Steam pipe blowing method for ultra-supercritical once-through boiler with no boiler water pump

A once-through boiler and ultra-supercritical technology, which is applied in the field of boiler steam blowing, can solve the problems of large impact on the boiler blowing temporary system, difficult recovery of water and heat, long blowing construction period, etc., to reduce impact, reduce time, and reduce times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

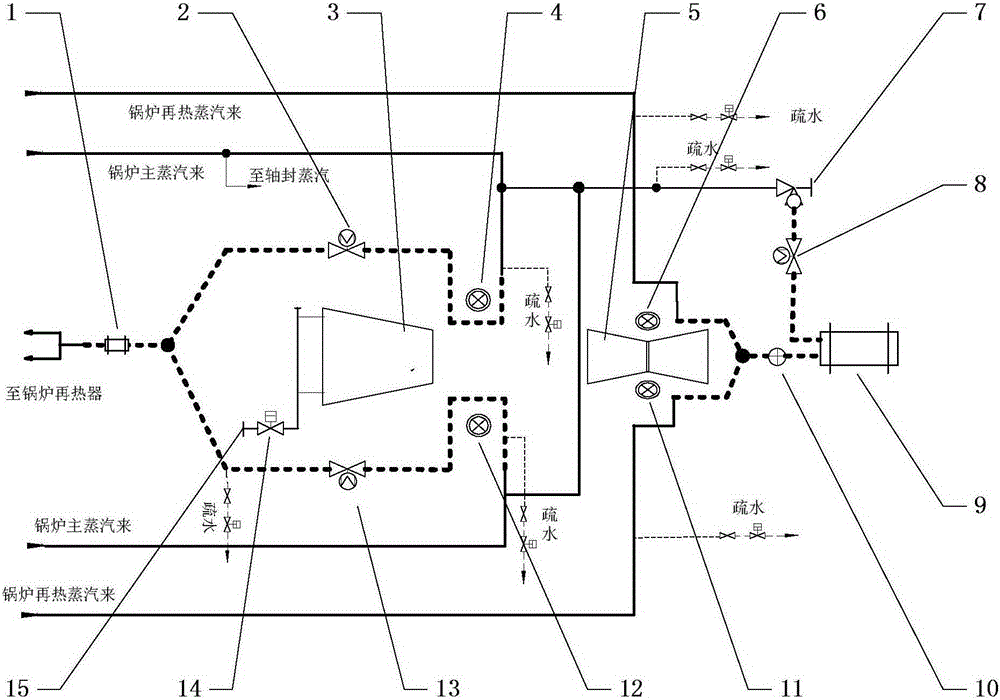

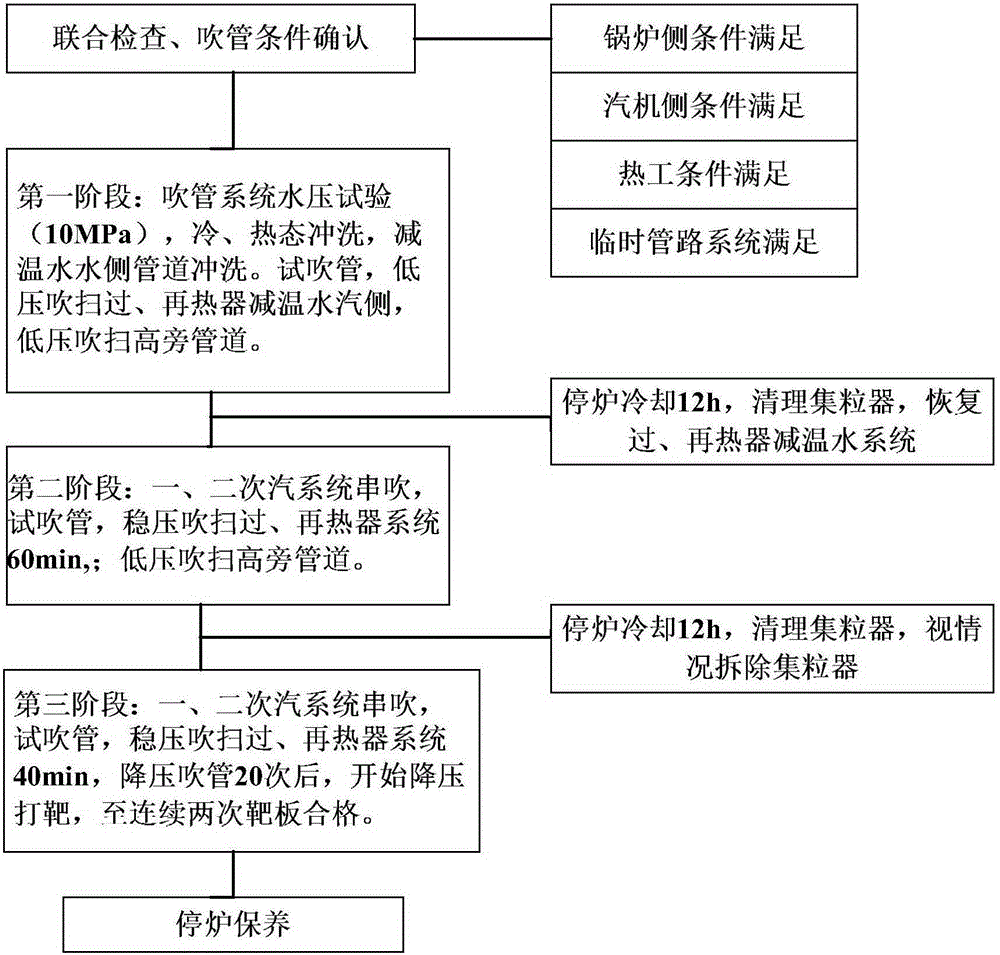

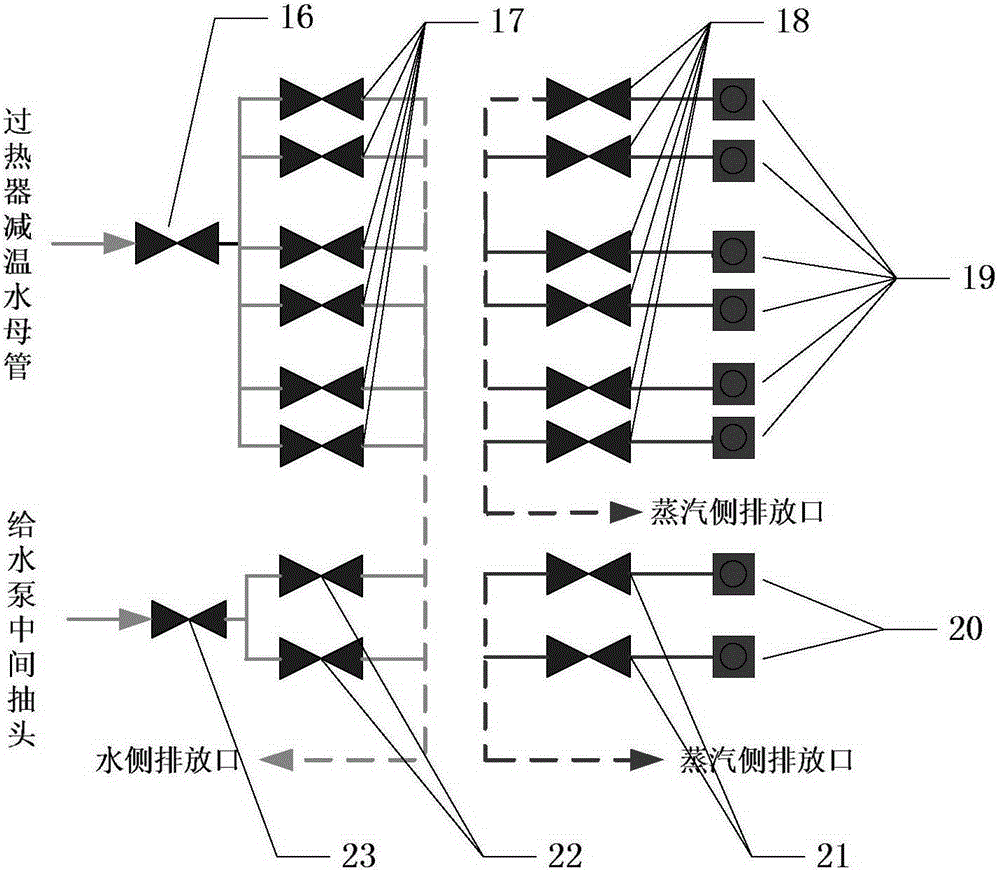

[0076] The present invention is used for the steam blowing method of ultra-supercritical furnaceless water pump once-through boiler such as Figure 1 to Figure 3 As shown, the following steam blowpipe method is adopted: the boiler superheater and reheater are connected in series through a temporary system, and the boiler blowpipe adopts the blowpipe method combining constant pressure blowpipe and low pressure blowpipe. In addition, since the boiler does not have a furnace water circulation pump, it is difficult to recycle water and heat during the depressurization blowpipe process, and the external displacement is large, which requires a large amount of demineralized water. Therefore, in order to ensure that the blowpipe can continue, in addition to preparing sufficient demineralized water In addition, the boiler drainage recovery system including the pre-filter should be put into operation during the blowpipe process after the hot cleaning. In addition, when the pressure is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com