Quantitative air distribution economic combustion energy saving control system

An energy-saving control system and economical combustion technology, applied in the direction of combustion method, combustion control, fuel supply adjustment, etc., can solve the problem of not considering the boiler structure and combustion process, coal type, calorific value, air intake volume, environmental pollution, etc. problem, to achieve the effect of improving the overall work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

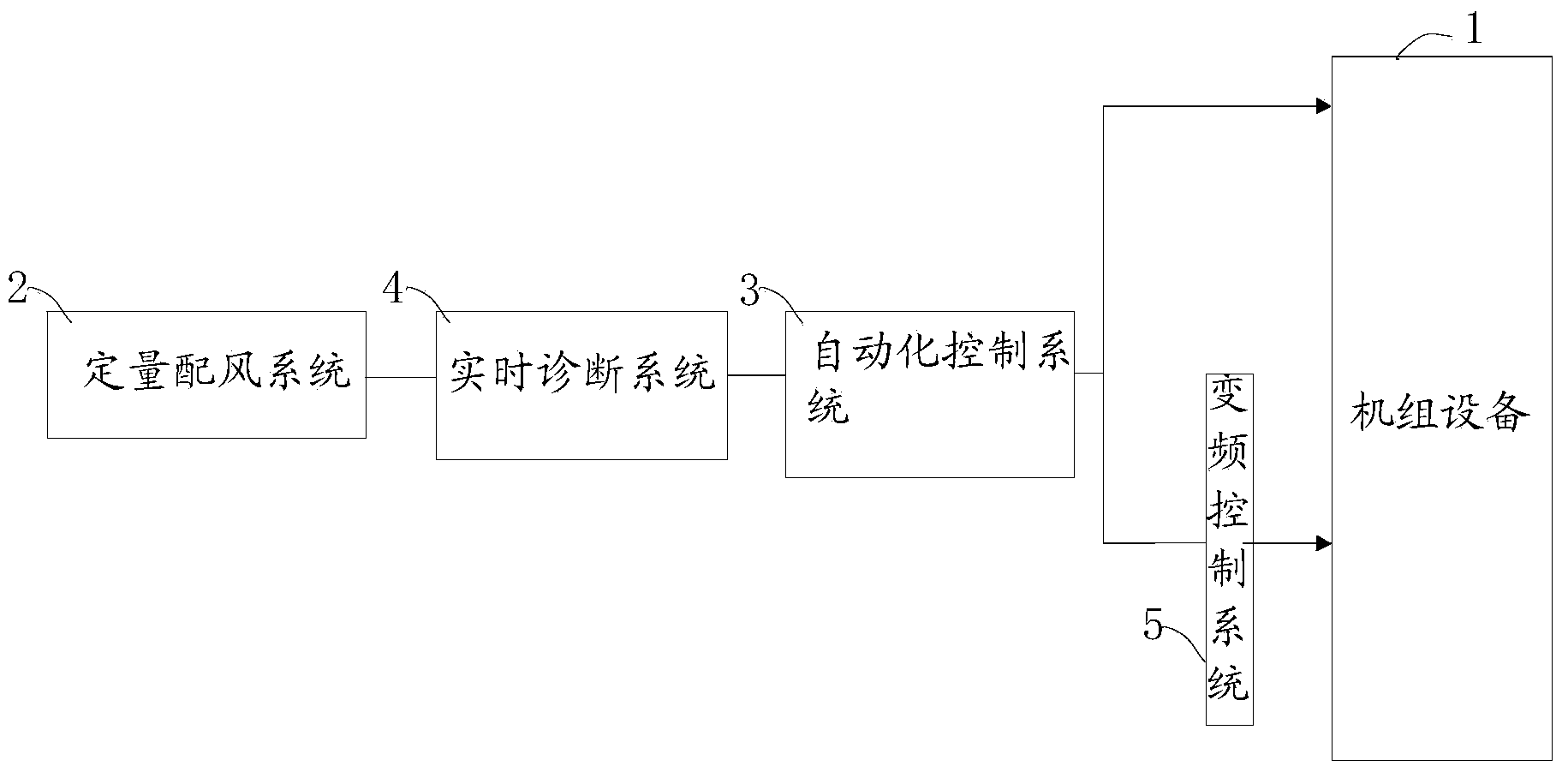

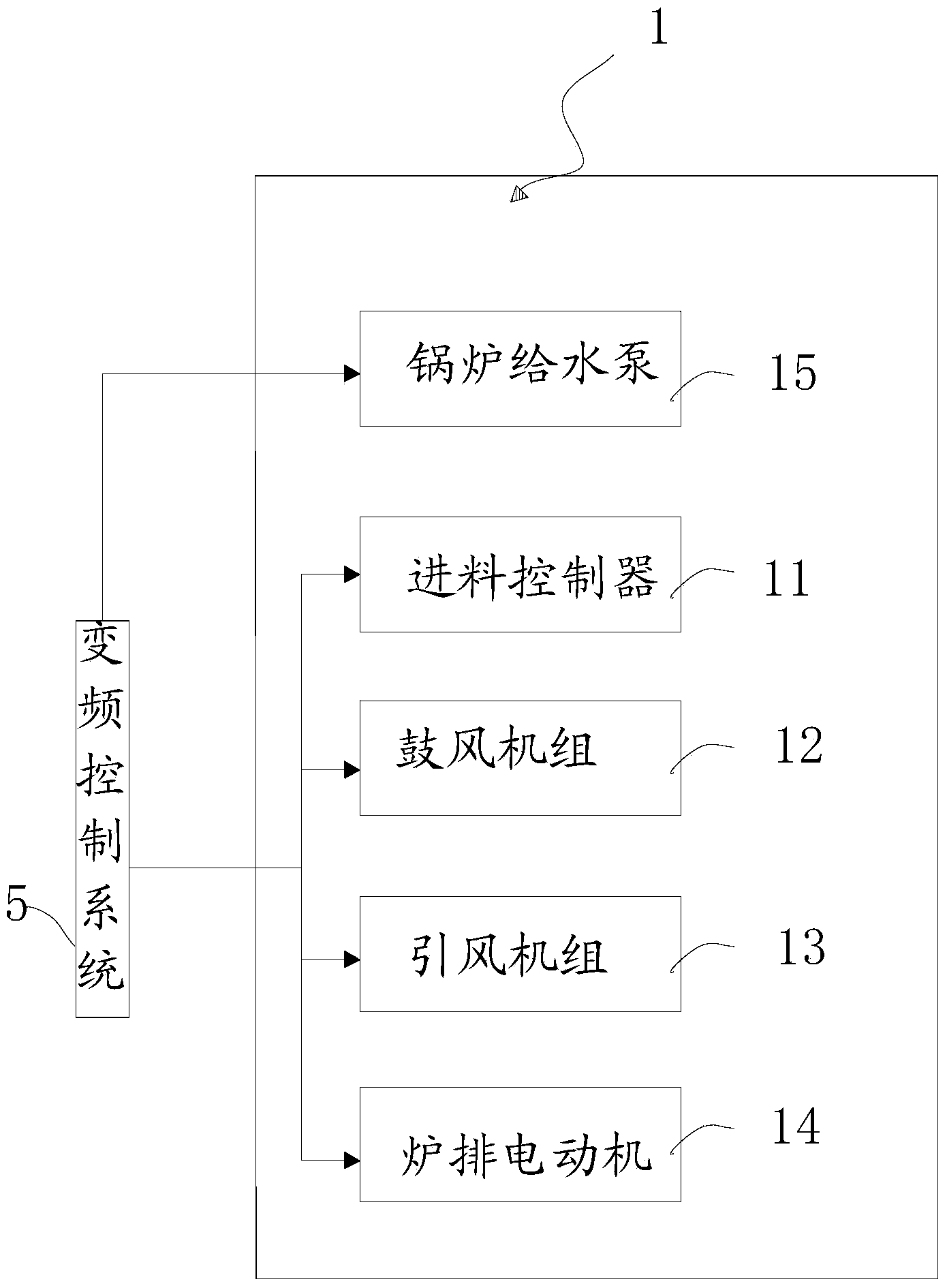

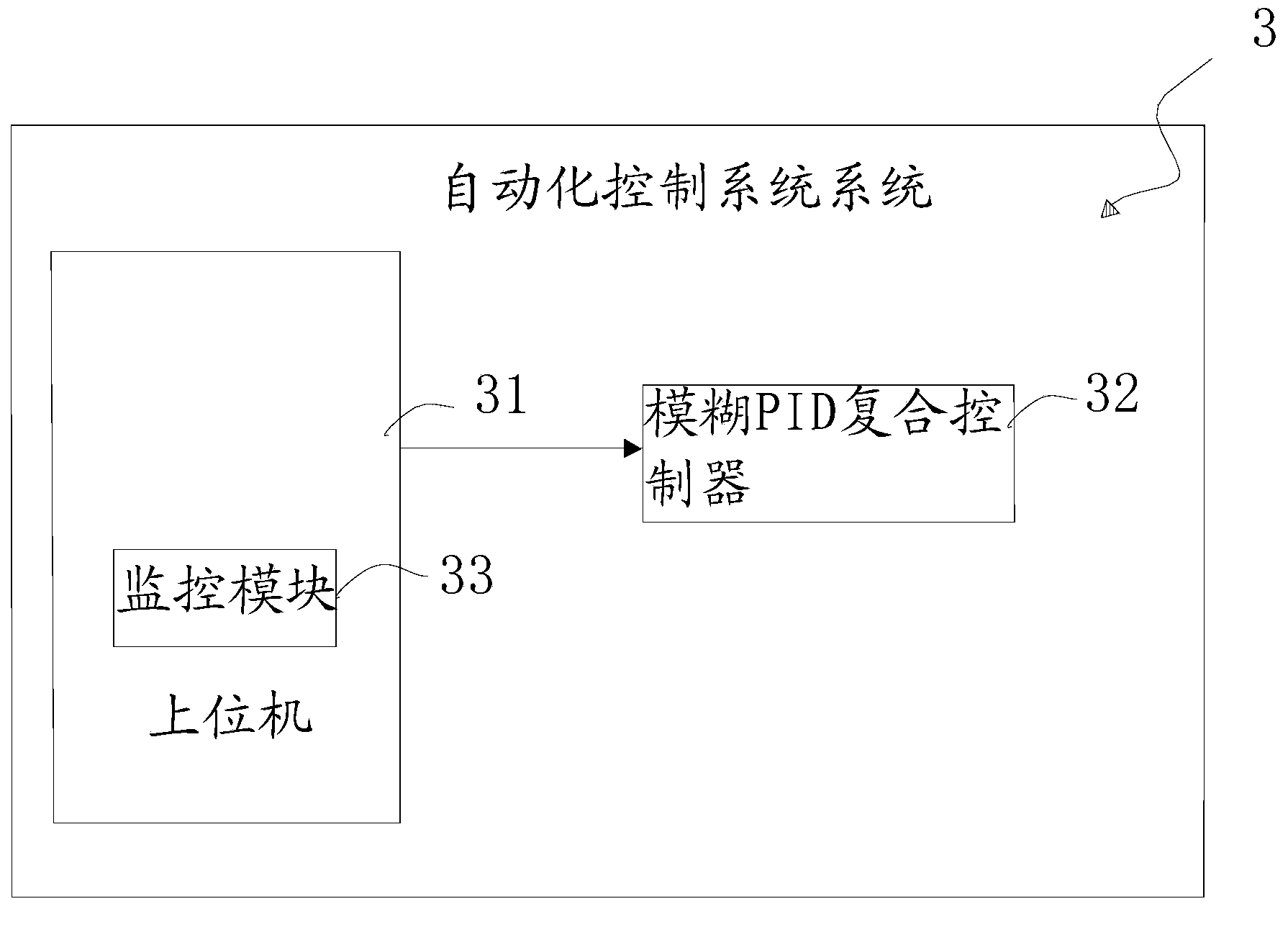

[0020] as attached Figure 1 to Figure 3 As shown, Embodiment 1 of the present invention provides a quantitative air distribution economical combustion energy-saving control system, including unit equipment 1, such as figure 2 As shown, the unit equipment 1 includes a feed controller 11, a blower unit 12, an induced draft unit 13, a grate motor 14, and a boiler feed water pump 15, and also includes a quantitative air distribution system 2 electrically connected to the unit equipment 1, an automatic Control system 3 and real-time diagnosis system 4;

[0021] The quantitative air distribution system 2 is used to control the speed of the blower unit 12, the induced draft unit 13 and the grate motor 14 of the unit equipment 1 to reach a reasonable ratio;

[0022] The real-time diagnosis system 4 is used to receive the boiler performance parameters sent by the automatic control system and obtain the optimal control scheme through analysis and calculation, and generate and send ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com