Intelligent interactive platform and interactive method of reducer parts manufacturing

A technology of intelligent interaction and parts, applied in computer parts, manufacturing computing systems, sustainable manufacturing/processing, etc., can solve the problem of not covering the whole life cycle of customized reducer parts, so as to reduce production costs and improve Utilization rate, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

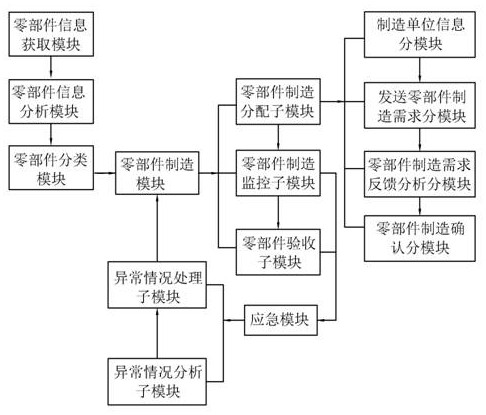

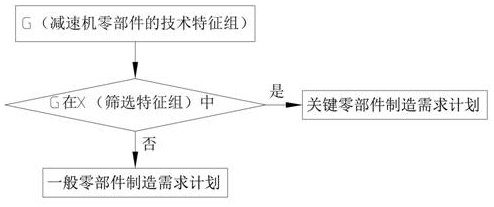

[0037] see figure 2 and image 3 , figure 2 The interactive schematic diagram of the interactive platform extracted for the purpose of hierarchical management and manufacturing of reducer parts according to the present invention. image 3 It is a schematic diagram of the implementation of the component manufacturing demand plan according to the embodiment of the present invention.

[0038] The intelligent interactive platform for the manufacture of reducer parts in this embodiment includes a platform similar to that made by figure 1 The interaction management system formed by the interaction of each module in the platform composition shown in figure 1 , as long as the functions set by the present invention can be realized), one or more key component manufacturing units and more than one general component manufacturing unit.

[0039] The key parts manufacturing unit is used to receive the key parts manufacturing demand plan of the interactive management system and feedbac...

Embodiment 2

[0047] The intelligent interaction method based on the intelligent interaction platform for the manufacture of reducer parts includes the following steps:

[0048] S1: Obtain the information of the parts of the reducer, and generate the technical feature group G of the parts of the reducer;

[0049] S2: Determine whether at least one feature of the technical feature group G of the reducer parts falls into the preset screening feature group X in the interactive management system;

[0050] When at least one feature of the technical feature group G of the reducer components falls into the preset screening feature group X in the interaction management system, the interaction management system generates a manufacturing requirement plan for key components and sends it to the manufacturing unit for key components. Send key parts manufacturing demand plan;

[0051] When none of the features in the technical feature group G of the reducer parts falls into the preset screening feature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com