A construction method of energy composite controller for electric vehicle permanent magnet hub motor

A composite controller, in-wheel motor technology, applied in motor generator control, electronic commutation motor control, electric vehicles, etc., can solve the problems of permanent magnet demagnetization output torque, torque fluctuation, pulsation, etc., and achieve good temperature control. And torque control, ensure real-time adjustment, improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

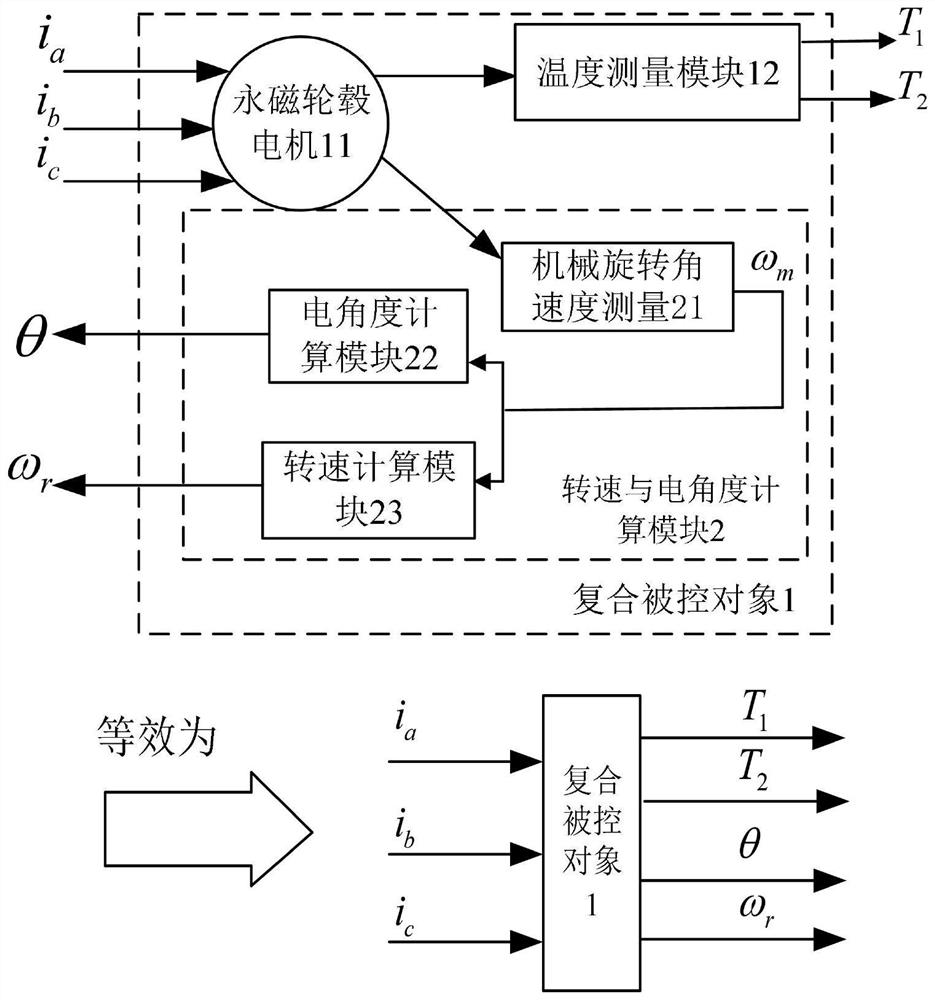

[0022] like figure 1 As shown, the composite controlled object 1 is jointly constructed by the permanent magnet hub motor 11, the temperature measurement module 12 and the rotational speed and electrical angle calculation module 2, and the input of the composite controlled object 1 is the three-phase control current i for controlling the permanent magnet hub motor 11 a i b i c and the motor winding temperature T 1 and motor case temperature T 2 , the output is the electrical angle θ and the motor speed ω r . Wherein, the temperature measurement module 12 detects the motor winding temperature T of the permanent magnet in-wheel motor 11 1 and motor case temperature T 2 And output, the rotational speed and electrical angle calculation module 2 obtains the electrical angle θ and the motor rotational speed ω of the permanent magnet hub motor 11 r and output. The rotation speed and electrical angle calculation module 2 is composed of a mechanical rotation angular velocity me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com