Method for preparing calibration standard sheet and method for calibrating with the standard sheet

A technology of calibration standards and standard slices, which is applied in the field of preparation of calibration standard slices, can solve the problems of actual precision constraints, high calibration frequency, sample damage, etc., and achieve the effect of improving measurement accuracy and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] An example of the preparation method of the calibration standard sheet of the present invention is as follows:

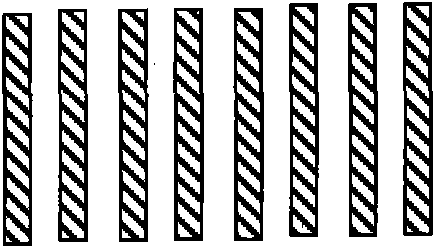

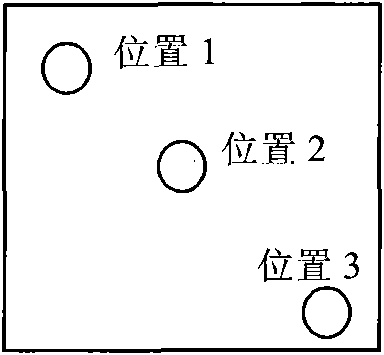

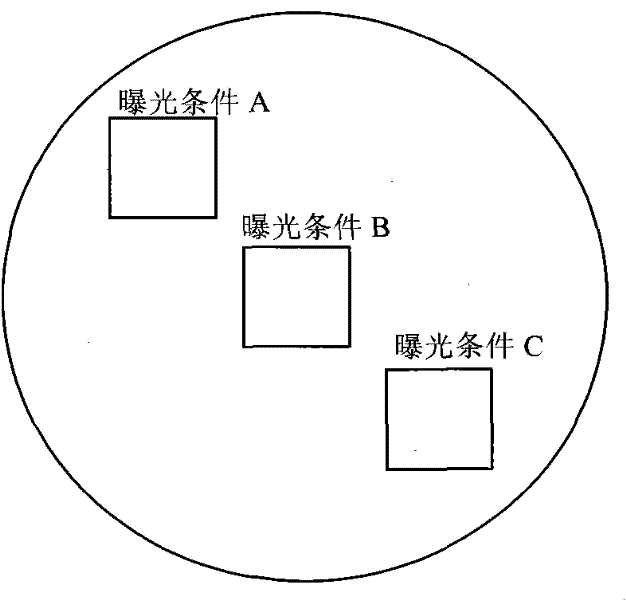

[0019] Prepare a photomask first, on the photomask as figure 2 The same test patterns are placed in the three positions shown in position 1, position 2 and position 3 respectively. The test pattern can be as figure 1 The shown 100nm linear dense pattern may also be a 100nm spatial dense pattern. After the photomask is made, the actual values of the test patterns CD at the three positions are 101nm, 100nm, and 99nm. Mask manufacturers can accurately measure the values of these three points, and the difference is within 2nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com