Regeneration system and method of tetramethyl ammonium hydroxide developing waste liquid

A technology of tetramethyl ammonium hydroxide and regeneration system, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as voltage increase and reduction of electrode service life. , to achieve the effect of reducing pressure, reducing recovery costs and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

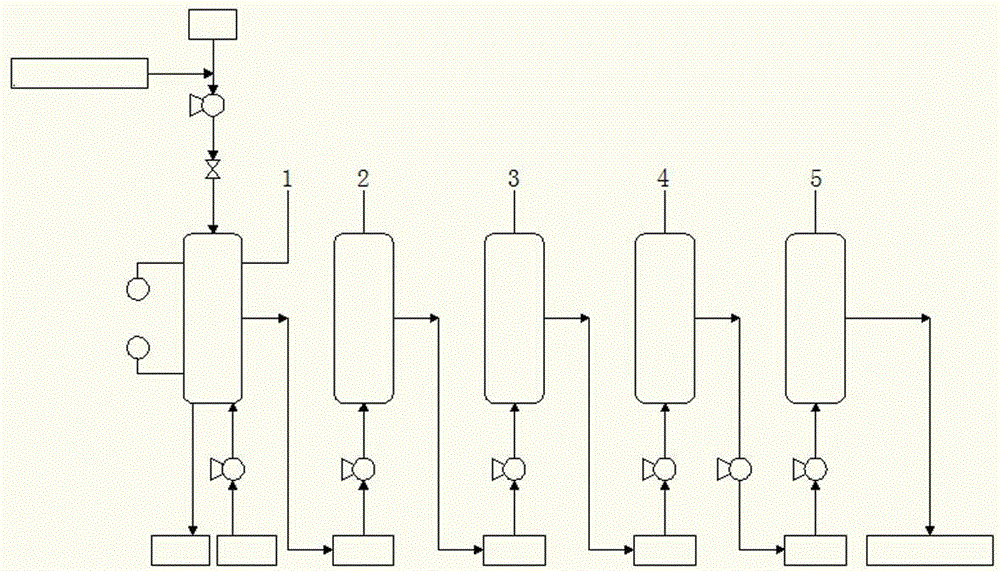

[0035] Such as figure 1 The shown use carbon dioxide gas for neutralization and recycling recovery system.

[0036] The regeneration system includes several feed pumps, neutralization separation towers, adsorption towers, cation exchange resin towers, anion exchange resin towers, and purification treatment towers, the neutralization separation tower, adsorption tower, cation exchange resin tower, anion exchange resin tower and purification Each treatment tower is provided with one set, the neutralization separation tower, adsorption tower, cation exchange resin tower, anion exchange resin tower and purification treatment tower are connected in turn by a feed pipe with a control valve. The regeneration system is used for tetramethyl hydrogen. The method of regeneration of ammonium oxide developing waste liquid is carried out as follows:

[0037] (1) Acid neutralization-separation: Carbon dioxide gas and tetramethylammonium hydroxide developing waste liquid with a flow rate of 120mL / ...

Embodiment 2

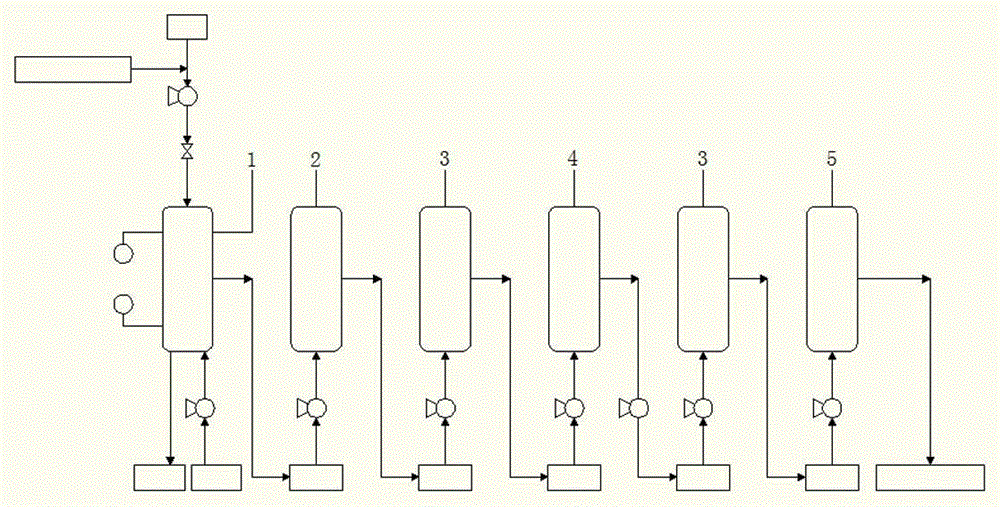

[0042] Such as figure 2 The shown use inorganic acid solution for neutralization, recycling and recycling system.

[0043] The regeneration system includes several feed pumps, neutralization separation towers, adsorption towers, cation exchange resin towers, anion exchange resin towers, and purification treatment towers, the neutralization separation tower, adsorption tower, cation exchange resin tower, anion exchange resin tower and purification Each treatment tower is provided with one set, the neutralization separation tower, adsorption tower, cation exchange resin tower, anion exchange resin tower and purification treatment tower are connected in turn through a feed pipe with a control valve. The regeneration system is used for tetramethyl hydrogen. The method of regeneration of ammonium oxide developing waste liquid is carried out as follows:

[0044] (1) Acid neutralization-separation: a sulfuric acid solution with a concentration of 1.2 mol / L is added to the neutralization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com