Multi-axis manipulator carrying mechanism

A technology of handling mechanisms and manipulators, which is applied in the direction of manipulators, program-controlled manipulators, conveyor objects, etc., can solve the problems of difficulty in reducing manufacturing costs and high input costs, and achieve the effects of improving cost performance, improving work efficiency, and increasing upgrade costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

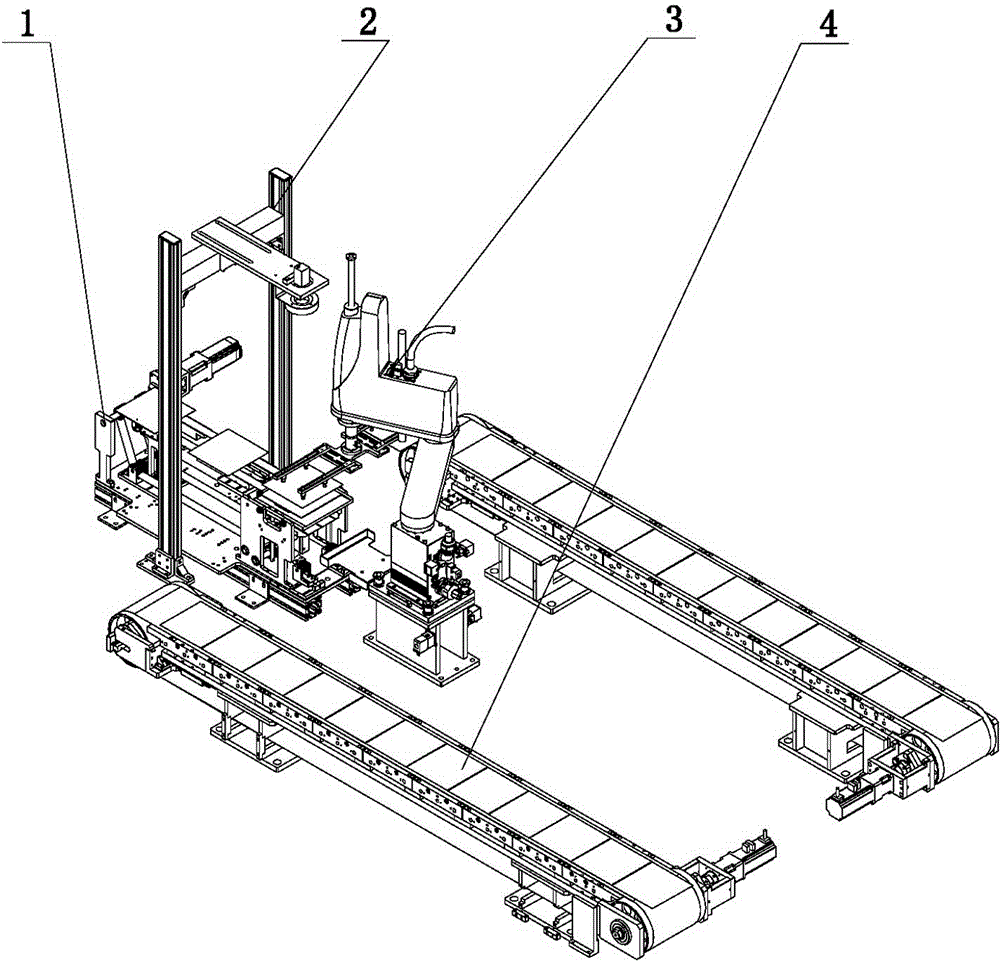

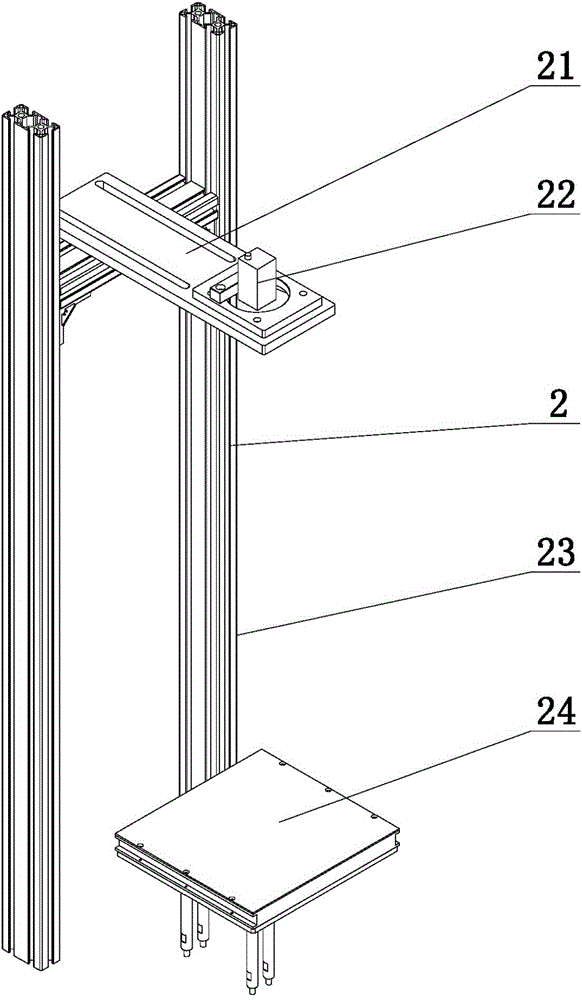

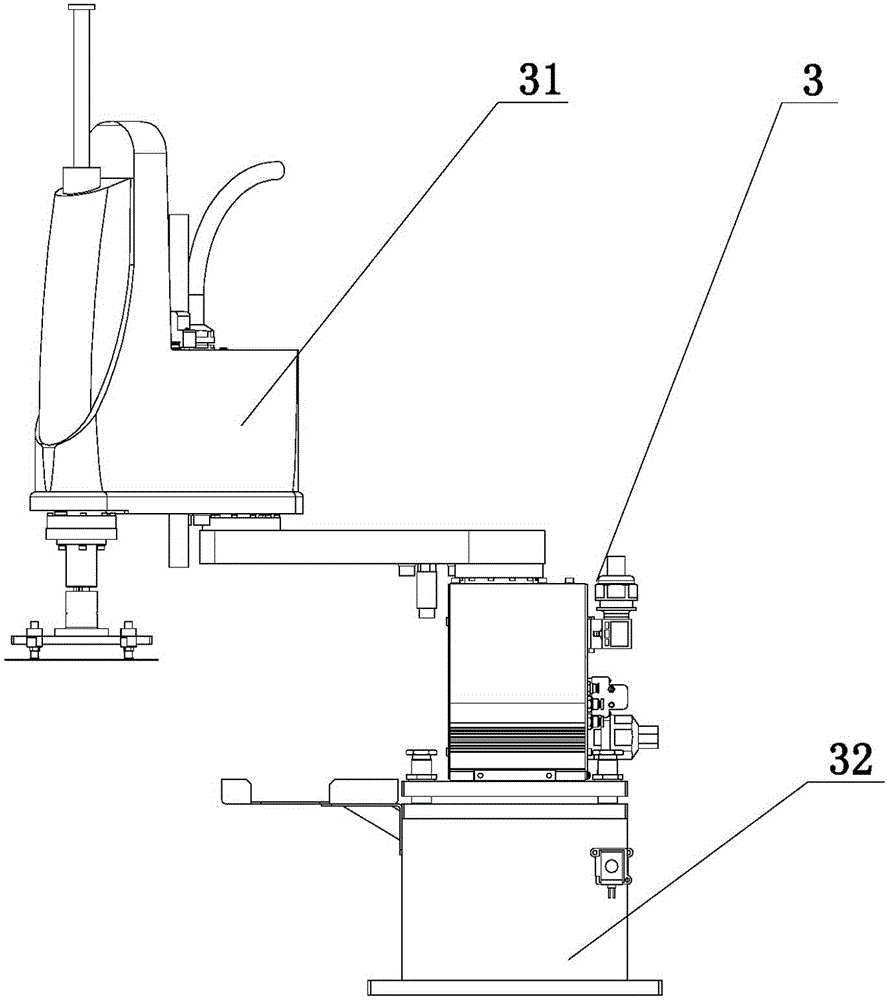

[0018] The present invention includes a feeding mechanism 1 and a handling manipulator mechanism 3, and is characterized in that: the feeding mechanism 1 includes a feeding conveyor belt 14 connected with a servo drive module 11; the handling manipulator mechanism 3 includes a machine base 32, the machine The top of the seat 32 is provided with a multi-axis manipulator 31 corresponding to the end of the feeding conveyor belt 14, the multi-axis manipulator 31 is provided with a rotating connecting frame 314, and both sides of the rotating connecting frame 314 are provided with mounting frames 311, and the two mounting frames 311 are provided with suction cup devices 313; above the feeding mechanism 1 corresponding to the end of the feeding conveyor belt 14 is provided with a CCD visual monitoring system 2; below the end of the feeding conveyor belt 14 is provided with a backlight 24.

[0019] The surface of the feeding conveyor belt 14 is provided with a vacuum adsorption hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com