Waste heat power generation system of multiple glass kilns

A glass kiln and waste heat power generation technology, which is applied in the control system, steam generation method using heat carrier, furnace, etc., can solve the problems of large fluctuation range of exhaust gas waste heat parameters, high one-time investment cost, and low waste heat utilization efficiency. Achieve the effects of reducing one-time construction investment, improving waste heat utilization rate, and improving power generation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

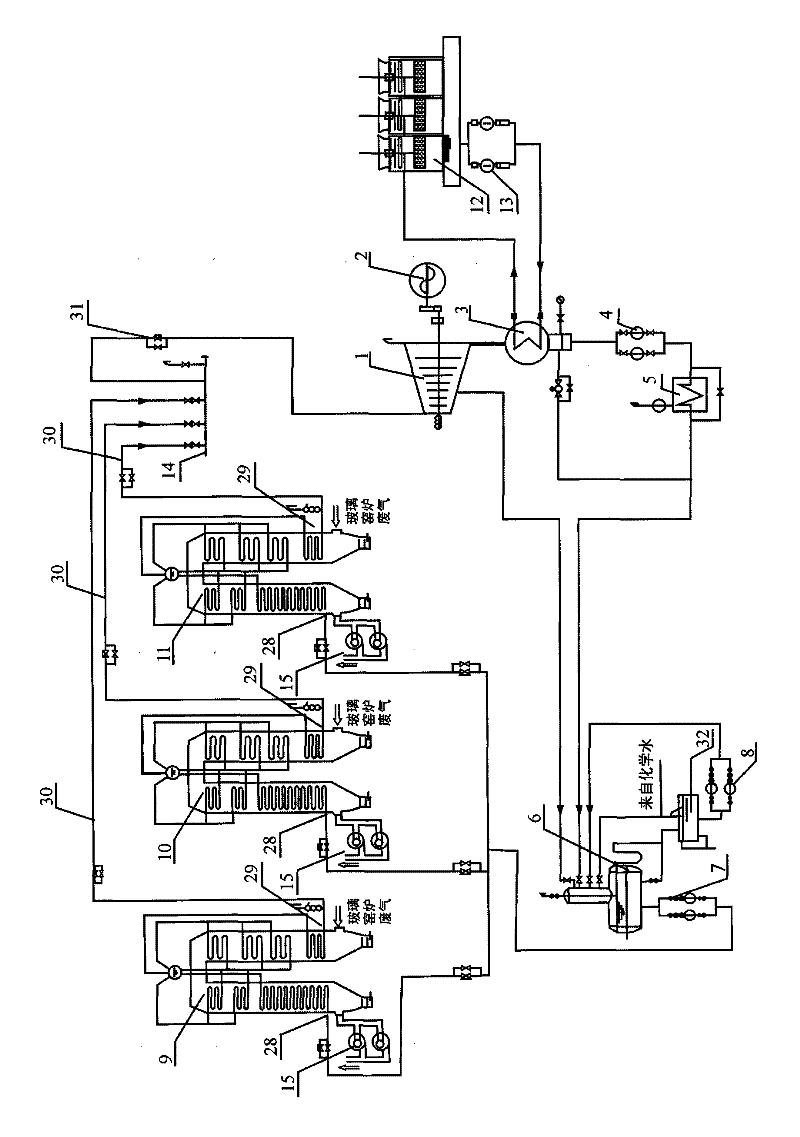

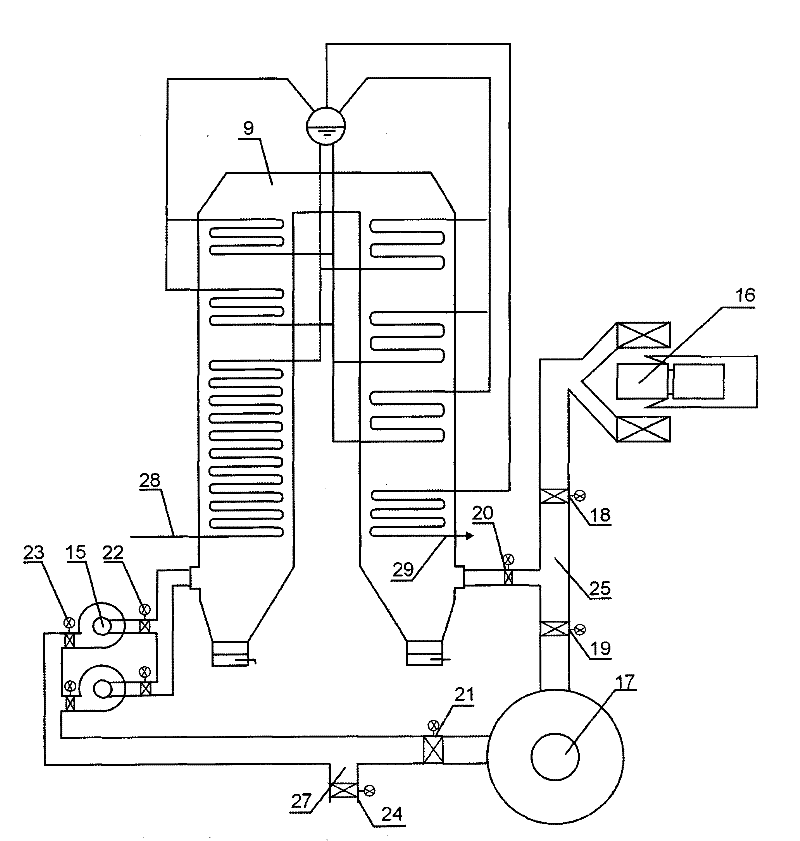

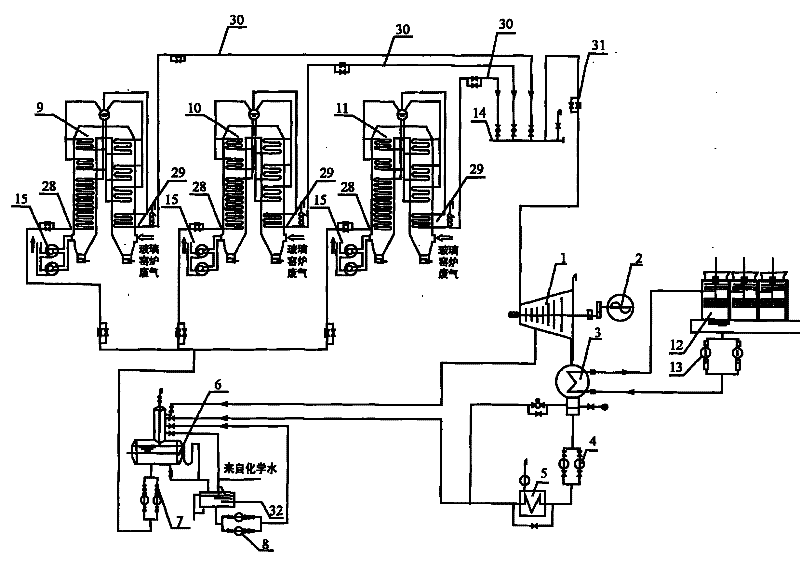

[0018] The detailed structure of the present invention, application principle, function and effect, refer to the appended figure 1 .2 Illustrate through the following implementation methods.

[0019]In the multiple glass kiln waste heat power generation system of the present invention, the flue gas outlets of multiple glass kilns 16 are in one-to-one correspondence with the flue gas inlets of multiple parallel waste heat boilers through the outlet flue 25, and the smoke of the waste heat boilers The gas outlet is connected to the chimney 17; the waste heat boiler is a single drum "Π" type waste heat boiler, that is, two vertical shaft flue gas channels are connected and arranged in a "Π" type. The water outlets of the boiler water pump 7 are respectively connected with the circulating water inlets 28 of multiple waste heat boilers, and the steam outlets 29 of multiple waste heat parallel boilers are connected with the steam collection cylinder 14 through the steam pipe 30, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com