Patents

Literature

46 results about "Manufacturing planning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

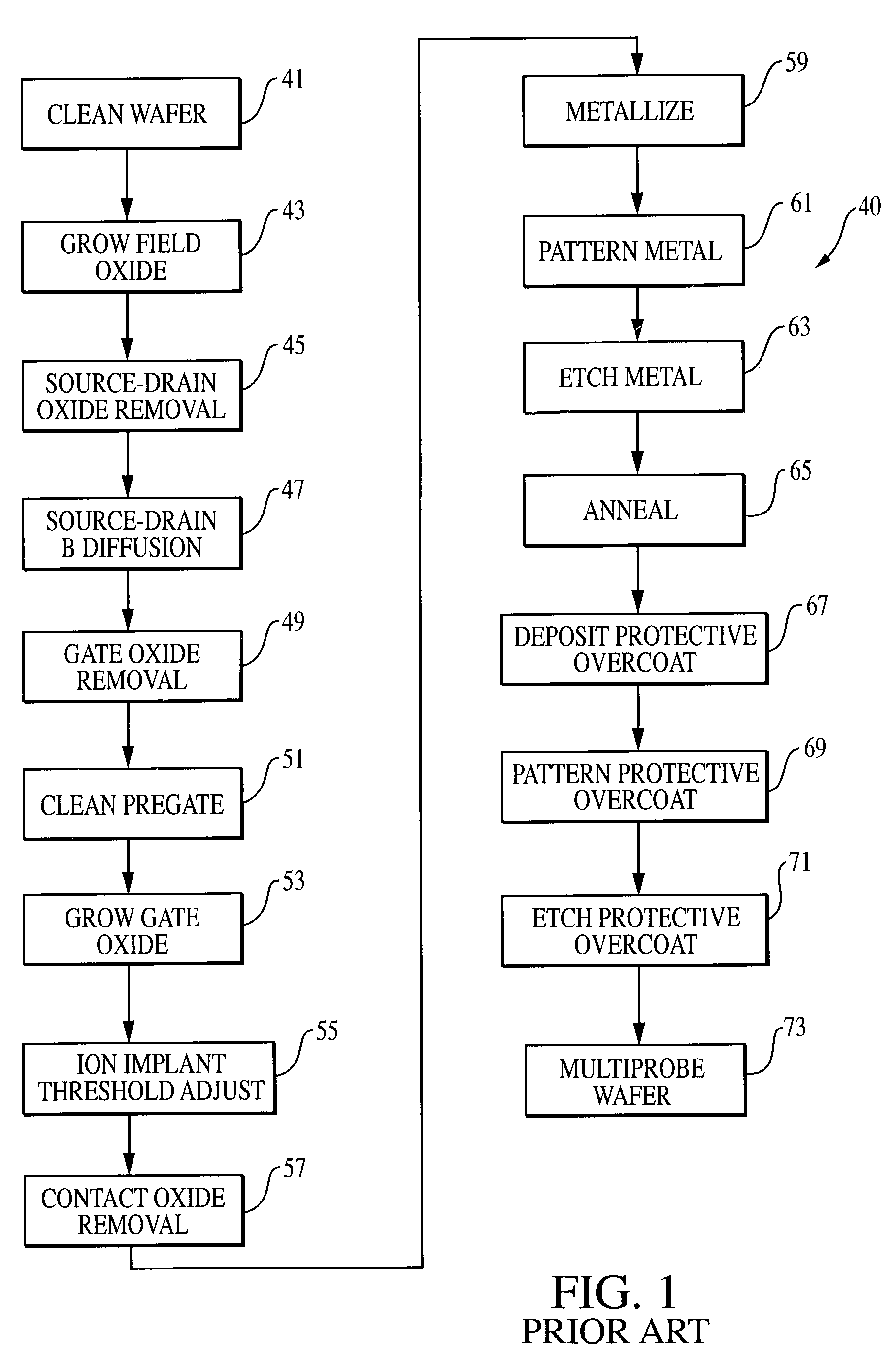

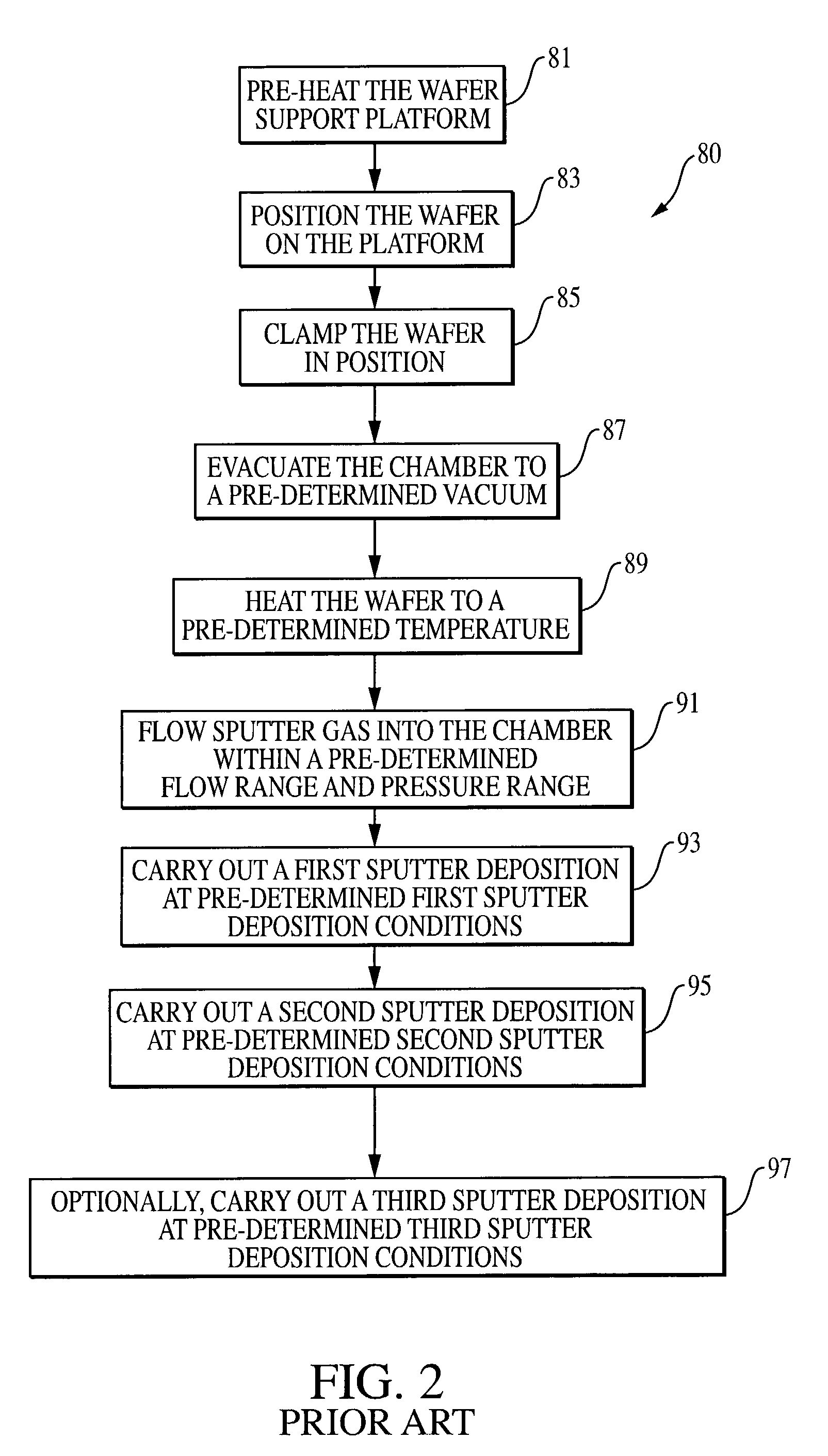

Computer integrated manufacturing techniques

InactiveUS7069101B1Process Control OptimizationQuality improvementData processing applicationsSemiconductor/solid-state device manufacturingConsequence analysisManufacturing technology

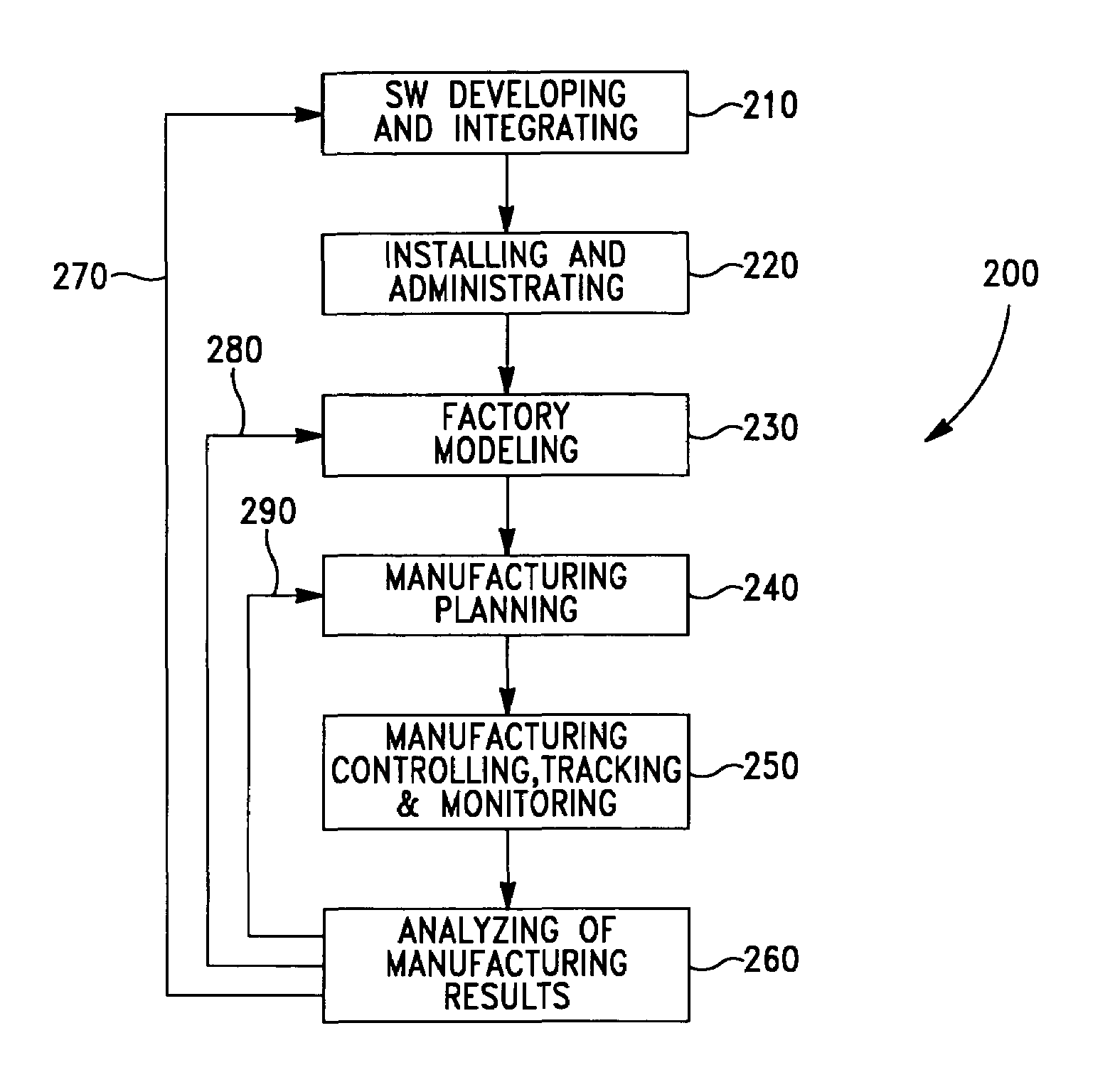

The present invention provides a novel distributed factory system framework including a novel factory automation lifecycle (200) having lifecycle activities for SW developing and integrating (210), installing and administrating (220), factory modeling (230), manufacturing planning (240), manufacturing controlling, monitoring and tracking (250) and analyzing of manufacturing results (260). The factory lifecycle comprises framework components. The distributed factory system framework also includes application components and software building blocks. The framework components are adapted for managing the application components, while the application components are utilized to provide instructions for managing a process such as a wafer fab. The building blocks are adapted for forming or modifying framework and application components. The distributed factory system framework provides computer implemented methods for integrating processing systems and facilitates process and equipment changes.

Owner:APPLIED MATERIALS INC

Computer integrated manufacturing techniques

InactiveUS7174230B2Data processing applicationsSemiconductor/solid-state device manufacturingConsequence analysisManufacturing technology

The present invention provides a novel distributed factory system framework including a novel factory automation lifecycle (200) having lifecycle activities for SW developing and integrating (210), installing and administrating (220), factory modeling (230), manufacturing planning (240), manufacturing controlling, monitoring and tracking (250) and analyzing of manufacturing results (260). The factory lifecycle comprises framework components. The distributed factory system framework also includes application components and building blocks. The framework components are adapted to for managing the application components, while the application components are utilized to provide instructions for managing a process such as a wafer fab. The building blocks are adapted for forming or modifying framework and application components. The distributed factory system framework provides computer implemented methods for integrating processing systems and facilitates process and equipment changes.

Owner:APPLIED MATERIALS INC

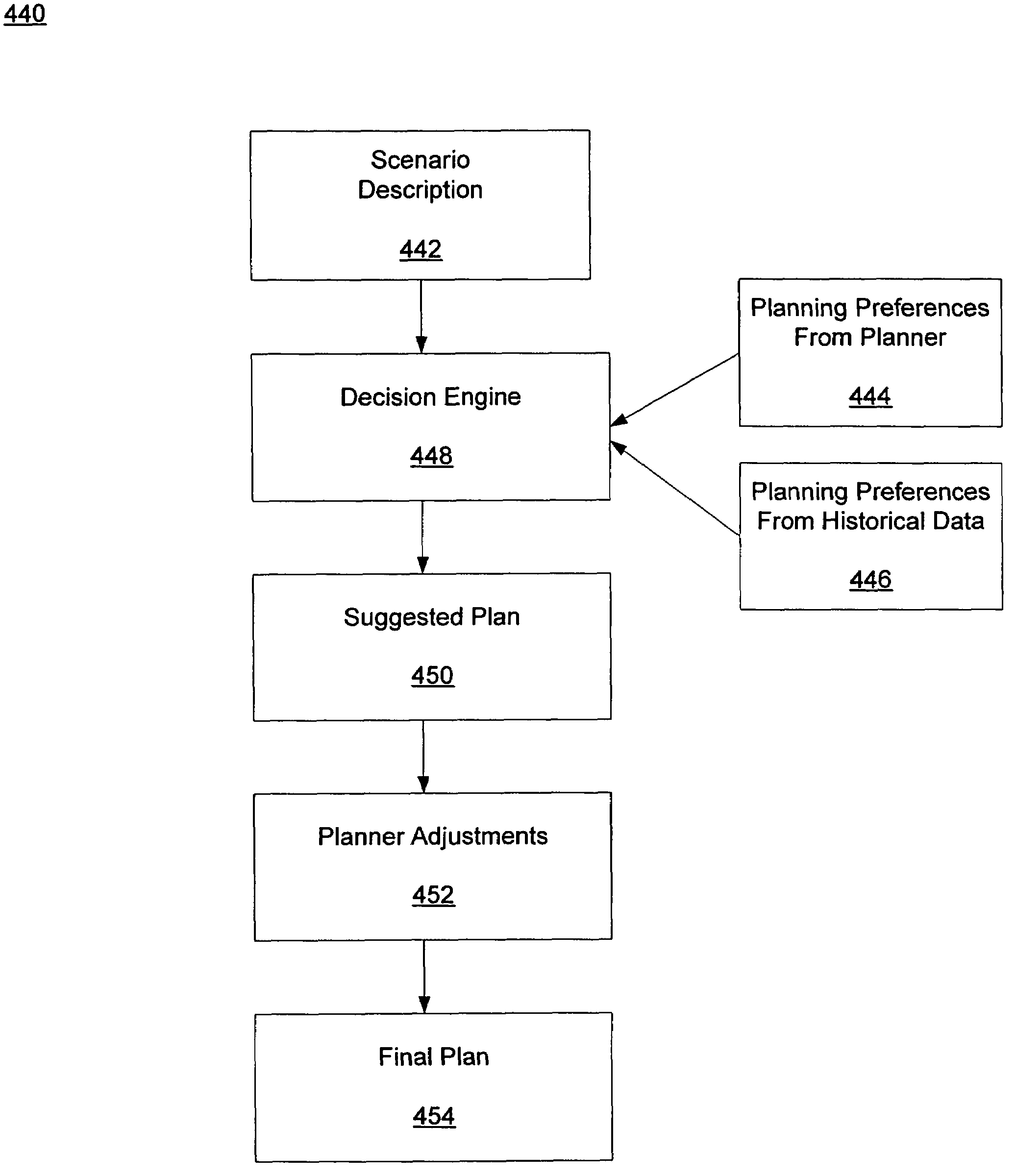

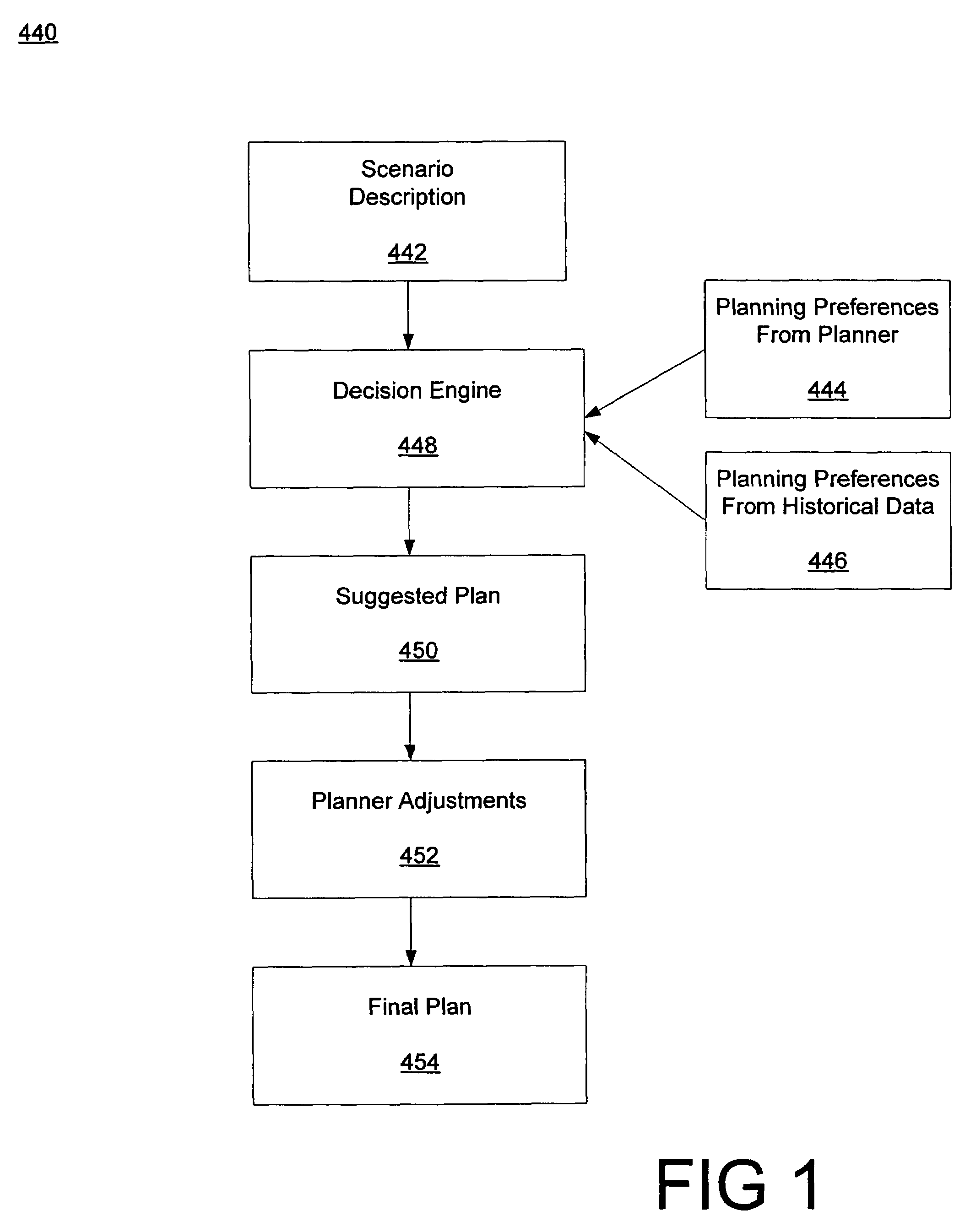

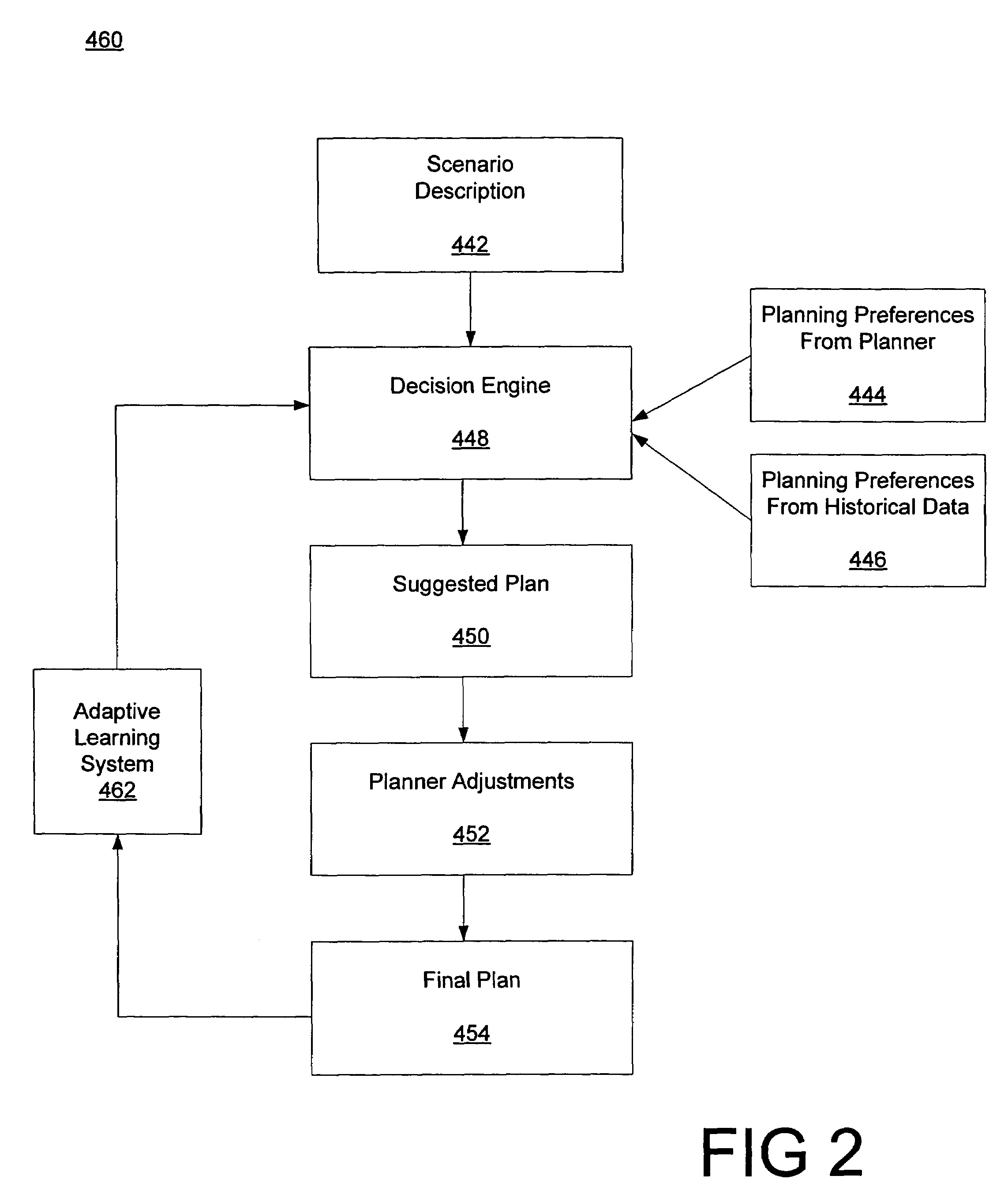

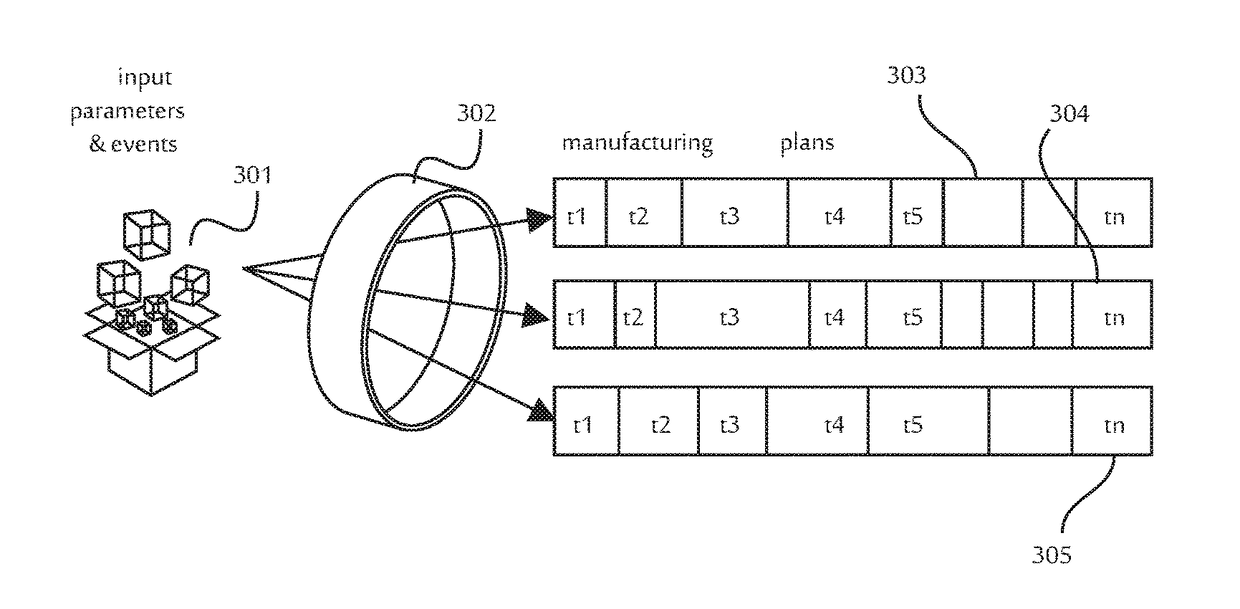

Method and apparatus for planning a manufacturing schedule using an adaptive learning process

An apparatus and method for a production planning system using a process of adaptive learning is disclosed. A production planning system receives production objects wherein each production object has at least one attribute. In one embodiment, the production objects include information relating to product to be manufactured. After receipt of production objects, multiple preference scores according to the attributes of the production objects are calculated. In one embodiment, each preference score represents desirability of transition from manufacturing a first object to a second object. The system subsequently identifies a suggested production plan which includes a sequence order of two or more objects in response to the preference scores. In one embodiment, the planning preferences are updated or modified by an adaptive learning system in response to adjustments of the suggested production plant by a planner.

Owner:E2E PROCESSING INC +1

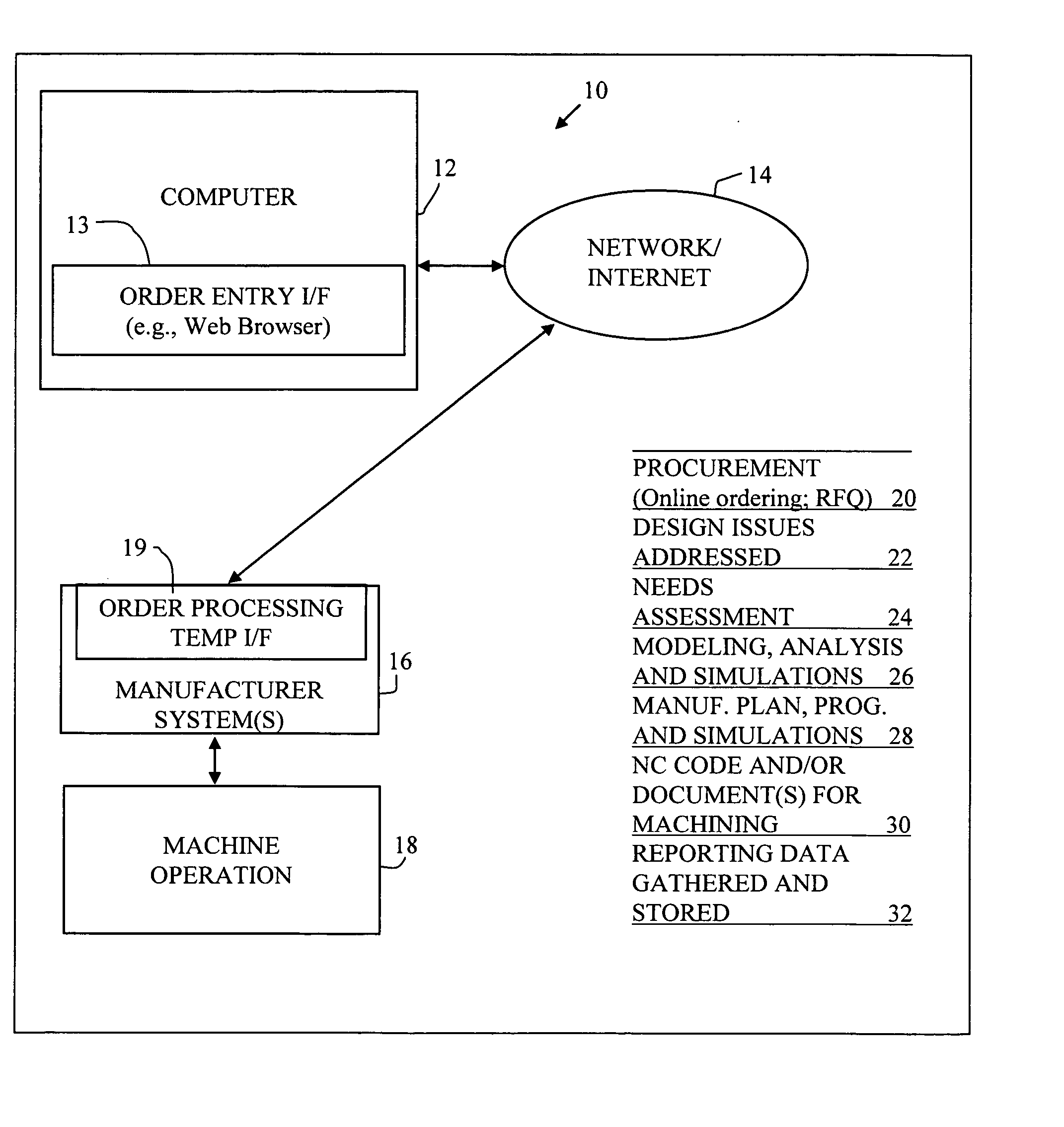

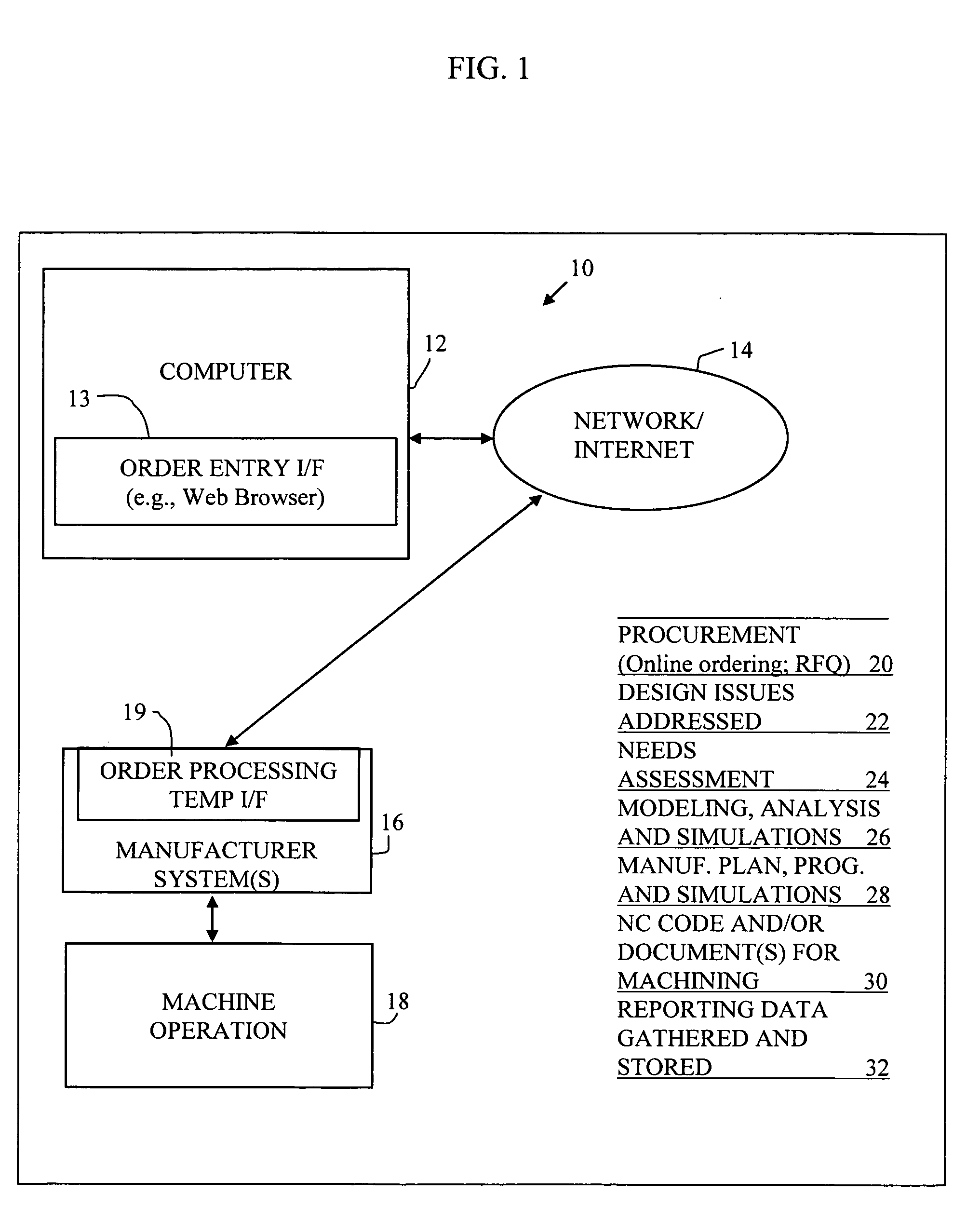

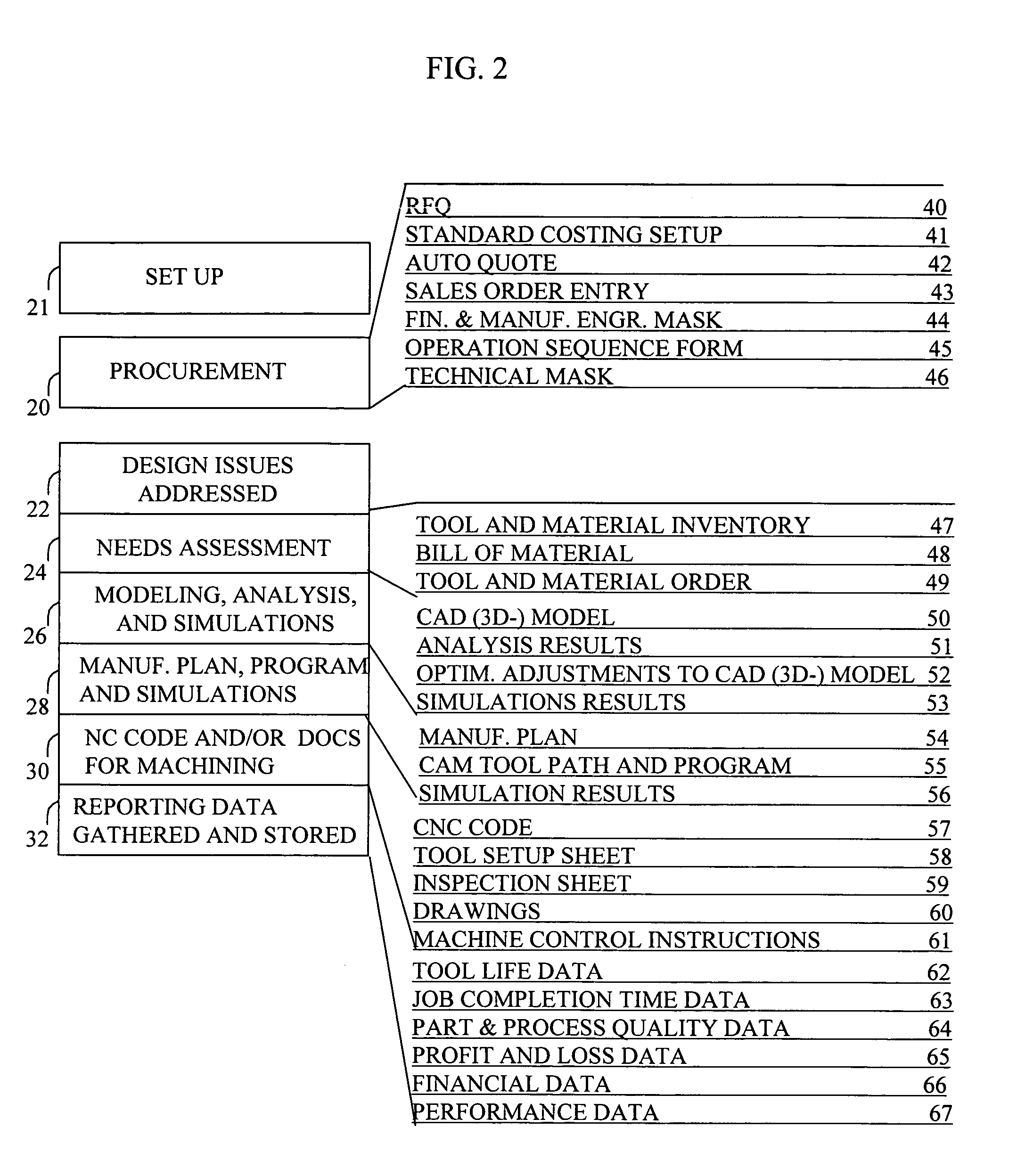

Data entry and system for automated order, design, and manufacture of ordered parts

InactiveUS20060129461A1Increased riskImprove product qualityProgramme controlCommerceManufacturing planningOrder form

A part data entry system is provided. In that system, an order processing template is provided to facilitate sales and order processing, tool planning, CA (computer aided) (e.g., CAD / CAM) parametric modeling, computer simulation, and the generation of a factory machine program. The order processing template comprises financial and manufacturing engineering planning fields and technical fields. A part information population mechanism is provided to populate the order processing template with the part information. An order template population mechanism is provided to populate other ones of the financial and manufacturing planning fields and the technical fields that are not populated by the part information population mechanism. An order processing template interface, or a set of such interfaces, is provided to provide, for a given ordered part, from the order processing template, CA-specific information to a CA computer system before the CA computer system performs CAD modeling on the part. The order processing template interface further provides, for the given ordered part, from the order processing template, ERP-specific information to an ERP computer system before the ERP computer system performs scheduling of machines and resources, material reservation, or RFQ calculations.

Owner:PANKL GEROLD +1

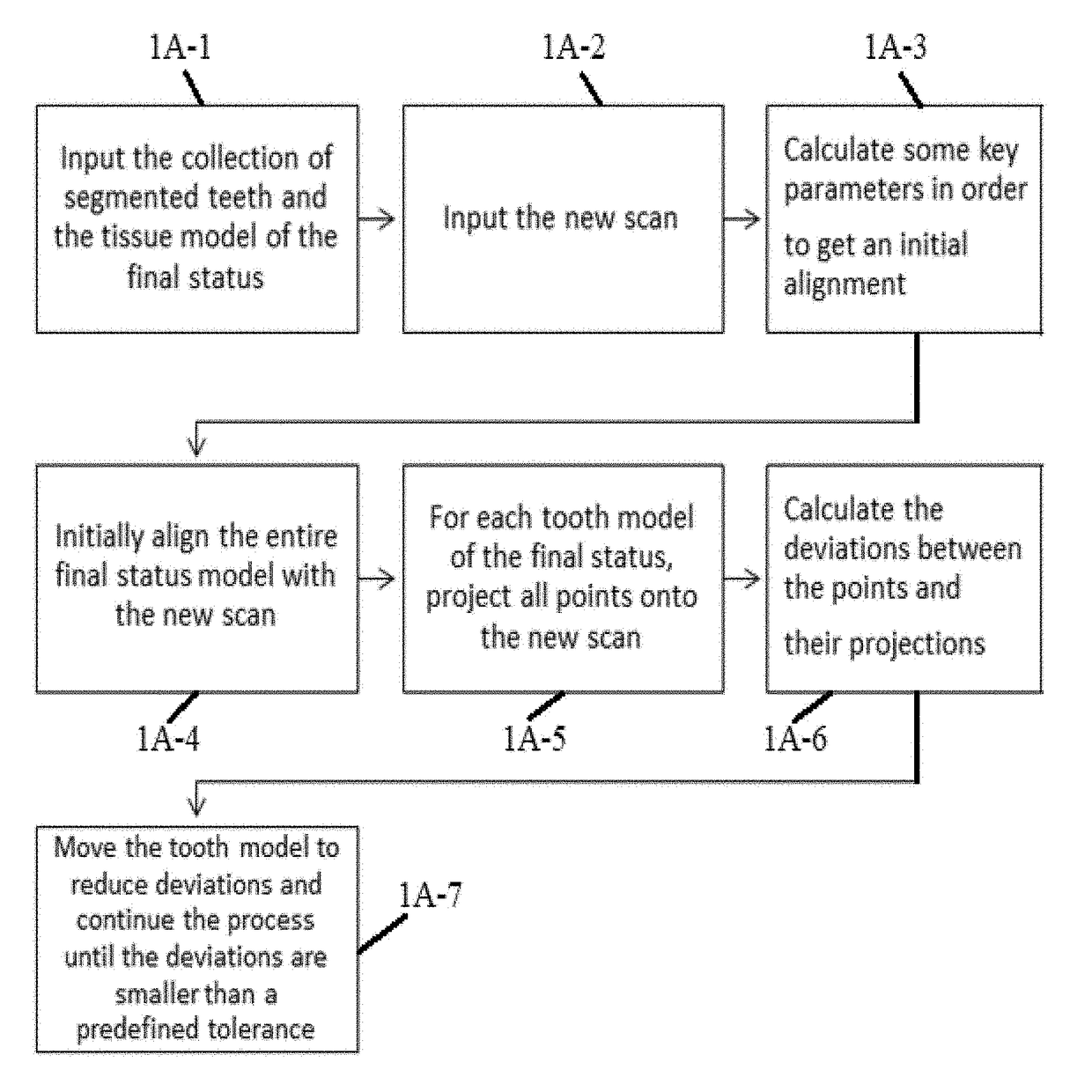

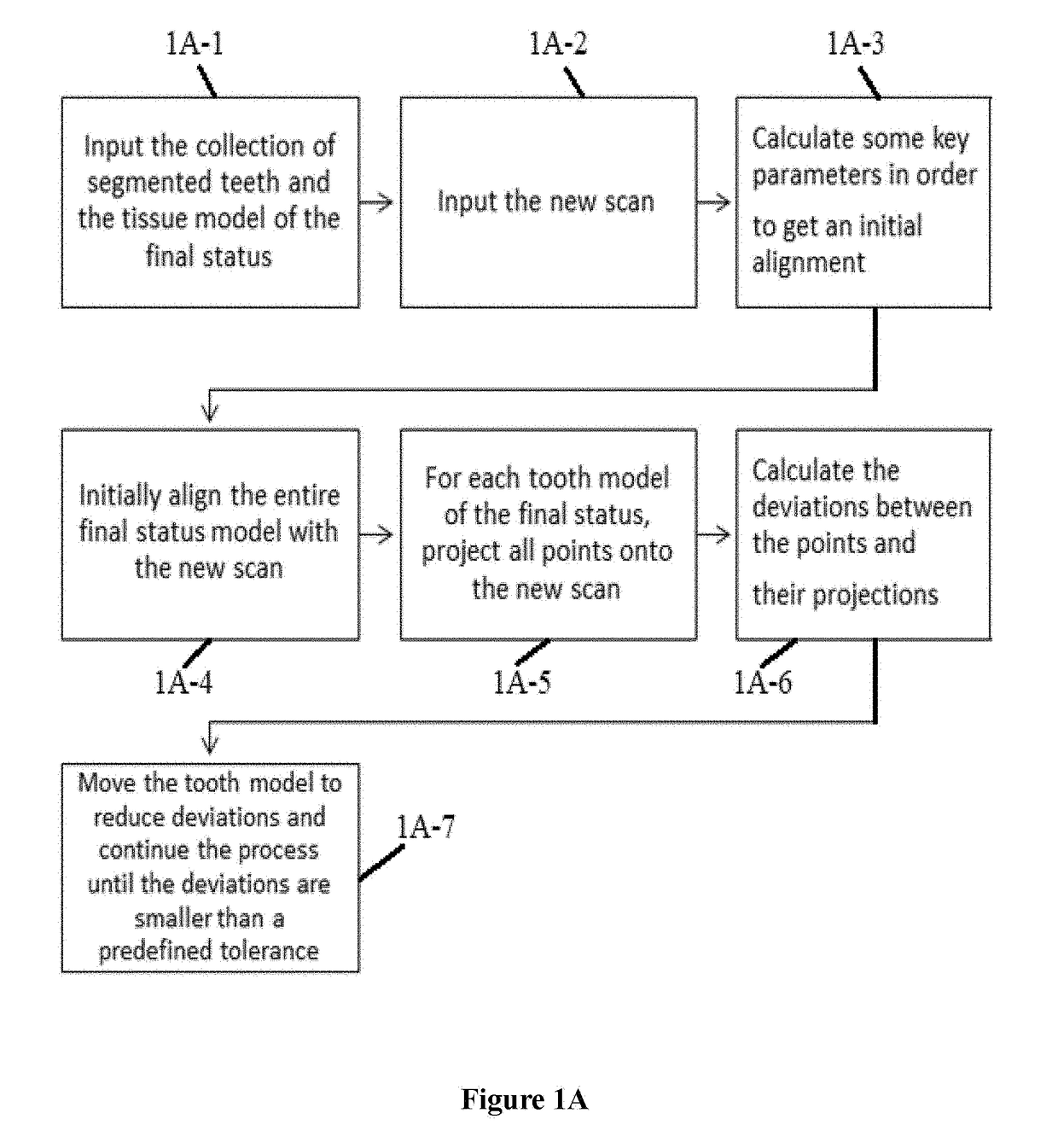

Orthodontic process with dynamic planning and incremental implementation

The present invention provides an orthodontic process phased into two or more sub-processes for repositioning a patient's teeth. In each sub-process, a complete treatment plan is established, but not all (i.e. only some) appliances in the plan are fabricated to move the teeth, out of the expectation that teeth movement may not completely follow the full course as planned. The entire orthodontic process is thus featured with dynamic planning and incremental implementation of the plans, to address ever-changing treatment profile.

Owner:GUIDEMIA TECH INC

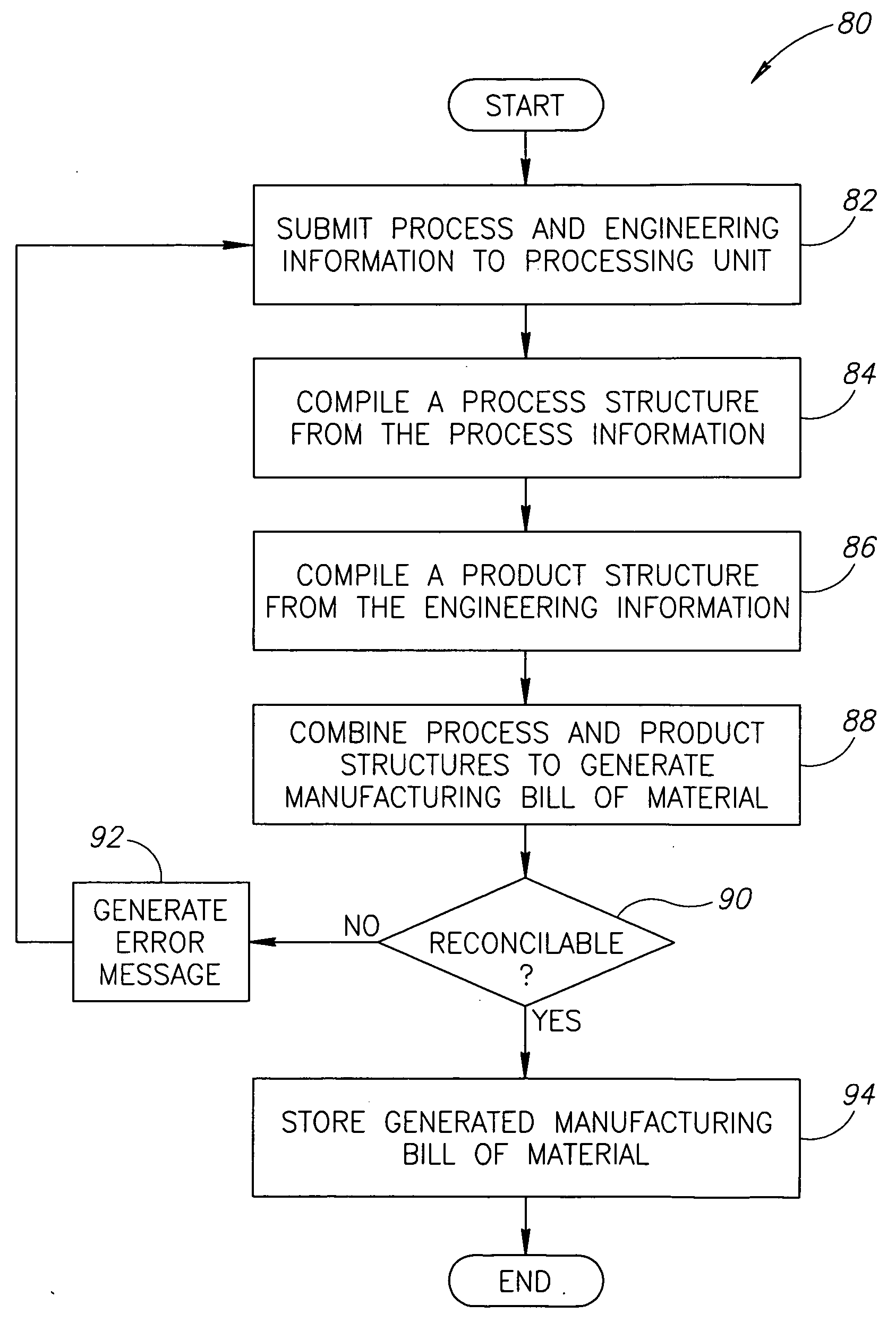

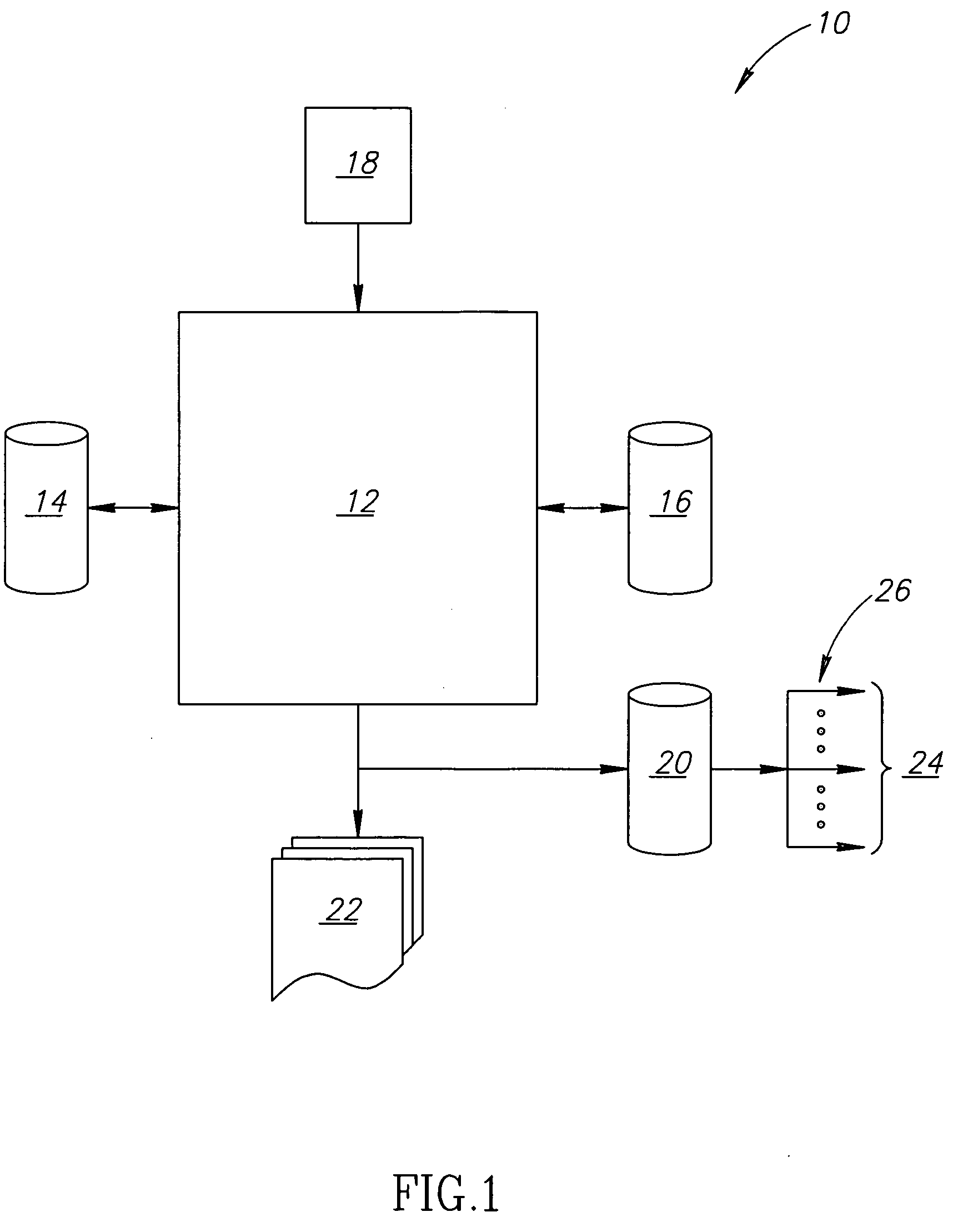

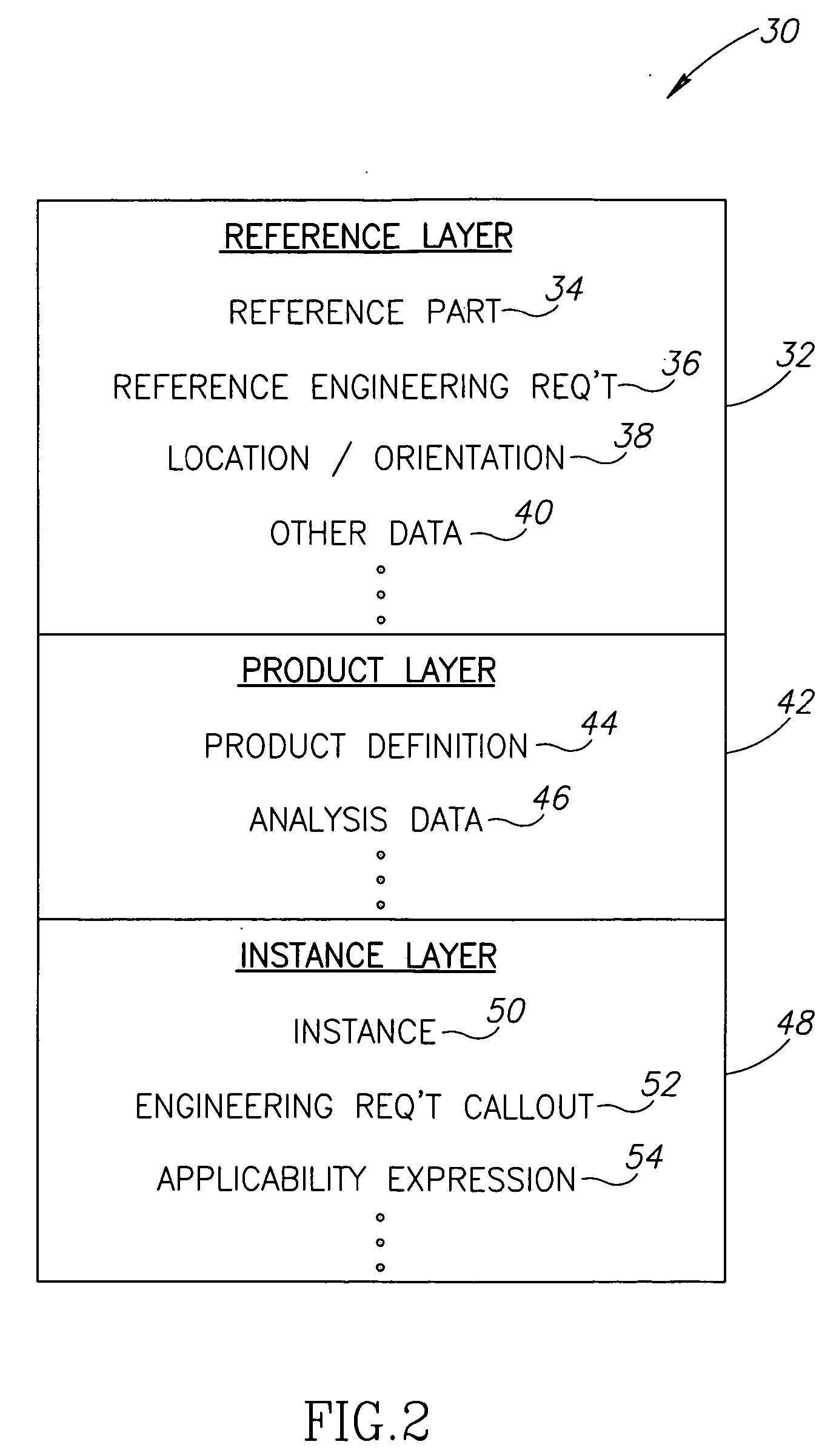

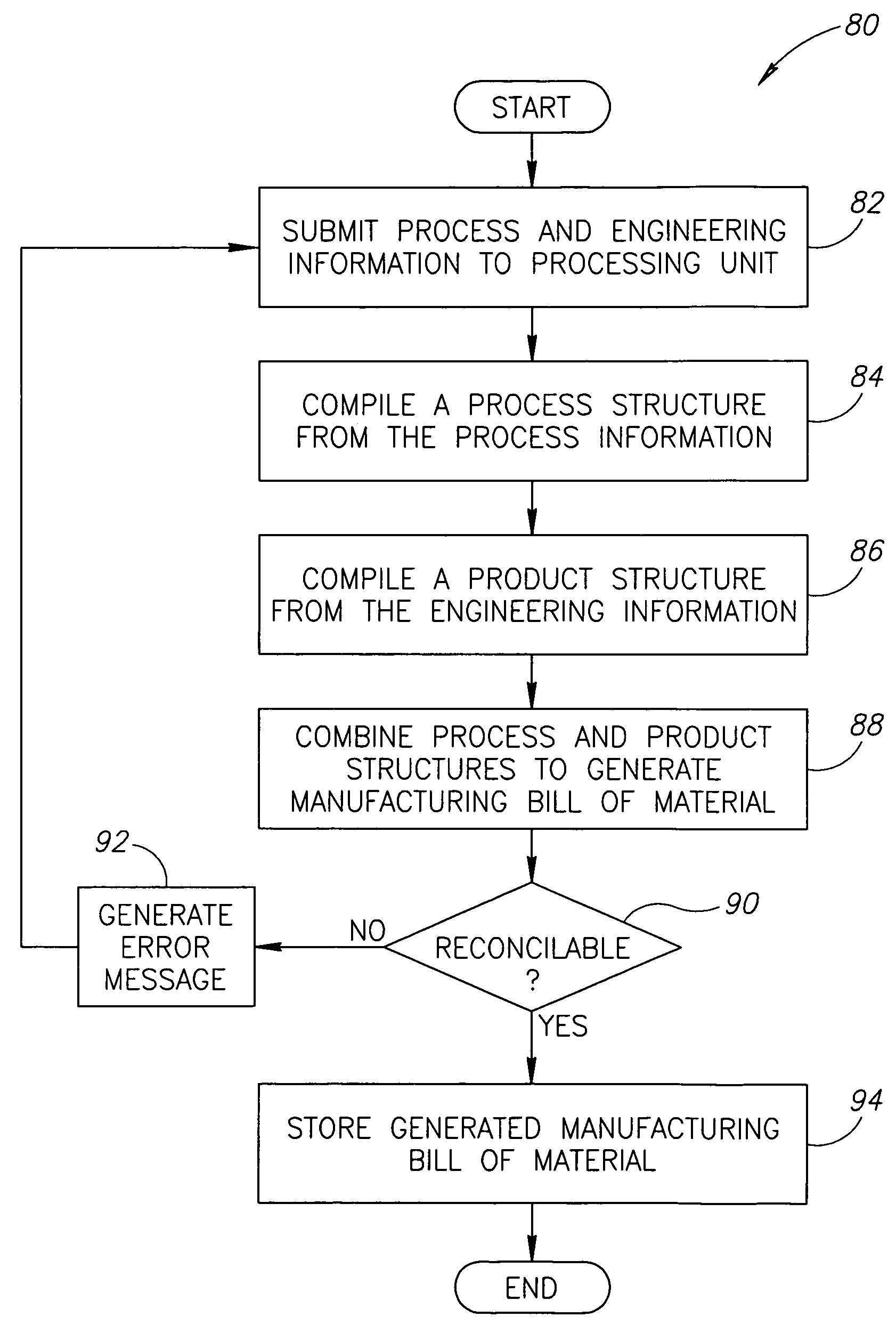

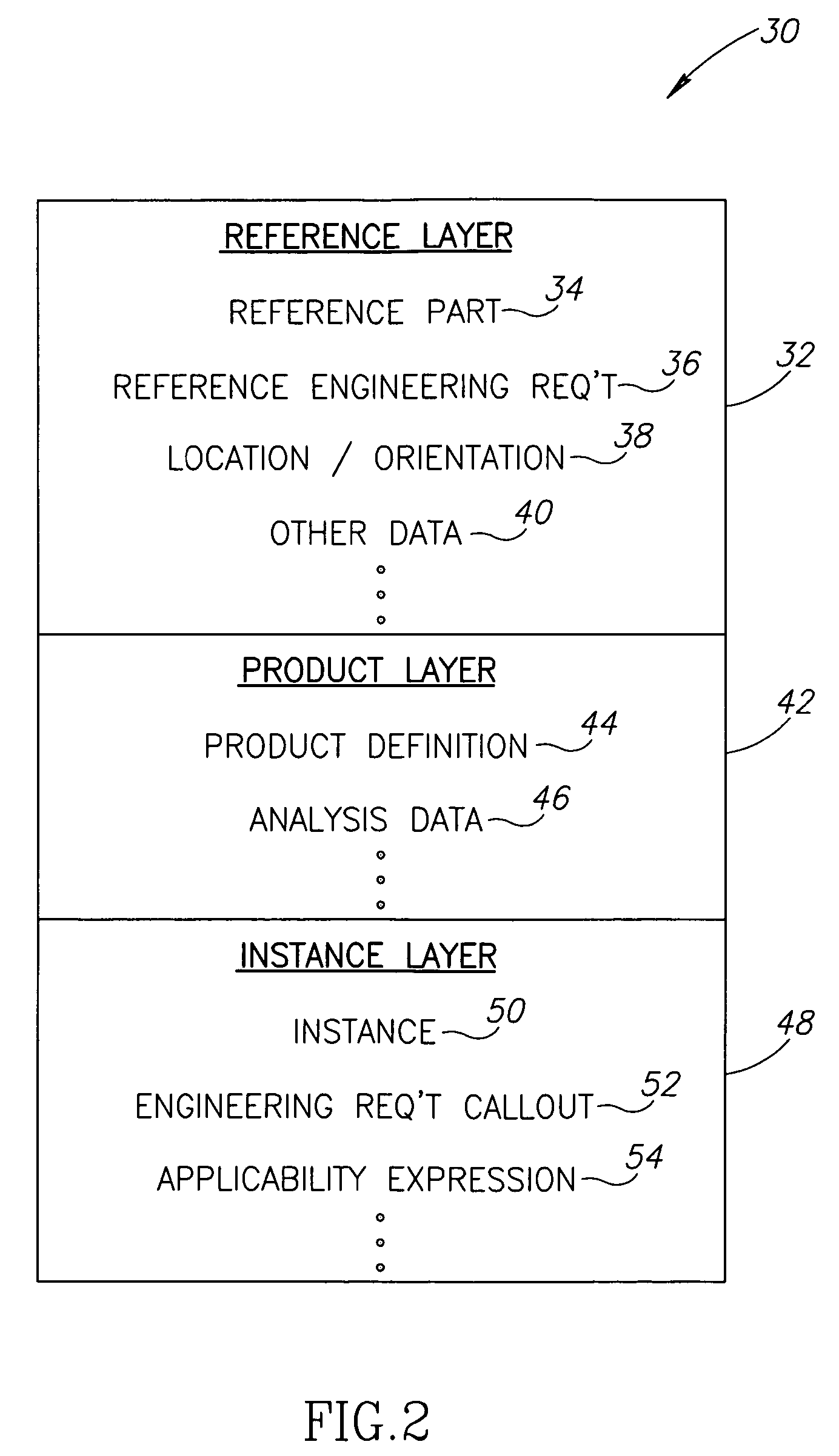

Systems and methods for process-driven bill of material

ActiveUS20060129262A1ResourcesSpecial data processing applicationsBill of materialsManufacturing planning

The present invention is directed to systems and methods for compiling production and planning information. In one embodiment, a system for planning the production of a product includes at least one database configured to store engineering information related to the product, and further configured to store process information related to the product, and a processor coupled to the at least one database to combine selected information from the at least one database to generate a manufacturing planning document that defines the product. In another embodiment, a method of generating a manufacturing bill of material for a selected product includes compiling a process data structure from the process information, compiling a product data structure from the engineering information, and generating a manufacturing bill of material by combining the process data structure and the product data structure.

Owner:THE BOEING CO

Method for process-driven bill of material

ActiveUS7321804B2ResourcesSpecial data processing applicationsBill of materialsManufacturing planning

The present invention is directed to systems and methods for compiling production and planning information. In one embodiment, a system for planning the production of a product includes at least one database configured to store engineering information related to the product, and further configured to store process information related to the product, and a processor coupled to the at least one database to combine selected information from the at least one database to generate a manufacturing planning document that defines the product. In another embodiment, a method of generating a manufacturing bill of material for a selected product includes compiling a process data structure from the process information, compiling a product data structure from the engineering information, and generating a manufacturing bill of material by combining the process data structure and the product data structure.

Owner:THE BOEING CO

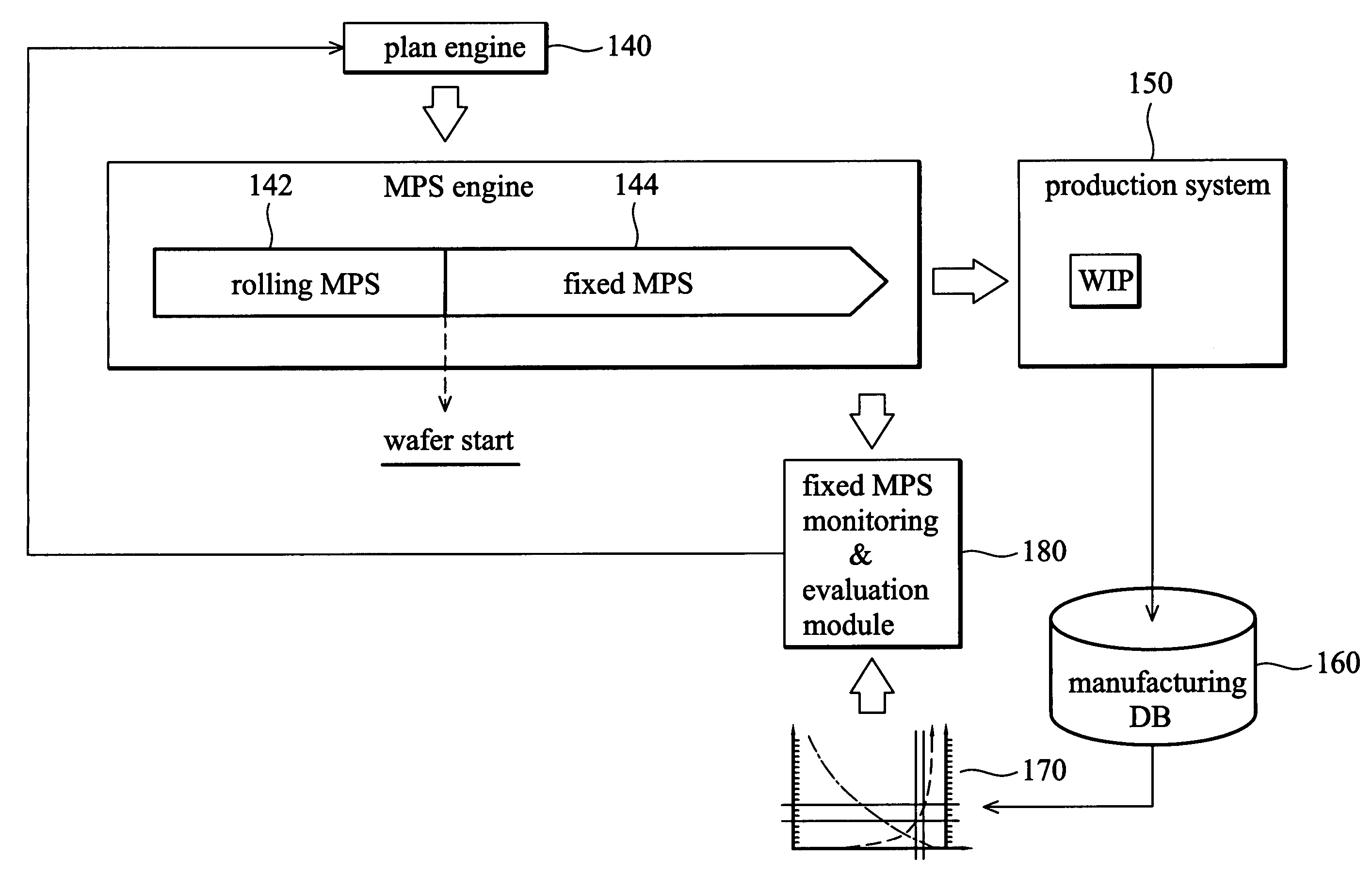

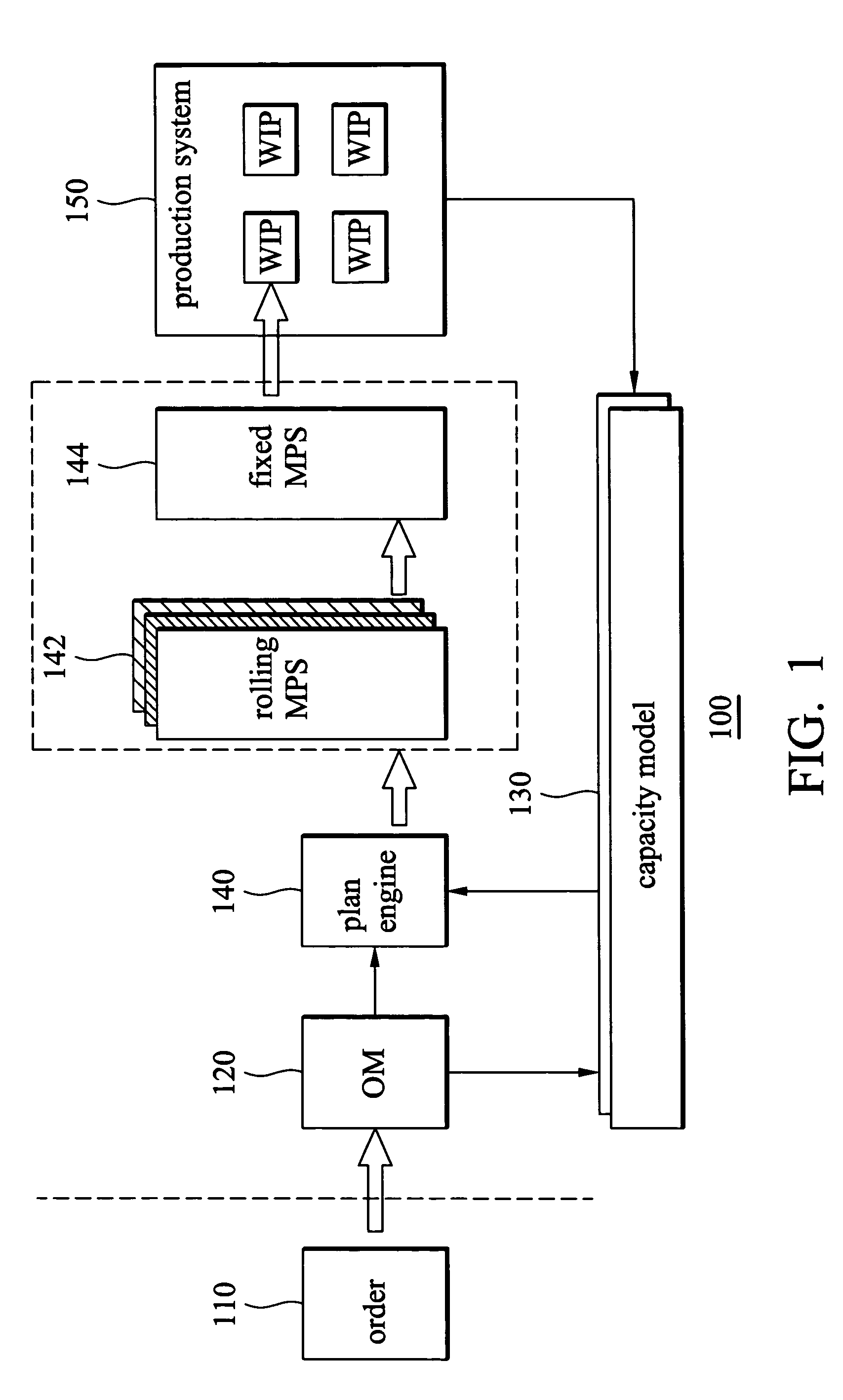

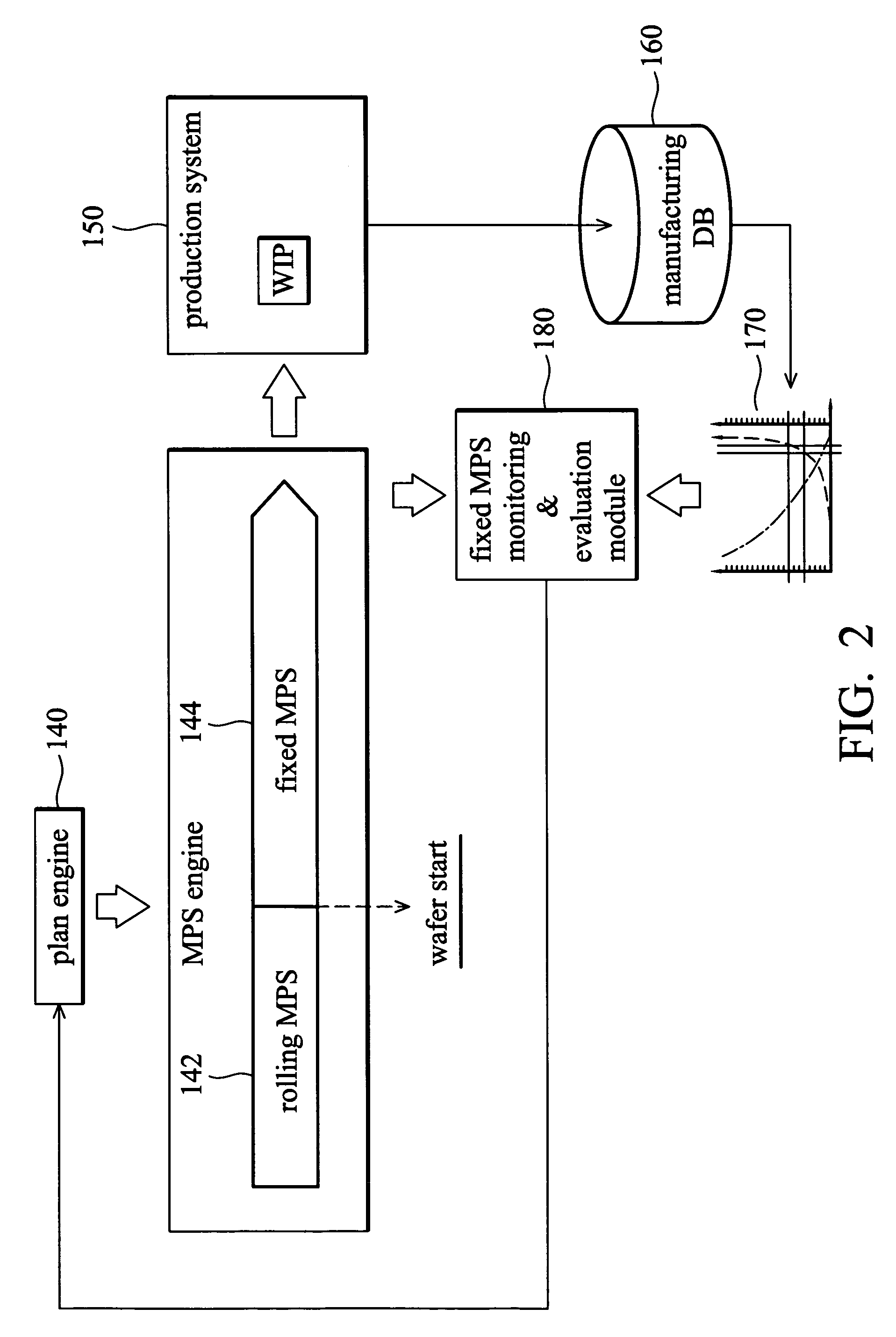

System and method for manufacturing planning and control

InactiveUS7130707B2Total factory controlSpecial data processing applicationsControl systemProgram planning

A customer-orientated manufacturing planning and controlling system. An order management module is programmed to receive an order for a product and reserve a capacity for the order based on a capacity model that considers a plurality of capacity vectors in a production system. A plan engine generates a fixed production schedule for the order based on the capacity model. A priority management engine provides a priority for the order. A production schedule monitor and evaluation module determines whether the order in process conforms to the fixed production schedule by statistical process control (SPC) and whether to adjust the fixed production schedule and to adjust the priority based on a dynamic achievement model of historical fixed production schedules, based on historical production information in a production database storing production information of the production system.

Owner:TAIWAN SEMICON MFG CO LTD

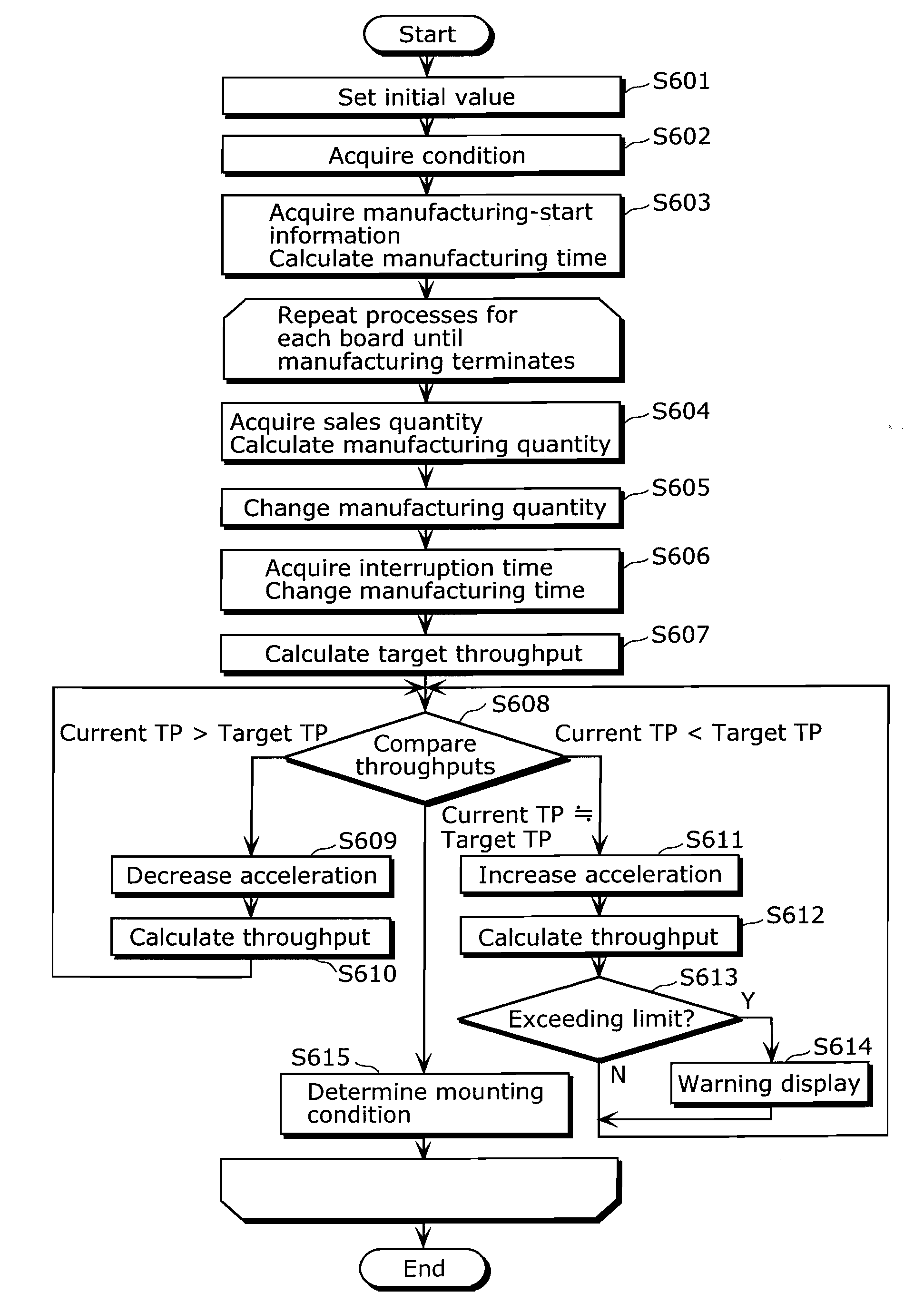

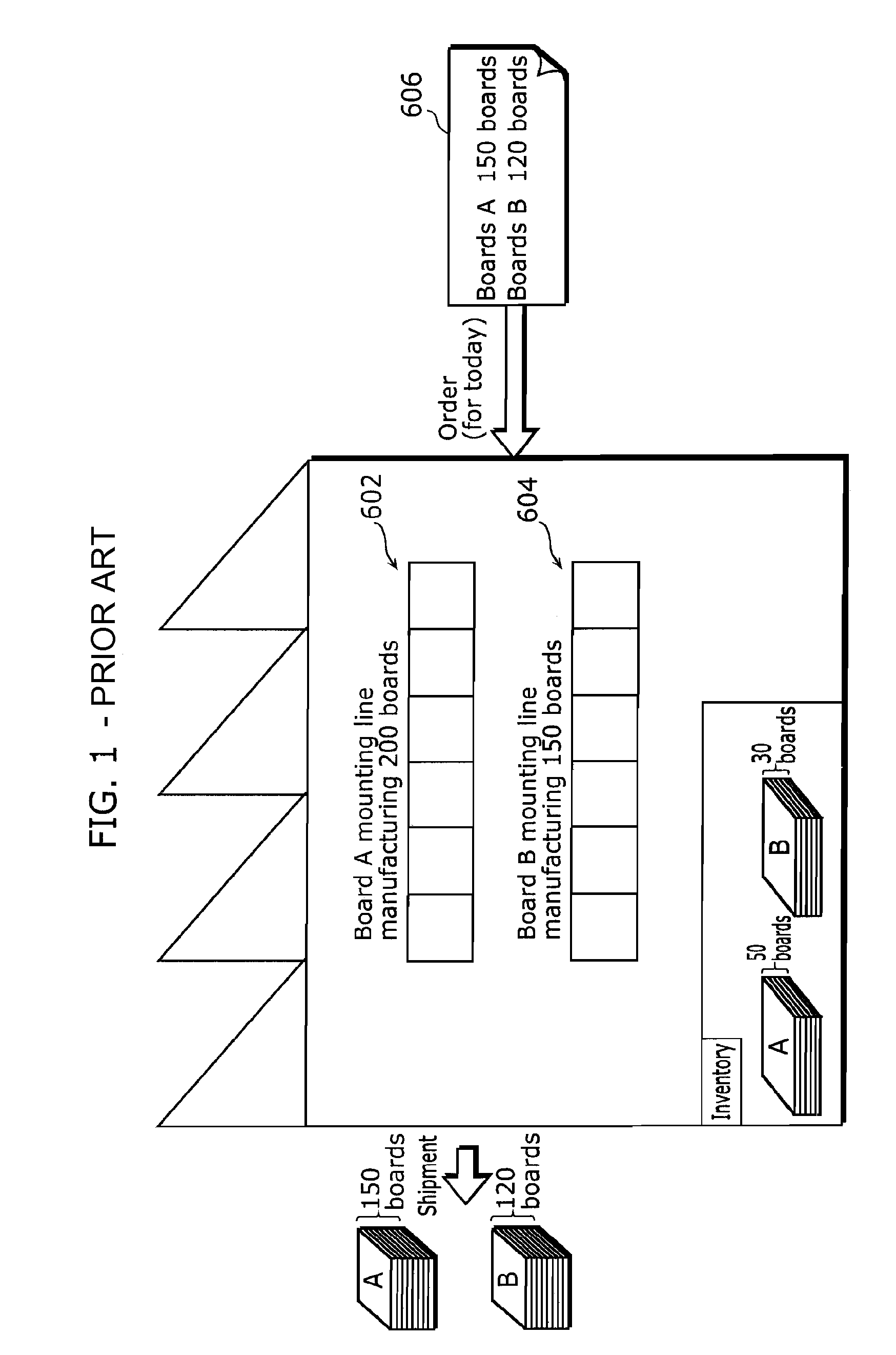

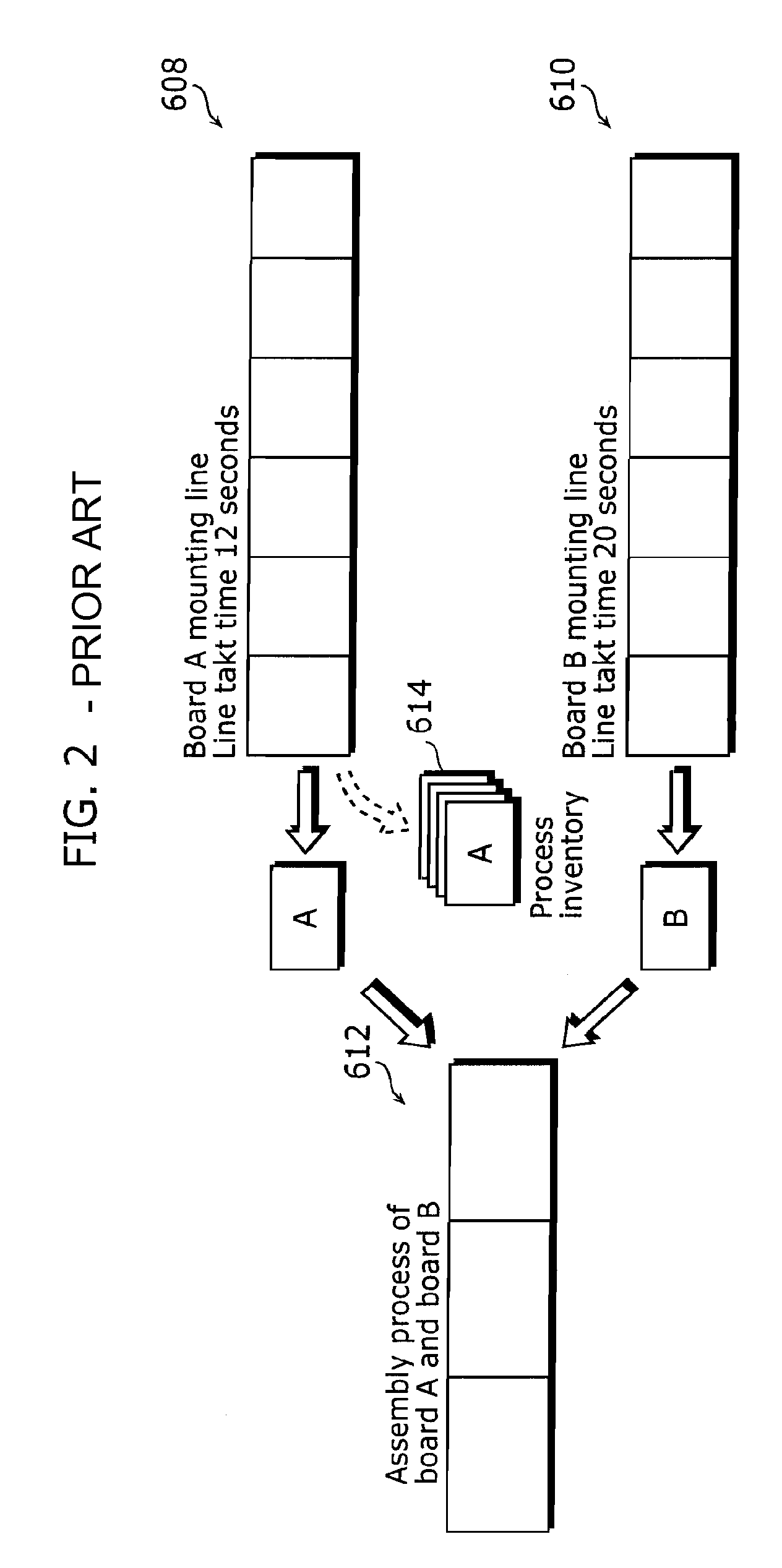

Manufacturing management method, manufacturing management apparatus, and mounter

InactiveUS7801634B2Reduce cost lossExtended production timeProgramme controlDigital computer detailsManufacturing planningManufacturing management

A mounter for a manufacturing management method suppresses an occurrence of inventory shortage or excess inventory as much as possible, and provides energy savings when manufacturing is not performed at full capacity. A throughput determining step acquires manufacturing information included in a manufacturing plan while manufacturing equipment is manufacturing mounted boards and determines a throughput of the manufacturing equipment for the mounted boards based on the manufacturing information while the manufacturing equipment is manufacturing a sequence of the mounted boards. A manufacturing condition determining step determines a manufacturing condition for decreasing power consumption of the manufacturing equipment within a range of throughput not lower than the determined throughput in the case where the throughput determined in the throughput determining step is equal to or lower than a current throughput of the manufacturing equipment.

Owner:GK BRIDGE 1

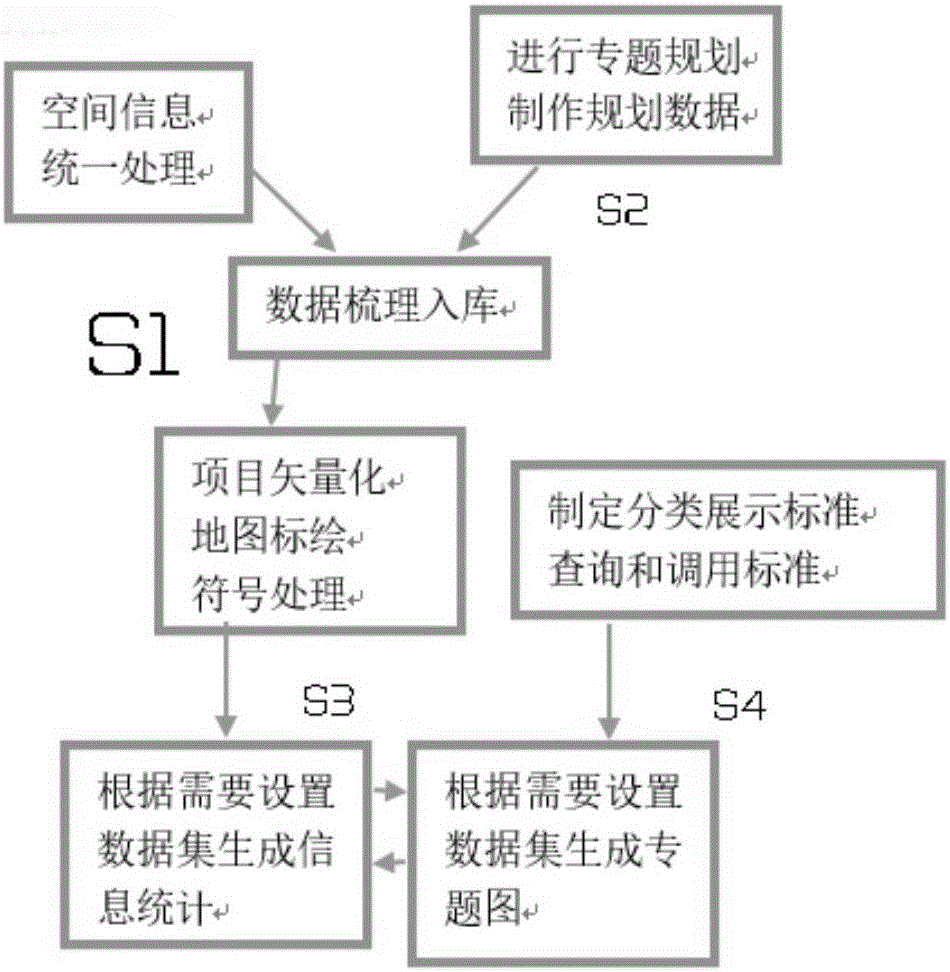

Method and system for thematically displaying industrial map system projects on basis of data linkage

InactiveCN106202245AExtended multi-dimensionalIntuitive information interactionSpecial data processing applicationsManufacturing planningThematic map

The invention discloses a method and a system for thematically displaying industrial map system projects on the basis of data linkage. The method includes carrying out data combing and warehousing on spatial information processed in a unified manner and thematic planning and manufacturing planning data and storing the spatial information and the planning data in background servers; vectorizing and processing the warehoused data on GIS (geographic information system) platforms, plotting vectorized and processed spatial data on industrial maps, representing the spatial data in a classified manner by the aid of signs when the spatial data are plotted, converting the industrial spatial information into corresponding point, line and surface elements and displaying the point, line and surface elements on electronic maps; configuring data interaction between front-end assemblies and the background servers in B / S (browser / server) architectures and dynamically generating industrial information thematic maps. The method and the system have the advantages that flow data processing modes are established, accordingly, the data utilization rate can be increased, and the aggregation and inline degrees of the data can be improved.

Owner:TAIHUA WISDOM IND GRP CO LTD

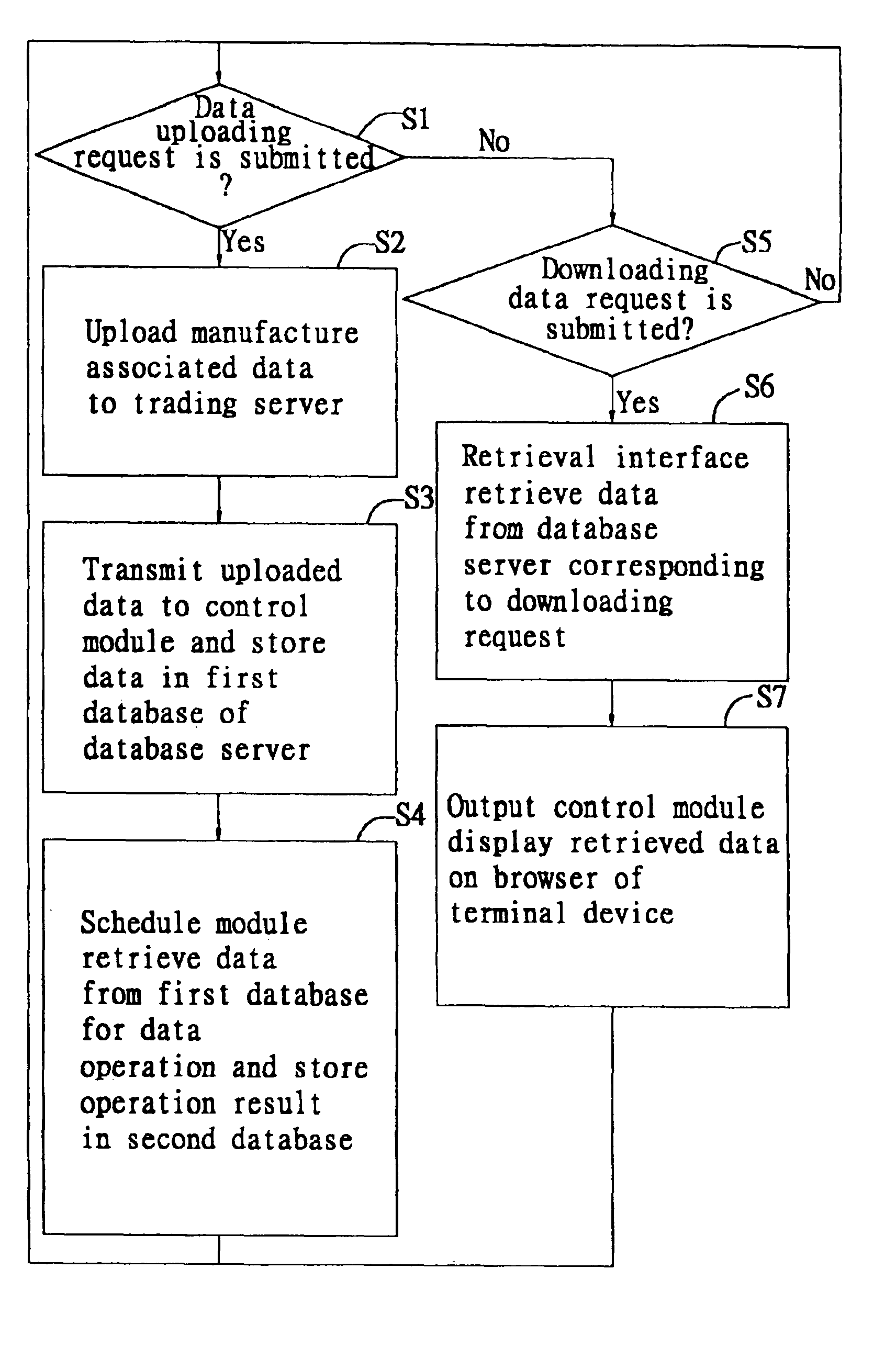

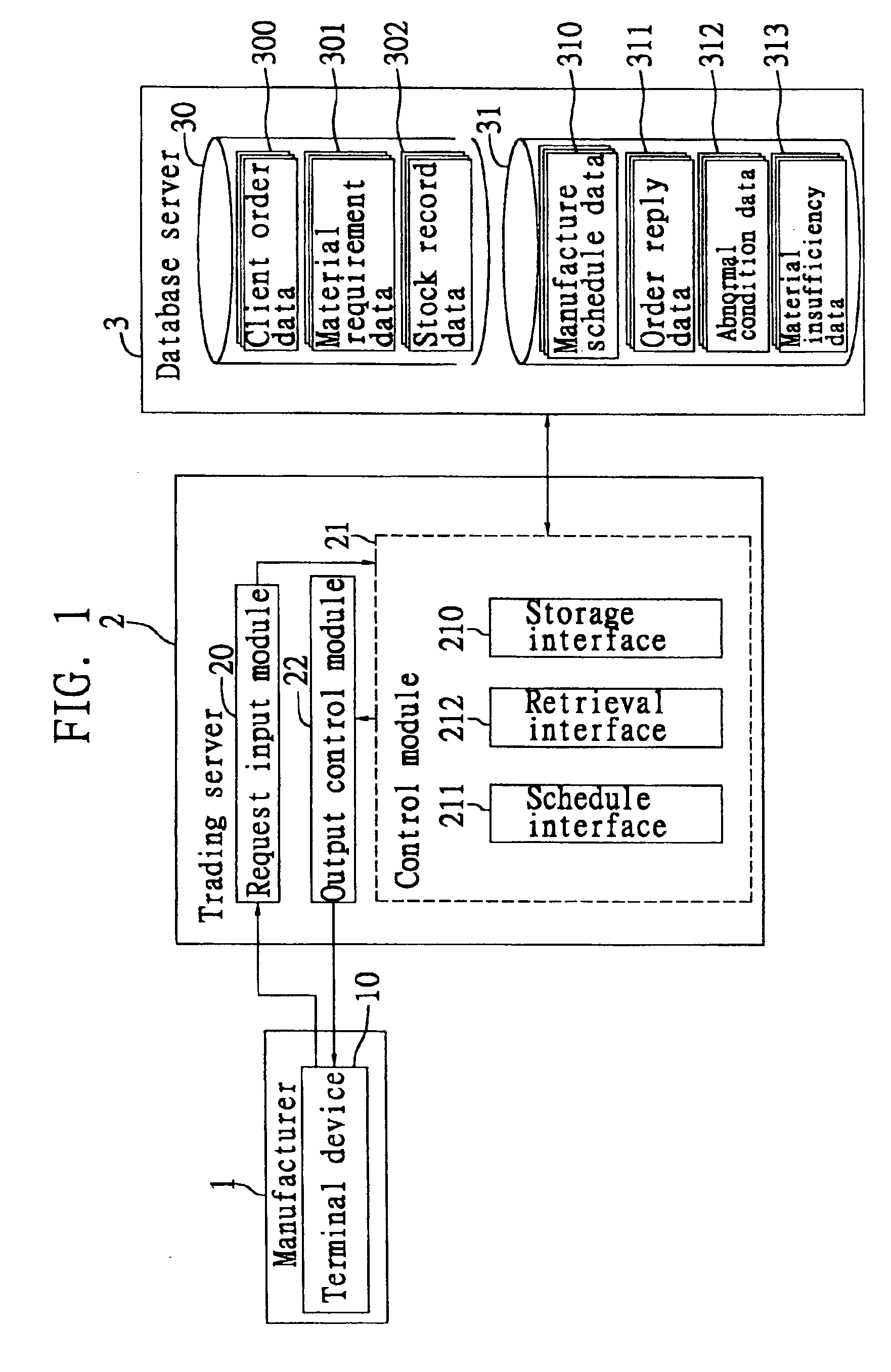

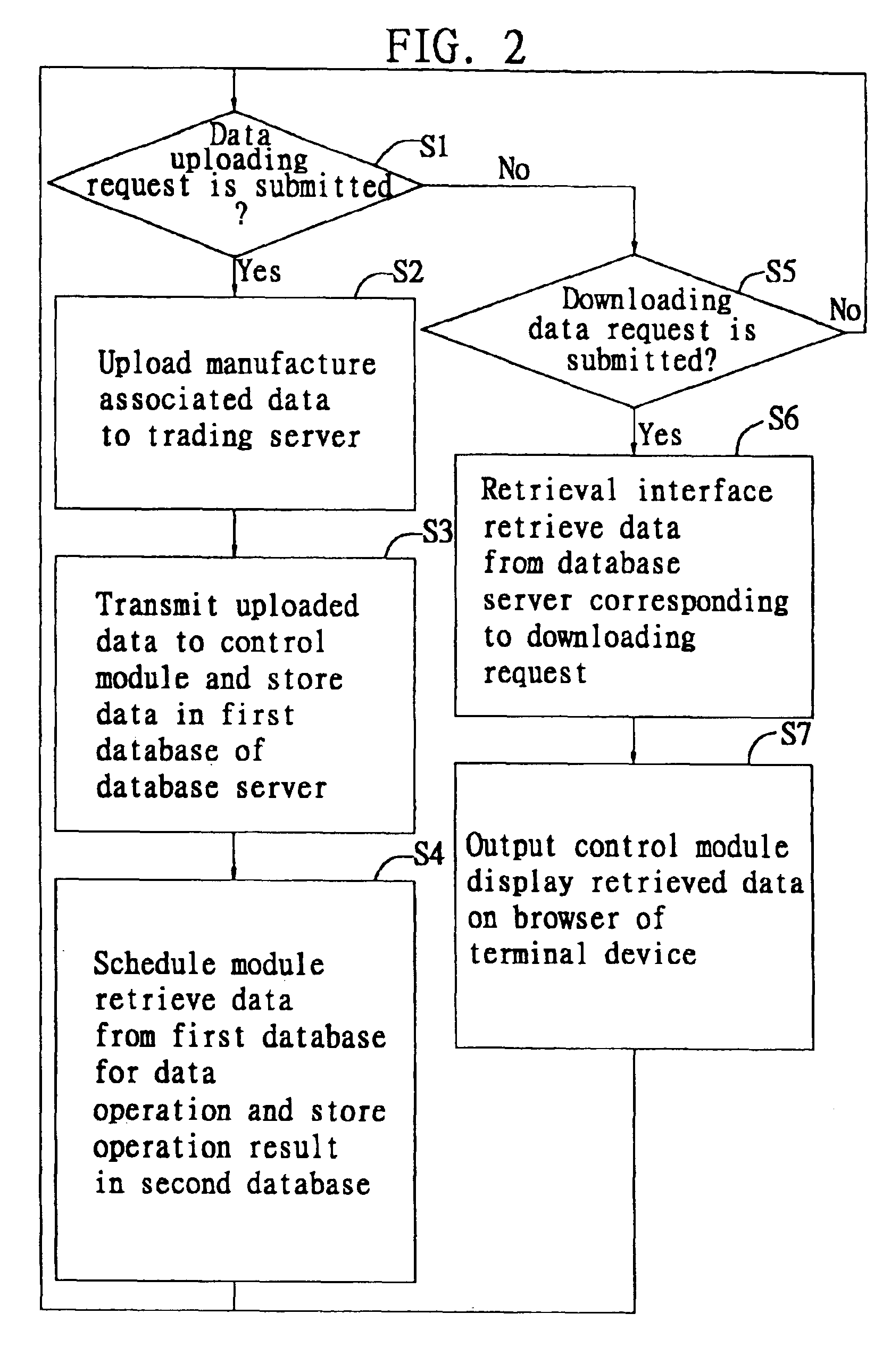

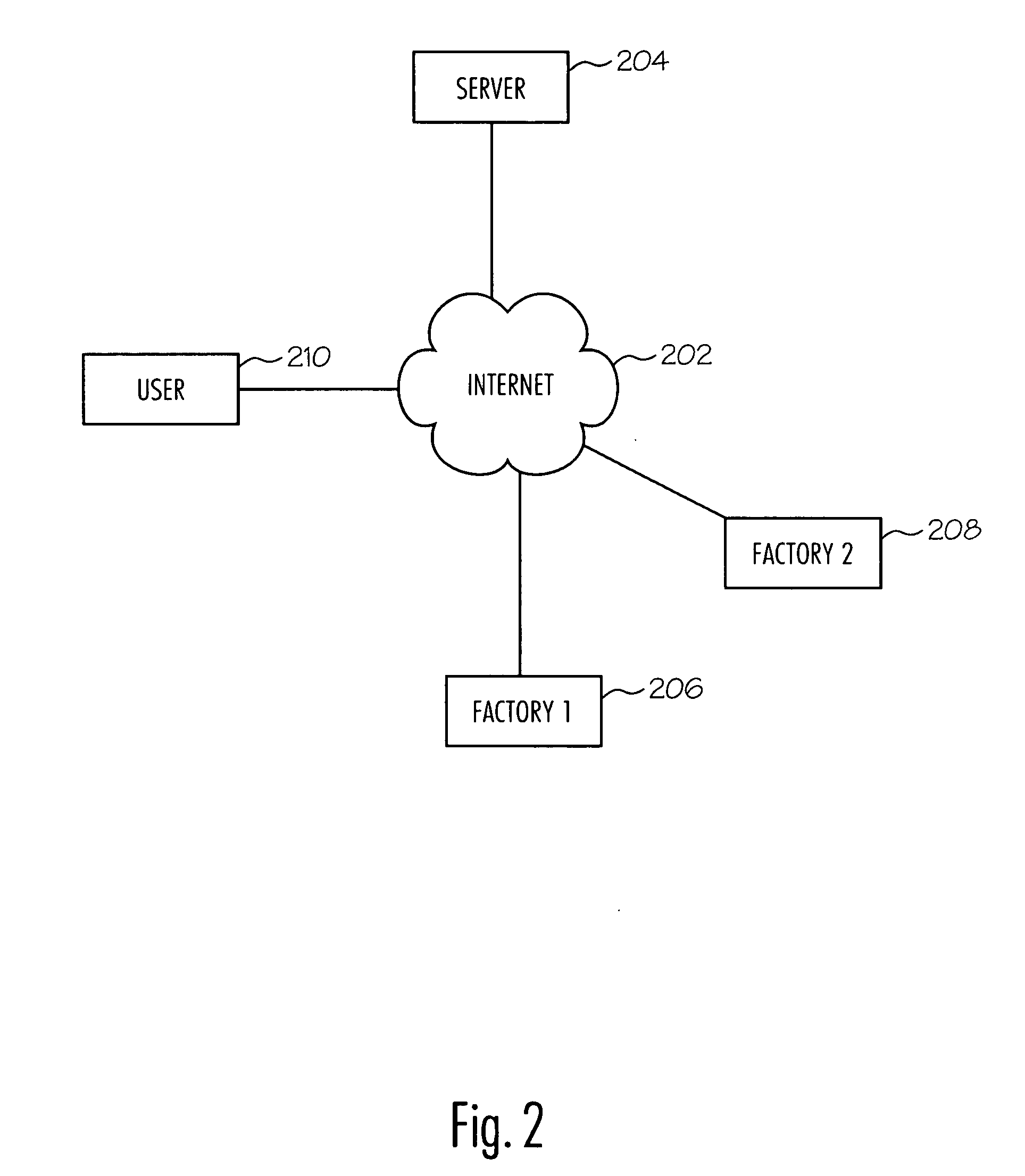

Method and system for estimating exportation time

InactiveUS6901416B2Reduce stock productsDigital data processing detailsForecastingData operationsOperant conditioning

A method and system for estimating exportation time are proposed, for connecting a manufacturer through a network to a system for estimating exportation time, wherein the system estimates product exportation time for client orders received by the manufacturer according to practical operating conditions in product manufacture. In the use of the foregoing method and system, a first database stores uploaded and manufacture operating data from the manufacturer, so as to prompt the system to perform data operation and processing according to the stored data. Operation data results are stored in a second database, and used as reference to provide manufacture schedule data, order reply data, abnormal condition data and material insufficiency data to be downloaded by the manufacturer, so as to allow the manufacturer to execute product manufacture according to the downloaded data, and immediately realize problems in product manufacture to solve.

Owner:INVENTEC CORP

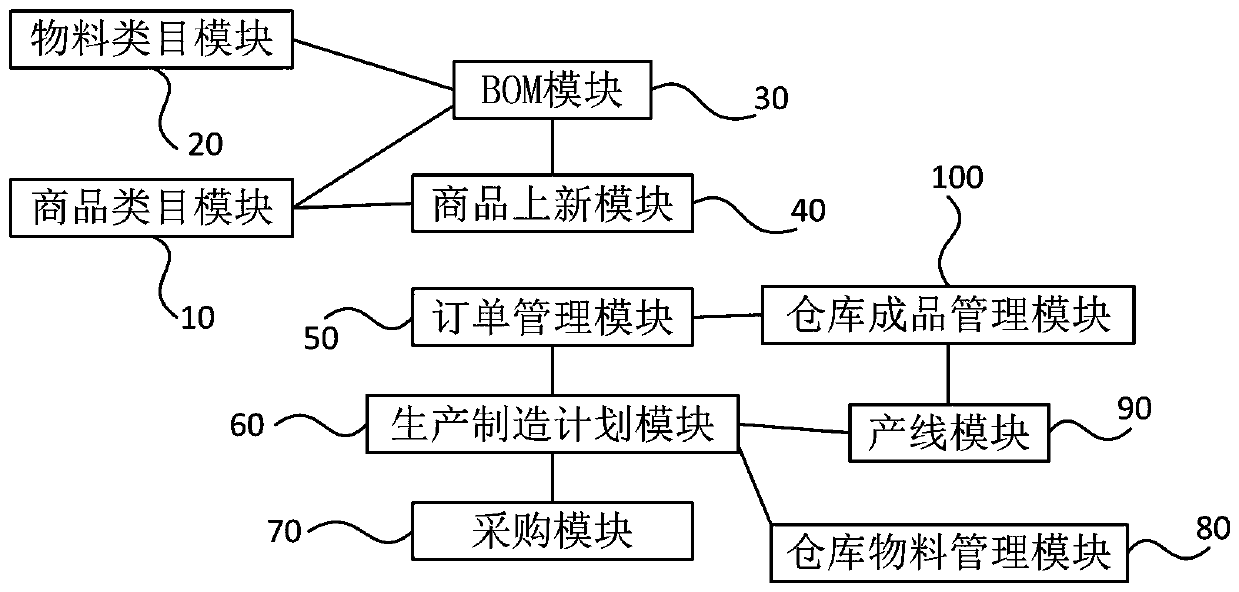

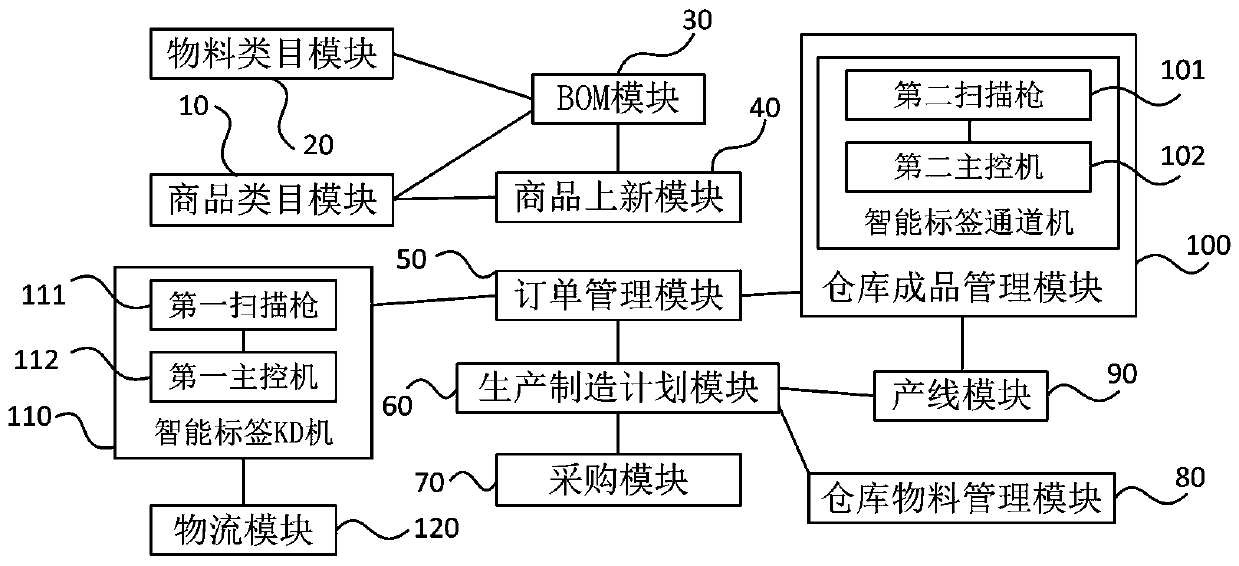

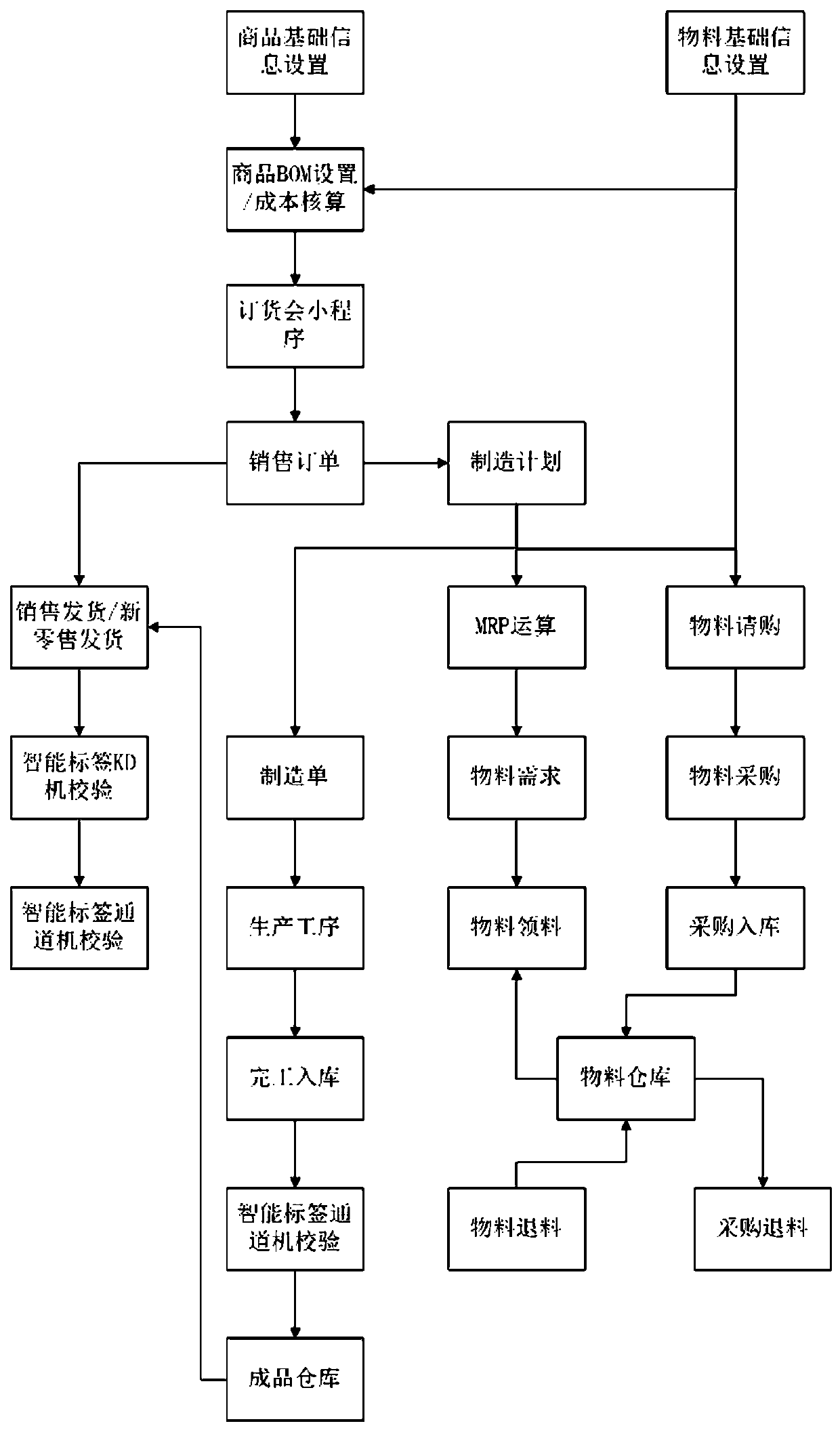

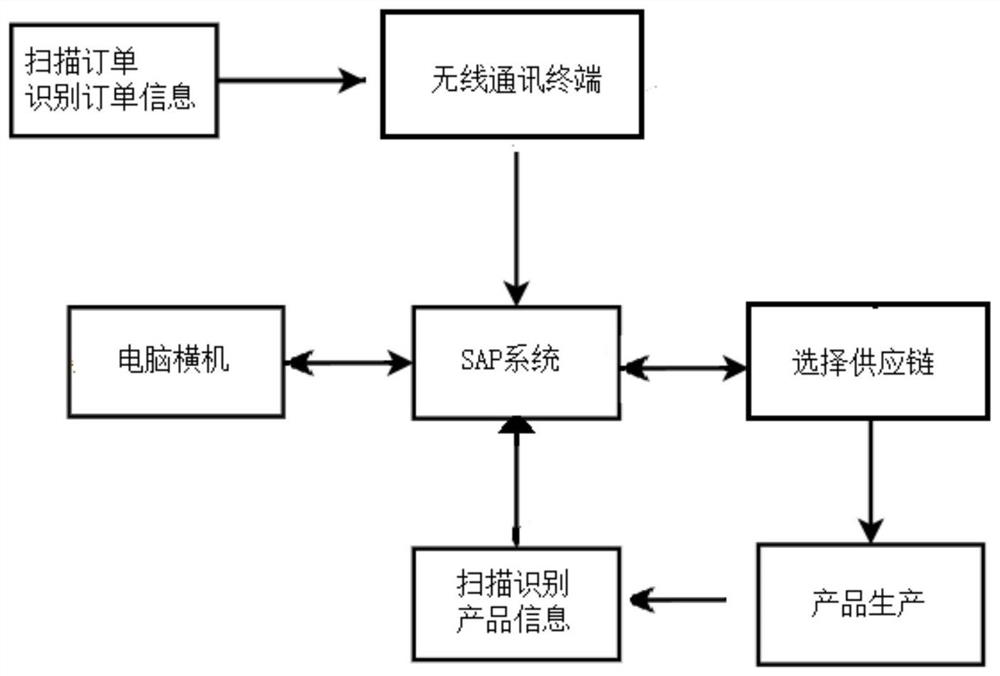

ERP commodity management system and method

PendingCN111242477AFacilitate integrated managementReal-time interactionBuying/selling/leasing transactionsResourcesProduction lineLogistics management

The invention discloses an ERP commodity management system and method. The system comprises a commodity category module, a material category module, a BOM module, a commodity new arrival module, an order management module, a production and manufacturing planning module, a purchasing module, a warehouse material management module, a production line module and a warehouse finished product managementmodule. Data of the modules interact mutually, functions are triggered mutually, data processing is more timely, and in addition, human factors can be reduced, computerized management of commoditiesin a series of processes such as design, material purchasing, selling, manufacturing, warehouse-in, ex-warehouse and logistics is achieved, enterprise management integration is facilitated, the collaboration of departments of an enterprise is enhanced, and the working efficiency and the accuracy of the departments are improved.

Owner:湖州朗讯信息科技有限公司

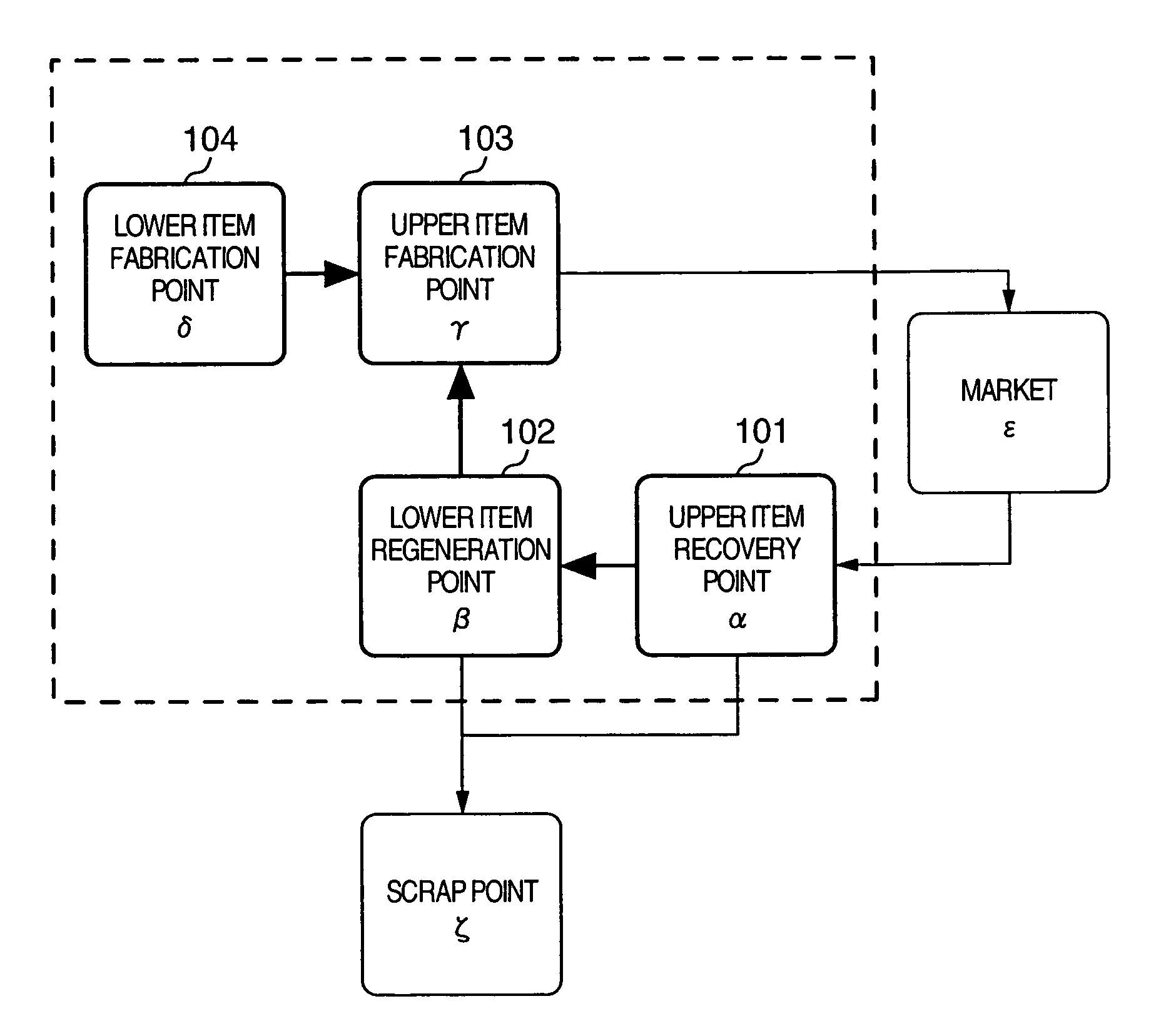

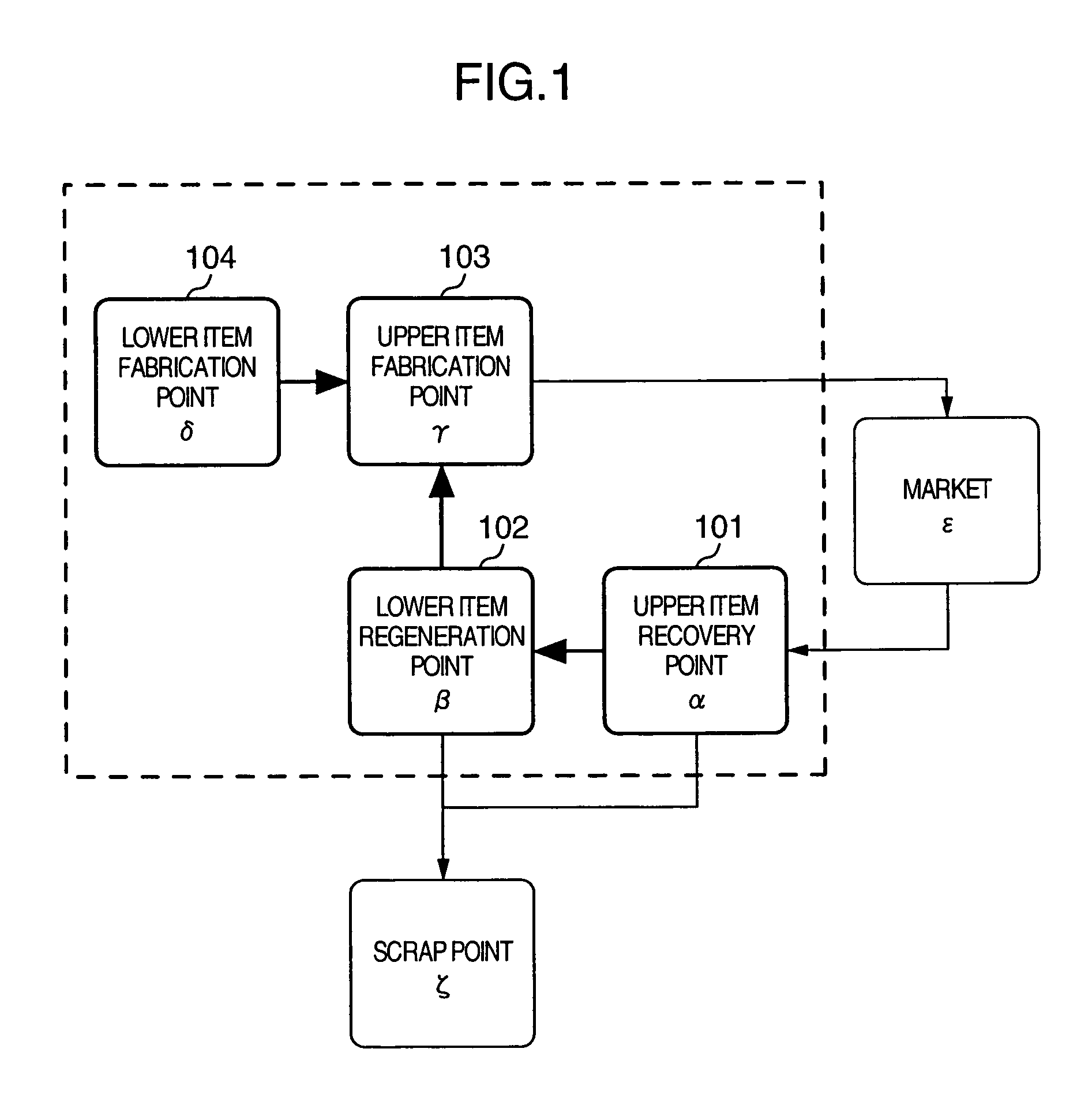

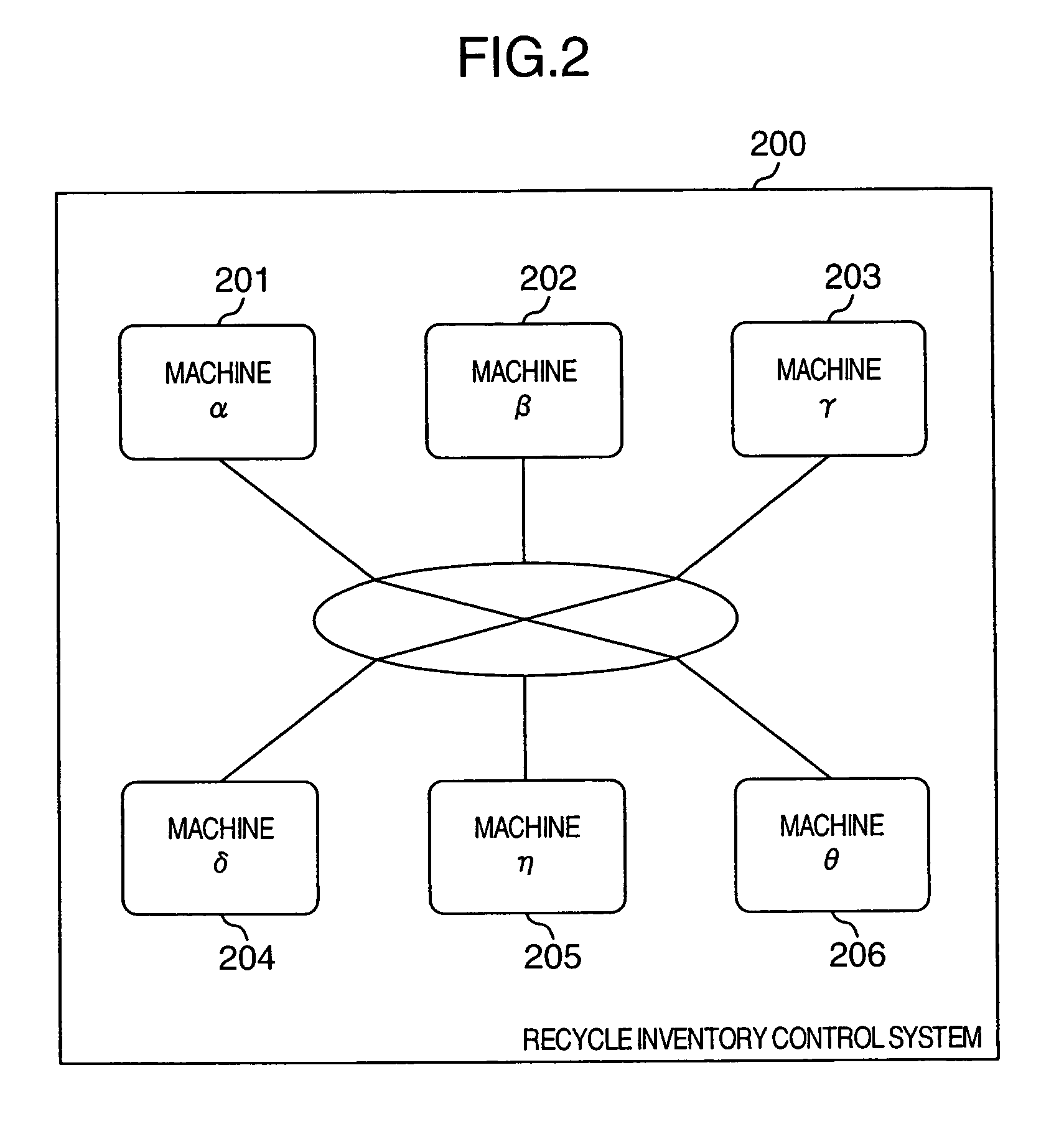

Inventory control system and method in recycle-oriented society

InactiveUS7624043B2Achieve synchronizationReduce excessSustainable waste treatmentHand manipulated computer devicesManufacturing planningControl system

In a physical distribution model of the circulation type, synchronization is established between a reuse plan and a delivery / fabrication plan to thereby reasonably reduce the excess and deficiency of inventory articles at a confluence point of regenerated reusable articles and newly delivered component parts. With regard to newly delivered lower-level items, predict a variation or fluctuation of stock quantity based on at least a delivery schedule of them and a present stock amount along with usage plans in manufacturing processes. As for lower-level items of regenerated articles, predict a delivery due date and an expected number of such regenerated lower-level items based on at least a stock quantity of recovered items collected for reuse purposes and a lead time for taking regenerated lower-level items out of the collected items, thereby controlling, based on the both prediction results, the stock quantity of the lower-level items in manufacturing processes.

Owner:HITACHI LTD

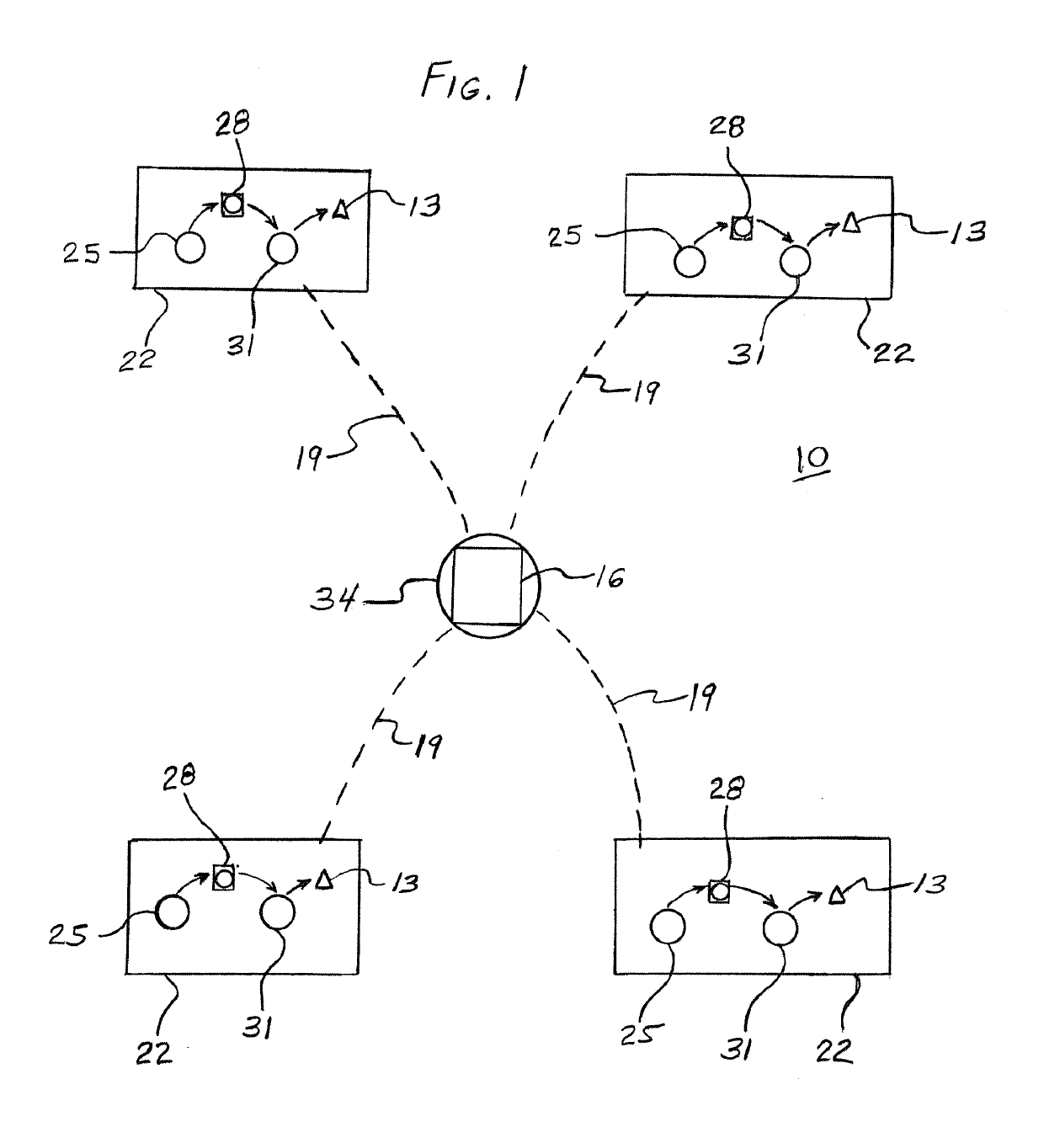

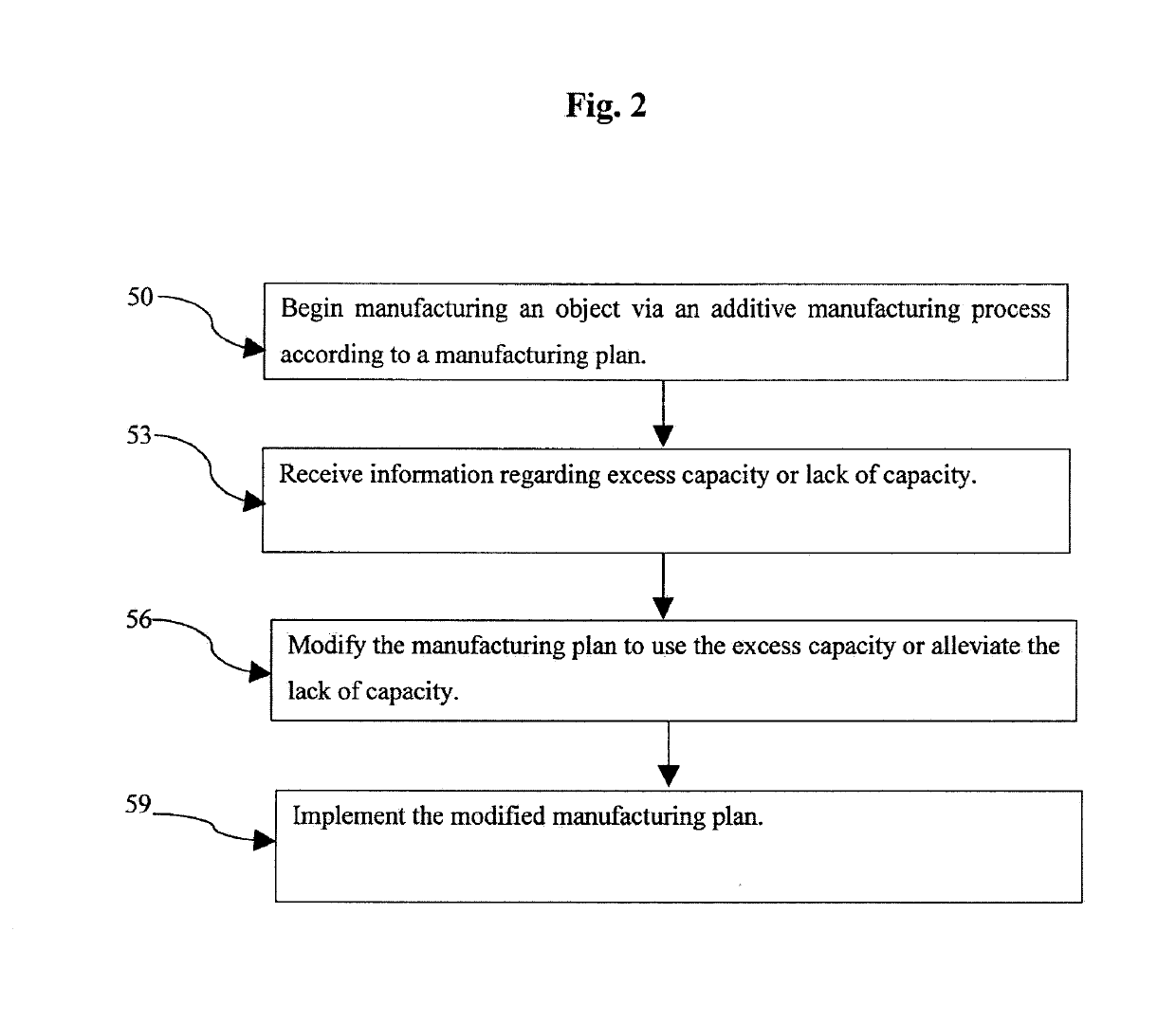

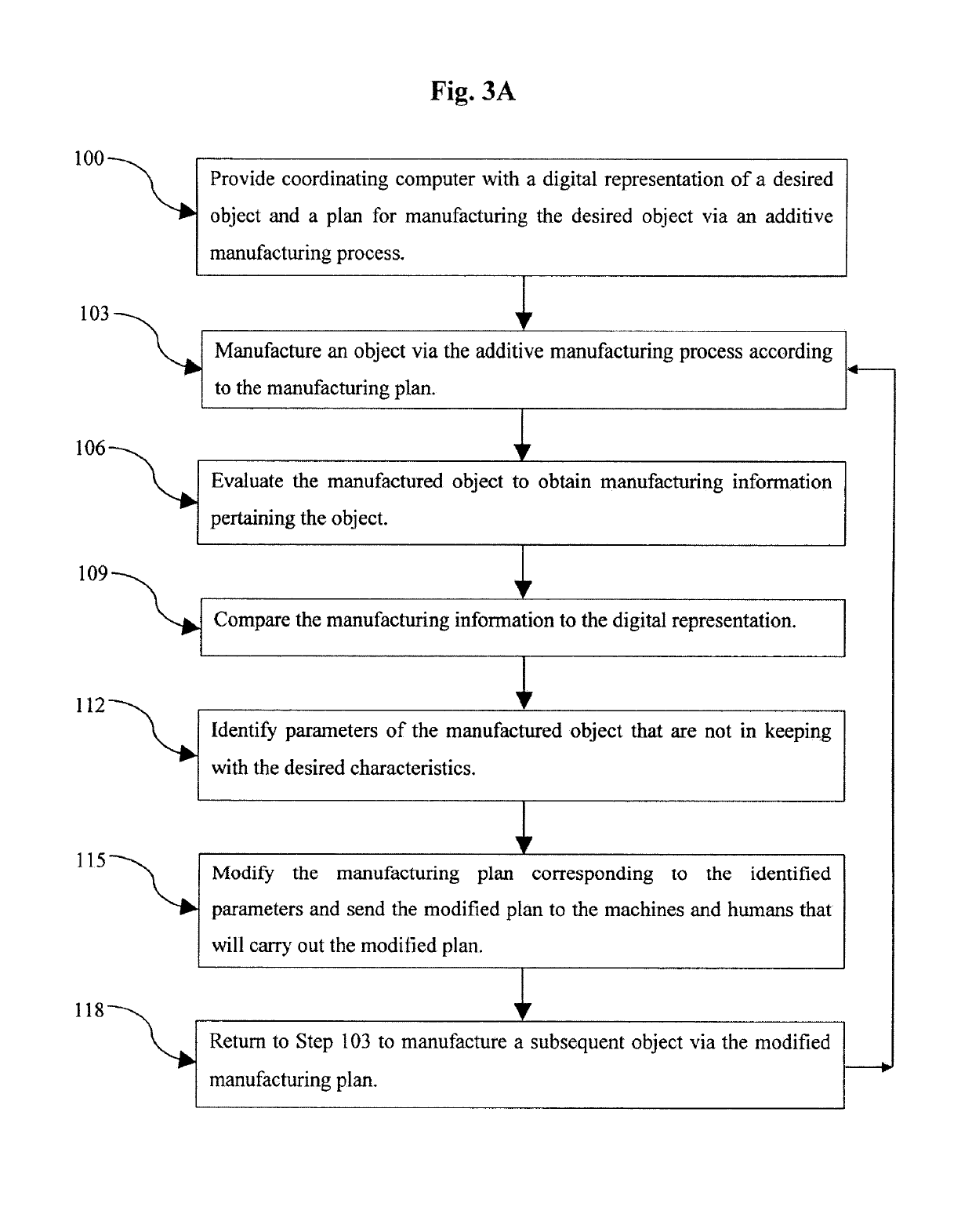

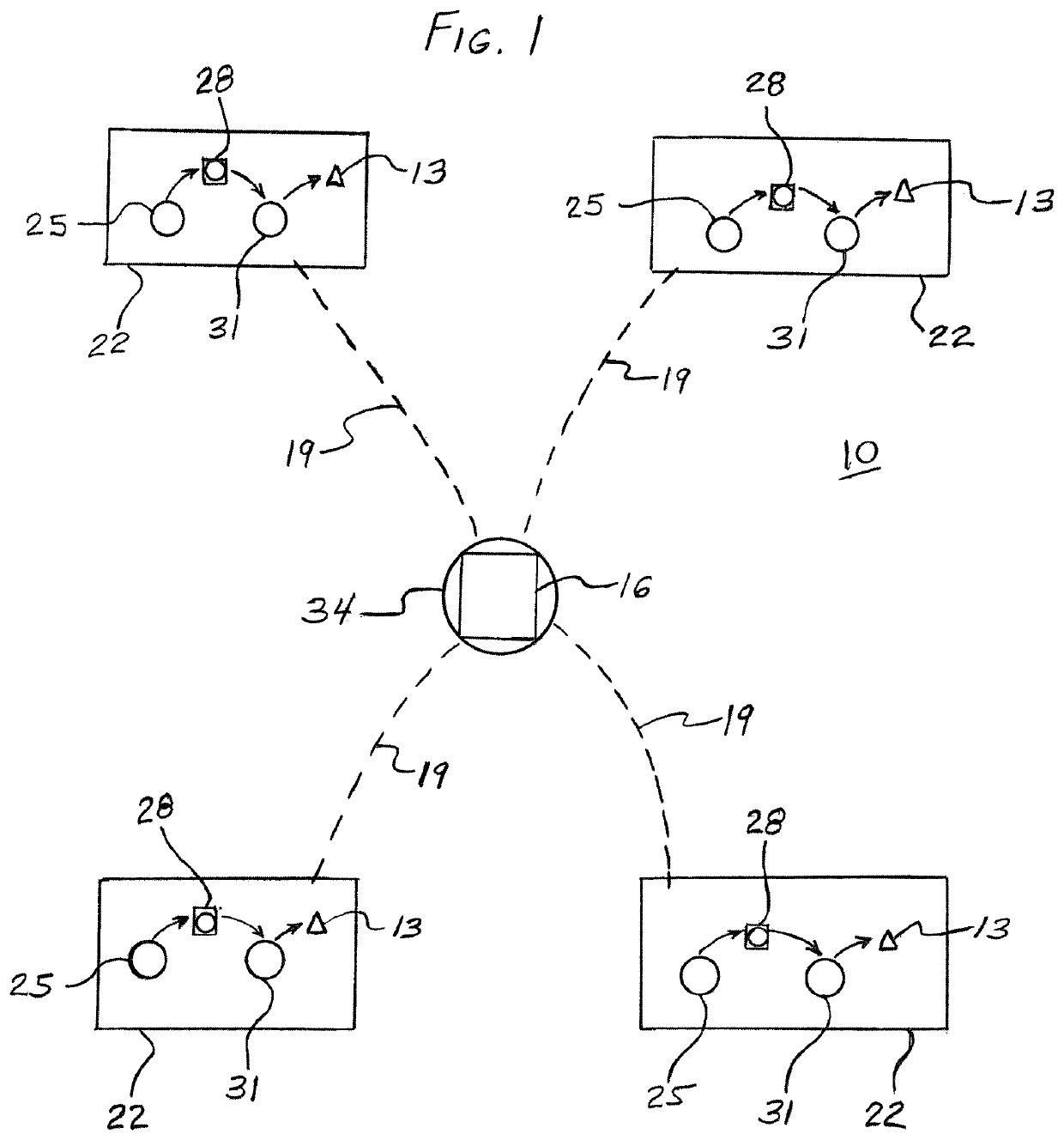

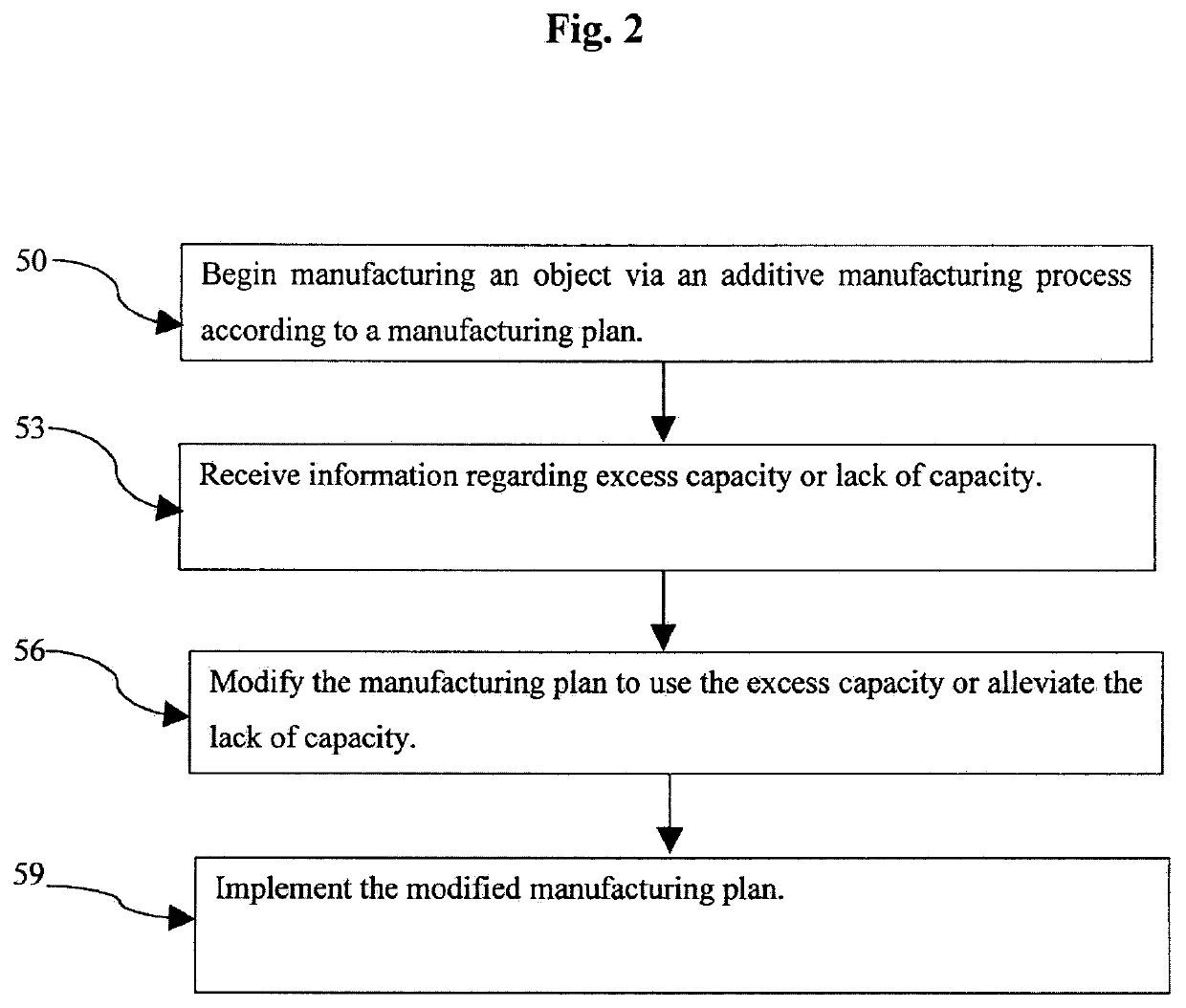

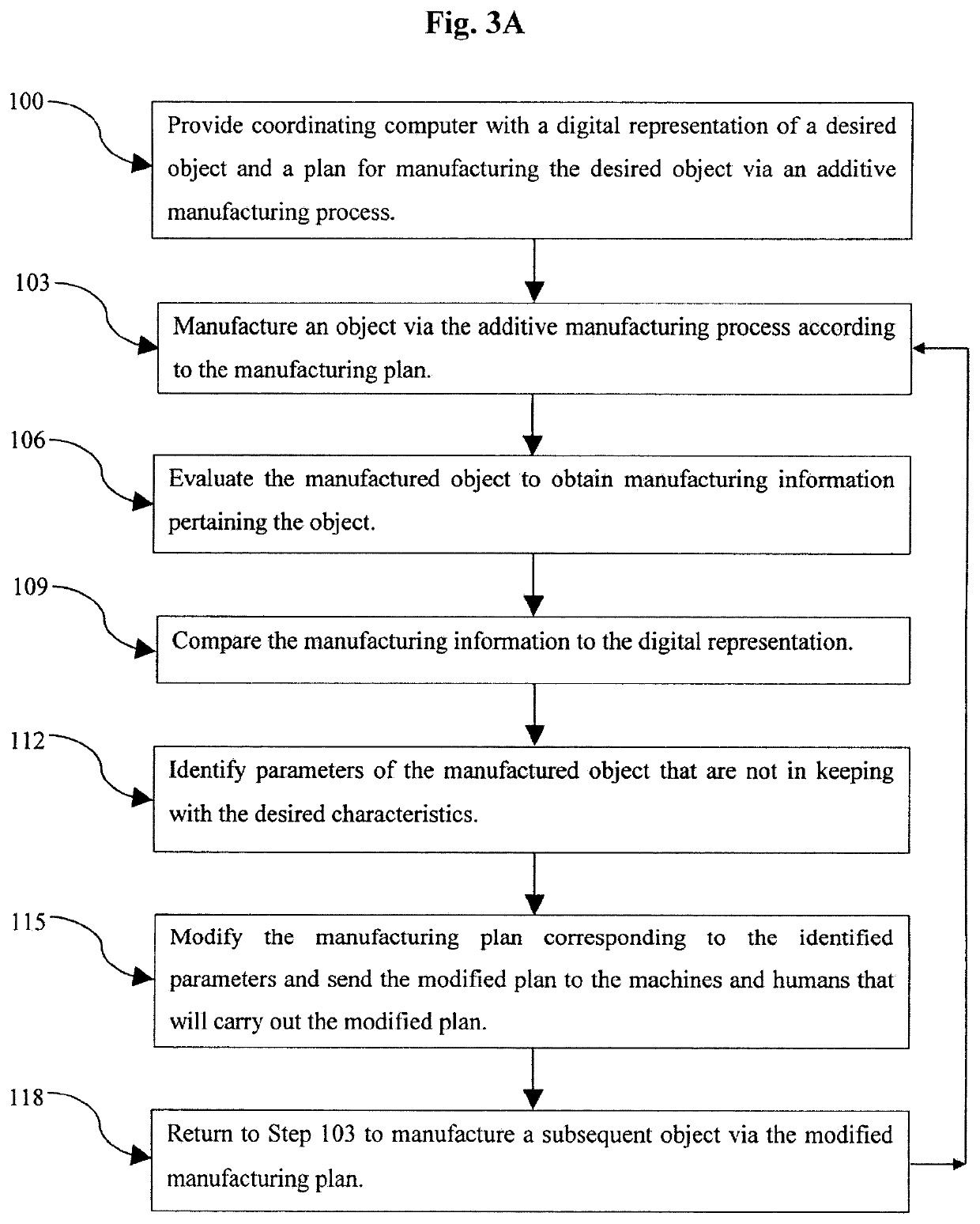

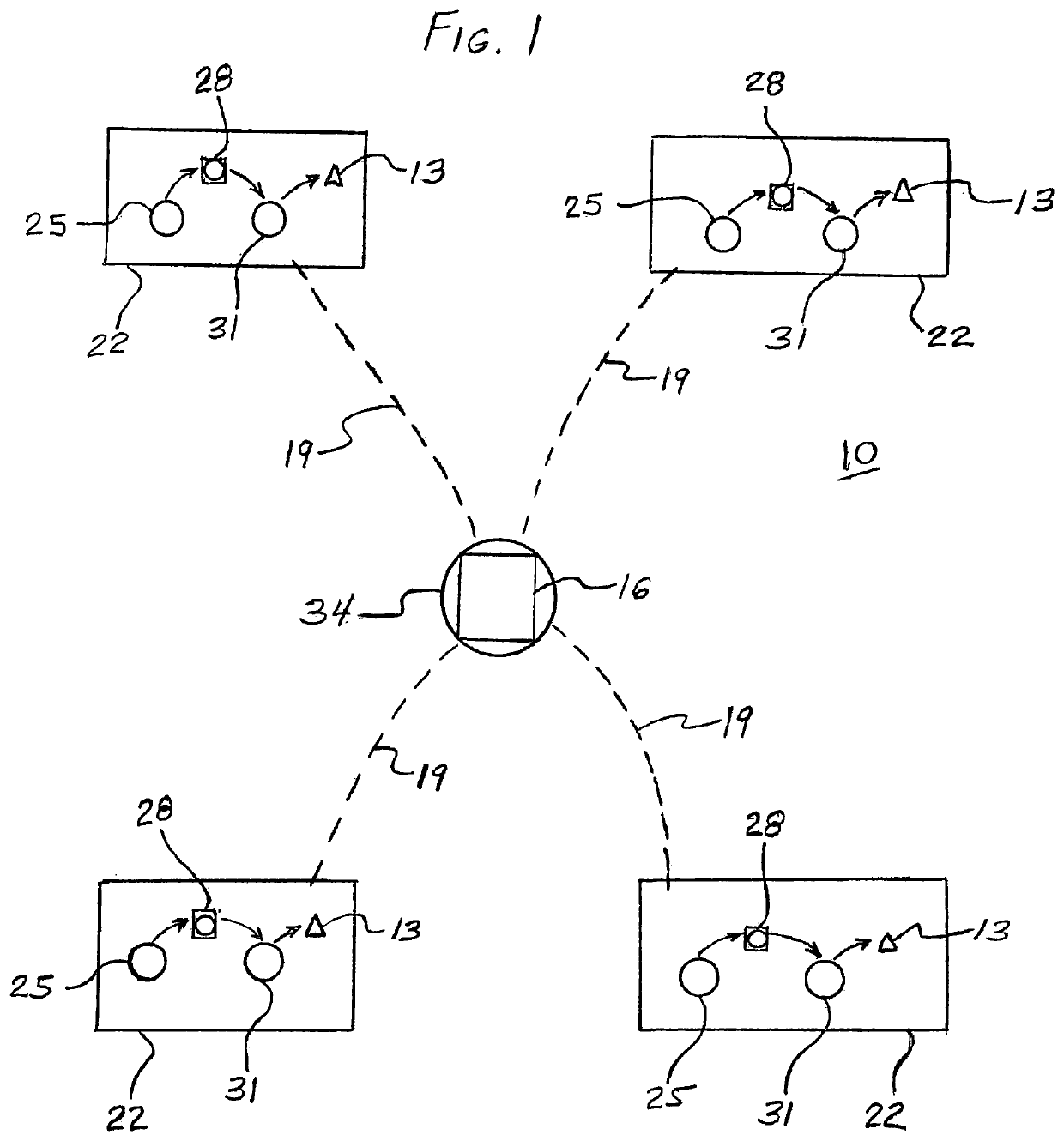

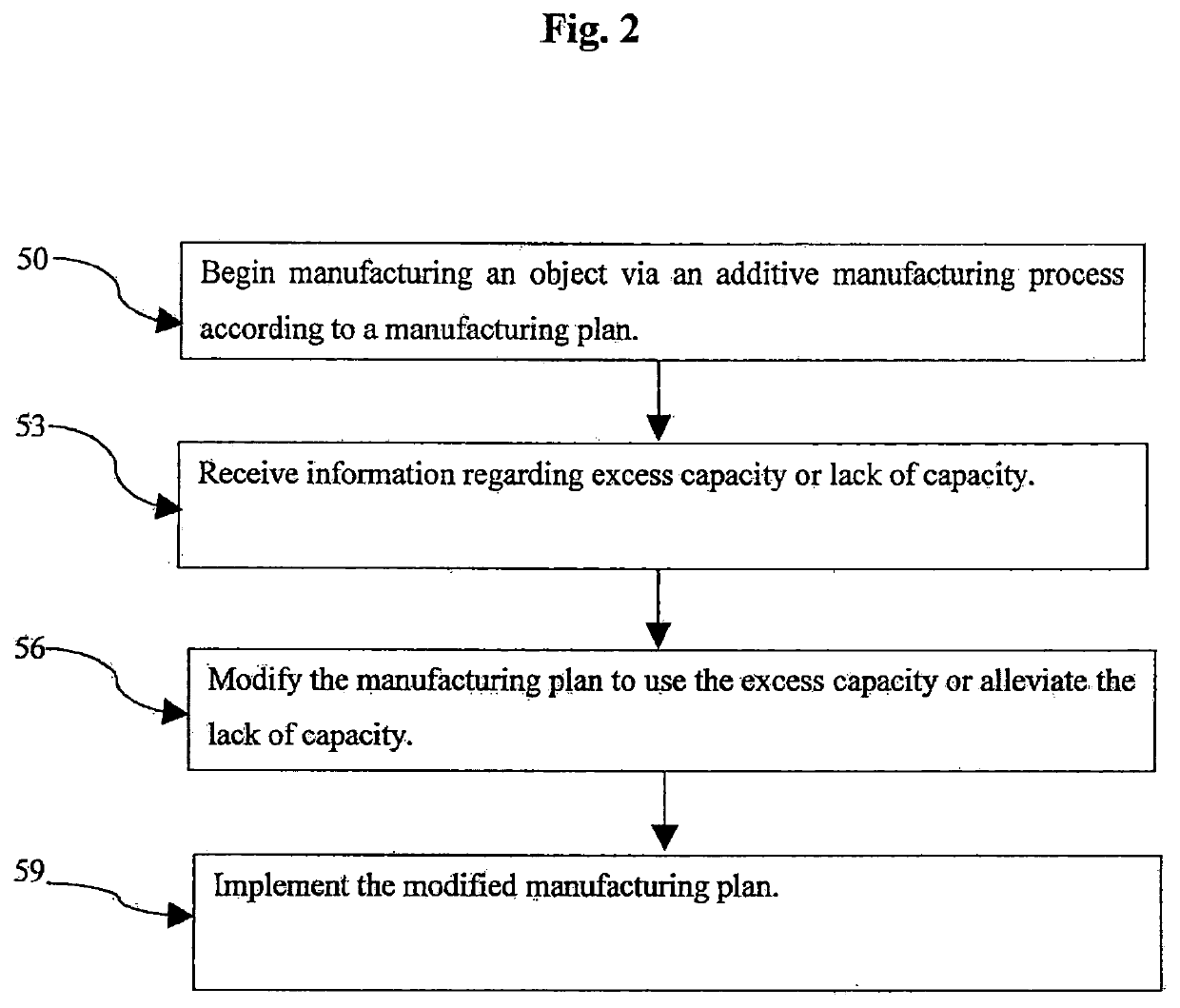

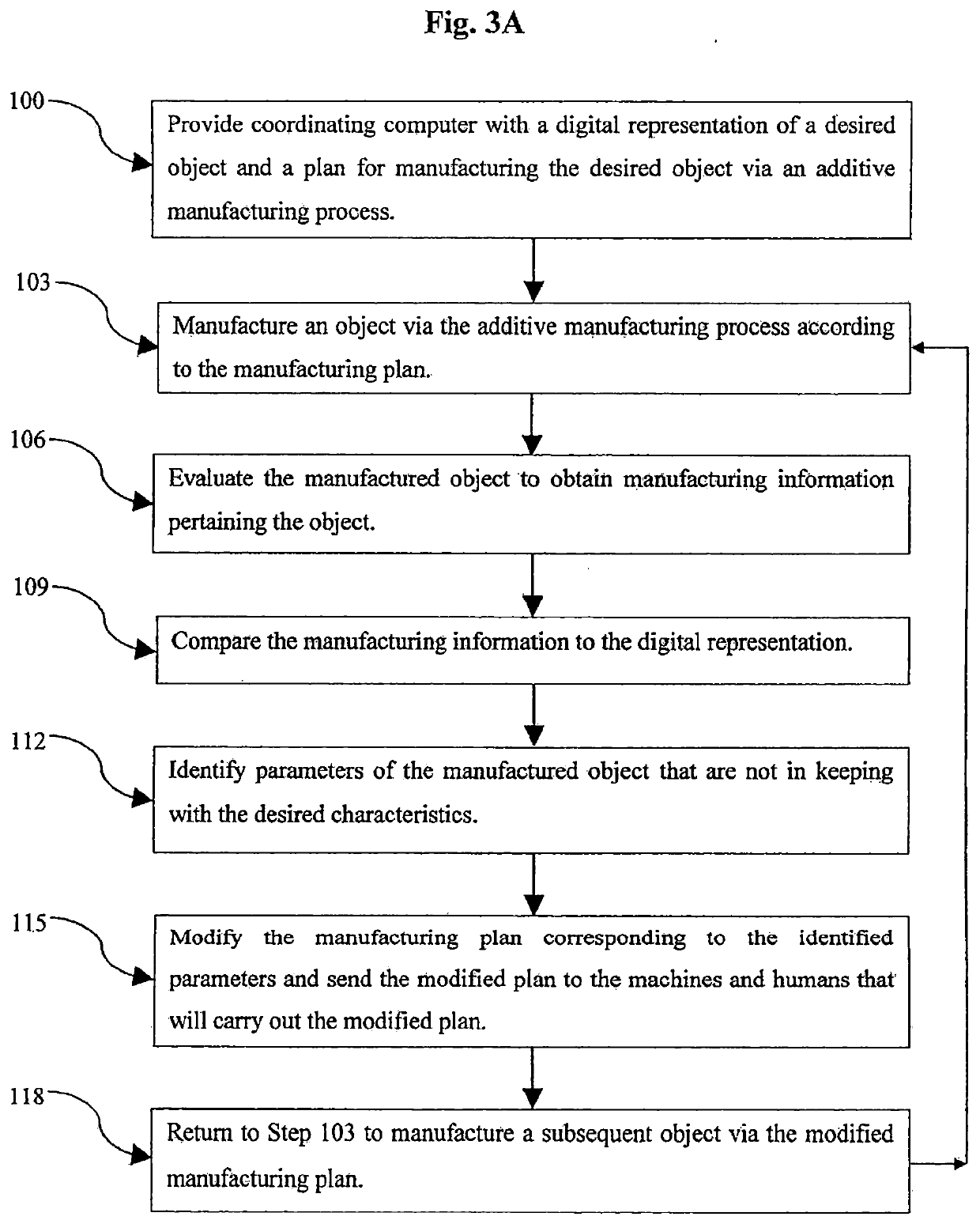

System And Method Of Manufacturing An Additively Manufactured Object

ActiveUS20190275745A1Increasing energy efficiency3D object support structuresManufactured ObjectManufacturing engineering

Owner:POSTPROCESS TECH INC

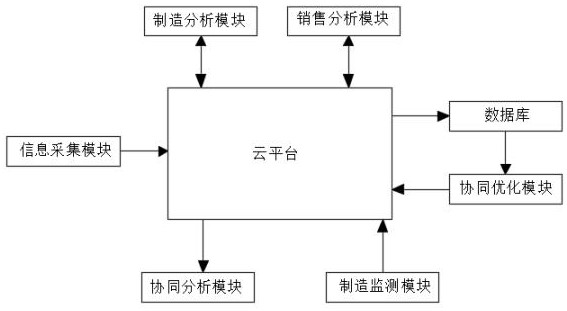

Collaborative manufacturing system for printing and packaging production line

ActiveCN114119268AImprove production efficiencyManufacturing priorityForecastingResourcesTimestampManufacturing planning

The invention discloses a collaborative manufacturing system for a printing and packaging production line, which relates to the technical field of production and manufacturing and comprises an information acquisition module, a collaborative optimization module, a database and a manufacturing monitoring module. The information acquisition module is used for acquiring historical manufacturing records of the SMT production line and sales information of various products; the manufacturing analysis module is used for receiving historical manufacturing records of the SMT production line and analyzing manufacturing coefficients of the products to obtain a manufacturing coefficient sequence of the products; the sales analysis module is used for receiving sales information of various products and analyzing sales coefficients of the products to obtain a sales coefficient sequence of the products; and the collaborative optimization module is used for evaluating a product manufacturing coefficient sequence and a sales coefficient sequence with timestamps stored in the database to obtain a value optimization sequence of the product, so that a reference is provided for a manager to arrange a manufacturing plan of the product, important and scarce products can be preferentially manufactured, and the collaborative manufacturing efficiency is improved.

Owner:科大智能物联技术股份有限公司

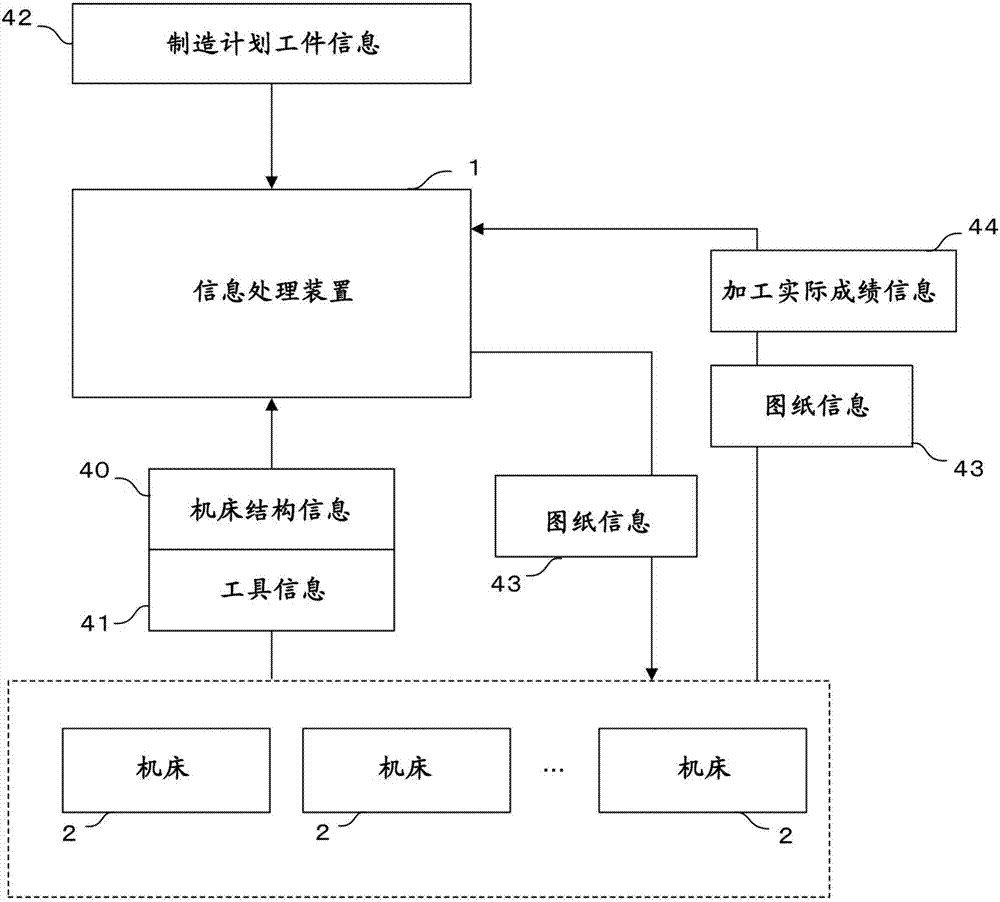

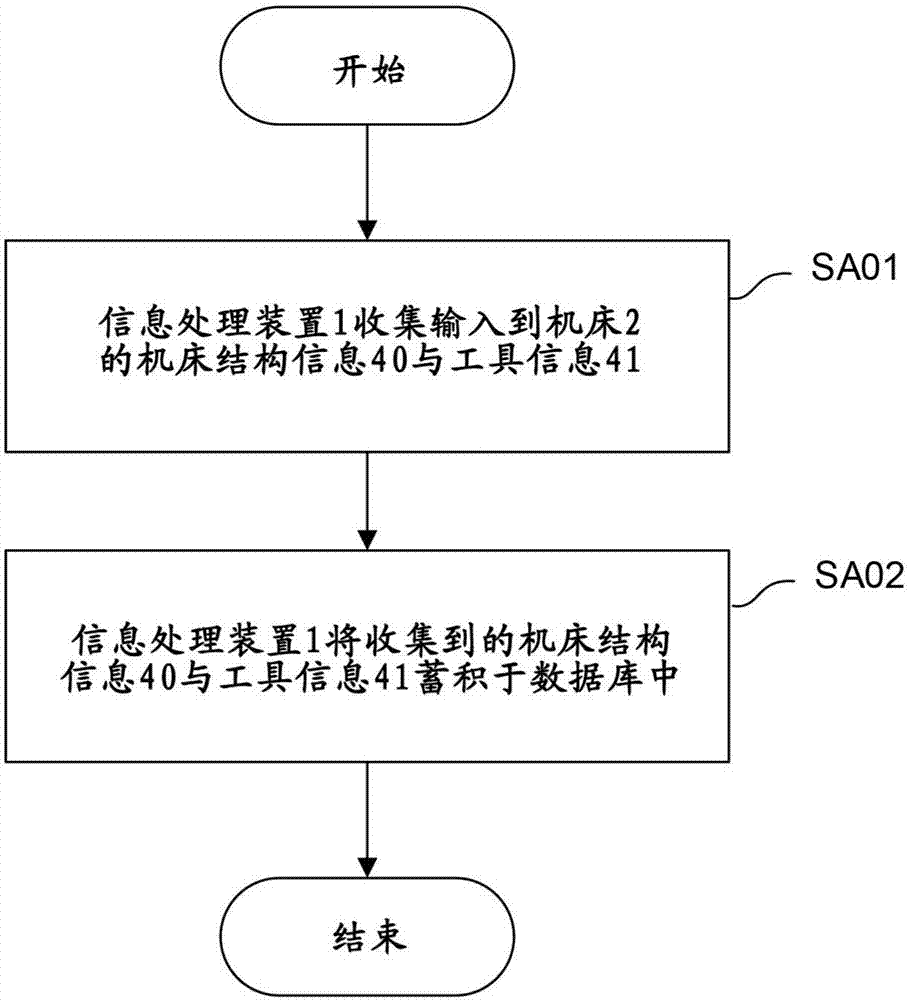

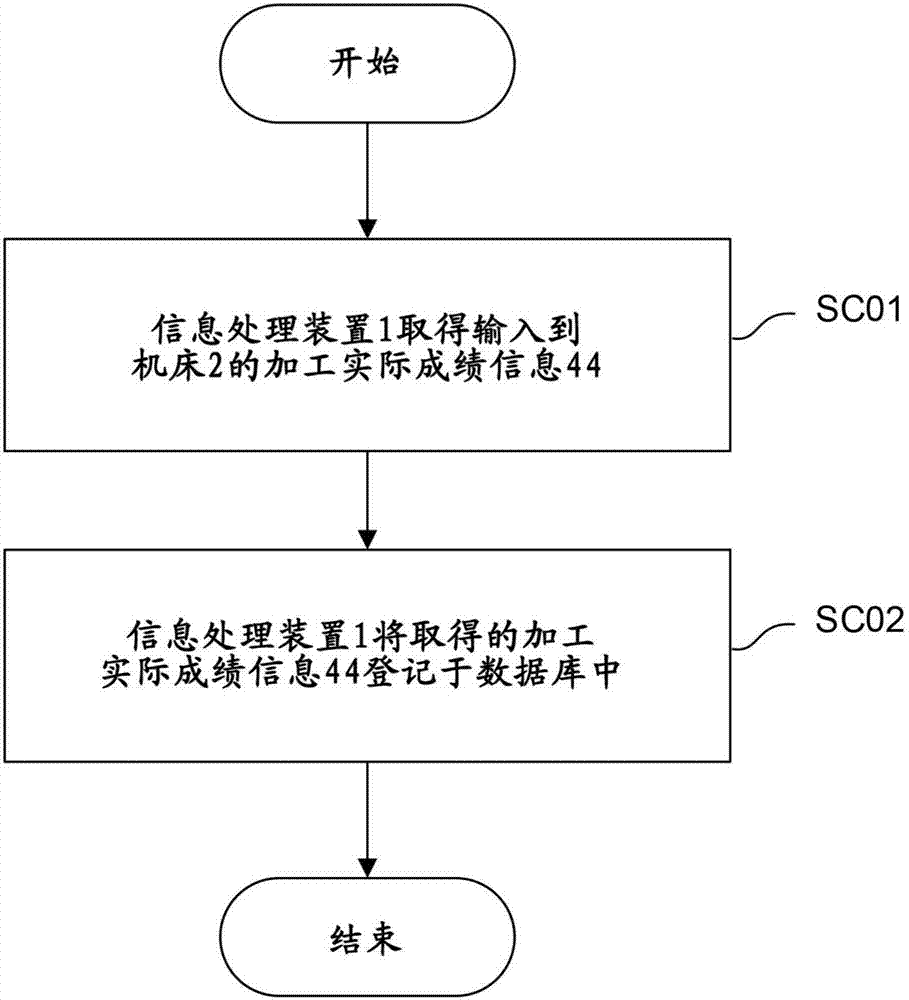

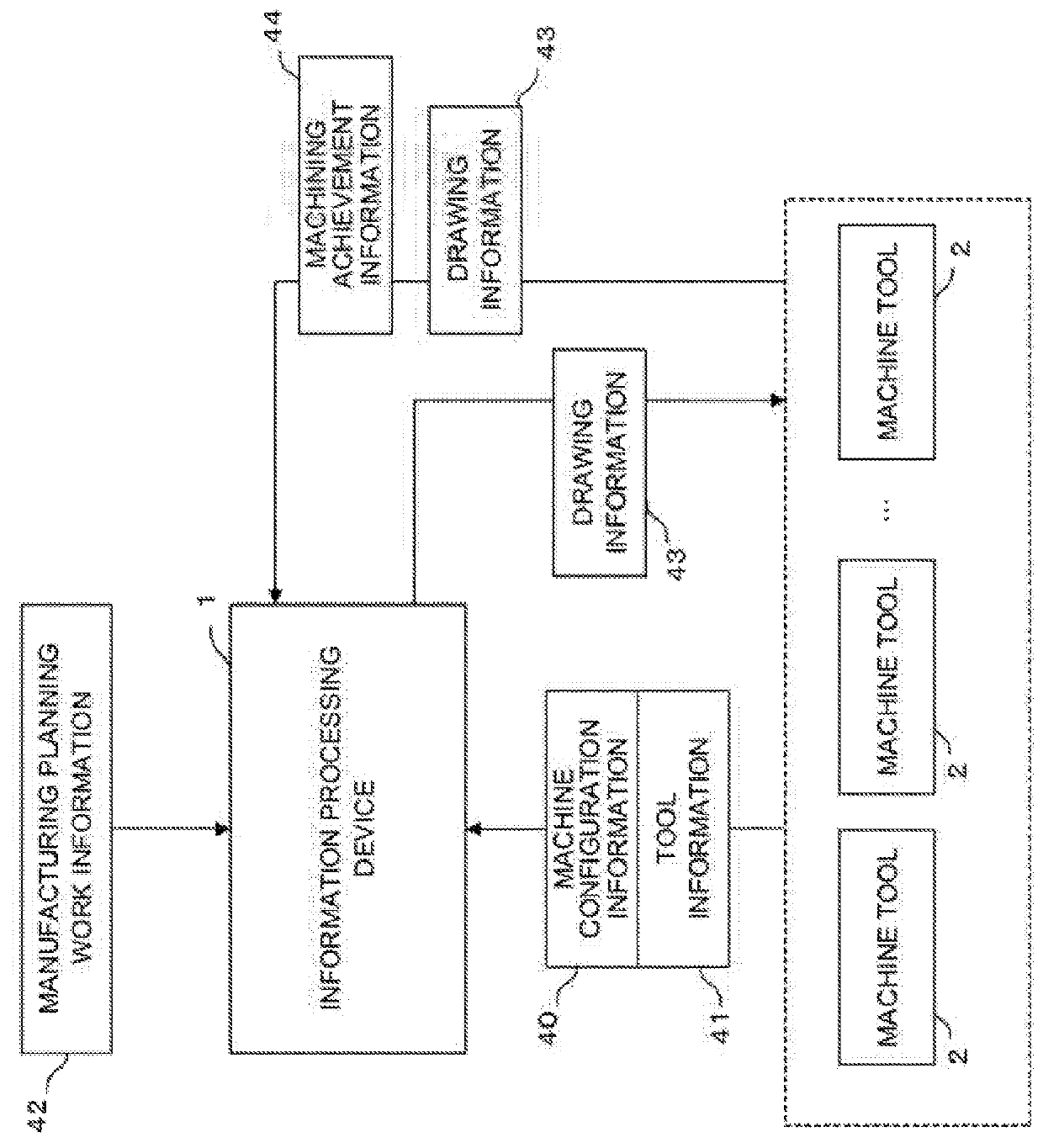

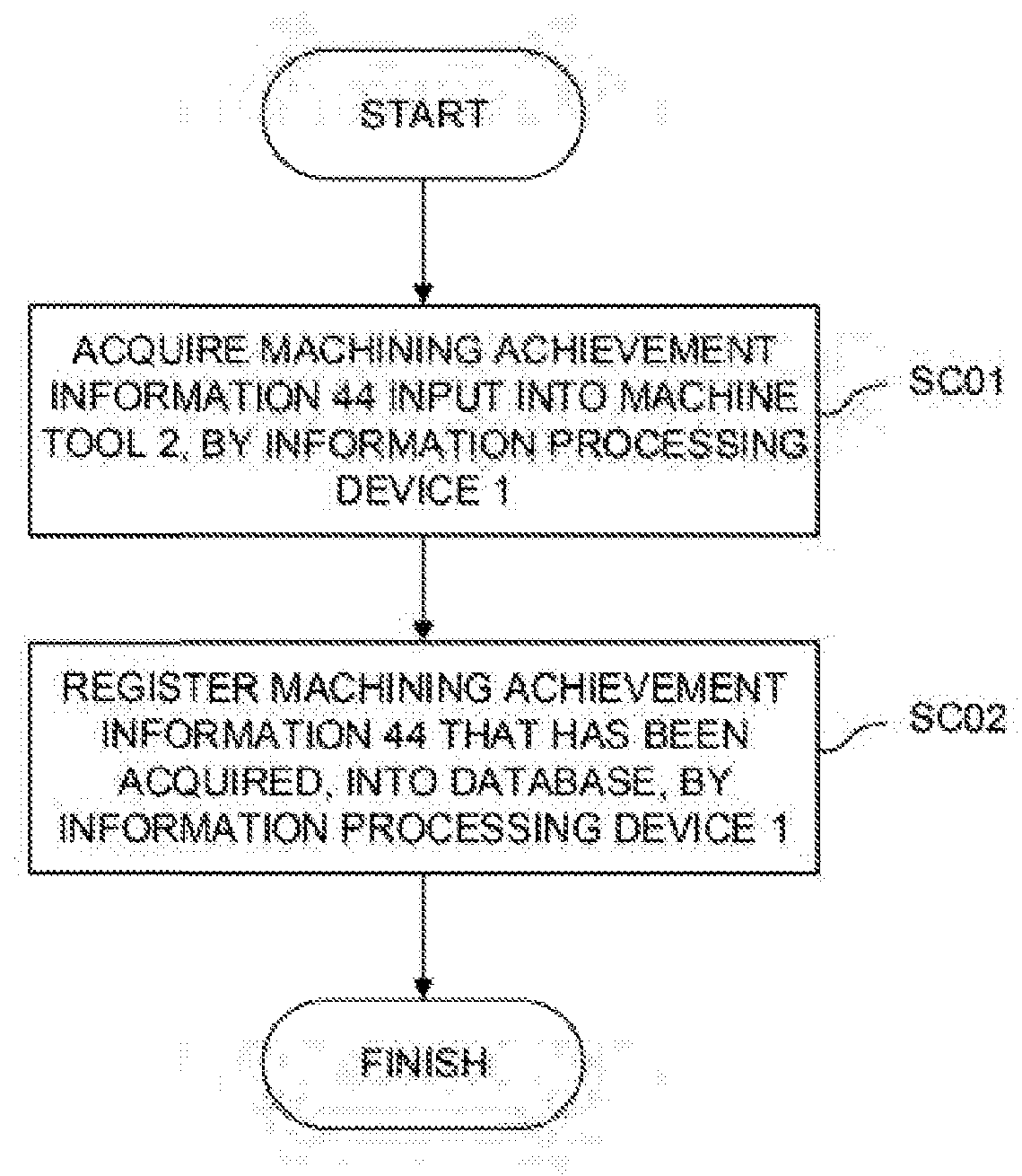

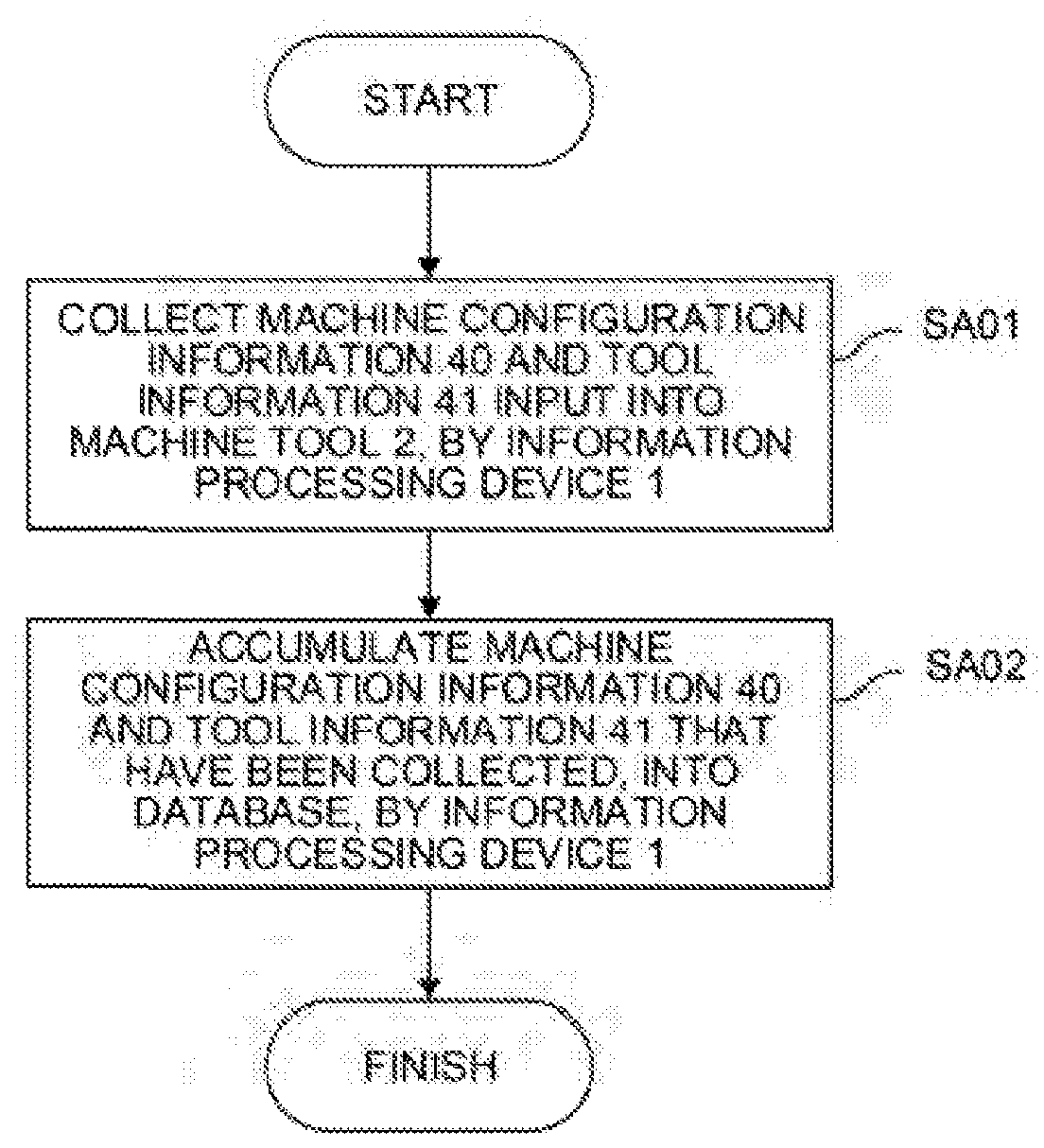

Information processing device

InactiveCN107957707ANo wasteProgramme controlComputer controlInformation processingMachine selection

An information processing device includes: for each of a plurality of machine tools, a machine information database configured to store machine configuration information and tool information of each of the plurality of machine tools, in association with each of the plurality of machine tools; an information collection unit configured to collect and store the machine configuration information and the tool information into the machine information database; a manufacturing planning work information input unit configured to receive manufacturing planning work information; a machine information collation unit configured to collate the manufacturing planning work information with the machine configuration information and the tool information to give a score to each of the plurality of machine tools, based on a result of the collation; and an optimum machine selection unit configured to select an optimum machine tool for machining, based on the score given to each of the plurality of machinetools.

Owner:FANUC LTD

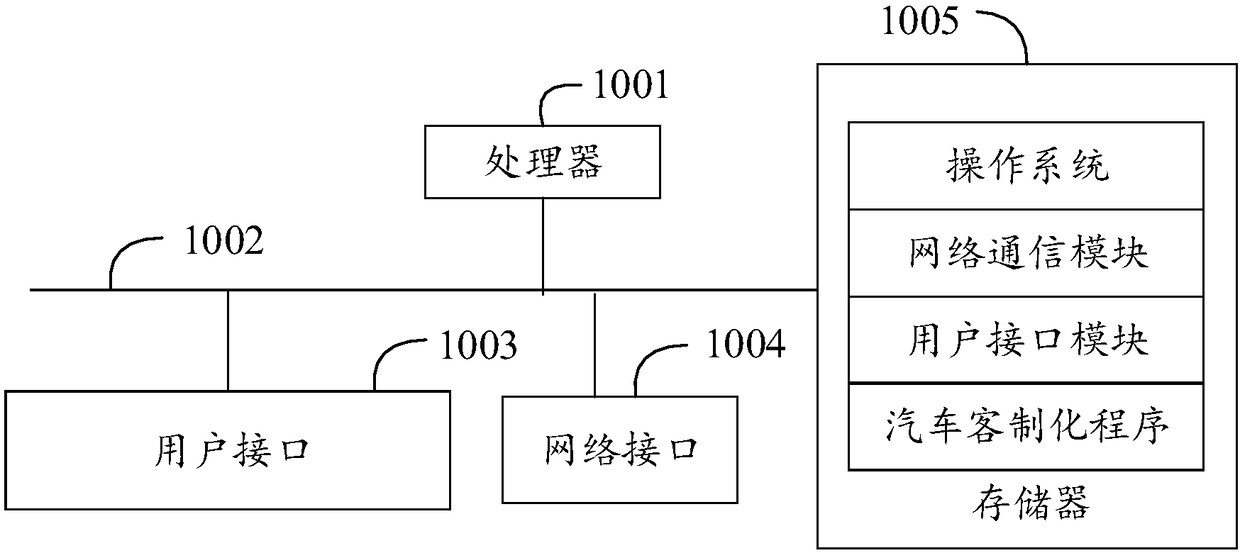

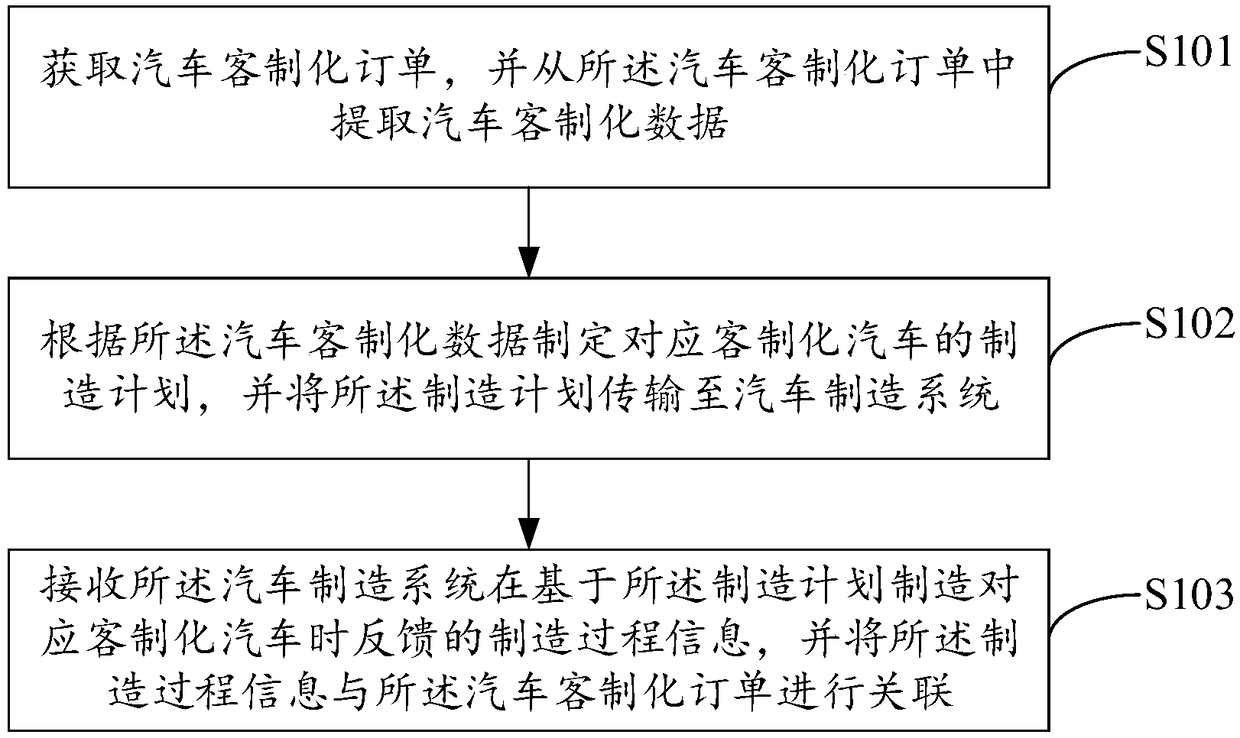

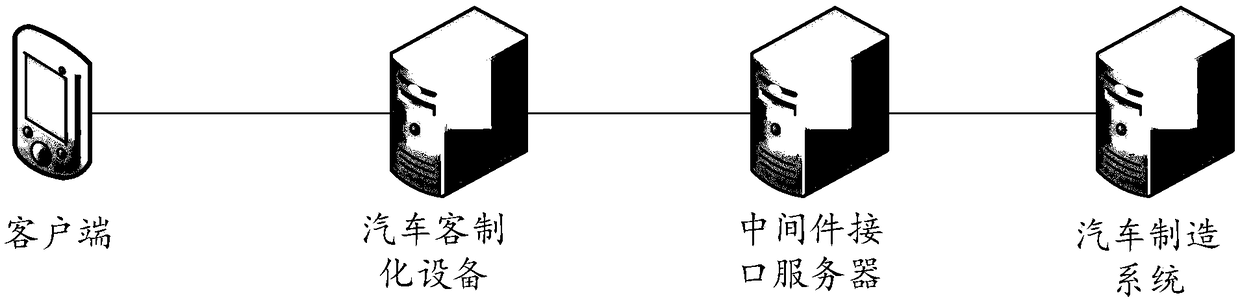

Automobile customization method and equipment and computer readable storage medium

InactiveCN108596722ARealize personalized customizationKnow the manufacturing situationBuying/selling/leasing transactionsManufacturing computing systemsPersonalizationManufacturing planning

The invention discloses an automobile customization method and equipment and a computer readable storage medium. The method comprises the following steps of: obtaining an automobile customization order and extracting automobile customization data from the automobile customization order; making a manufacturing plan of a corresponding customized automobile according to the automobile customization data and transmitting the manufacturing plan to an automobile manufacturing system; and receiving manufacturing process information fed back by the automobile manufacturing system when manufacturing the corresponding customized automobile on the basis of the manufacturing plan, and associating the manufacturing process information with the automobile customization order. The automobile customization order carries the automobile customization data input by a user when the order is submitted, so that the corresponding automobile can be conveniently manufactured by an automobile manufacturer on the basis of the automobile customization data,; and the manufacturing process information is associated with the automobile customization order, so that customers can conveniently know the manufacturing condition of the automobile, and personalized customization of the automobile and visualization of the manufacturing process can be realized in the automobile manufacturing process.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Aircraft assembly system

ActiveUS20180039725A1Efficient assemblyEasy to manufactureGeometric CADConfiguration CADFlight vehicleManufacturing planning

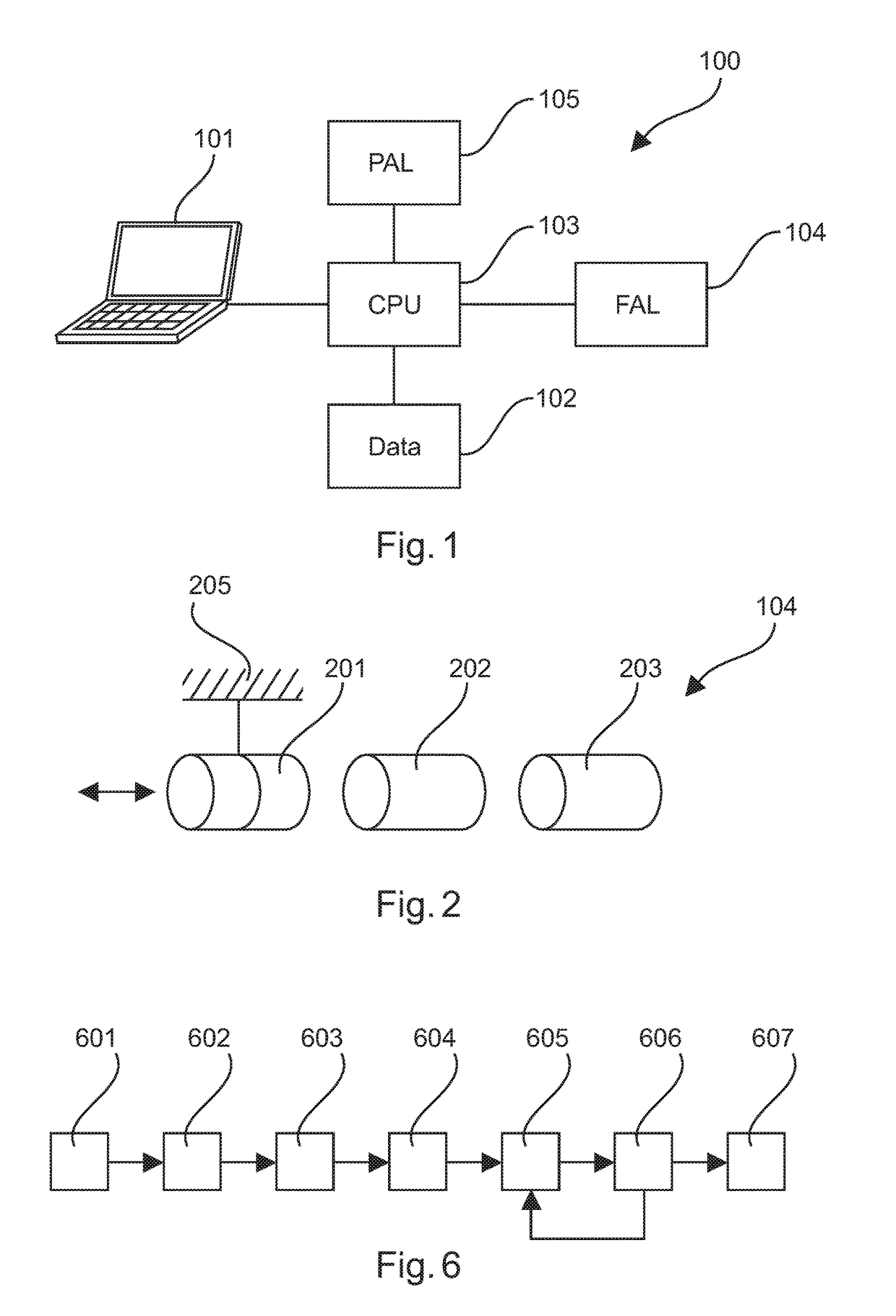

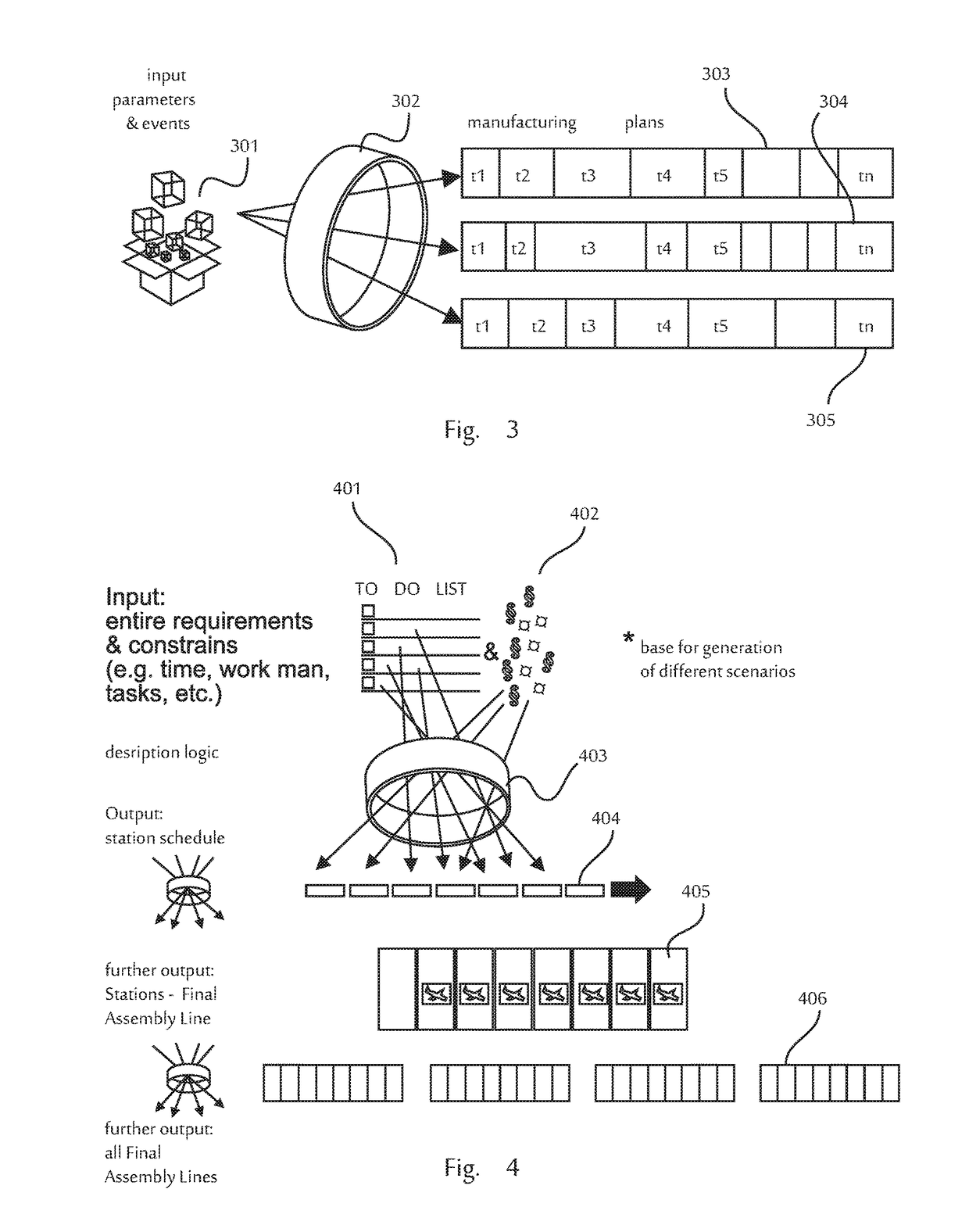

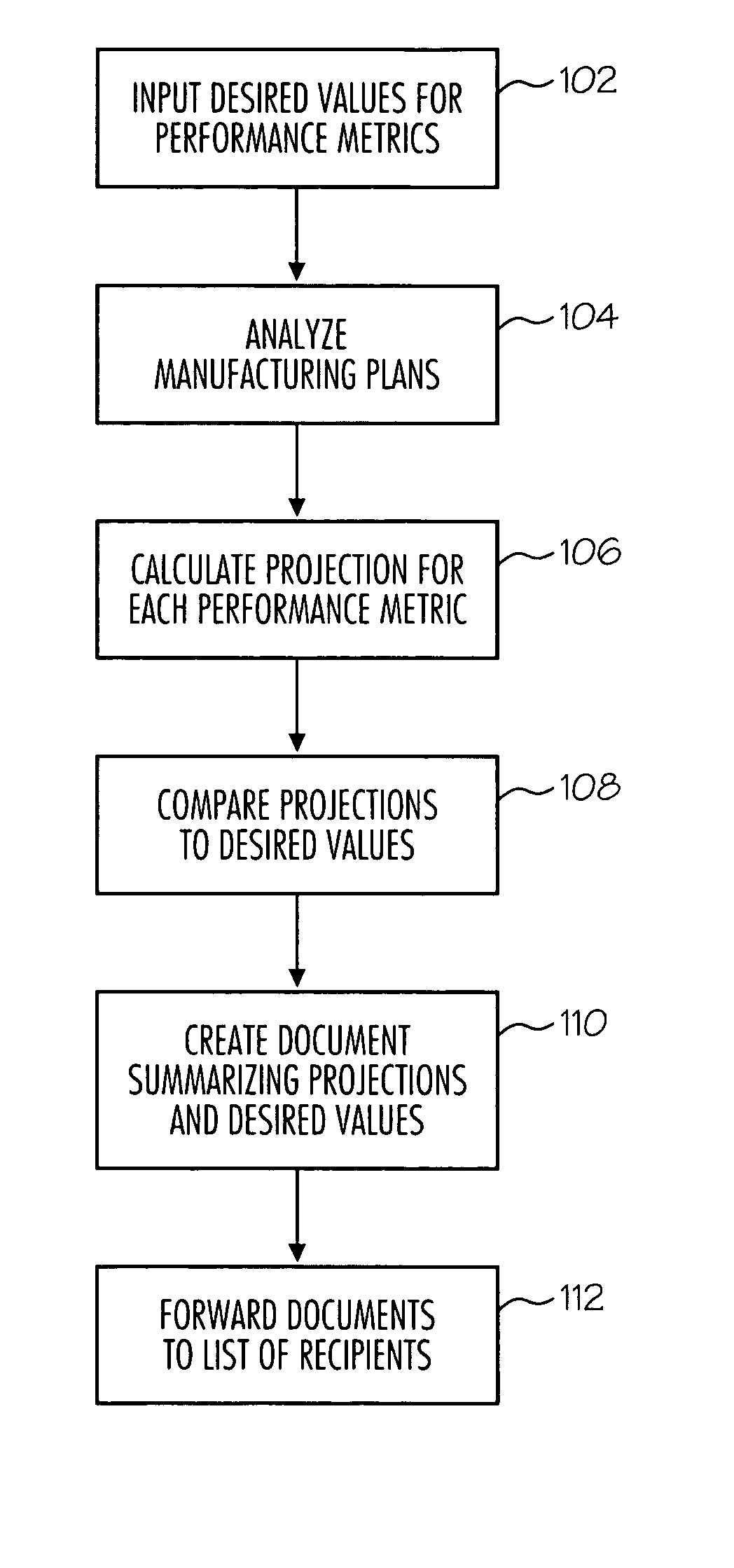

An aircraft assembly system as described herein includes an input module, a database, and a processing unit. The input module is adapted for inputting customer-specific data and, in particular, parameters which relate to the expected time of delivery, the number of personnel working in the aircraft assembly system or an apparatus of the system which cannot be used. By applying description logics, the processing unit generates a manufacturing plan in accordance with a set of rules and the input parameters. In order to improve the manufacturing plan, input parameters may be changed by the system in an iterative process. This may provide for an efficient use of resources available.

Owner:AIRBUS OPERATIONS GMBH

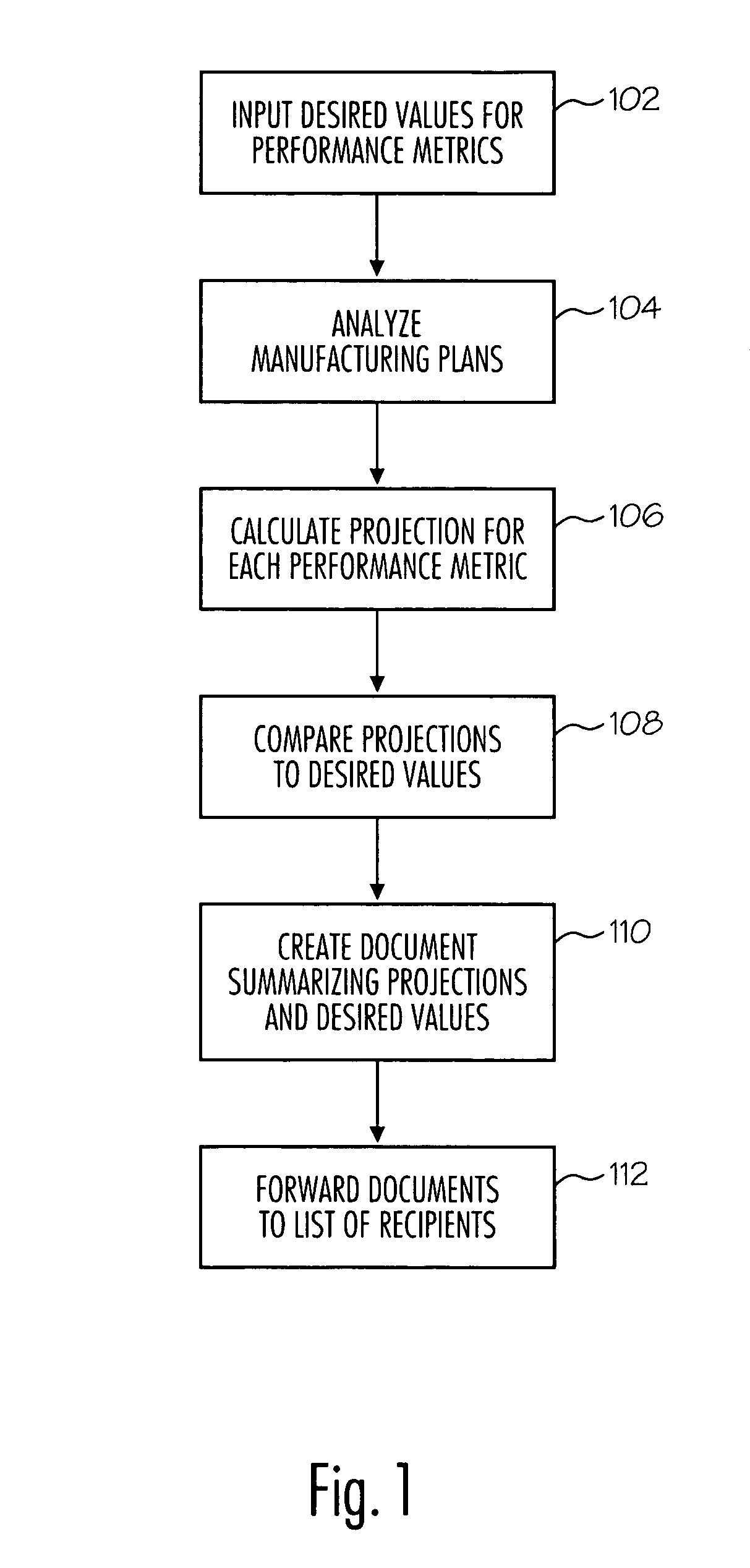

System and method for pro-active manufacturing performance management

A system and method of the present invention allows a user to monitor the production of a factory in real-time. The user inputs desired values for various performance metrics. Then an embodiment of the present invention analyzes manufacturing plans by directly accessing manufacturing planning software. Projections are calculated for each metric and the projections are compared to the desired values. A document is then created summarizing the desired values and the projections. The document may contain hyperlinks that enable a user to view details about any of the performance metrics. The document may also contain formatting that highlights various metrics for a variety of reasons, including the failure to meet a performance metric. The document also allows users to embed comments that are then forwarded to other users, as a means to allow collaboration from a plurality of users.

Owner:CDC SOFTWARE GLOBAL HLDG CORP

Information processing device

InactiveUS20180107197A1Eliminate wasteImprove selection accuracyComputer controlSimulator controlInformation processingMachine selection

An information processing device includes: for each of a plurality of machine tools, a machine information database configured to store machine configuration information and tool information of each of the plurality of machine tools, in association with each of the plurality of machine tools; an information collection unit configured to collect and store the machine configuration information and the tool information into the machine information database; a manufacturing planning work information input unit configured to receive manufacturing planning work information; a machine information collation unit configured to collate the manufacturing planning work information with the machine configuration information and the tool information to give a score to each of the plurality of machine tools, based on a result of the collation; and an optimum machine selection unit configured to select an optimum machine tool for machining, based on the score given to each of the plurality of machine tools.

Owner:FANUC LTD

Workshop production system based on Internet of Things and implementation method thereof

InactiveCN112508377AIncrease productivityReduce labor costsDatabase queryingResourcesManufacturing planningThe Internet

The invention provides a workshop production system based on the Internet of Things and an implementation method thereof. An intelligent and flexible system integrating manufacturing planning and production process management is constructed. According to the integrated system, through integration of software and hardware, the production efficiency is effectively improved, an easy-to-operate, easy-to-manage and high-efficiency production platform is built in the traditional manufacturing industry, the traditional industrial pattern and a rough development model are changed, three-dimensional digitization of the production process can be achieved through software and hardware integration, and therefore, production efficiency is improved, labor requirements are reduced, production period is shortened, and product quality is guaranteed.

Owner:陕西镁好互联网技术有限公司

System and method of manufacturing an additively manufactured object

ActiveUS11141922B2Increasing energy efficiency3D object support structuresManufacturing planningProcess engineering

Owner:POSTPROCESS TECH INC

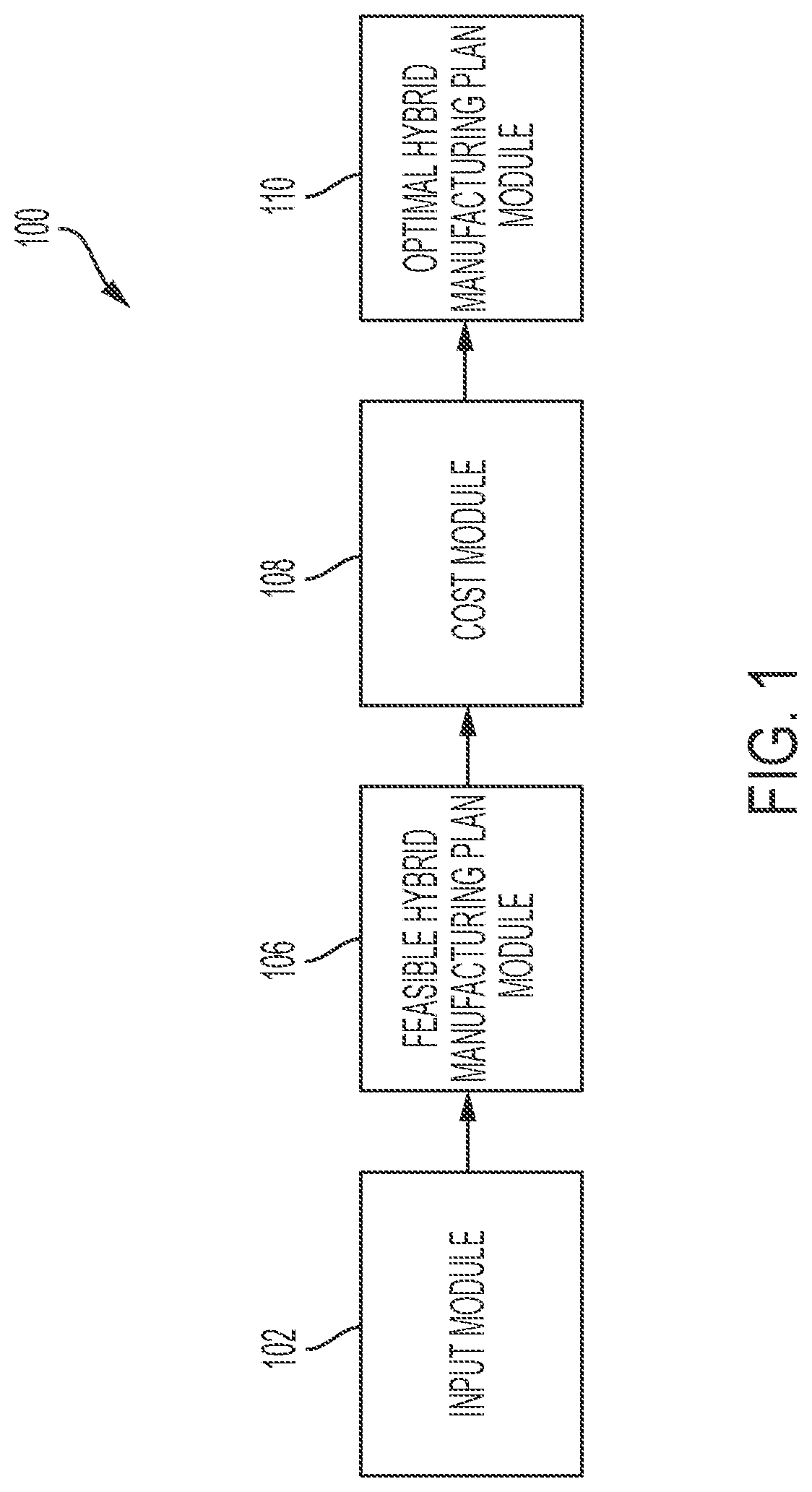

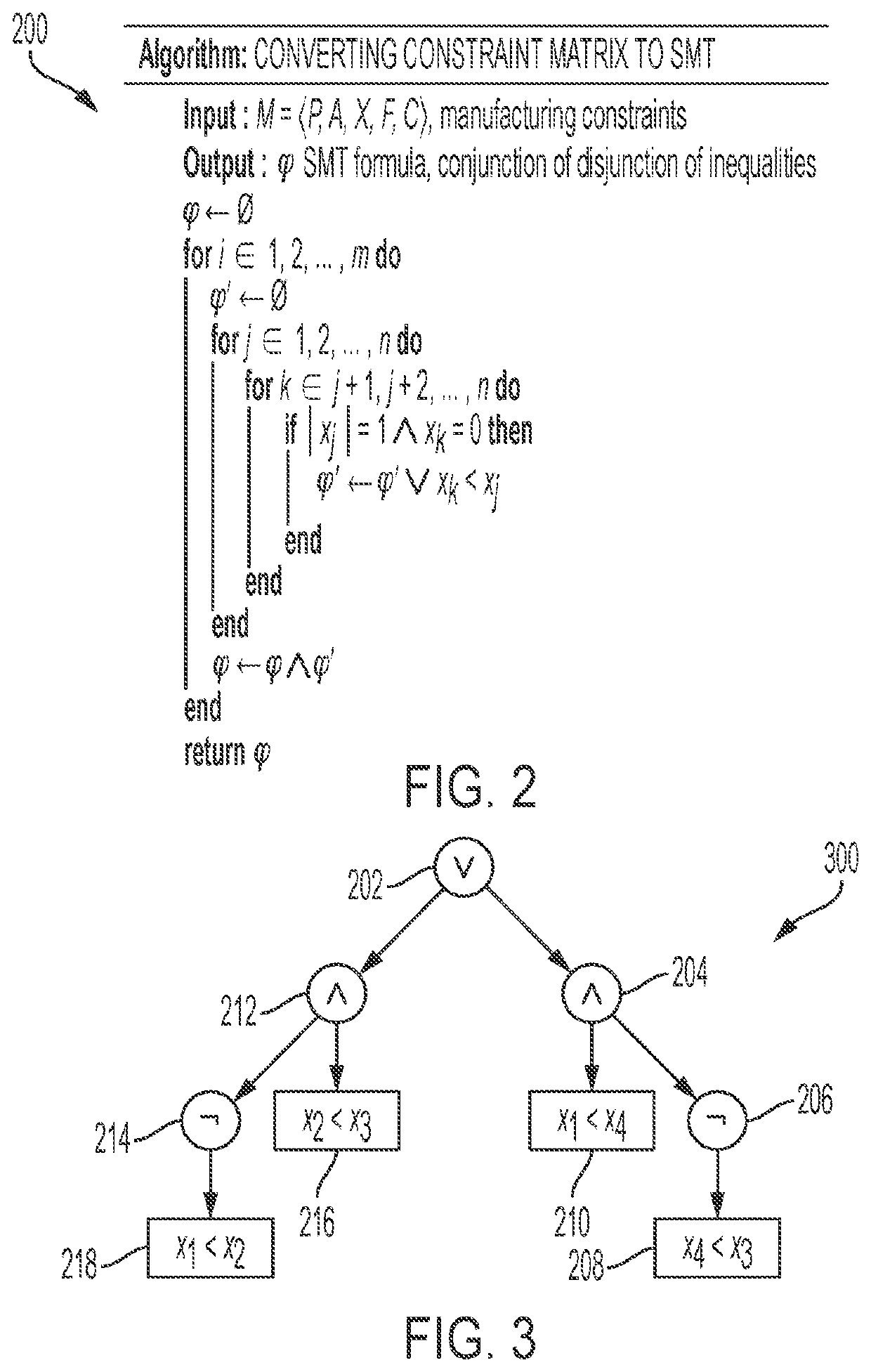

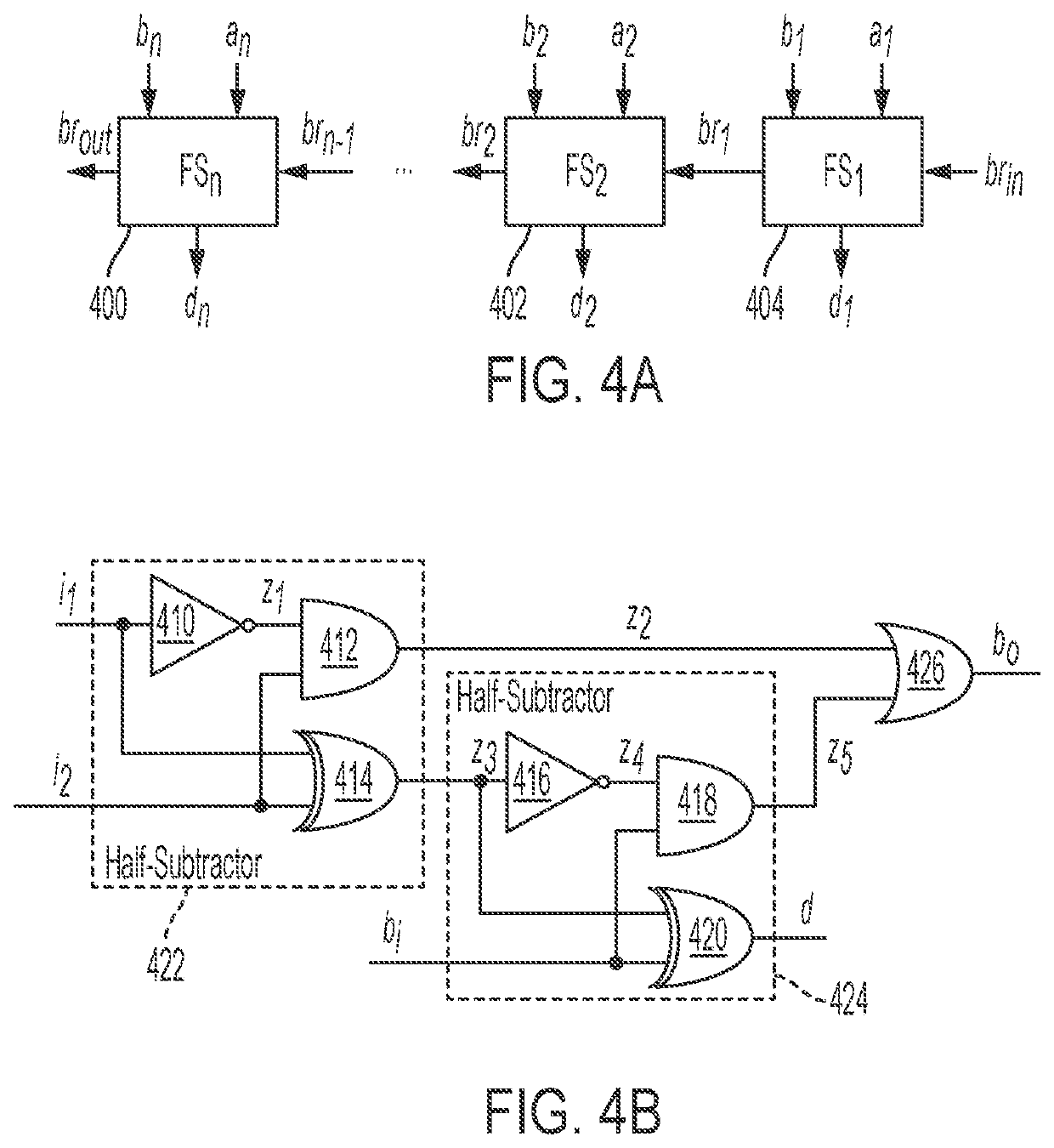

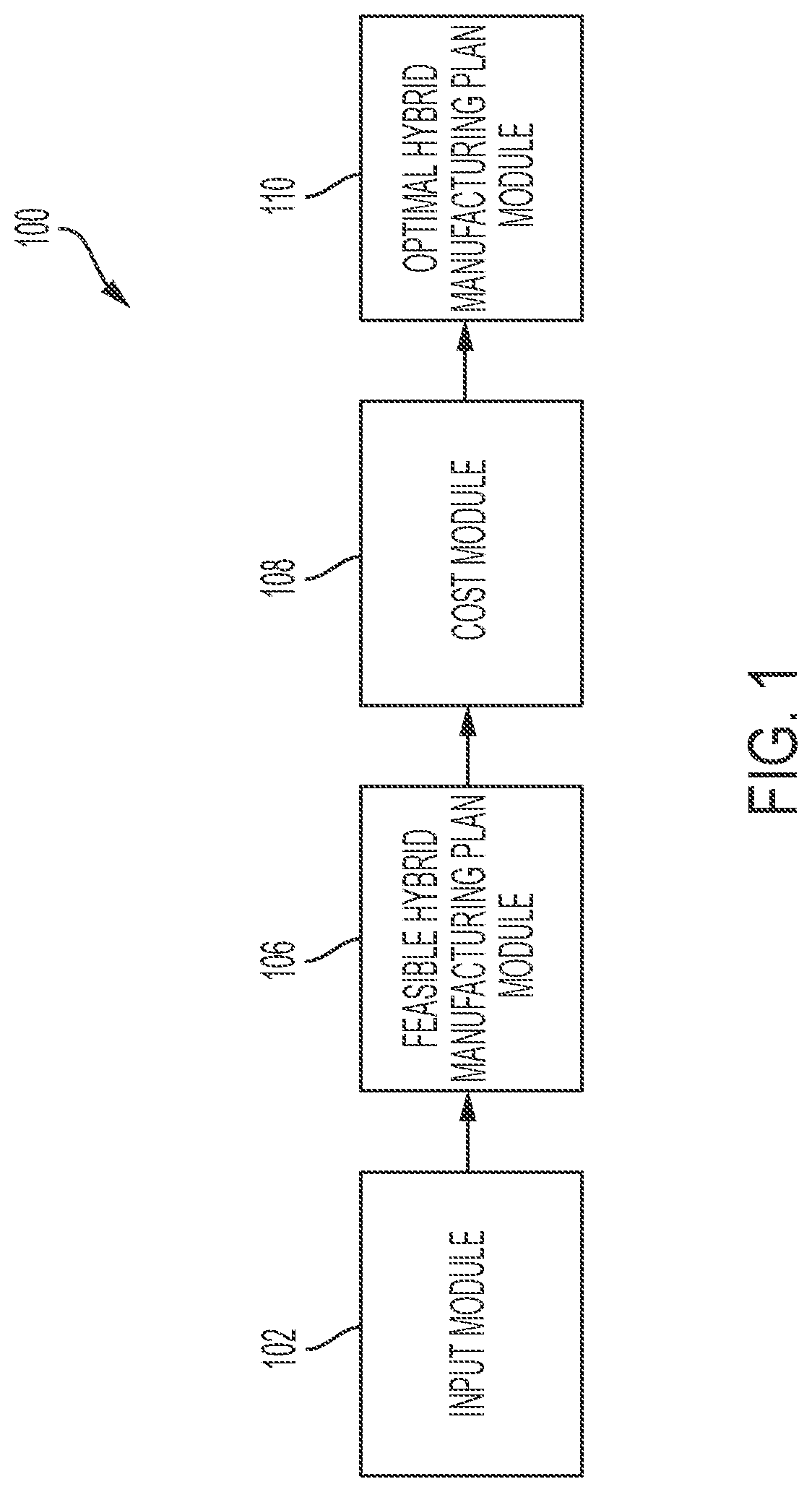

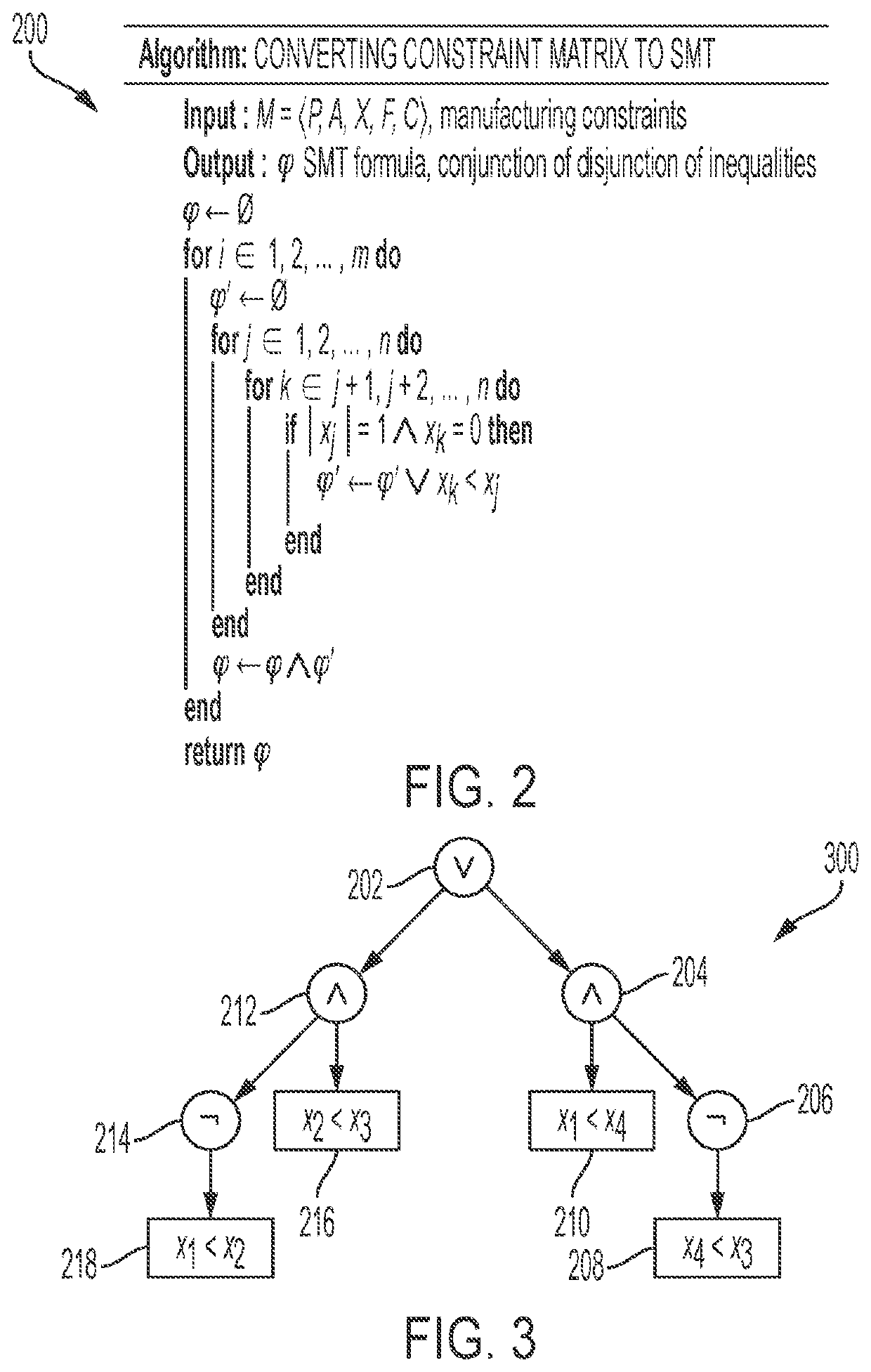

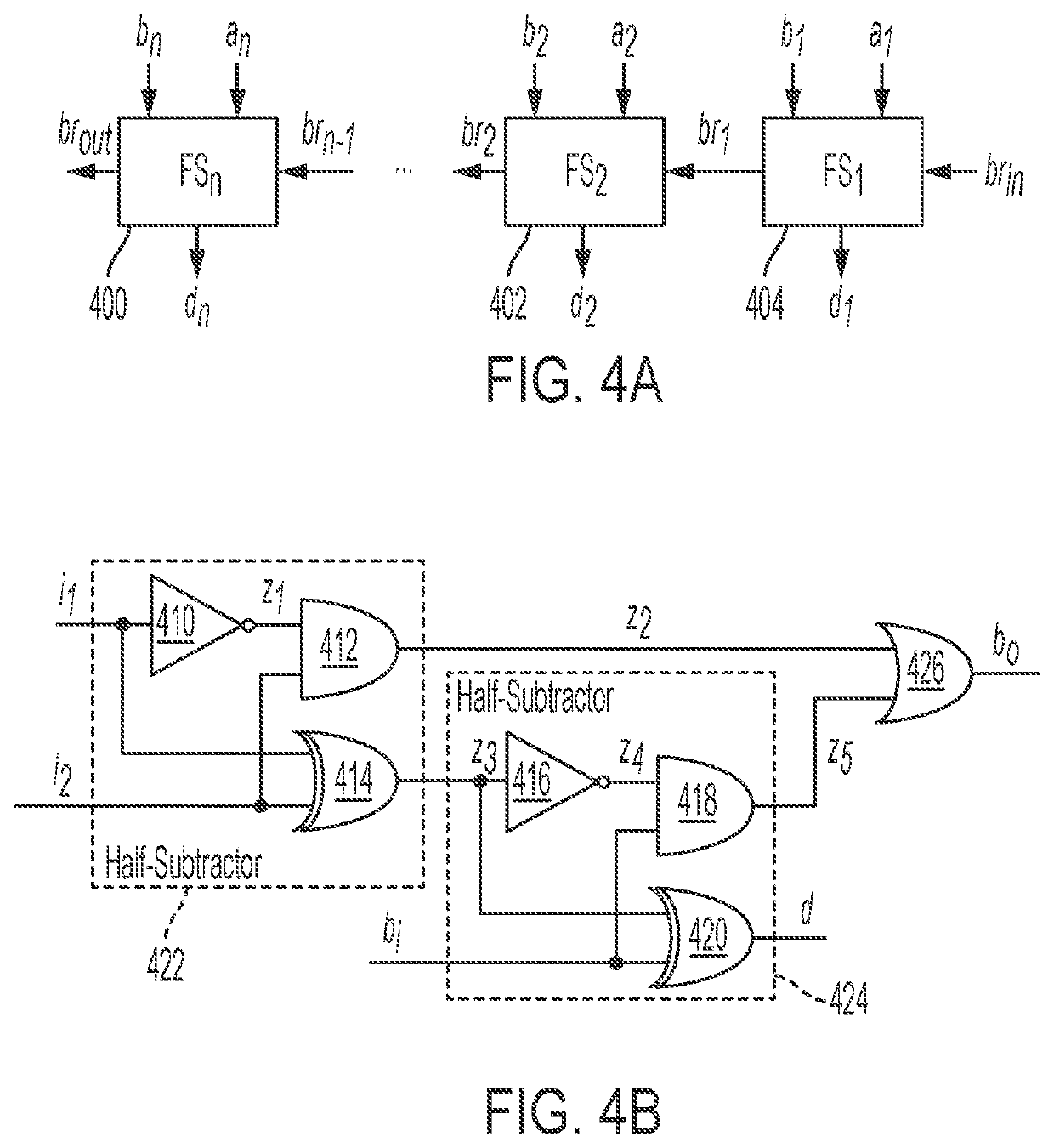

System and method for determining hybrid-manufacturing process plans for integrated circuits based on satisfiability modulo difference logic solver

ActiveUS11157672B1Computer designed circuitsProcessing steps orderManufacturing technologyManufacturing planning

One embodiment of the present disclosure provides a system for determining a hybrid-manufacturing plan for manufacturing an integrated circuit (IC). During operation, the system can obtain a set of hybrid-manufacturing constraints for manufacturing the IC. The set of hybrid-manufacturing constraints can include a set of primitives, a set of atoms, and an atom end-state vector. An atom can correspond to a unit of spatial volume of the IC. A primitive can represent an additive, subtractive, or a mixed manufacturing process corresponding to one or more atoms of the IC. Next, the system can determine a plurality of feasible hybrid-manufacturing plans based on the set of manufacturing constraints. Each feasible hybrid-manufacturing plan can represent an ordering of the set of primitives that satisfies the atom end-state vector. The system can then determine costs for manufacturing the IC using the plurality feasible hybrid-manufacturing plans. The system can determine, based on the costs, an optimized hybrid-manufacturing plan for manufacturing the IC.

Owner:XEROX CORP

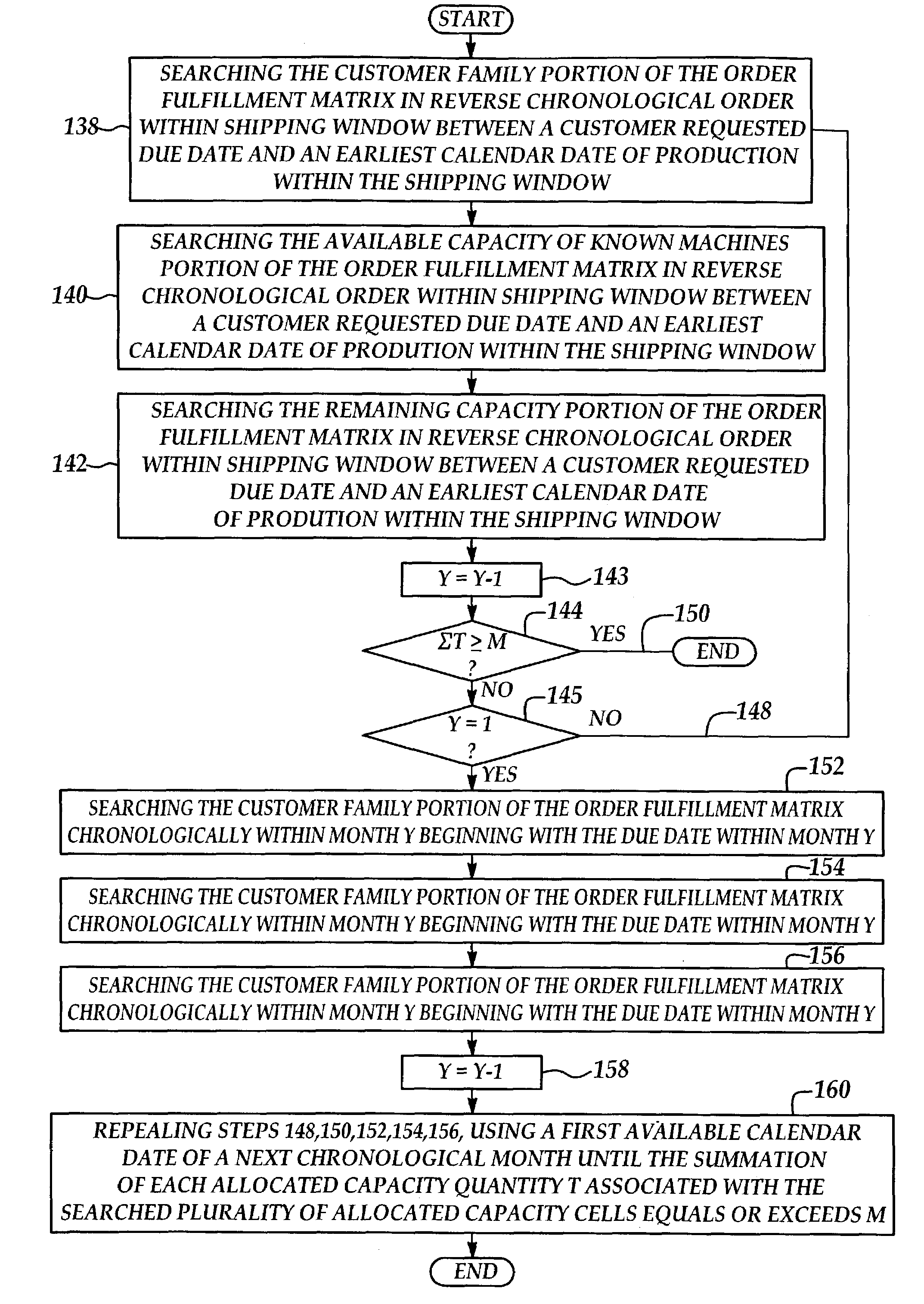

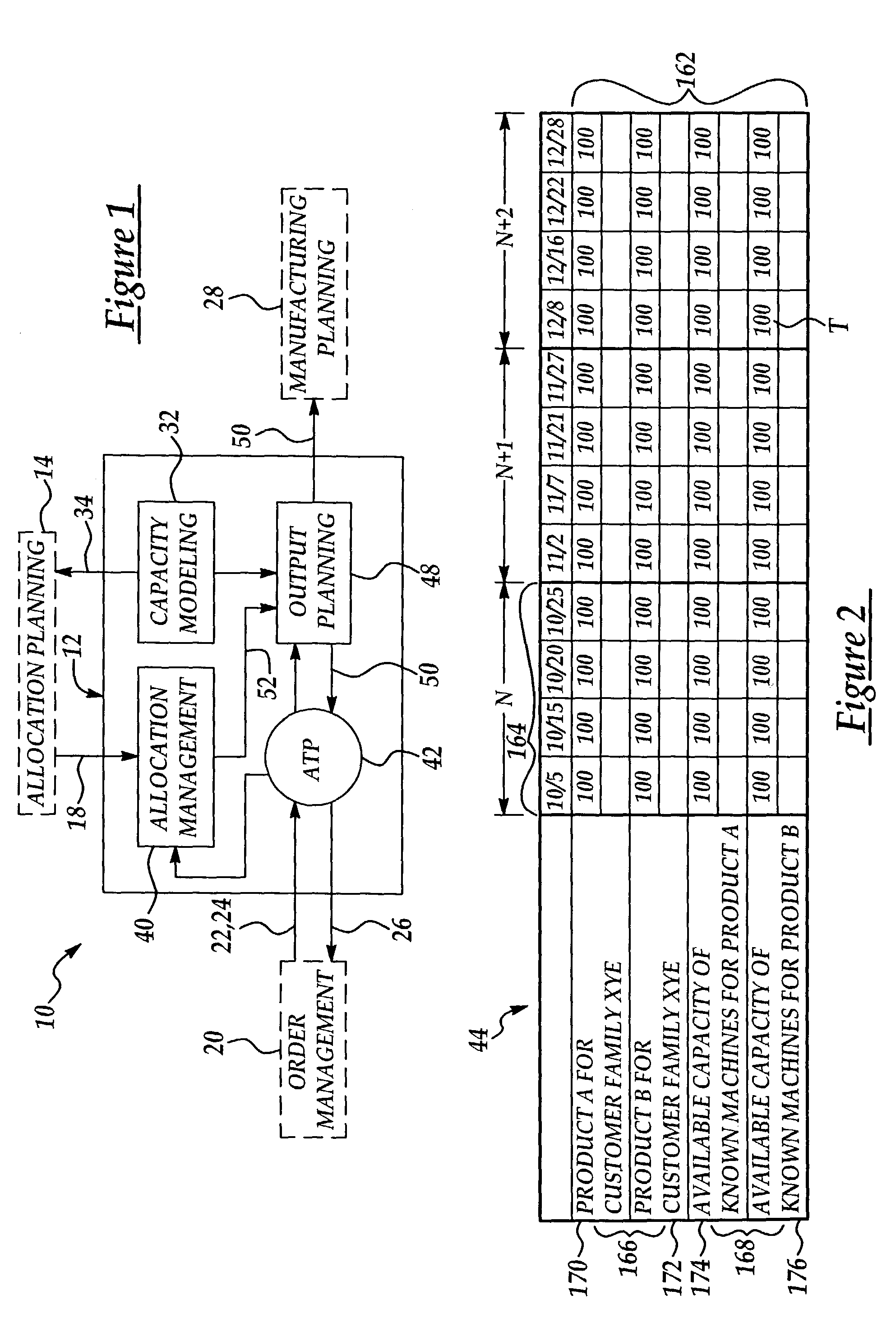

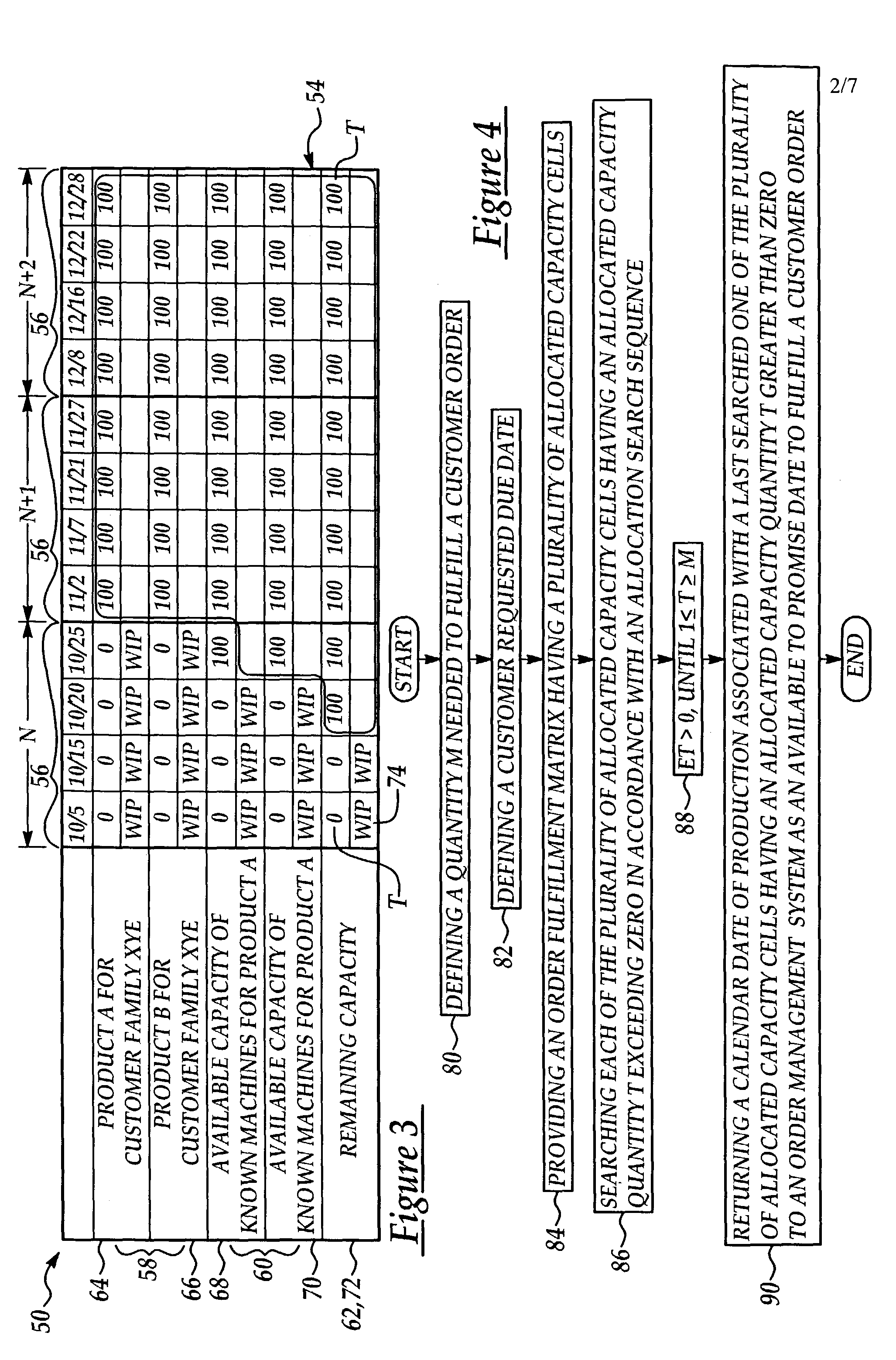

Automated supply management method for dynamically fulfilling a customer requested order

InactiveUS7389249B2Quality improvementEliminate the effects ofResourcesLogisticsOrder fulfillmentSupply management

An automated supply management system for dynamically fulfilling a customer requested order having an order fulfillment system for fulfilling a plurality of customer requests in accordance with a plurality of processing capacity restraints defined for a plurality of pieces of manufacturing equipment disposed within a manufacturing facility; an allocation planning system for receiving a plurality of capacity modeling data from the order fulfillment system, an order management system for communicating a plurality of consumption data and a customer requested due date to the order fulfillment system, wherein the order management system requests the customer requested due date and receives a calendar date of production available to promise from the order fulfillment system; and a manufacturing planning system for receiving an order fulfillment matrix from the order fulfillment system.

Owner:TAIWAN SEMICON MFG CO LTD

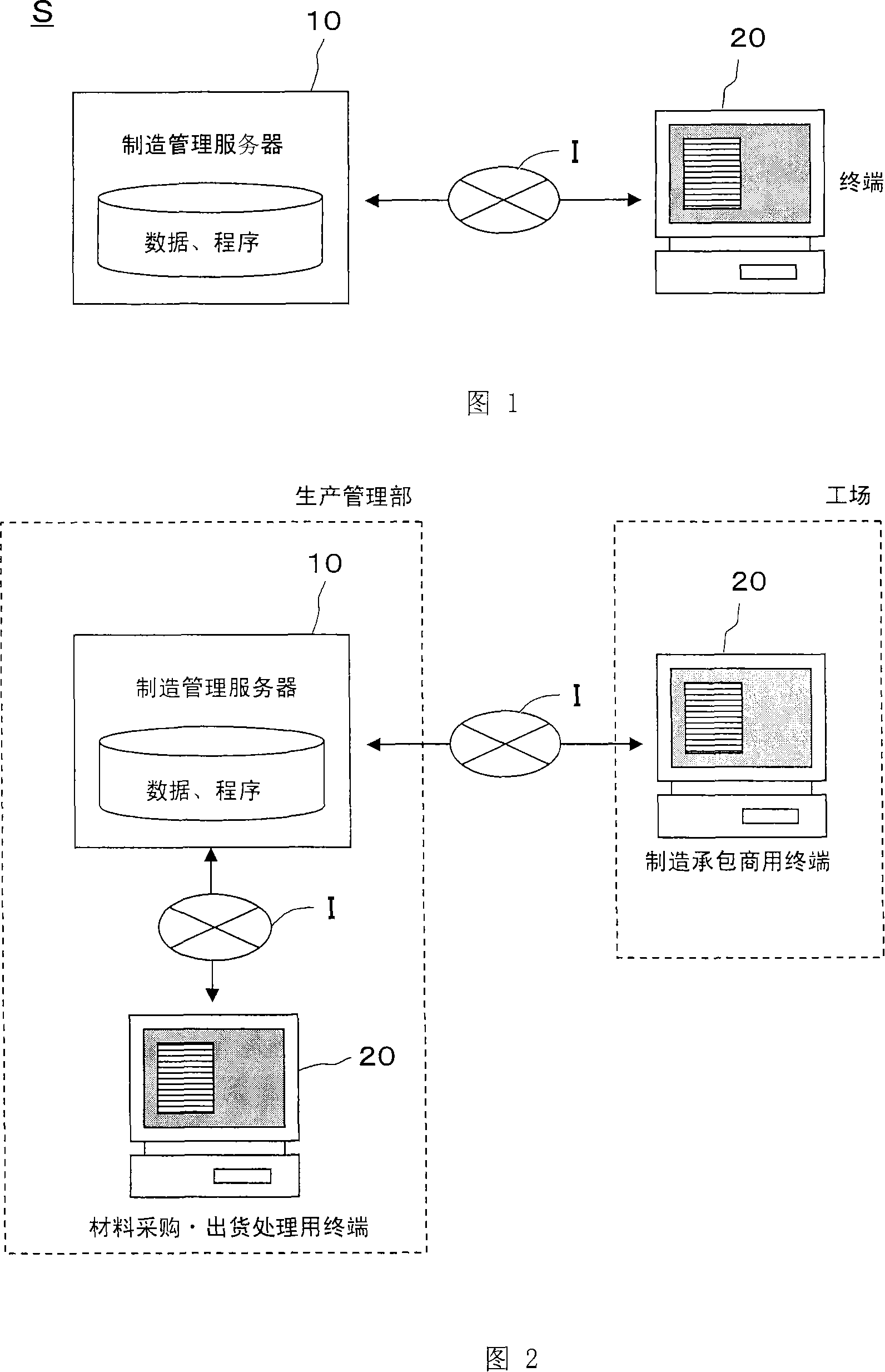

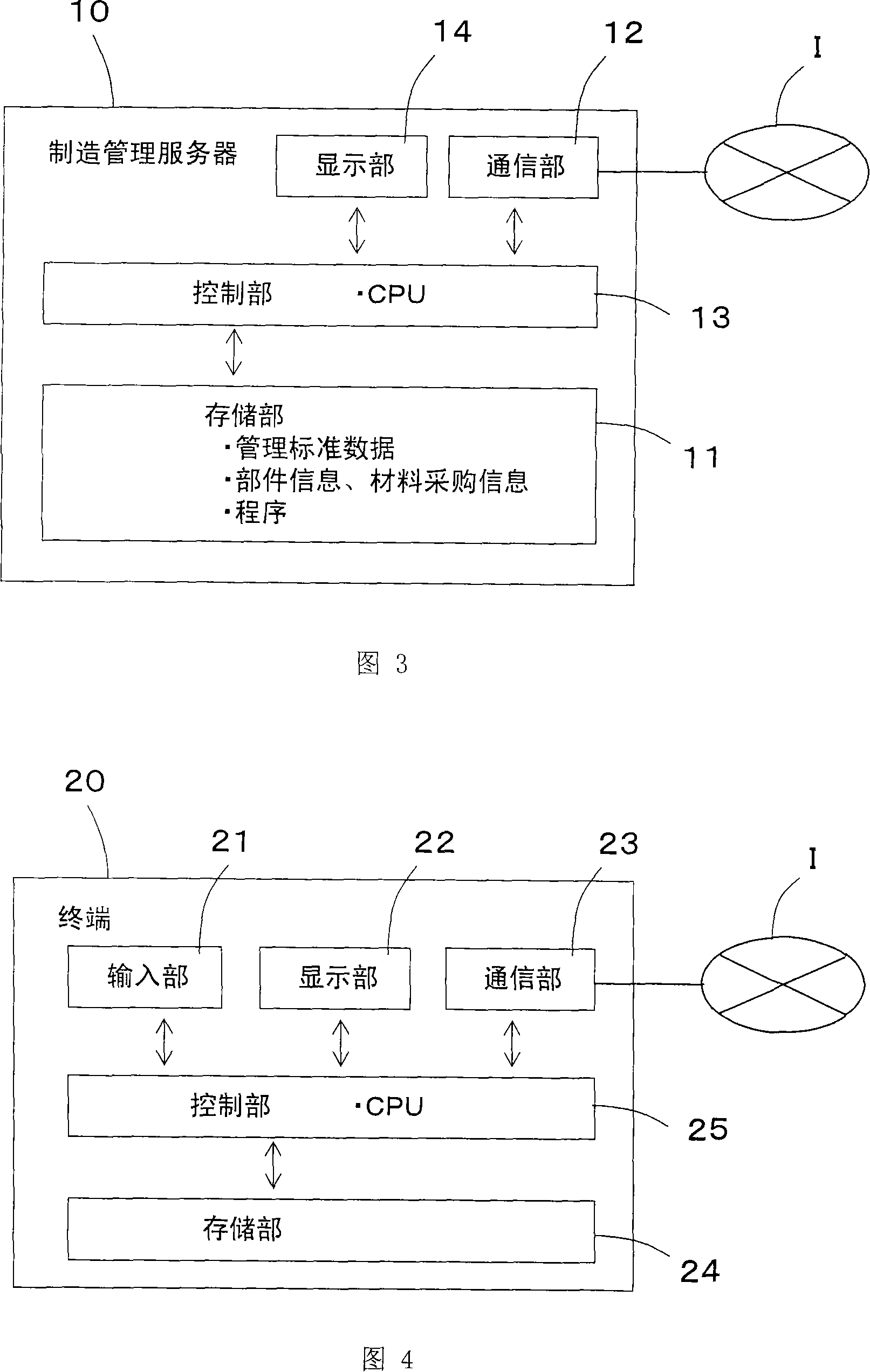

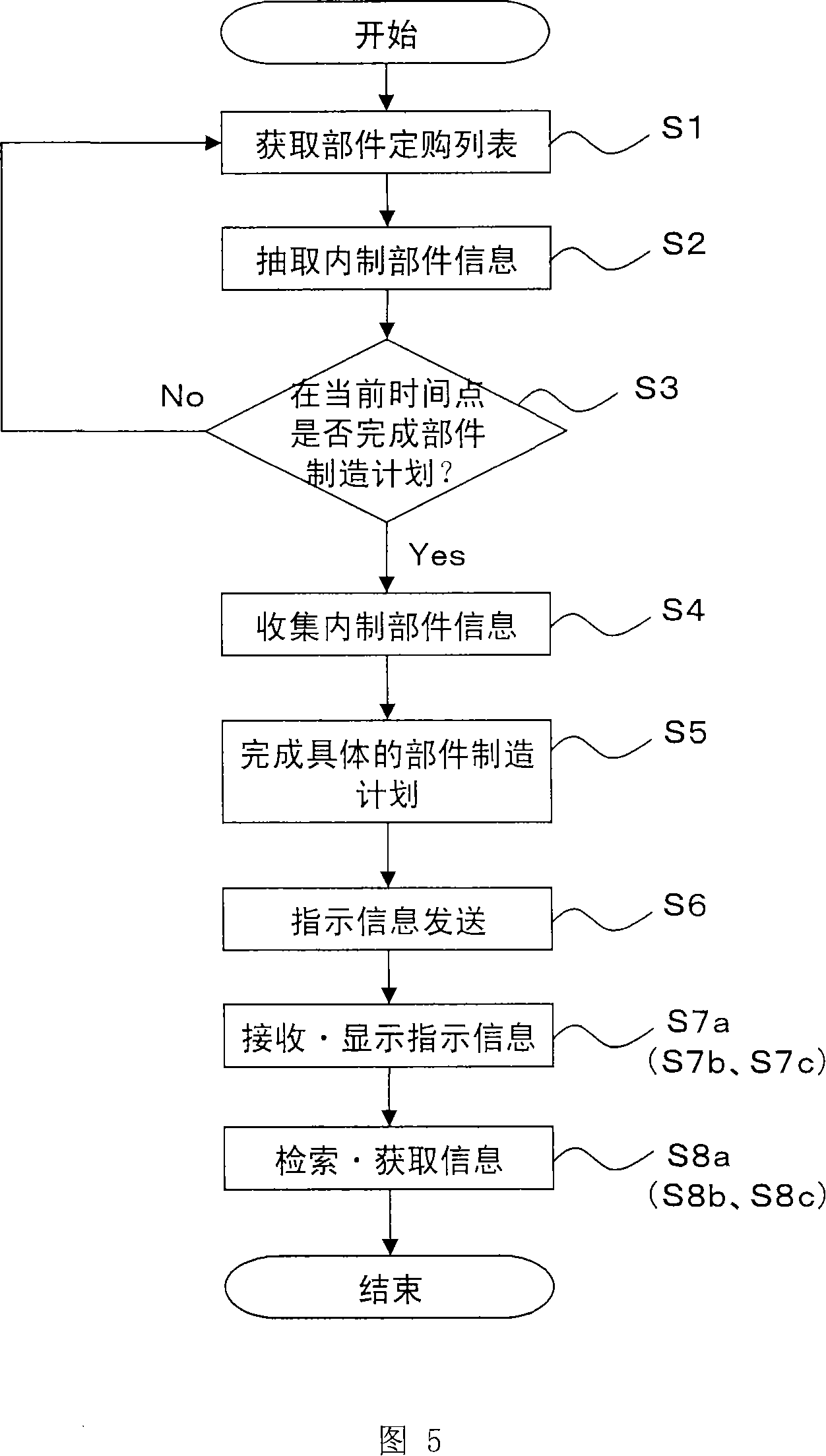

Production/shipment system and method

InactiveCN101151627AAvoid wastingEfficient collection and storageResourcesManufacturing planningComputer terminal

A manufacturing managing server 10 is stored beforehand with the data of various managing standard relative to the component manufacturing. Besides, various component information and material purchasing information are stored. The manufacturing managing server 10 receives the component purchasing list completed in previous procedure, abstracts and collects the component manufactured in the plant and completes the specific component manufacturing plane. Besides, the manufacture indicating information is transmitted to the terminal 20 of the manufacturing contractor in the plant. Besides, the material purchasing indication and discharging indication are transmitted to the terminal 20 of each manager. The manufacturing contractor, material purchasing manger and discharging manager obtain information from the manufacturing managing server 10 according to the requisition.

Owner:DAIWA HOUSE IND

System and method for determining hybrid-manufacturing process plans based on satisfiability modulo difference logic solver

ActiveUS11386509B2Geometric CADAdditive manufacturing apparatusManufacturing technologyManufacturing planning

One embodiment of the present disclosure provides a system for determining a hybrid-manufacturing plan for manufacturing an object. During operation, the system can obtain a set of hybrid-manufacturing constraints for manufacturing the object. The set of hybrid-manufacturing constraints can include a set of primitives, a set of atoms, and an atom end-state vector. An atom can correspond to a unit of spatial volume of the object. A primitive can represent an additive or a subtractive manufacturing process corresponding to one or more atoms of the object. Next, the system can determine a plurality of feasible hybrid-manufacturing plans based on the set of hybrid-manufacturing constraints. Each feasible hybrid-manufacturing plan can represent an ordering of the set of primitives that satisfies the atom end-state vector. The system can then determine costs for manufacturing the object using the plurality feasible hybrid-manufacturing plans. The system can determine, based on the costs, an optimized hybrid-manufacturing plan for manufacturing the object.

Owner:XEROX CORP

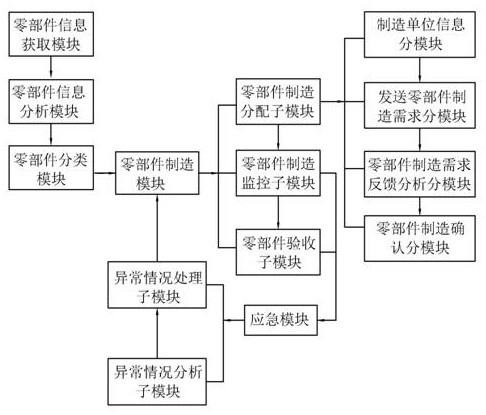

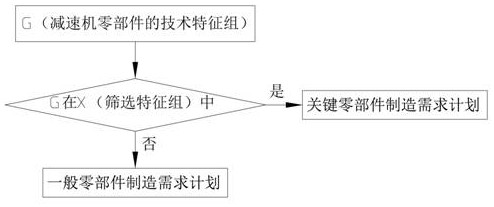

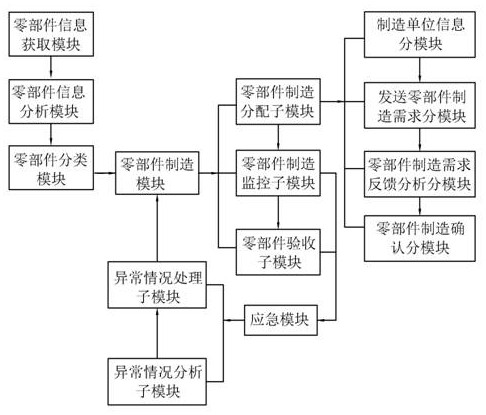

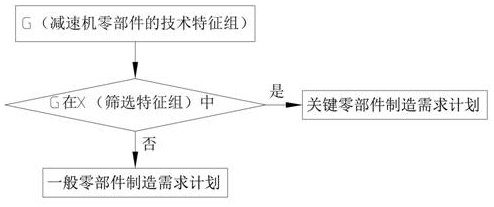

Intelligent interaction platform for manufacturing parts of speed reducer and interaction method of intelligent interaction platform

ActiveCN114186899AIncrease profitIncrease productivityCharacter and pattern recognitionResourcesManufacturing planningBusiness enterprise

According to the intelligent interaction platform for manufacturing the parts of the speed reducer and the interaction method of the intelligent interaction platform, various production resources inside and outside an enterprise are reasonably configured according to customized speed reducer manufacturing requirements, the parts of the speed reducer are intelligently managed in a graded mode and manufactured according to requirements, the utilization rate of the various resources is increased, and the production cost of products is reduced; and meanwhile, the production efficiency of products is improved. According to the specific scheme, an interactive management system, more than one key part manufacturing unit and more than one general part manufacturing unit are arranged; the key part manufacturing unit is used for receiving a key part manufacturing demand plan of the interactive management system and feeding back a manufacturing intention, and executing a manufacturing plan of the key parts of the speed reducer according to an instruction of the interactive management system; and the general part manufacturing unit is used for receiving a general part manufacturing demand plan of the interactive management system, feeding back a manufacturing intention and executing a manufacturing plan of general parts of the speed reducer according to an instruction of the interactive management system.

Owner:HANGZHOU JIE DRIVE TECH

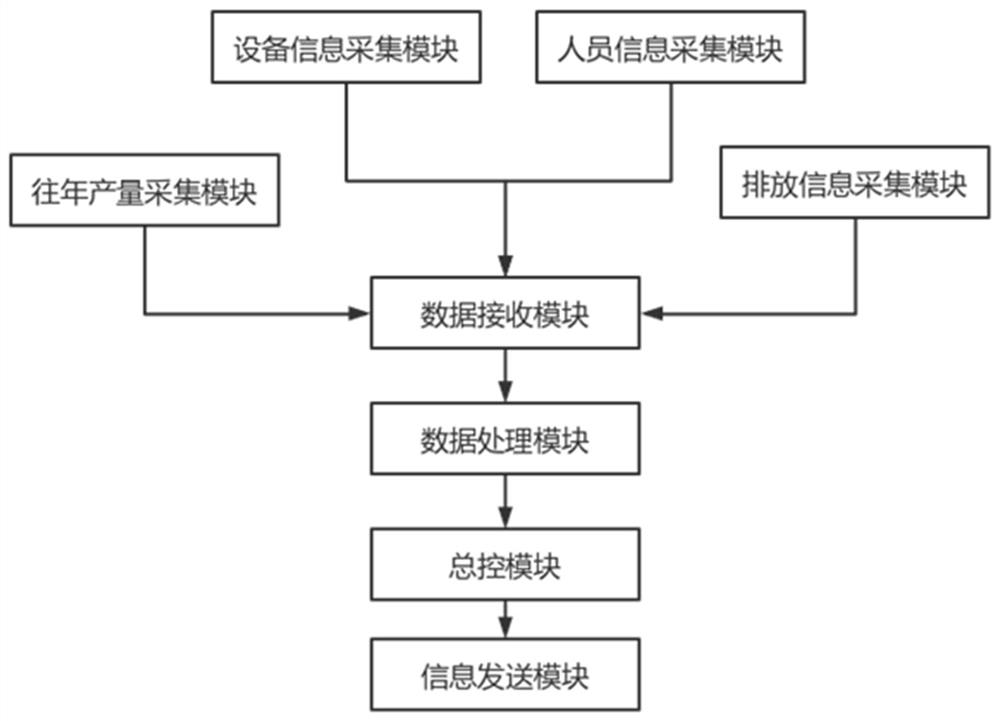

Glass deep processing manufacturing process planning system and method

PendingCN114862193ATimely repair and maintenanceTimely replacementResourcesComplex mathematical operationsTime informationManufacturing planning

The invention discloses a planning system and method for a deep processing and manufacturing process of glass. The planning system comprises a previous year yield acquisition module, an equipment information acquisition module, a personnel information acquisition module, an emission information acquisition module, a data receiving module, a data processing module, a master control module and an information sending module. The previous year yield acquisition module is used for acquiring annual yield information in a previous preset year; the equipment information acquisition module is used for acquiring production equipment information, and the production equipment information comprises equipment use time information, equipment maintenance information and equipment fault information; the personnel information acquisition module is used for acquiring production personnel information, and the production personnel information comprises the number of research and development personnel, the number information of processing personnel and the working duration information of the processing personnel. According to the invention, related information of the glass deep processing factory can be collected more comprehensively, so that more comprehensive processing and manufacturing planning is carried out, and different use requirements are met.

Owner:深圳市晶泰玻璃科技有限公司

Intelligent interactive platform and interactive method of reducer parts manufacturing

ActiveCN114186899BIncrease profitIncrease productivityCharacter and pattern recognitionResourcesManufacturing planningBusiness enterprise

Owner:HANGZHOU JIE DRIVE TECH

System And Method Of Manufacturing An Additively Manufactured Object

ActiveUS20220040929A1Increasing energy efficiency3D object support structuresManufacturing planningProcess engineering

Owner:POSTPROCESS TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com