Automatic pallet transfer device and conveying system

A technology of automatic conveying and transfer device, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of operator injury labor intensity, low degree of automation of equipment, high labor intensity, reduce the risk of falling, The effect of increasing the degree of automation and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

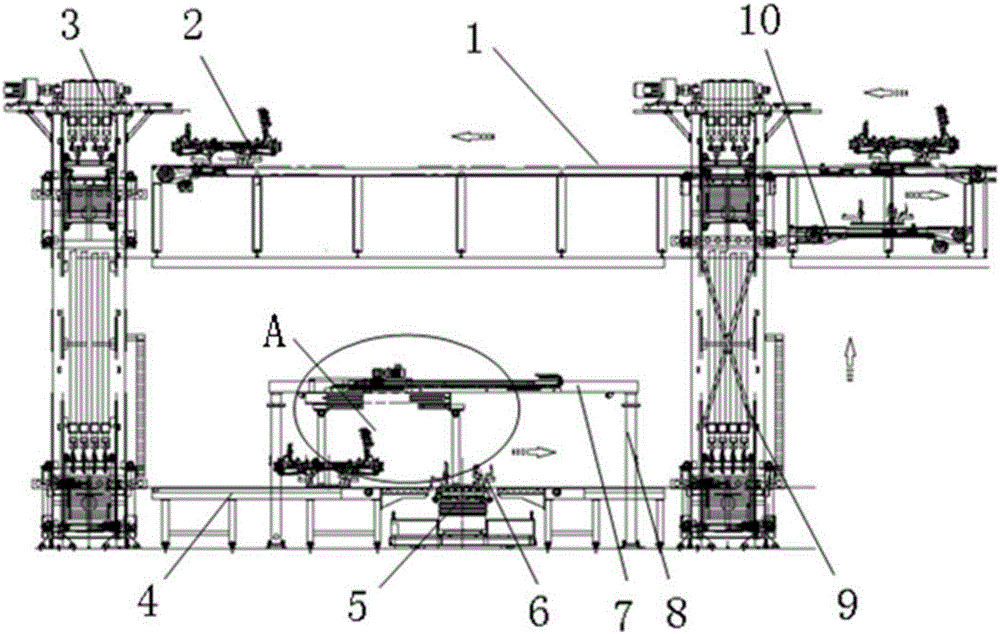

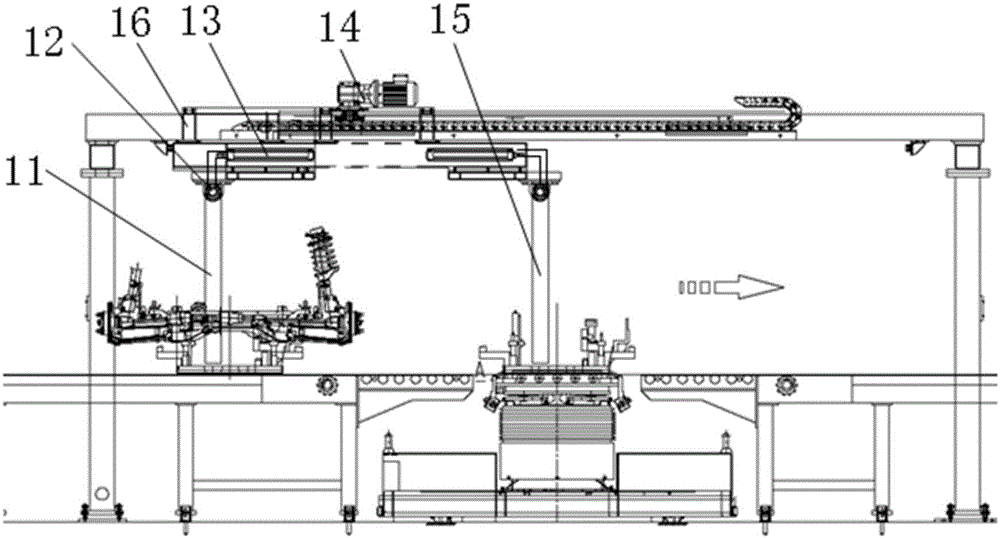

[0028] The application provides an automatic tray rotation device, such as figure 1 and figure 2 As shown, it includes the first aerial conveying line 1, the second aerial conveying line 10, the belt workpiece tray 2, the ground conveying line 4, the automatic conveying trolley 5, the first elevator 3, the second elevator 9 and the transfer device assembly.

[0029] One end of the first aerial conveying line is connected with the upper part of the first elevator; the upper part of the second elevator is connected with the workpiece loading station through the second aerial conveying line; the first aerial conveying line is used to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com