Cooling device for hydraulic braking systems

a technology of hydraulic braking and cooling device, which is applied in the direction of cycle brakes, cycle equipment, liquid fuel engines, etc., can solve the problems of inability to efficiently reduce temperature and danger of cyclists, and achieve the effect of improving the overheating of the conventional braking system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

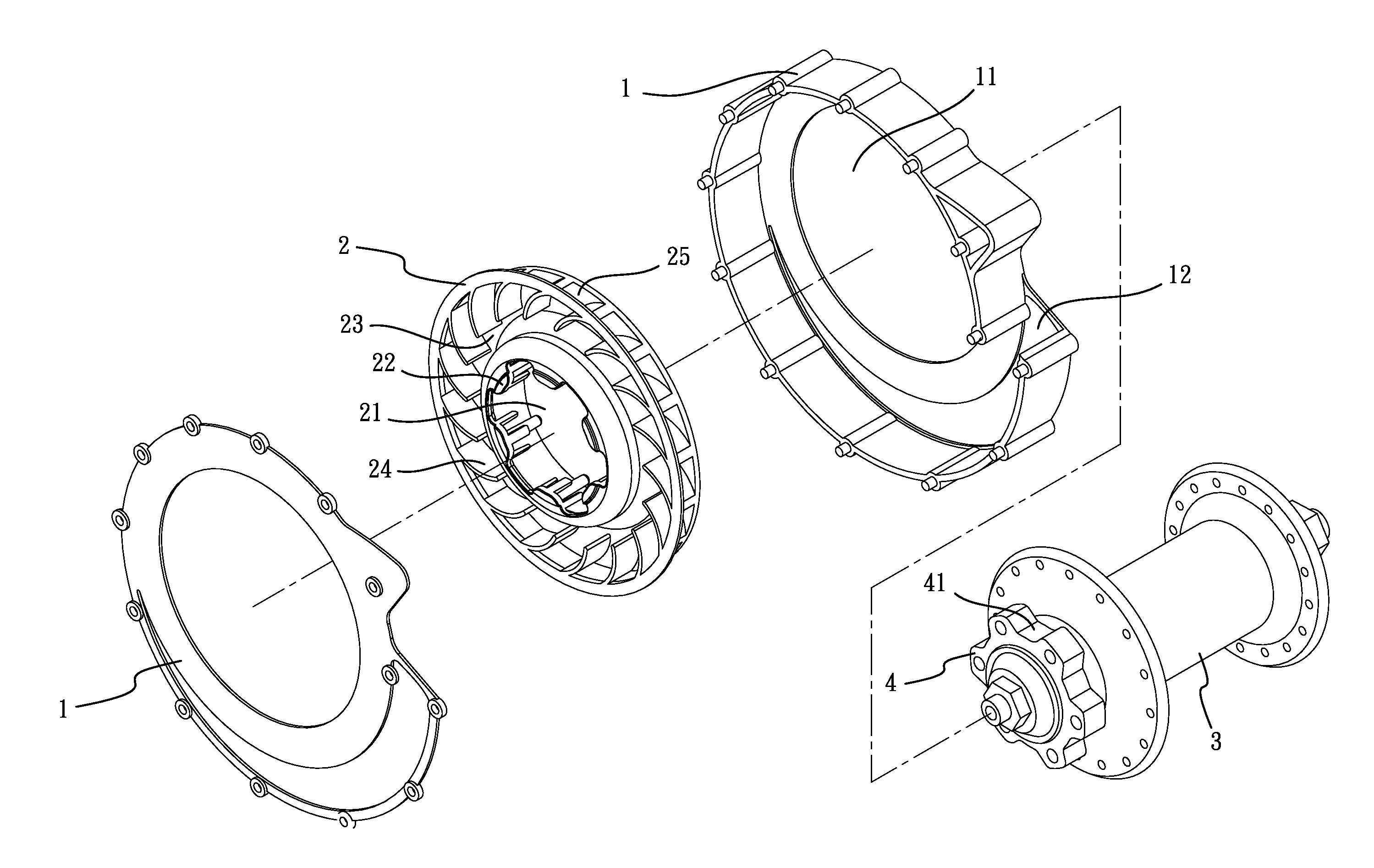

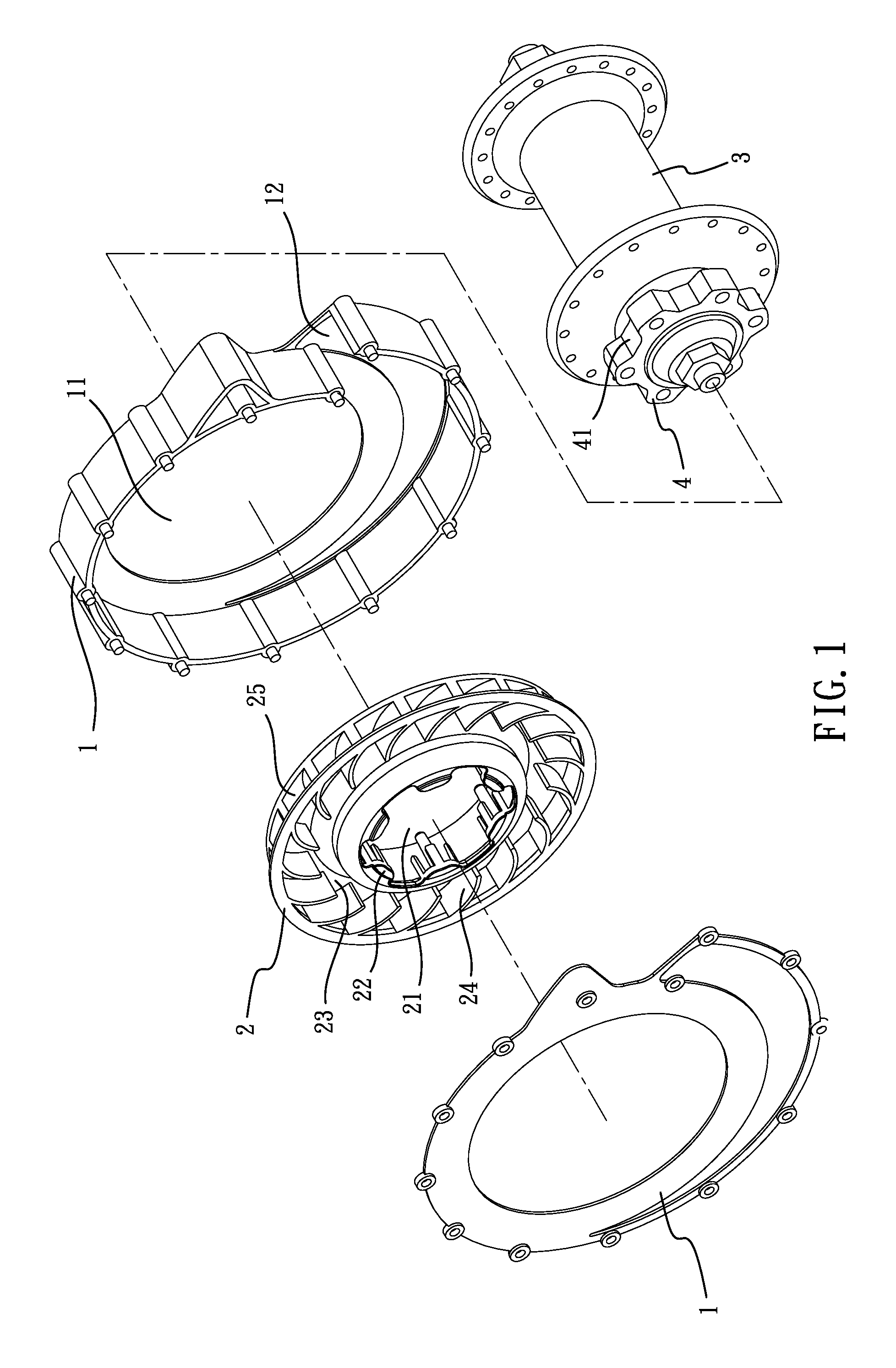

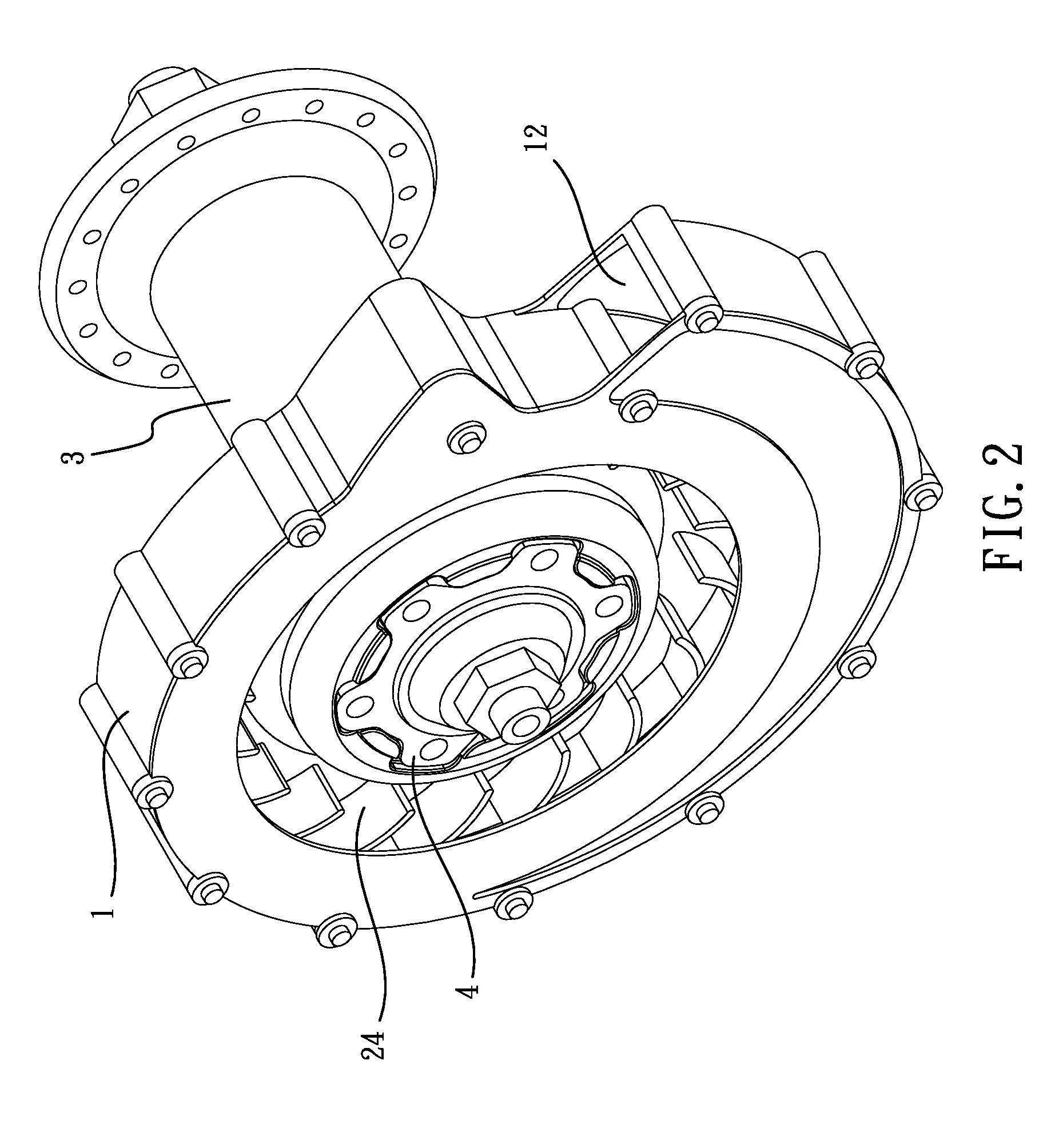

[0018]Referring to the drawings and initially to FIGS. 1 to 3, the cooling device for hydraulic braking systems in accordance with the present invention comprises a case 1, a turbine unit 2 and a ring 4 that is connected to an end of a hub 3. The case 1 is a spiral case and a thorough hole 11 is defined therethrough. A ventilation exit 12 is defined on the case 1 and communicates the inside and the outside of the case 1, so that the air convection between the inside and the outside of the case 1 is possible. The turbine unit 2 is located and operated in the case 1 and the turbine unit 2 has a fixing hole 21 which communicates with the through hole 11. A plurality of protrusions 22 is located at an inside of the fixing hole 21 and each protrusion 22 is an oval protrusion. The conjunction portions between the two sides of the protrusion 22 and the fixing hole 21 are two recesses so as to be pivotably connected with the ring 4. A guide groove 23 is defined in a side of the turbine unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com