Mushroom picking robot applicable to multilayer mushroom bed operation

A picking robot and operation technology, applied in mushroom cultivation, application, agriculture and other directions, can solve the problems of mushroom damage, low picking efficiency and high work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

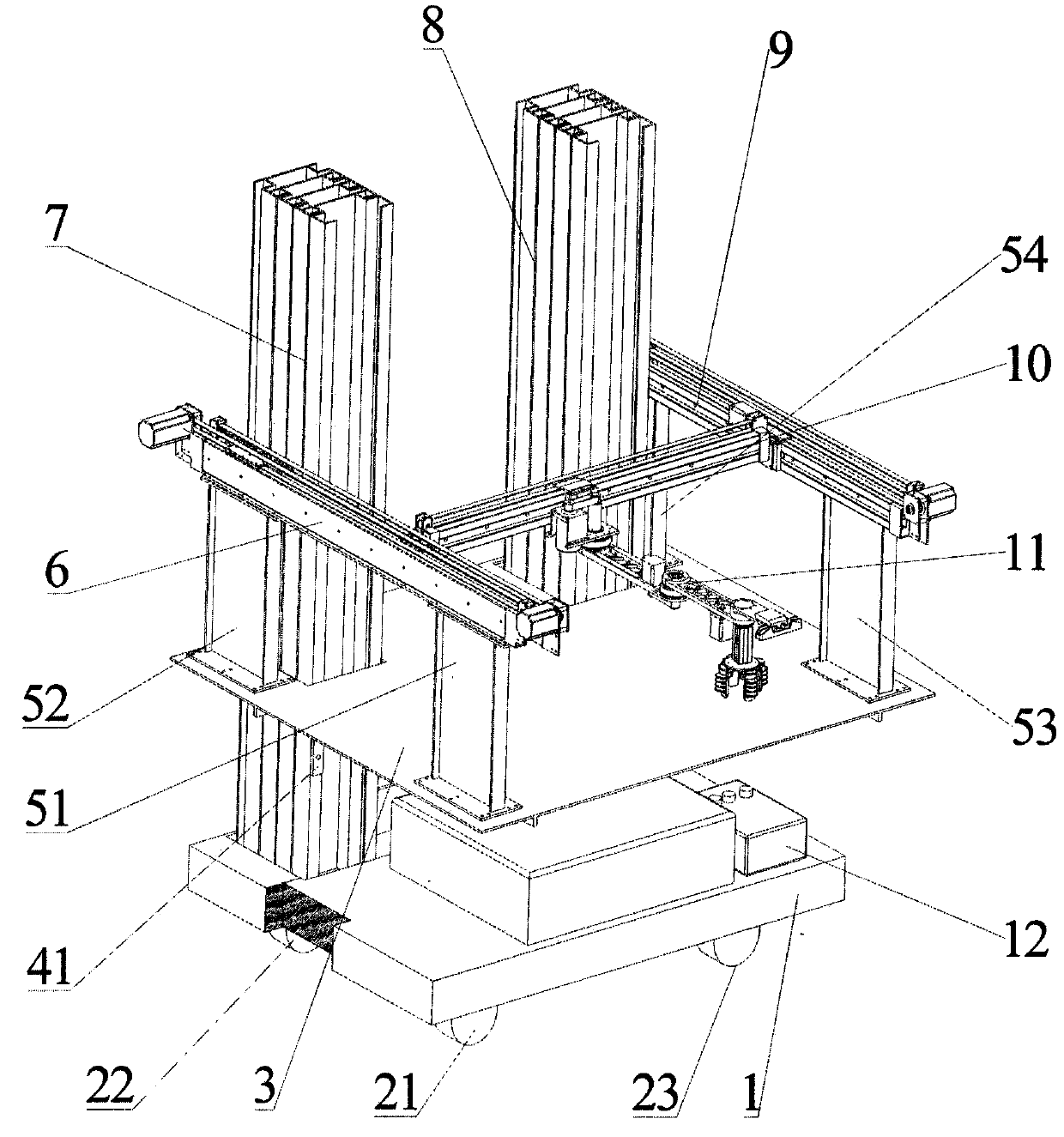

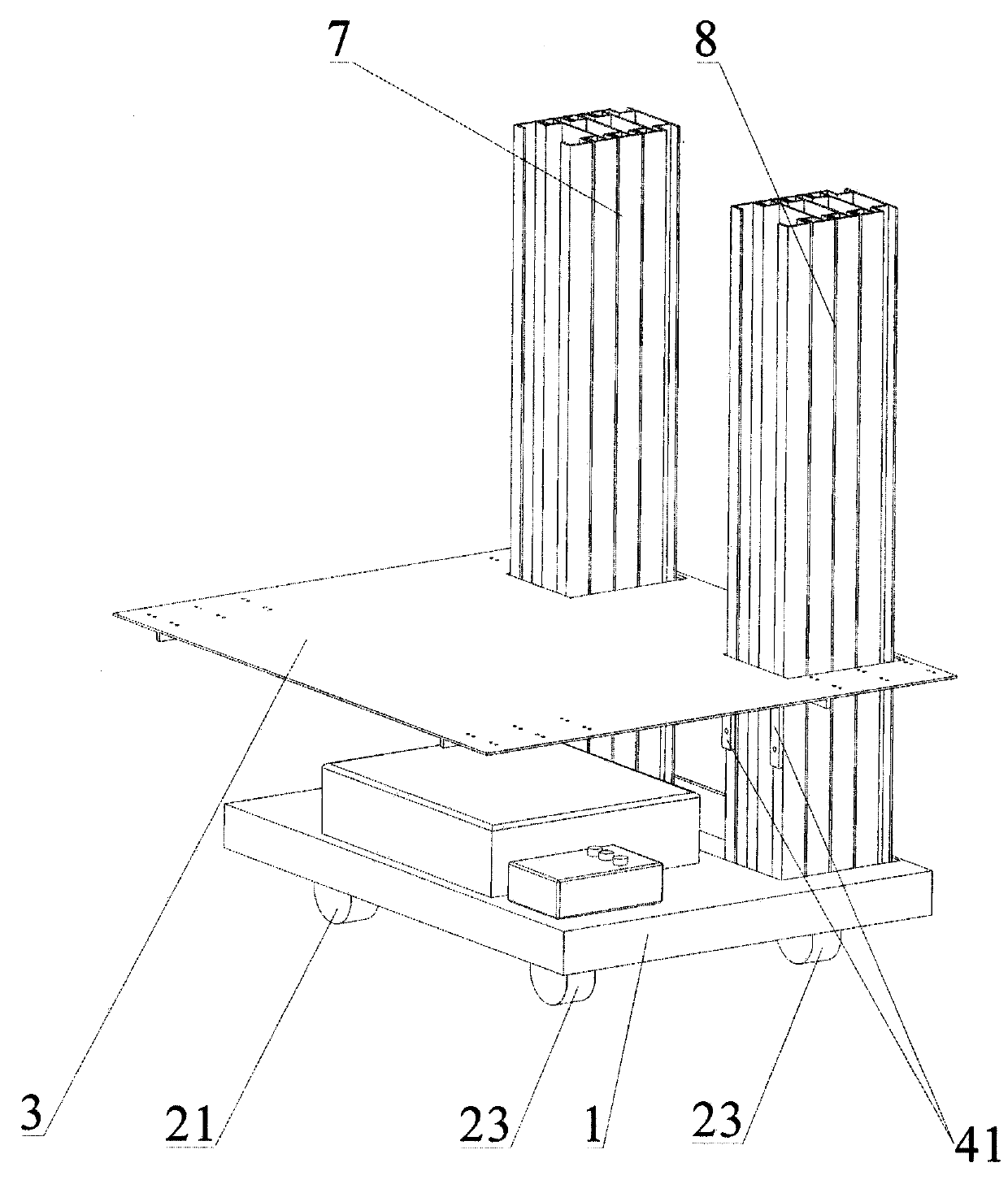

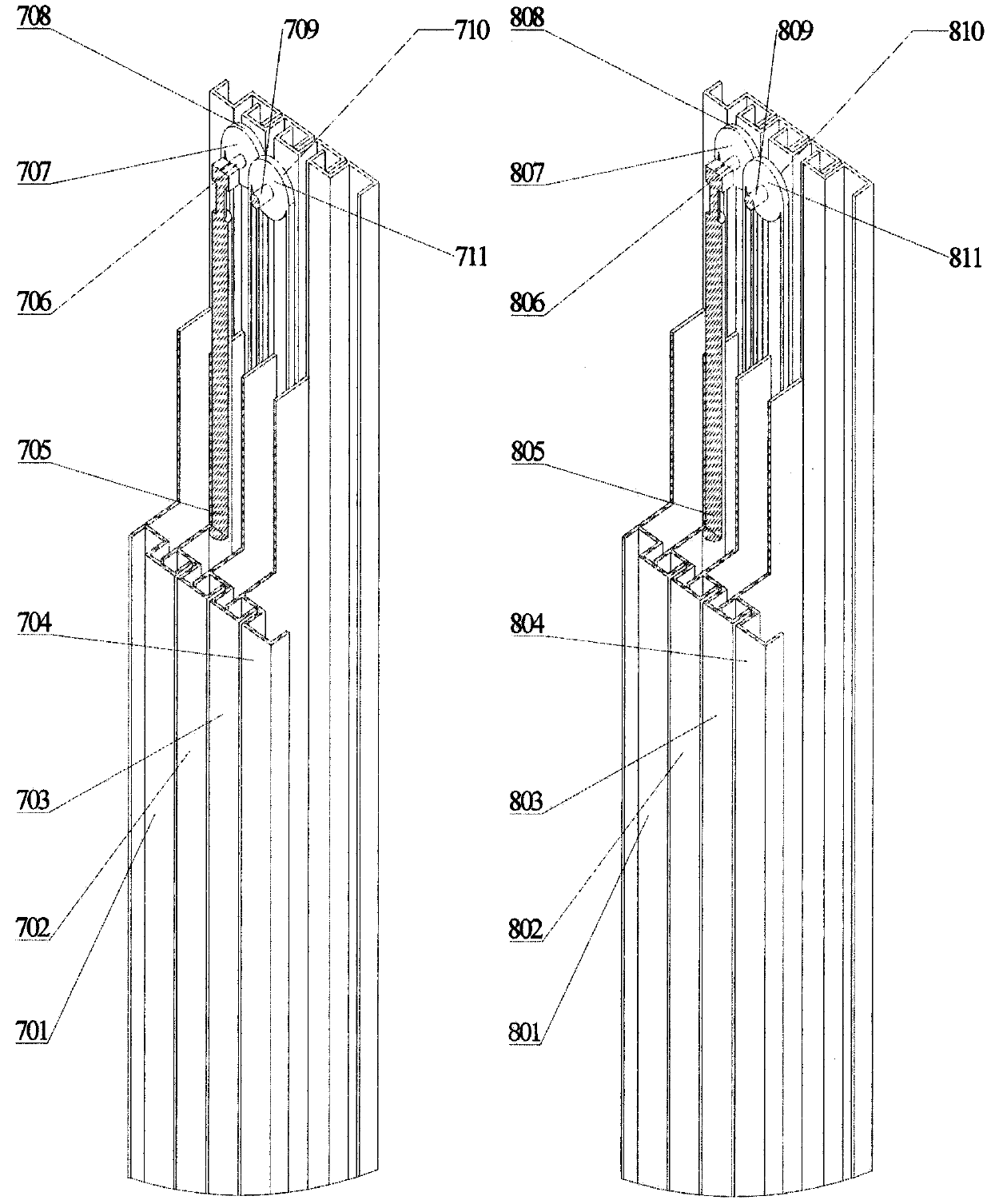

[0021]This embodiment relates to a mushroom picking robot suitable for multi-layer mushroom bed operations, including: a mobile lifting platform, and the mobile lifting platform is characterized in that it includes: a mobile platform chassis (1), a left front universal support wheel (21 ), left rear universal support wheel (22), right front universal support wheel (23), right rear universal support wheel (24), lifting platform lifting plate (3), lifting platform left fixed frame (41), lifting platform Right fixed frame (42), left mast telescopic mechanism (7), right mast telescopic mechanism (8), wherein left mast telescopic mechanism (7) comprises left first stage mast (701), left second stage mast Column (702), left third-level mast column (703), left fourth-level mast column (704), left lifting hydraulic rod (705), left first-level and second-level lifting support shaft (706), left first-level and second-level lifting support Bearing (707), left first and second level lifti...

Embodiment 2

[0023]This embodiment relates to a mushroom picking robot suitable for multi-layer mushroom bed operations, including: the telescopic guide rail platform is characterized in that it includes: a fixed support (51) for the stretching platform of the left front guide rail, a fixed support for the stretching platform of the left rear guide rail Seat (52), right front guide rail extension platform fixed support (53), right rear guide rail extension platform fixed support (54), left push guide rail mechanism (6), right push guide rail mechanism (9), X direction guide rail mechanism (10 ); the left propelling rail mechanism (6) includes: left P motor (601), left P motor fixed plate (602), left P motor fixed support plate (603), left P motor intermediate support tube (604), Left P synchronous wheel support bearing (605), left P synchronous wheel (606), left P guide rail rear fixed sleeve (607), left Y guide rail follow-up synchronous wheel module (608), left Y guide rail rear fixed sle...

Embodiment 3

[0025] This embodiment relates to a mushroom picking robot suitable for multi-layer mushroom bed operations. It is characterized in that it includes: the picking robot arm. It is characterized in that it includes: a boom motor (1101), a boom motor fixed support ( 1102), big arm joint synchronous belt (1103), big arm motor synchronous wheel (1104), big arm joint fixed block (1105), big arm joint synchronous wheel shaft (1106), big arm joint bearing (1107), wire slot cover Plate (1108), arm arm (1109), forearm motor (1110), forearm motor synchronous wheel (1111), forearm joint synchronous belt (1112), forearm joint bearing (1113), forearm joint synchronous wheel shaft (1114), arm forearm (1115), end rotation motor (1116), end rotation motor holder (1117), miniature active synchronous wheel (1118), miniature synchronous belt (1119), miniature driven synchronous wheel (1120) , camera fixing support (1121), camera (1122), terminal lifting cylinder (1123), terminal picking claw (112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com