Method for measuring temperature by using thermal wave meter

A technology for measuring temperature and thermal wave instrument, which is applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve the problems of weak process simulation, time-consuming, inability to simulate, etc., and achieve process simulation Strong performance, wide application range and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

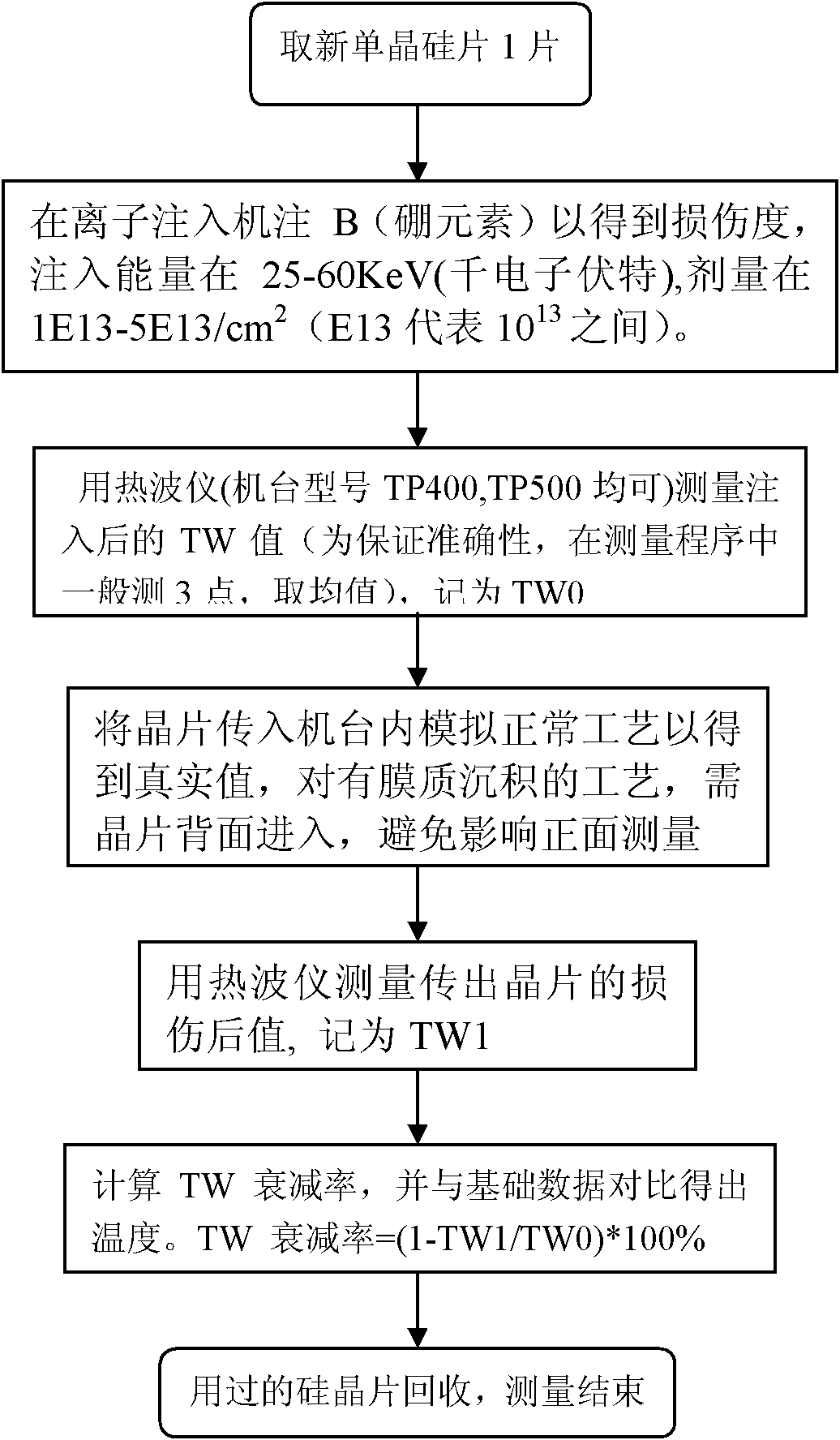

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail, and practical application example:

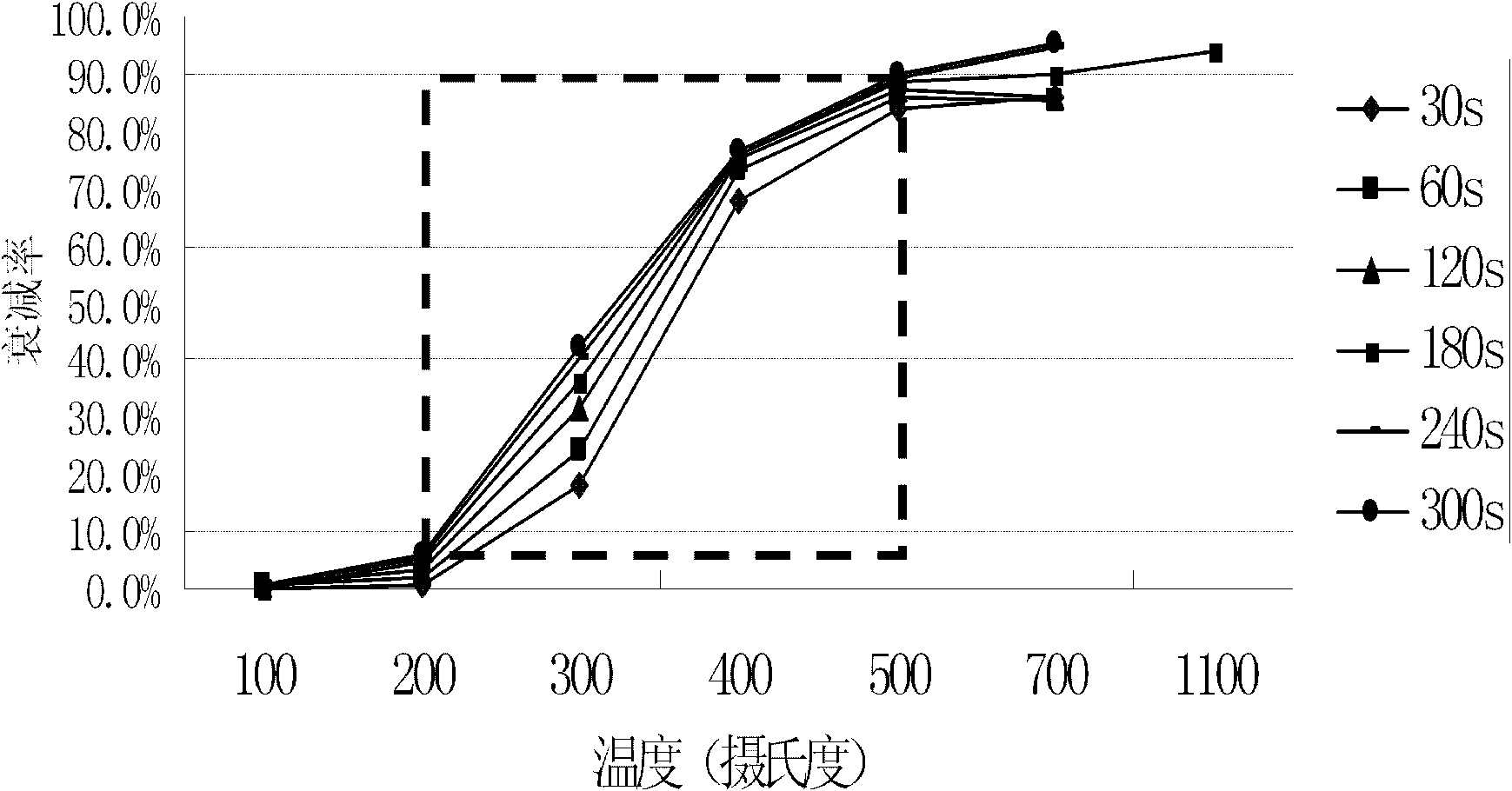

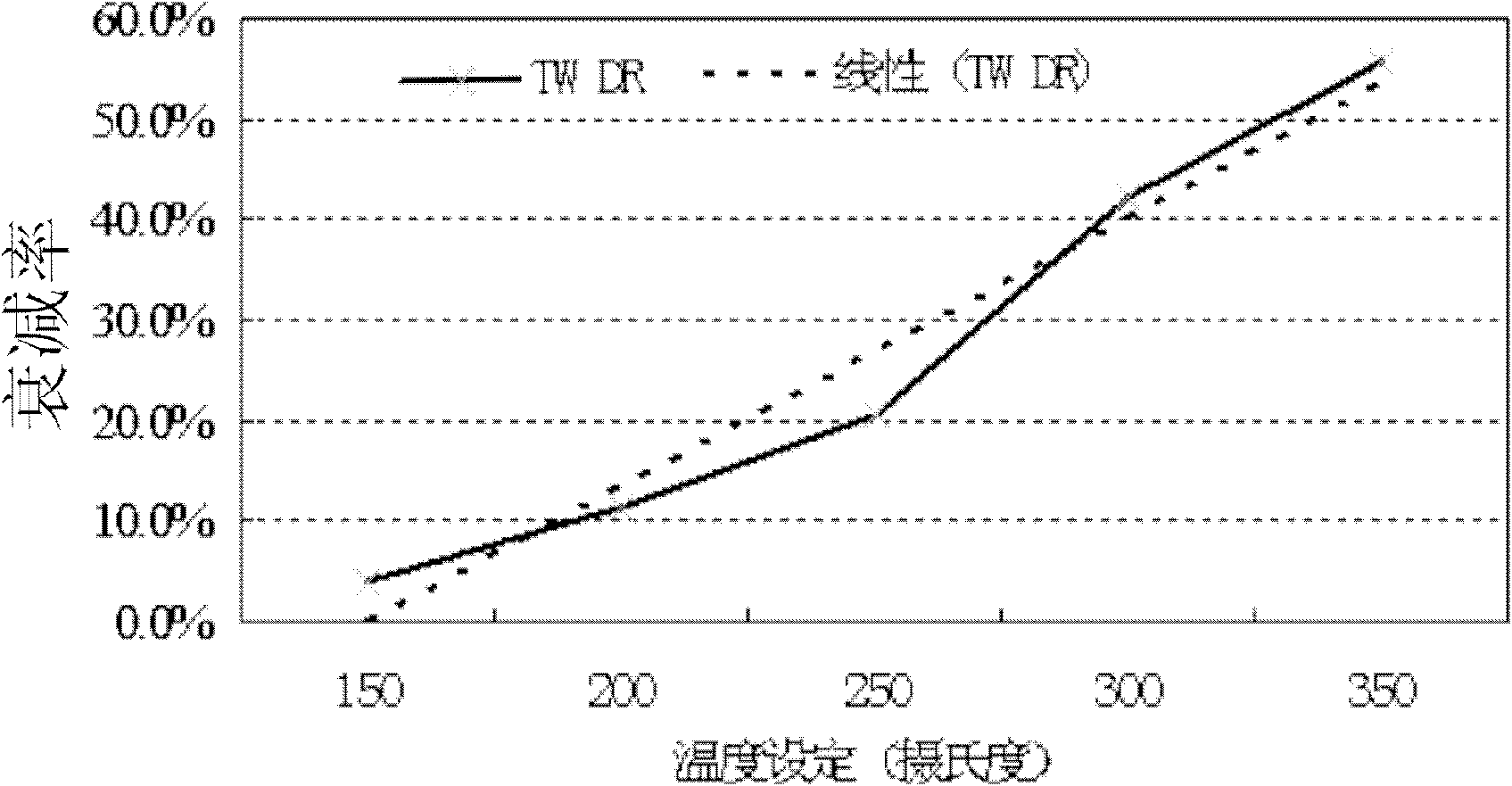

[0030] see figure 1 , a method for measuring temperature using a thermal wave instrument, the steps are as follows:

[0031] (1) Take a piece of silicon wafer, the type of wafer can be selected as P-TYPE (resistivity: 0.5-100ohm.cm).

[0032] (2) Inject B (boron element) into the ion implanter to obtain the damage degree, the implantation energy is 25-60KeV (kiloelectron volts), and the dose is 1E13-5E13 / cm 2 (E13 stands for 10 13 )between.

[0033] (3) measure the thermal wave signal value TW0 after injection with a thermal wave instrument;

[0034] (4) Pass the wafer into the machine (simulate the normal process to obtain the real value), so that the machine can work normally. When the machine is working, the temperature generated in the cavity will repair the damage of the inserted wafer. ; For processes with film deposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com