Exhaust heat recovery and dust removal integrated type biomass boiler

A biomass boiler and tail heat recovery technology, applied in preheating, heating devices, steam generation, etc., can solve problems such as large smoke and dust, insufficient combustion, and non-compliance with energy-saving and emission-reduction policies, and achieve broad application prospects and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with accompanying drawing, the present invention is described in further detail.

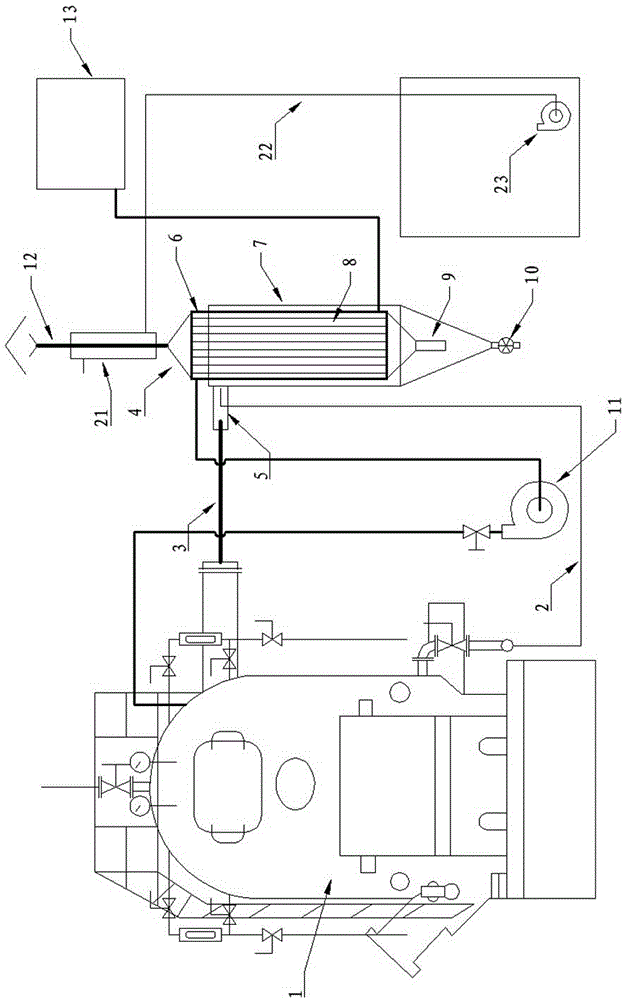

[0023] Such as figure 1 The tail heat recovery and dust removal integrated biomass boiler shown in the figure includes boiler body 1, boiler tail gas pipe 3, boiler sewage pipe 2 and cyclone dust removal tail heat efficient recovery device 4, and cyclone dust removal tail heat high efficiency recovery device 4 consists of tube and tube heat exchange The boiler tail gas pipe 3 is tangentially connected to the cyclone dust collector 7. After the cyclone dust is removed, the dust is discharged through the air locker 10 at the bottom of the cone, and the tail gas is connected to the cone through the swirl rising pipe 9. After being dispersed evenly It passes through the tubes 8 and is discharged through the exhaust pipe 12 after being concentrated by the upper cone bucket; the soft water pool 13 is connected to the lower part of the shell side of the tube heat exchanger, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com