Piezoelectric precision spraying device

A spraying device and precise technology, which is applied in the field of piezoelectric precision spraying devices, can solve the problems of transducer resonant frequency point drift, small atomization amount, and low production efficiency, and achieve simple installation process, wide application range, and easy installation. The effect of low difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

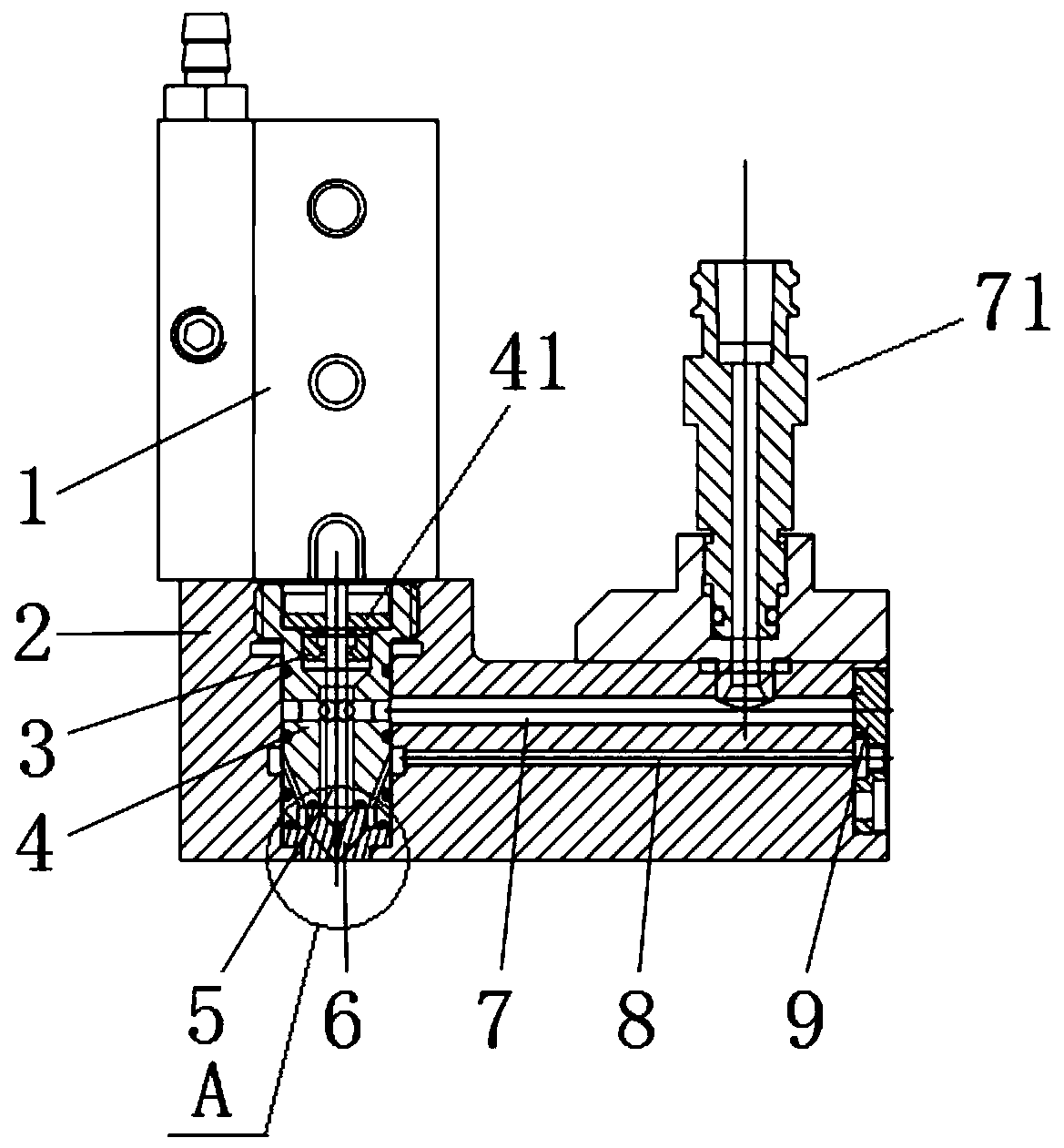

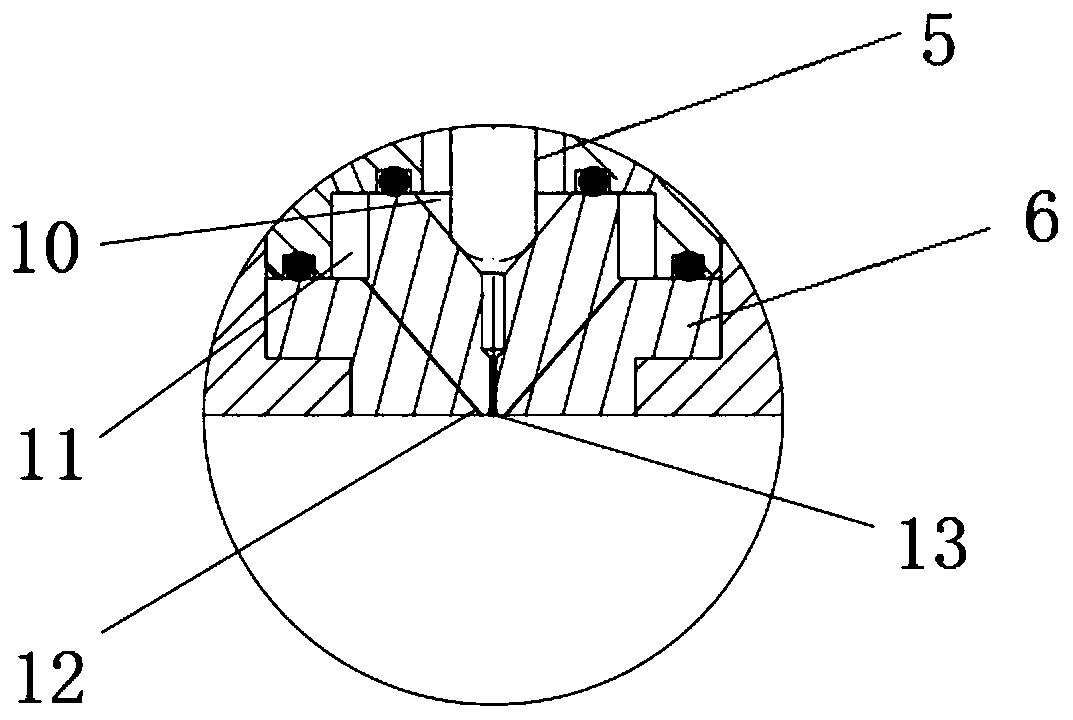

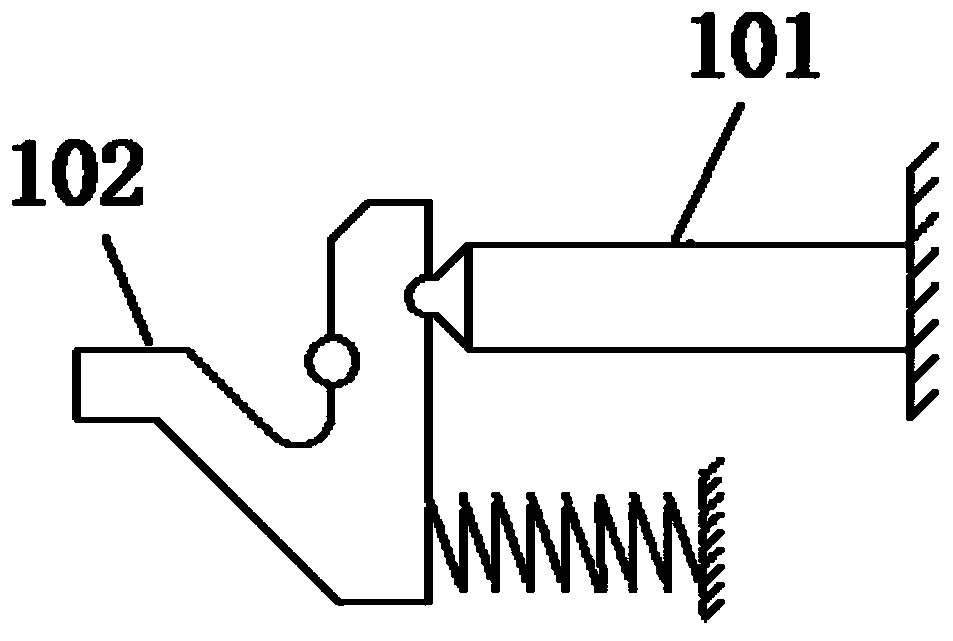

[0031] Such as Figure 1 to Figure 3 As shown, in the present invention, the driving body 1 includes piezoelectric ceramics 101 connected to each other and a lever amplification mechanism 102. Based on the principle of lever amplification, the lever amplification mechanism 102 amplifies the micro-displacement generated by the expansion and contraction of the piezoelectric ceramics 101 under the action of an electric field to Specified stroke required for spraying. Piezoelectric ceramic 101 is used as the driving source, and the quantitative adjustment of the displacement parameters required for spraying can be realized by adjusting the electrical parameters, which effectively expands the viscosity of the liquid or liquid-solid mixture (the liquid is mixed with an appropriate amount of tiny particles) that is suitable for the spraying device. scope. Piezoelectric ceramic 101 is used as a driving source, and it is a common and mature technology in the industry to cooperate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com