a range of 70-500 mum, a material of the wear-resistant layer is a wear-resistant material which has a thermal conductivity coefficient higher than 0.3 W / m.K and thickness smaller than 50 mum, and the compound thermal-conductive interface material is fixed to an optical module plugging structure through the adhesive layer. The compound thermal-conductive interface material is composed of the thermal-conductive layer, the adhesive layer and the wear-resistant layer, wherein the wear-resistant layer provides scratch-resistant performance, and meanwhile, high thermal conductivity of the thermal-conductive layer under protection of the wear-resistant layer is used for improving the interface thermal resistance; therefore, the compound thermal-conductive interface material is suitable for the gap-filling cooling occasion, which is used for filling a gap between the optical module and the shell cooler, with plugging requirements.

Owner:JONES TECH

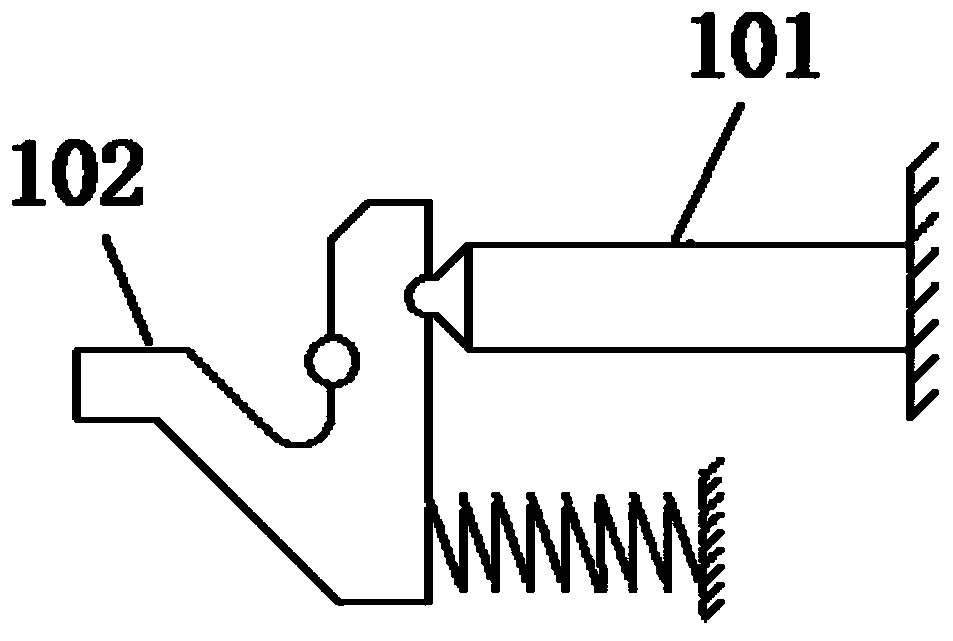

Spike heating transmission gear

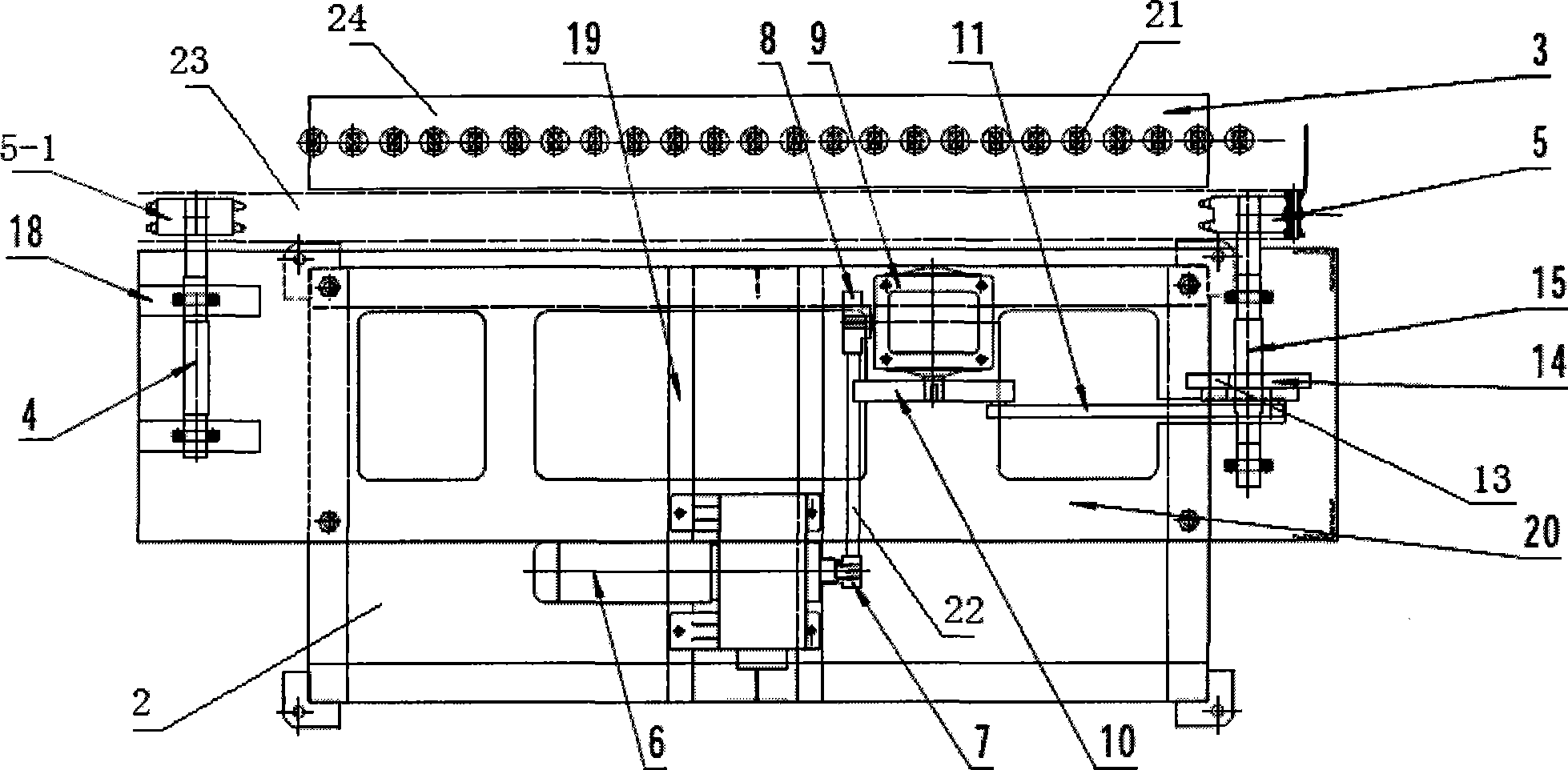

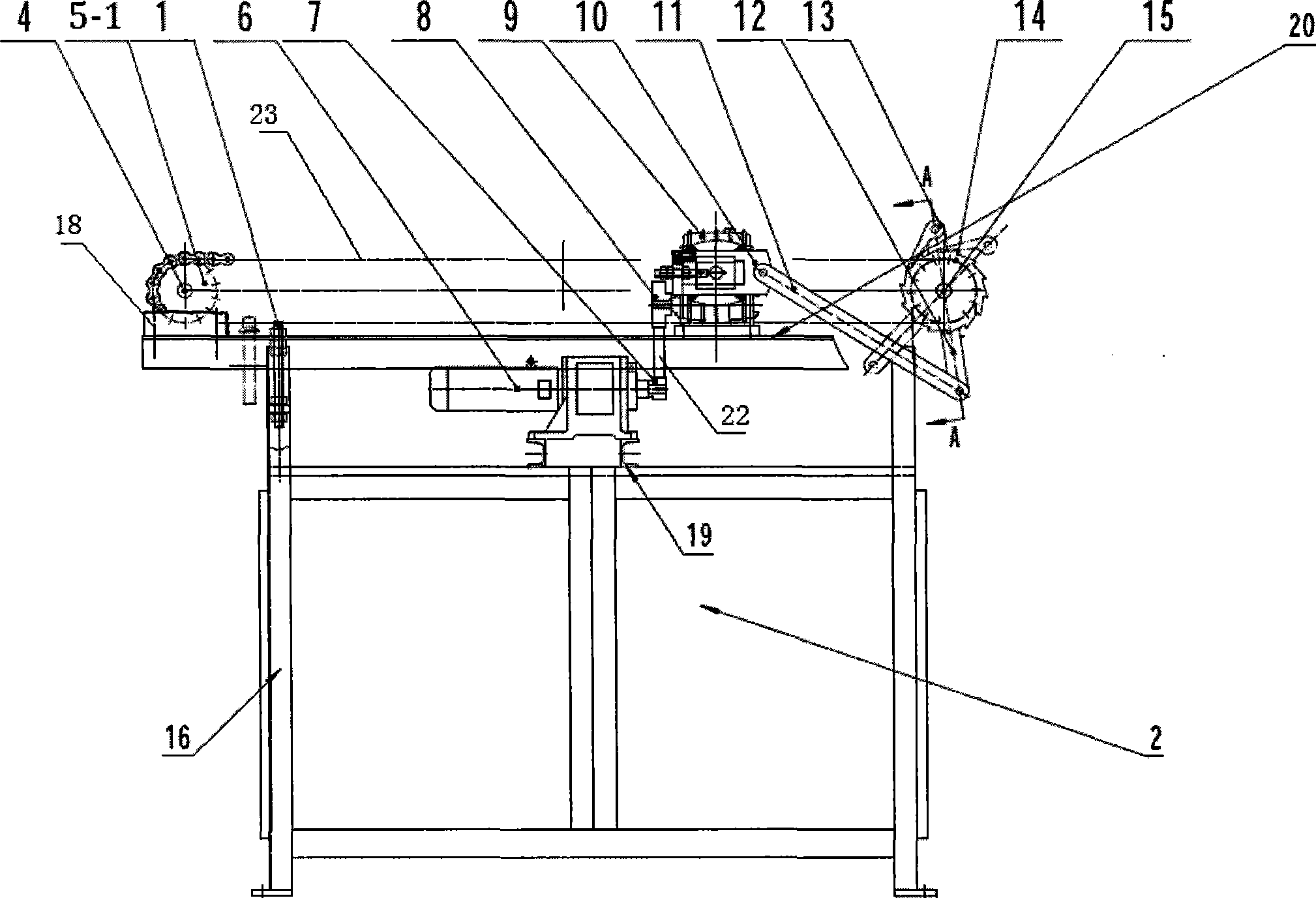

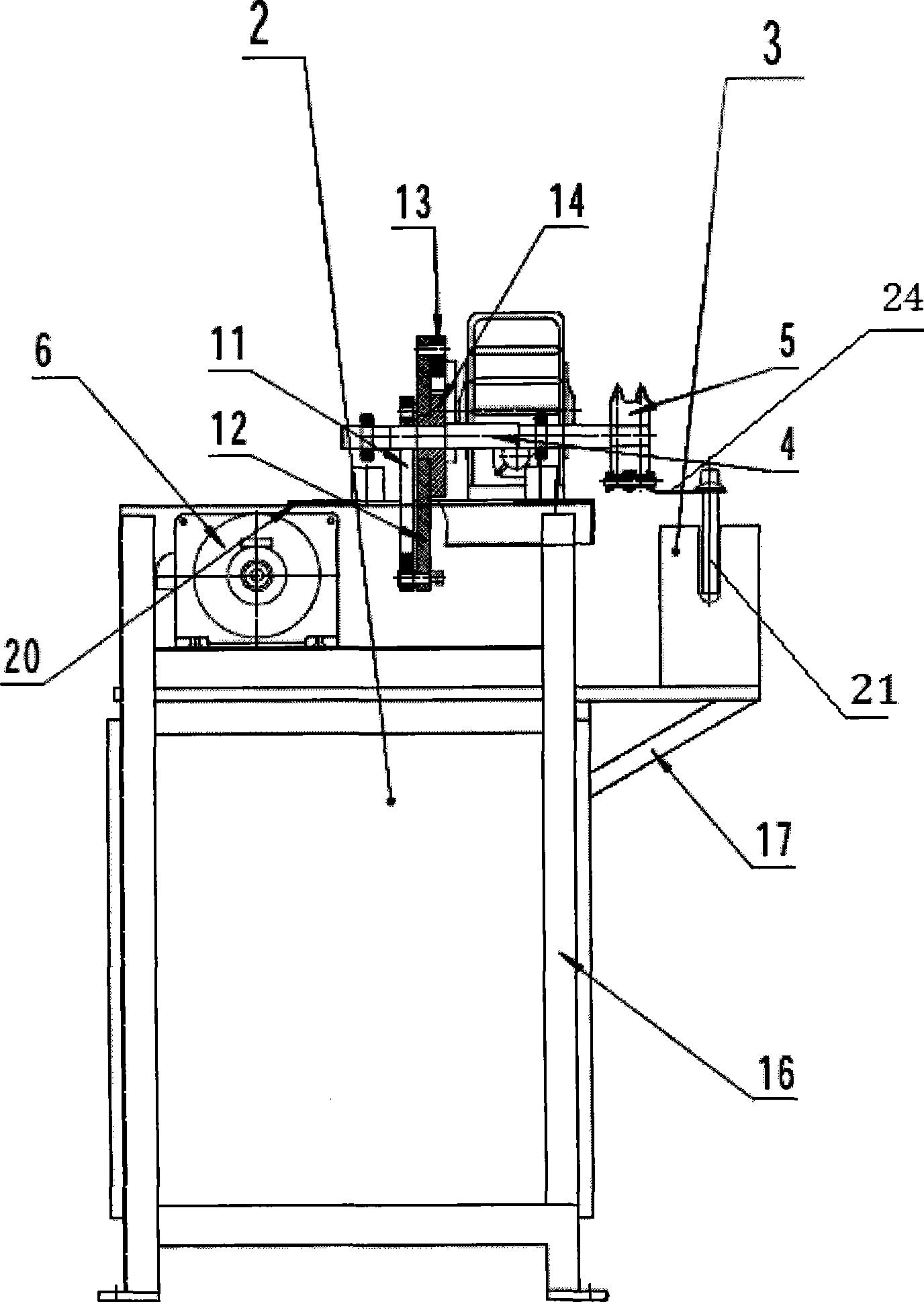

The invention relates to a heating transmission device for spikes, which is applicable to the heating transmission of railway thread spikes needing to heat rolling thread. The structure of the heating transmission device for the spikes is characterized in that the device comprises a capacitor cabinet, a sensor, a motor, a reducer, a connecting rod, a rocker, a ratchet wheel, a detent, a driving shaft, a chain, a driven shaft and a clamping plate; the capacitor cabinet is arranged on the ground surface; the motor and the reducer are arranged on the capacitor cabinet; one end of the reducer is connected with the motor by a belt; the other end of the reducer is sequentially connected with the connecting rod, the rocker and the ratchet wheel; the detent is arranged on the top end of the rocker; the detent is matched with the ratchet wheel; the driving shaft and the driven shaft are respectively arranged at the two ends of the capacitor cabinet and are connected with each other by the chain; the chain is connected with the clamping plate; the sensor is arranged below the clamping plate; the head of the spike is clamped on the clamping plate; and the spike body of the spike is arranged in the sensor. The heating transmission device has the advantages of reasonable and compact structural design, good heating effect, being difficult to be over-heated and low preparation cost.

Owner:QIFENG PRECISION IND SCI TECH

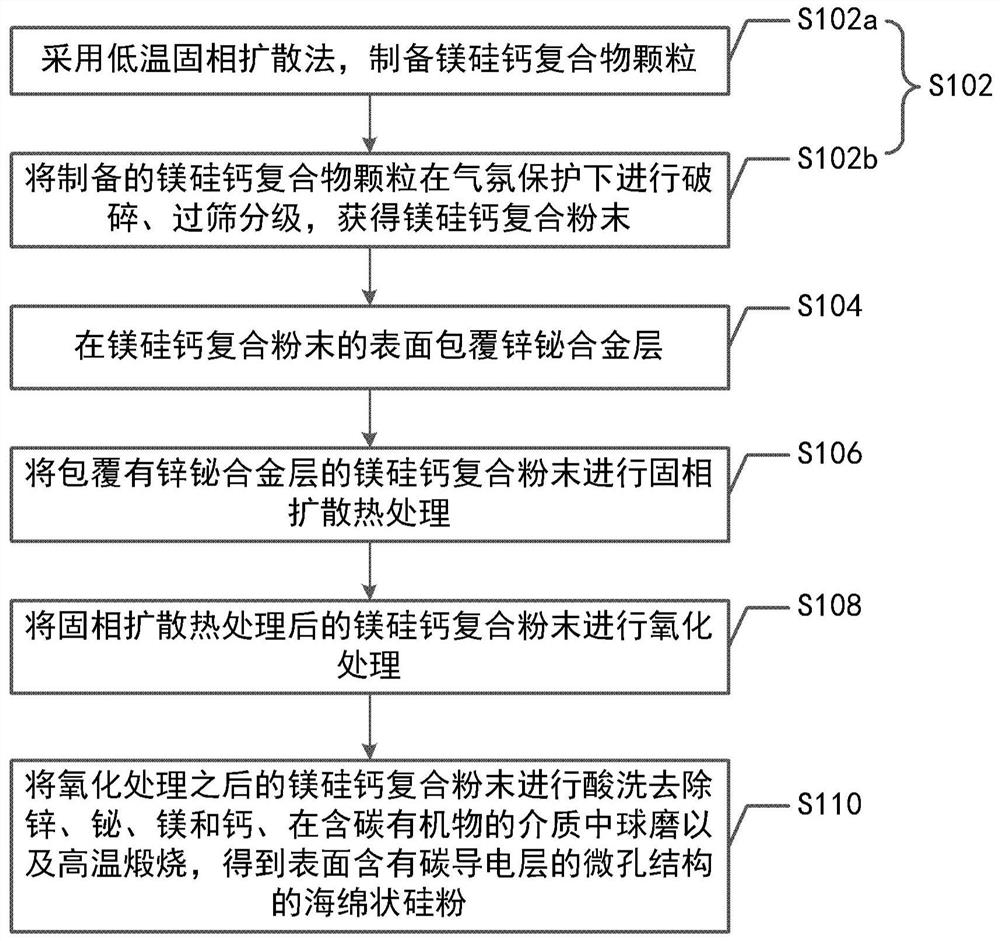

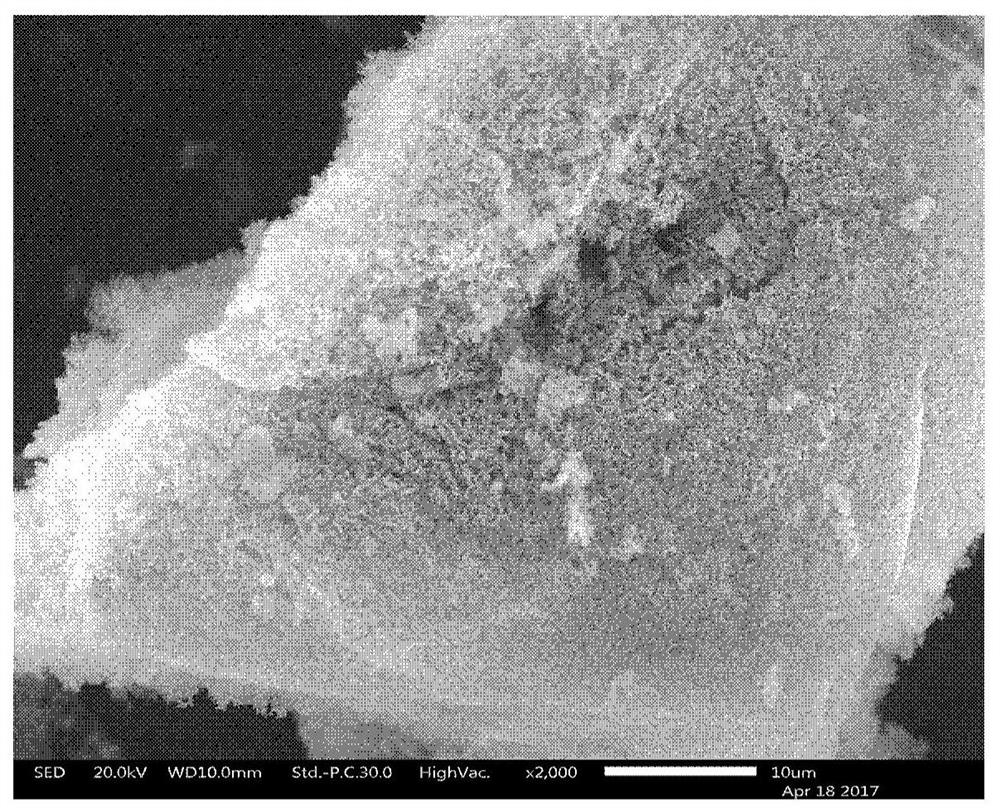

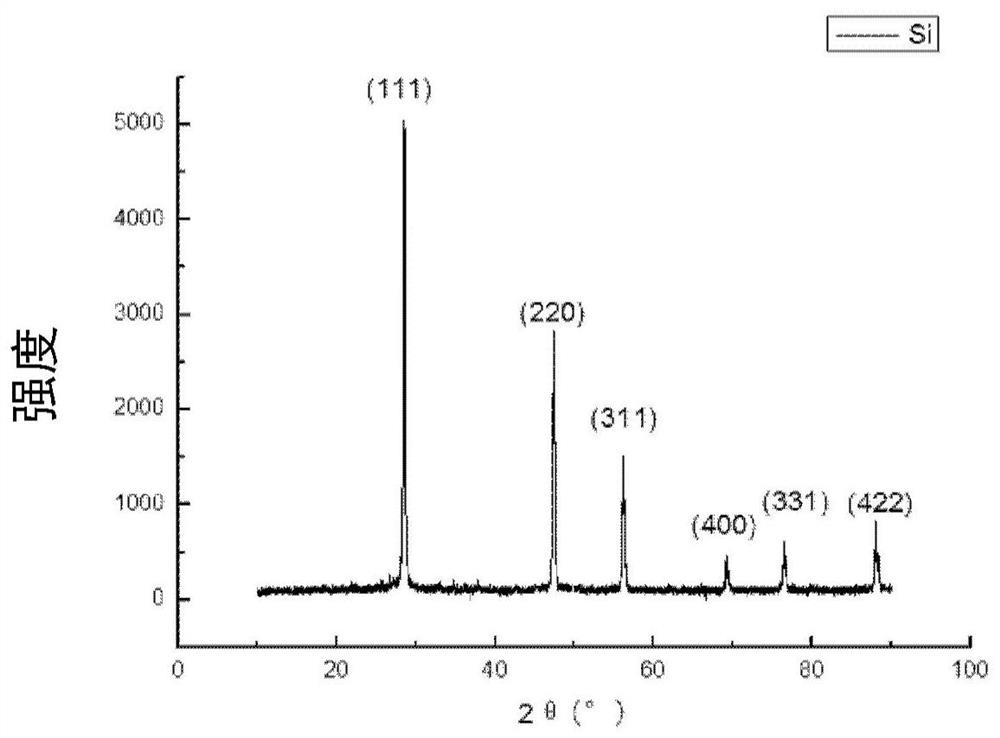

Sponge silicon powder and its preparation method and lithium ion battery

ActiveCN108039484BHigh crystallinityAchieving Controlled Slow OxidationSiliconCell electrodesSilicon particleBattery cell

The invention discloses spongy silicon powder which can be used in the negative electrode of a lithium ion battery and a preparation method of the spongy silicon powder. The preparation method of thespongy silicon powder comprises the following steps: coating the surface of magnesium-silicon-calcium composite powder with a zinc-bismuth alloy layer; carrying out solid-phase diffusion heat treatment on the magnesium-silicon-calcium composite powder coated with the zinc-bismuth alloy layer; oxidizing the magnesium-silicon-calcium composite powder after the solid-phase diffusion heat treatment; pickling the oxidized magnesium-silicon-calcium composite powder to remove zinc, bismuth, magnesium and calcium, and carrying out ball milling and calcining in a medium containing carbon-containing organic matters to obtain spongy silicon powder with a microporous structure with a carbon conductive layer on the surface. The spongy silicon powder overcomes the safety risks of ignition and explosionof workshop magnesium powder dust in the prior art, and is suitable for industrial batch production. The spongy silicon powder has a microporous structure with a carbon conductive layer on the surface, microporous gaps are uniform, the crystallinity of silicon particles is high, and the total oxygen content of the powder is less than 5%; the spongy silicon powder has relatively good conductivity and relatively high first charge-discharge coulombic efficiency when being used as a negative electrode material.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

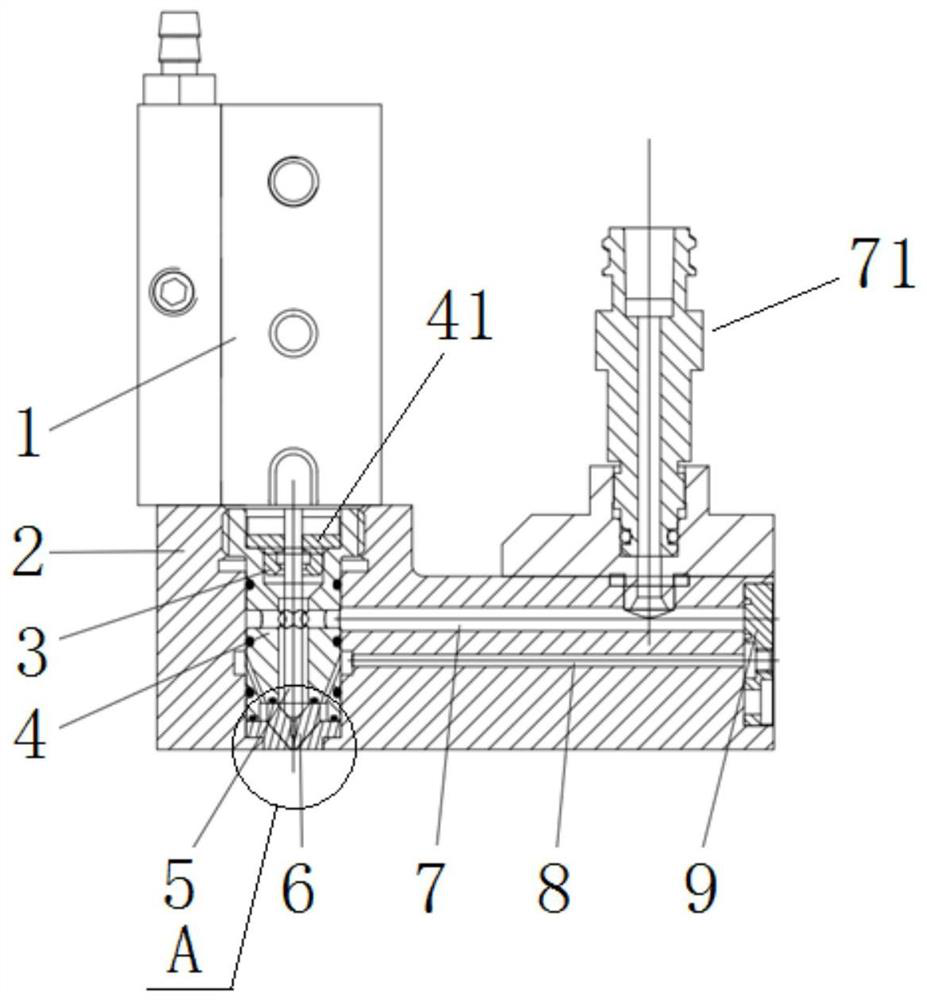

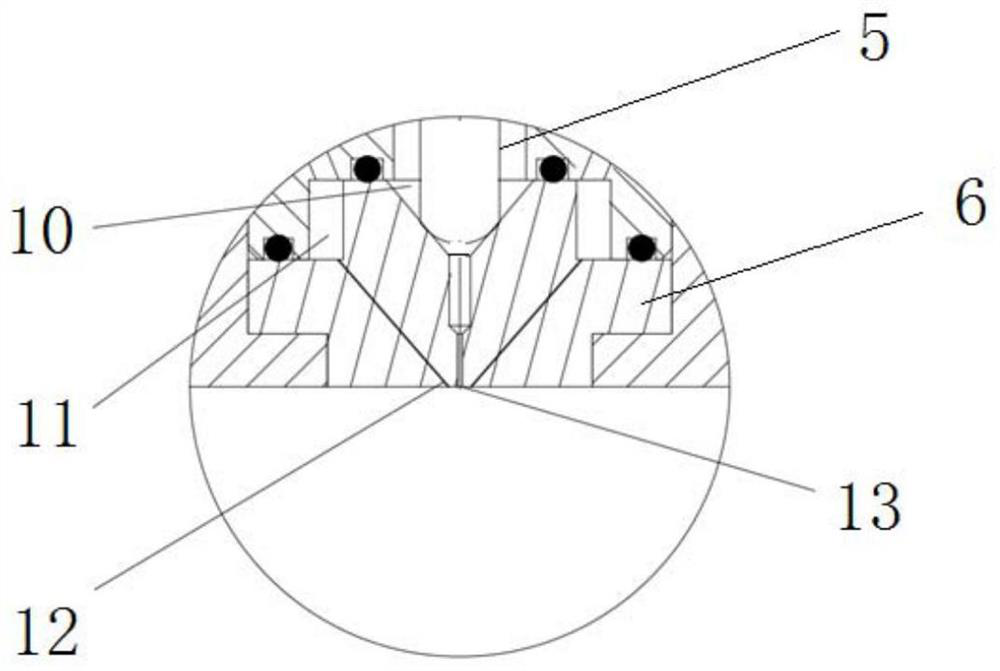

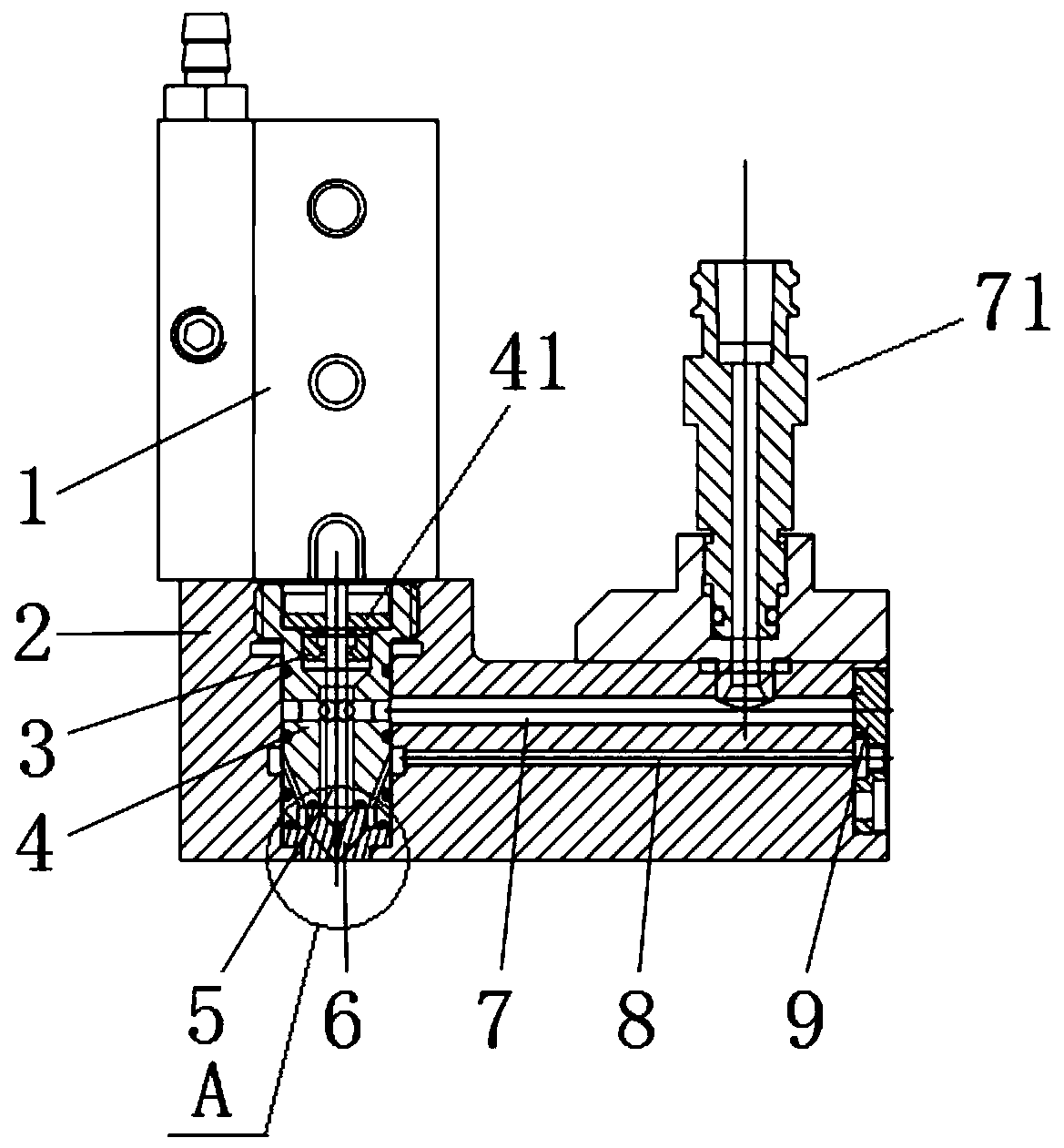

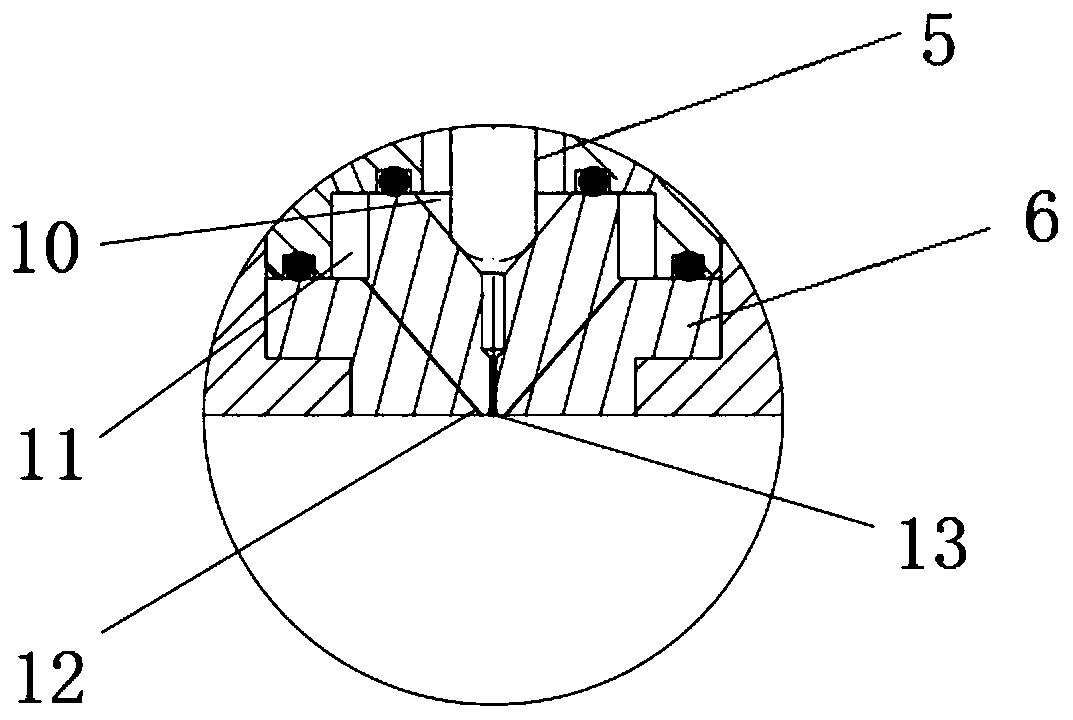

Piezoelectric precision spraying device

ActiveCN110918355BPrecise thickness controlEfficient sprayingLiquid spraying apparatusStructural engineeringMechanical engineering

The piezoelectric precision spraying device of the present invention, the driving body includes piezoelectric ceramics connected to each other and a lever amplification mechanism, and the lever amplification mechanism amplifies the micro-displacement generated by the expansion and contraction of the piezoelectric ceramics under the action of an electric field to a specified stroke, and also includes A channel carrier, the channel carrier is provided with a cavity seat, and the cavity seat is provided with a liquid cavity and an air cavity, and the liquid cavity and the gas cavity are respectively connected with the liquid channel and the gas flow channel opened on the channel carrier. The channel is connected, the lever amplifying mechanism is connected with a push rod, and the push rod extends into the liquid cavity, and the bottom of the liquid cavity communicates with the nozzle. The purpose is to provide a piezoelectric precision spraying device with simple structure, low use cost, low installation and adjustment difficulty and high spraying precision.

Owner:福之匠精工科技(昆山)有限公司

A construction method of energy composite controller for electric vehicle permanent magnet hub motor

ActiveCN112701973BImprove overheatingHigh control precisionSpeed controllerElectronic commutation motor controlTemperature controlElectric machinery

The invention discloses a construction method of a permanent magnet hub motor energy composite controller for an electric vehicle. The composite controlled object is composed of a permanent magnet hub motor, a temperature measurement module, and a rotation speed and electrical angle calculation module. The PARK transformation module, the CLARK transformation module and The PWM inverter modules are connected in series to form a composite inverter control module. The intelligent heat control module is composed of a temperature setting module, a heat calculation module, a heat regulation module, a heat PI regulation module, and a current conversion module connected in series. Module, coordinate transformation module, torque error calculation module, reference torque calculation module, torque estimation module, target torque given module, PI adjustment module, phase angle update module and current conversion module together constitute a composite temperature control torque module , to measure the temperature of the in-wheel motor itself to feedback and adjust the running state of the motor, and the compound temperature control torque module and the thermal control module are jointly regulated to realize temperature and torque control.

Owner:JIANGSU UNIV

Clamping tool for cutting machining

PendingCN114871845AIncrease temperatureImprove overheatingWork clamping meansPositioning apparatusMachine partsFixed frame

The invention relates to a clamping tool for cutting machining. The clamping tool comprises a base, a movable frame, a fixed frame and clamping plates. A plurality of anti-overheating assemblies capable of preventing the surface temperature of the movable frame from being too high are fixedly installed on the outer surface of the back side of the movable frame, and each anti-overheating assembly comprises a fixed shell, a temperature sensing assembly capable of sensing the temperature to control movement and a cooling assembly capable of cooling in time after the temperature rises. A plurality of anti-overheating assemblies are fixedly installed on the outer surface of the back side of the movable frame, and a temperature sensing assembly and a cooling assembly are movably installed at the top end and the right end of the interior of the fixed shell correspondingly. According to the clamping tool for cutting machining, the movable frame can have an anti-overheating function, when a clamping plate in the clamping tool clamps and cuts a machined part, even if high-temperature heat generated in the cutting process can be transmitted to the surface of the movable frame, the clamping plate is prepared to be loosened to take out the machined part after cutting is completed, and the movable frame can be prevented from being overheated. And the safety accident that both hands of an operator are scalded due to careless contact with the surface of the movable frame is avoided.

Owner:YANSHAN UNIV

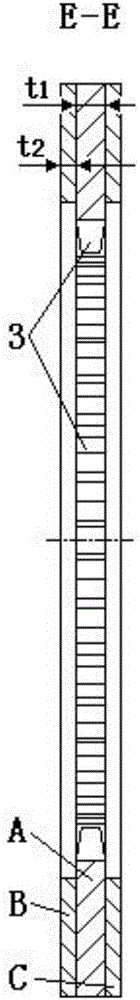

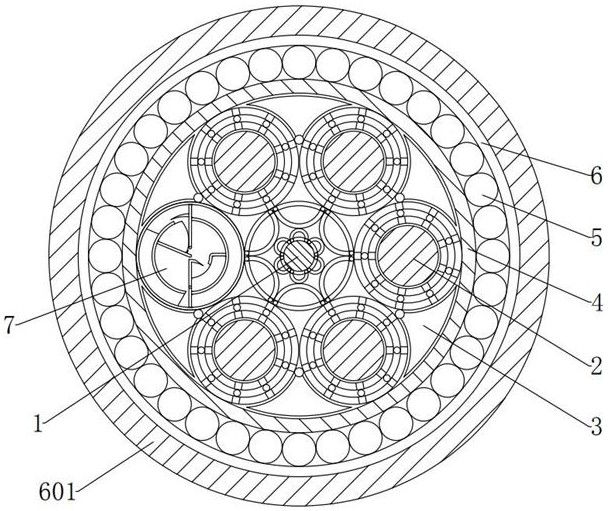

Dynamic cable for ocean engineering

PendingCN114783678AFully absorbedAvoid overall overheatingSubmarine cablesInsulated conductorsInsulation layerClassical mechanics

The invention provides a dynamic cable for ocean engineering, which comprises a power supply core and an inner sheath, and is characterized in that a plurality of anti-overheating assemblies capable of preventing the cable core from overheating are arranged between the middle end of the left inner wall of the inner sheath and the left end of the power supply core in a penetrating manner; the anti-overheating assembly comprises outer shells, inner shells, supporting strips, a heat conduction assembly capable of conducting guiding in time after the cable core generates heat and a cooling assembly capable of conducting cooling in time after the cable core generates heat, a plurality of outer shells are arranged between the middle end of the left inner wall of the inner wrapping sleeve and the left end of the power supply core in a penetrating mode, and the inner shells are fixedly installed in the centers of the interiors of the outer shells; a supporting strip is fixedly installed between the left inner wall of the outer shell and the left outer wall of the inner shell. According to the dynamic cable for ocean engineering, the anti-overheating effect in the cable core can be enhanced, and in the long-distance power transmission process of the submarine cable, even if heat is generated due to resistance, the heat can be absorbed and decomposed in time, the insulation layer wrapping the cable is prevented from aging, and normal use of the cable is guaranteed.

Owner:杨宁

Piezoelectric precision spraying device

ActiveCN110918355APrecise thickness controlEfficient sprayingLiquid spraying apparatusEngineeringMechanical engineering

The invention discloses a piezoelectric precision spraying device. A driving main body comprises piezoelectric ceramic and a lever amplifying mechanism which are connected with each other; the lever amplifying mechanism amplifies micro-displacement generated by stretching and retracting of the piezoelectric ceramic under the action of an electric field to a specified stroke. The driving main bodyalso comprises a flow channel carrier, and a cavity seat is arranged in the flow channel carrier; a liquid cavity and an air cavity are formed in the cavity seat, and the liquid cavity and the air cavity are respectively communicated with a liquid flow channel and an air flow channel which are formed in the flow channel carrier; the lever amplifying mechanism is connected with a push rod, the pushrod extends into the liquid cavity, and the bottom of the liquid cavity is communicated with a nozzle. The aim of the invention is to provide the piezoelectric precision spraying device which is simple in structure, low in use cost, low in installation and adjustment difficulty and high in spraying precision.

Owner:福之匠精工科技(昆山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com