Diagnostic methods for selective catalytic reduction (SCR) exhaust treatment system

a selective catalytic reduction and exhaust treatment technology, applied in the direction of exhaust treatment electric control, machines/engines, mechanical equipment, etc., can solve the problems of unhealthy nhsub>3/sub>sensors, and the performance of scr catalysts are degraded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

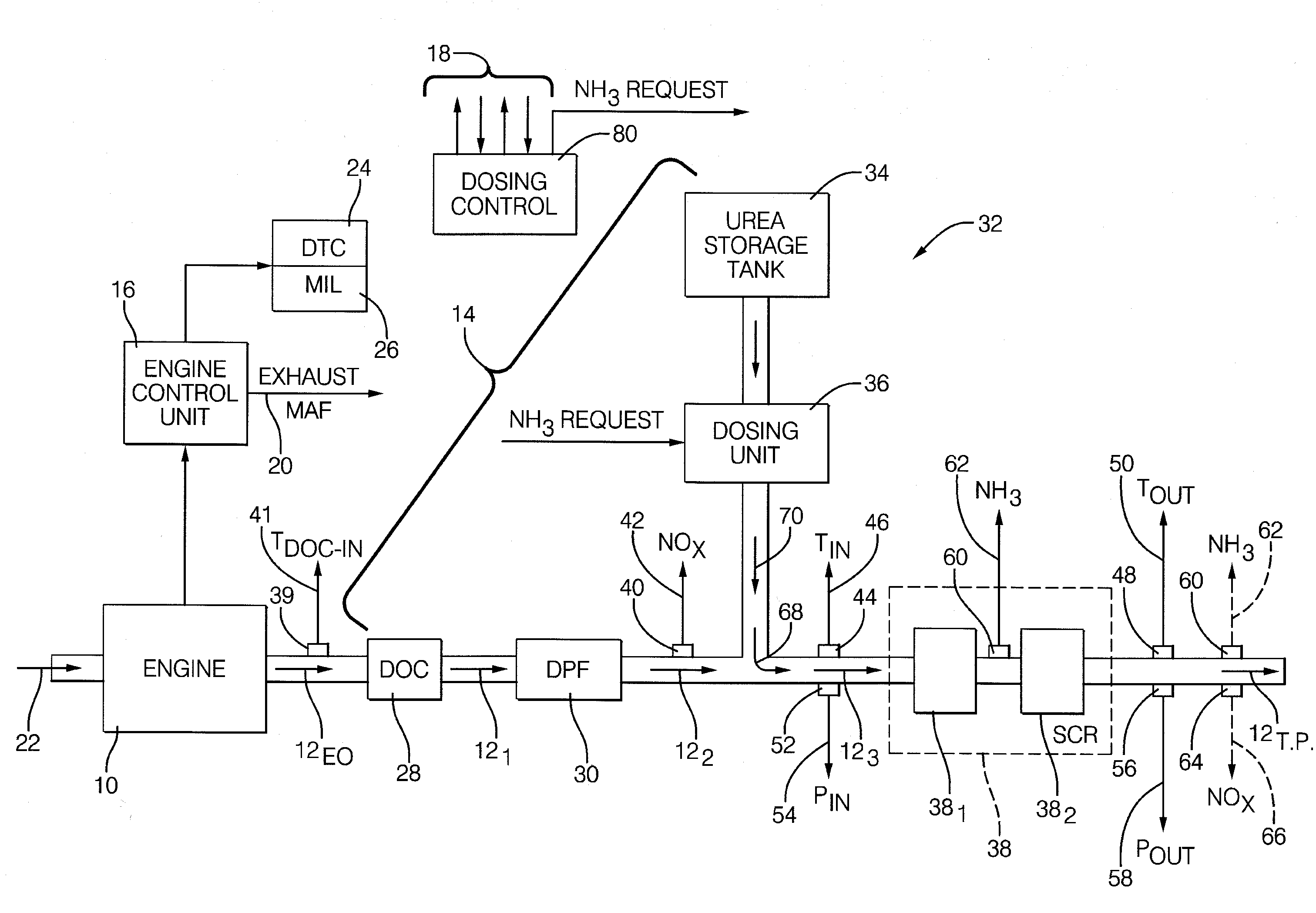

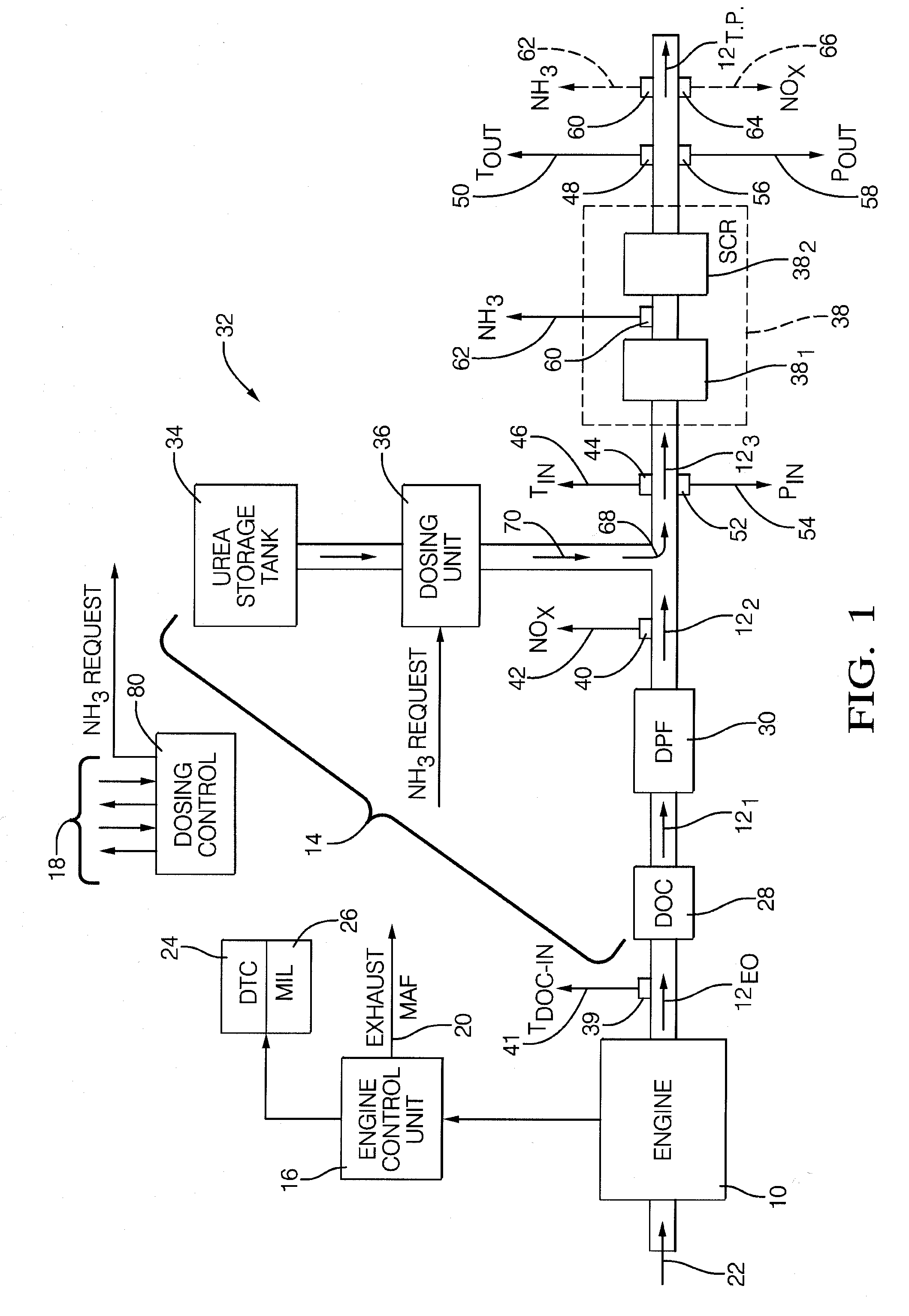

[0024]Referring now to the drawings wherein like reference numerals are used to identify identical components in the various views, FIG. 1 is a diagrammatic and block diagram showing an exemplary diesel cycle internal combustion engine 10 whose combustion exhaust gas 12 is fed to an exhaust gas treatment system 14. The exhaust gas is represented as a stream flowing through the exhaust gas treatment system 14 and is shown as a series of arrows designated 12EO (engine out), 121, 122, 123 and 12TP (tail pipe). It should be understood that while the invention will be described in connection with an automotive vehicle (i.e., mobile) embodiment, the invention may find useful application in stationary applications as well. In addition, embodiments of the invention may be used in heavy-duty applications (e.g., highway tractors, trucks and the like) as well as light-duty applications (e.g., passenger cars). Moreover, embodiments of the invention may find further useful application in various...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com