Semi-conductor manufacturing factory layout

A technology for manufacturing plants and semiconductors, which is applied in the field of configuration forms of semiconductor manufacturing plants, and can solve problems such as configuration forms that are difficult to solve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

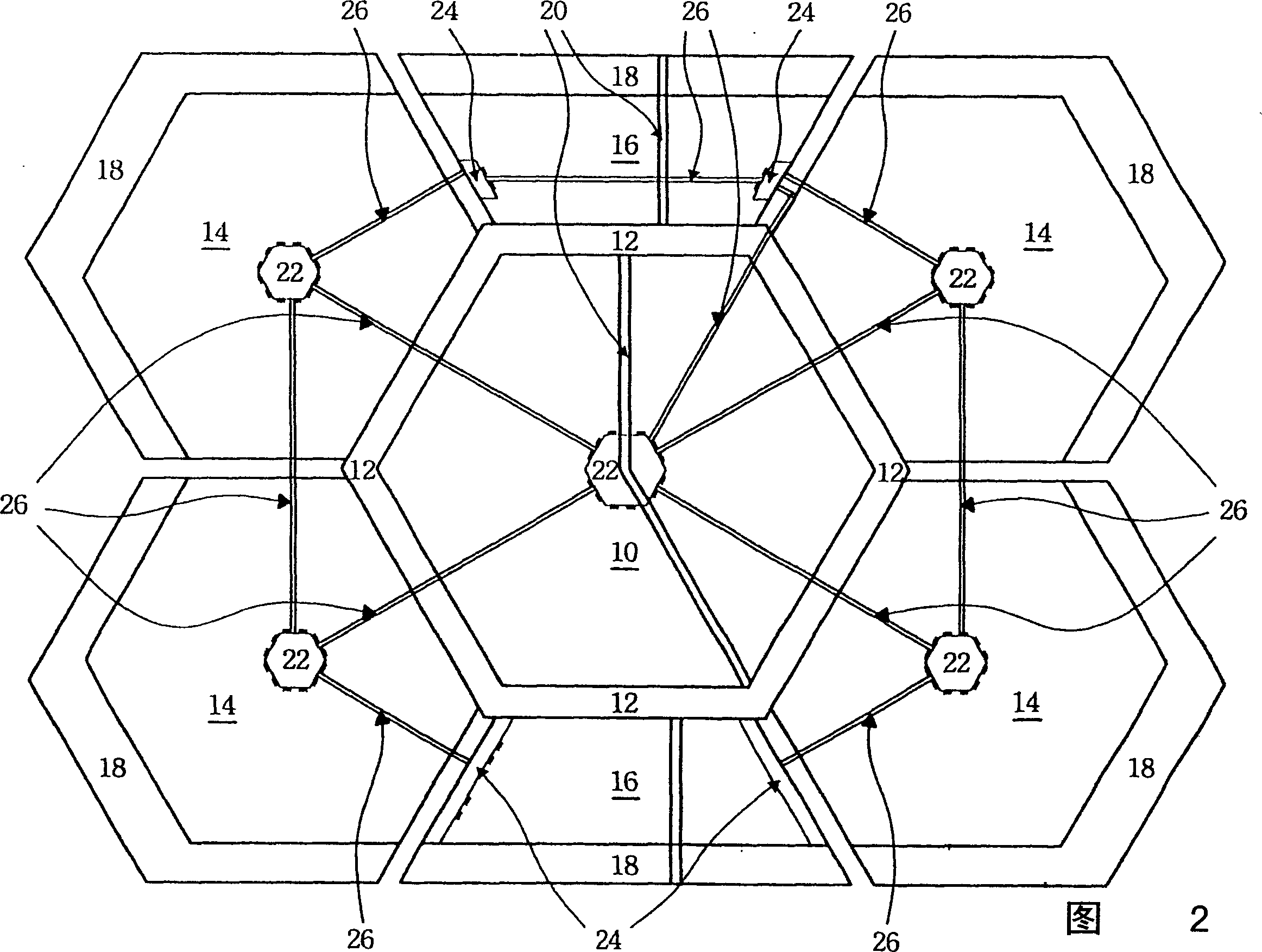

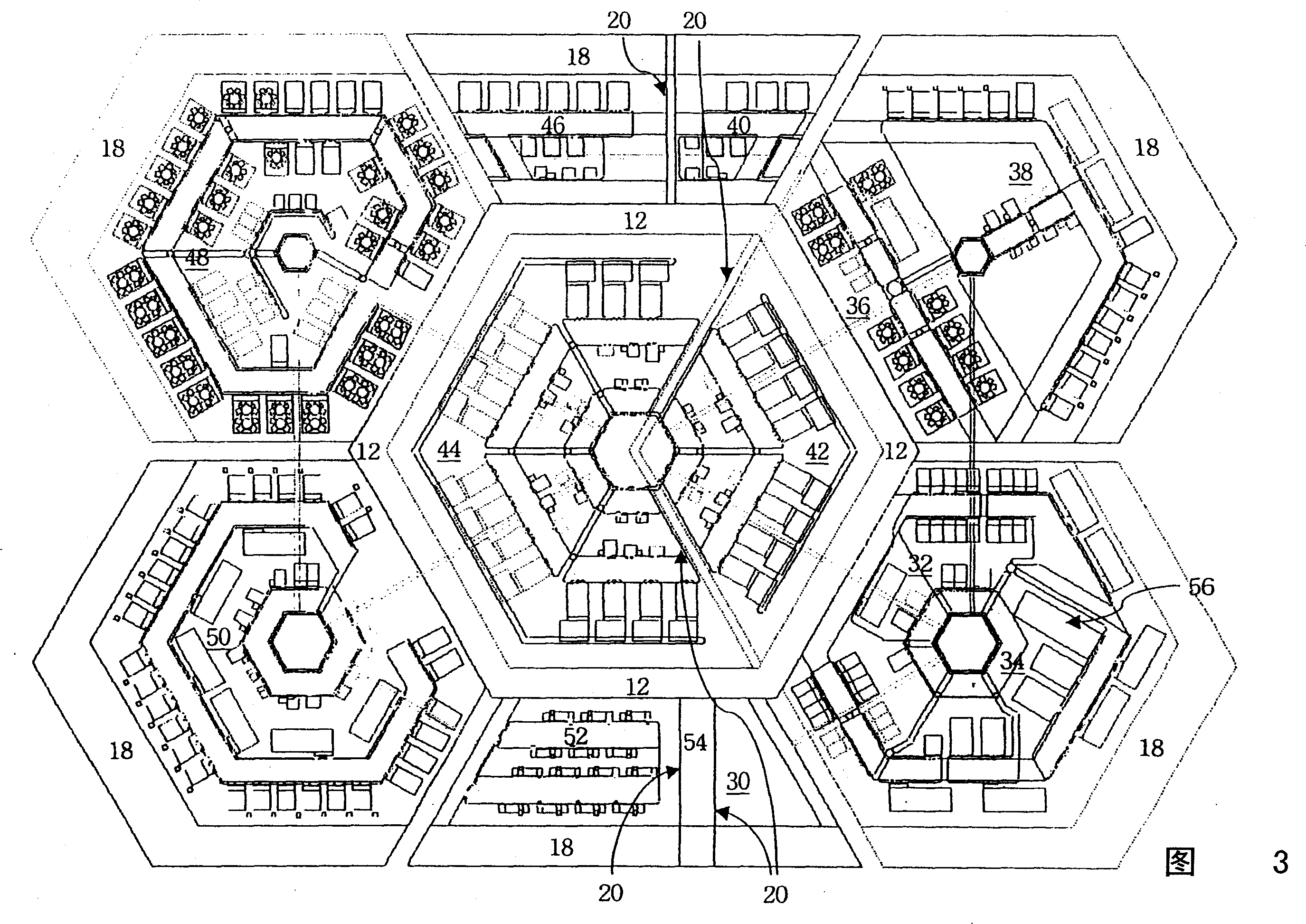

[0021] Referring to Fig. 2, the configuration form of the present invention can be divided into seven main areas, which are respectively a regular hexagonal area 10 in the center and four equiangular (120°) but not equilateral hexagonal areas around it. 14, and the upper and lower trapezoidal regions 16 (the inner angles are respectively 60°, 120°, 120°, and 60°) corresponding to adjacent hexagons. These seven main areas will provide the layout of the process areas in the semiconductor factory area, and each area can include more than one process area depending on the environmental characteristics of each process area, the relationship between logistics and the area requirements.

[0022] Continue to refer to Figure 2, the area of the central regular hexagonal area 10 needs to meet the area requirements of the process area in this area, and the area is determined by the machine equipment, maintenance space, personnel operation and material handling in the process area in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com