Wet clutch friction plate with bionic oil groove structure

A wet clutch and bionic oil technology, applied in clutches, friction linings, friction clutches, etc., can solve the problems of different friction performance and heat dissipation effect, and achieve the effect of large friction coefficient, increased service life and sufficient heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further analyzed below in conjunction with accompanying drawing.

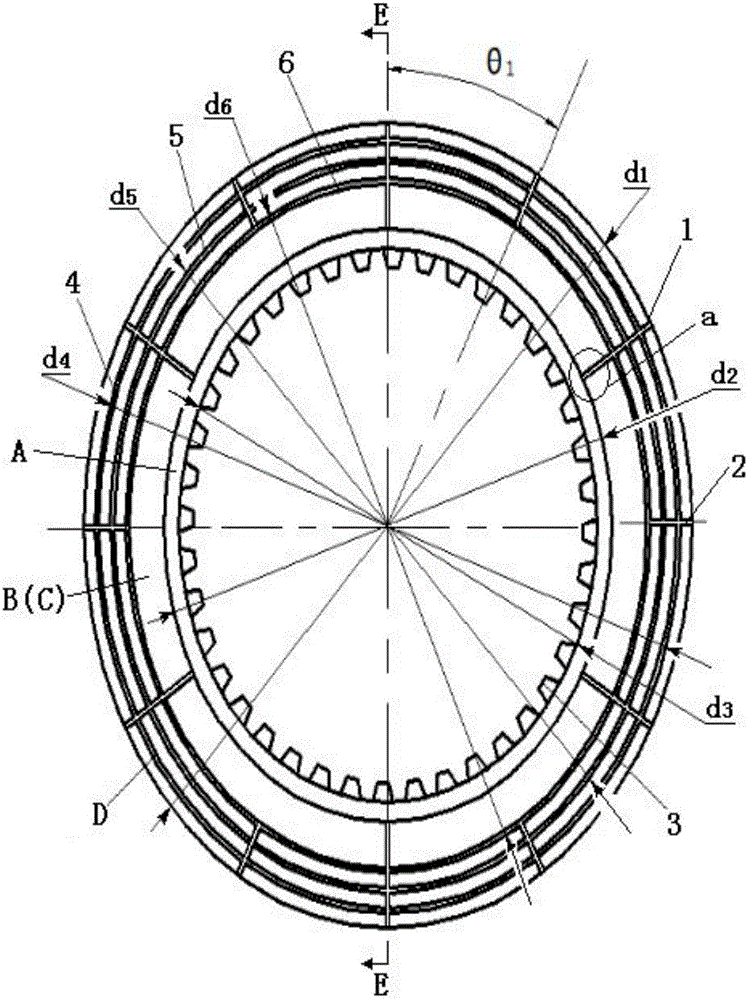

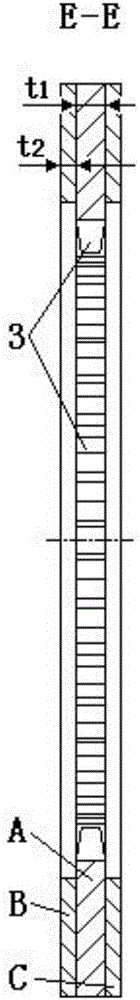

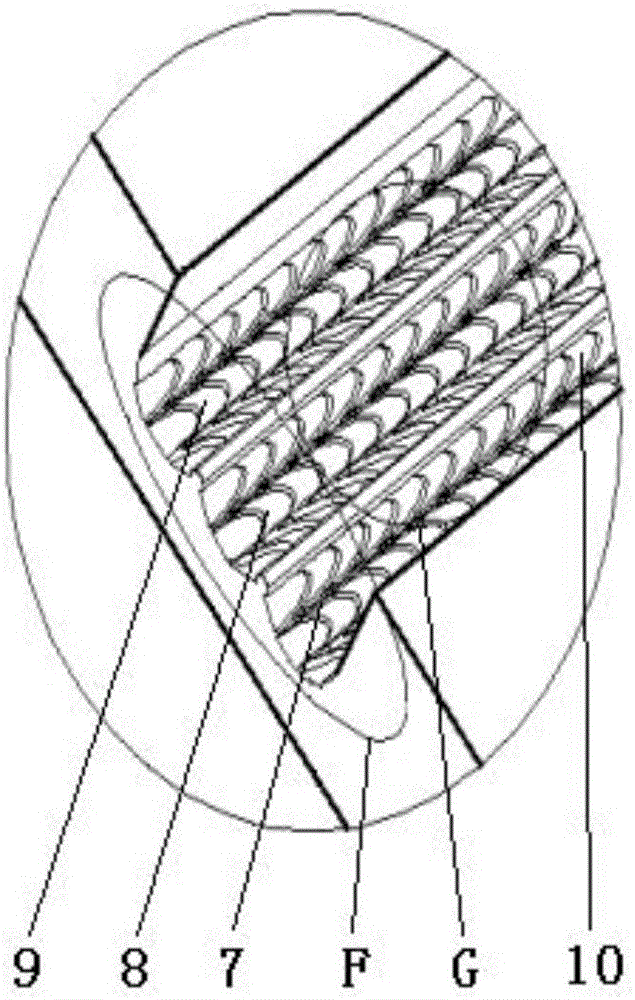

[0037] Such as figure 1 , figure 2 As shown, the present invention is composed of chip A, friction lining IB and friction lining IIC. The chip A is in the shape of an annular disk, and the material is 65Mn. The outer diameter of chip A is d 1 160-180mm, inner diameter d 3 110-125mm, thickness t 11.5-2mm, the inner circumference of chip A is provided with spline teeth 3; friction lining ⅠB and friction lining ⅡC) are made of sintered copper-tin metal or metal powder metallurgy, symmetrically fixed on the front and back sides of chip A, The outer diameter of friction lining IB and friction lining IIC is the same as the outer diameter of chip A, which is 160-180mm, and the inner diameter of friction lining IB and friction lining IIC is d 2 118-135mm, friction lining ⅠB and friction lining ⅡC thickness t 2 Both are 0.6-0.8mm; the surface of friction lining IB and friction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com