Method and apparatus for planning a manufacturing schedule using an adaptive learning process

a manufacturing schedule and learning process technology, applied in the field of information processing apparatus and methods, can solve the problems of inability to plan an efficient manufacturing process, inability to apply critical know-how, and increasing challenges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]In the following description, for purposes of explanation, numerous specific details are set forth to provide a thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that these specific details may not be required to practice the present invention. In other instances, well-known circuits and devices are shown in block diagram form to avoid obscuring the present invention.

[0021]In the following description of the embodiments, substantially the same parts are denoted by the same reference numerals.

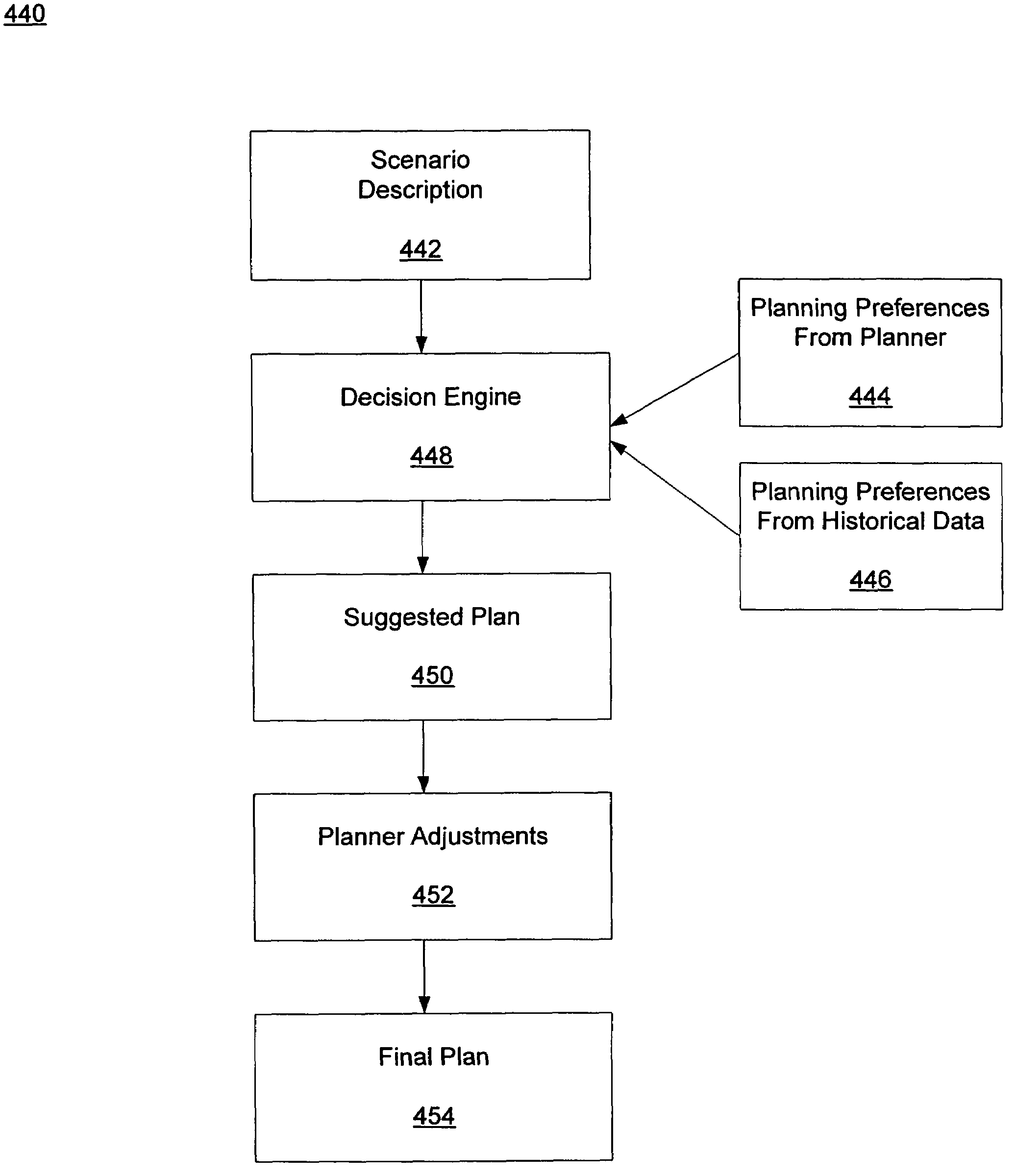

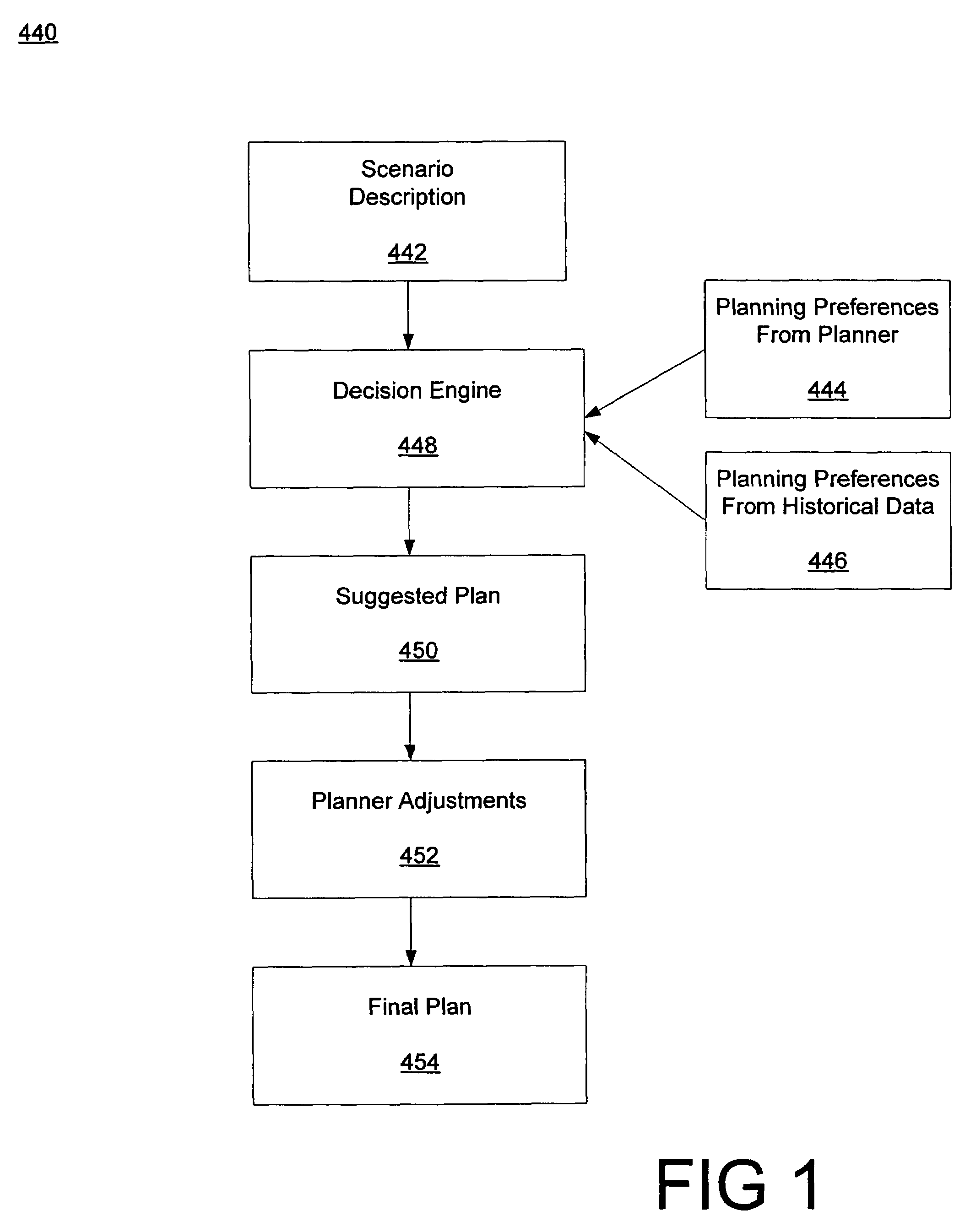

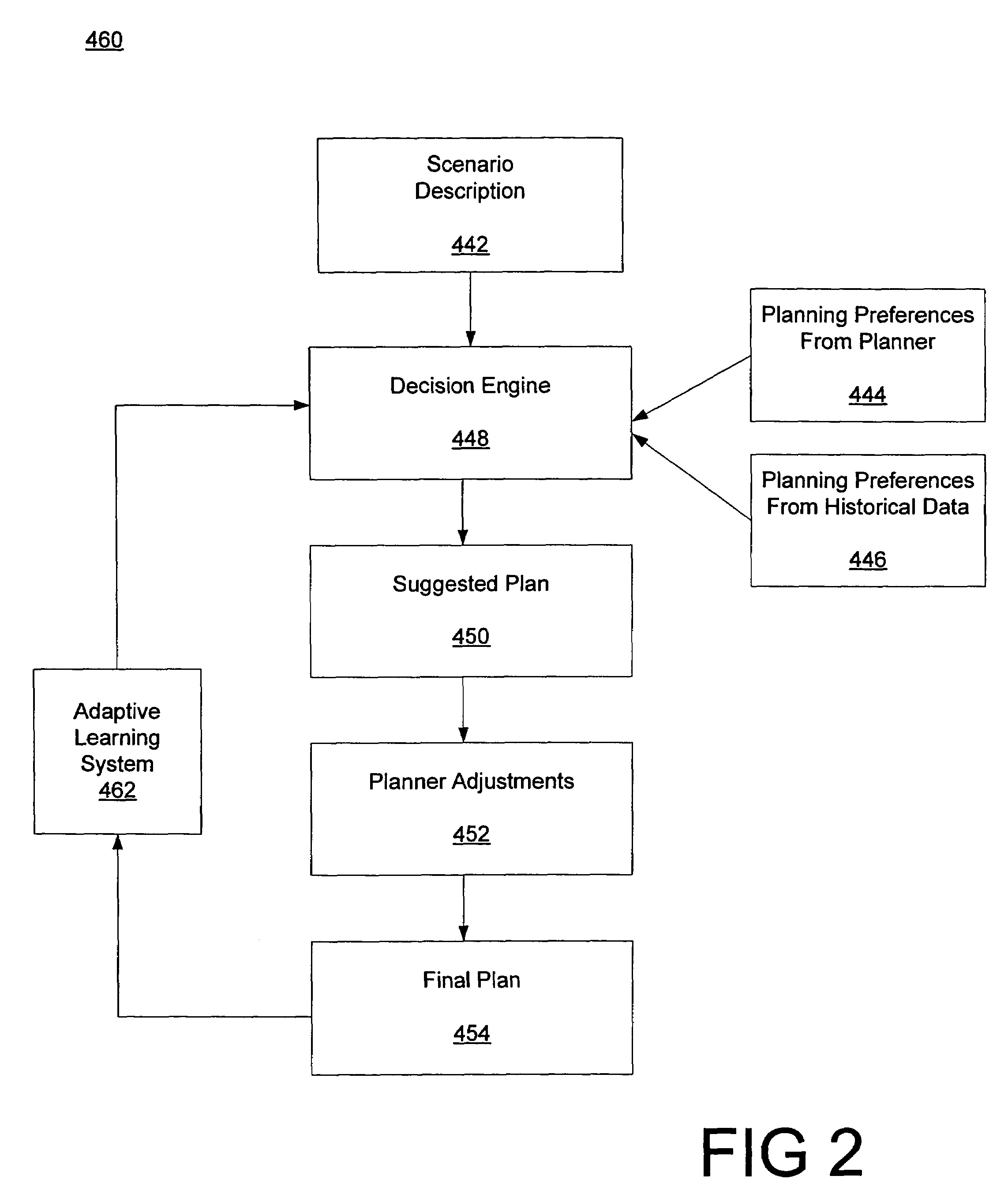

[0022]A production planning system for providing manufacturing schedules using planning preferences is disclosed. In one aspect, the production planning system generates a manufacturing schedule that includes a preferred ordering of tasks to be manufactured by a production line. The production planning system, in one embodiment, identifies multiple attributes associated with each task. Attributes identify characteristics of an item tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com