Glass kiln denitration generating system

A power generation system, glass kiln technology, applied in the direction of machines/engines, steam generation method using heat carrier, waste heat treatment, etc., can solve the problems of increased operating costs, huge equipment, increased investment, etc., to reduce equipment investment and save investment cost, the effect of simplifying the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

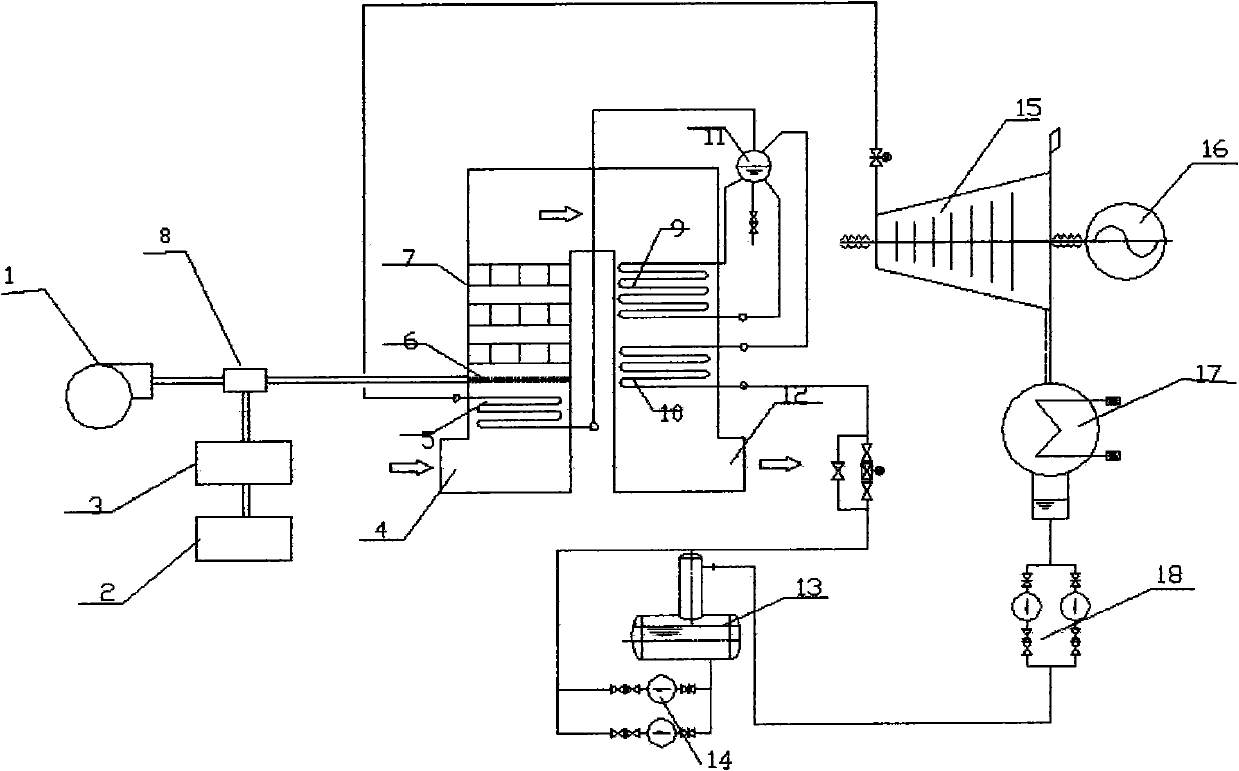

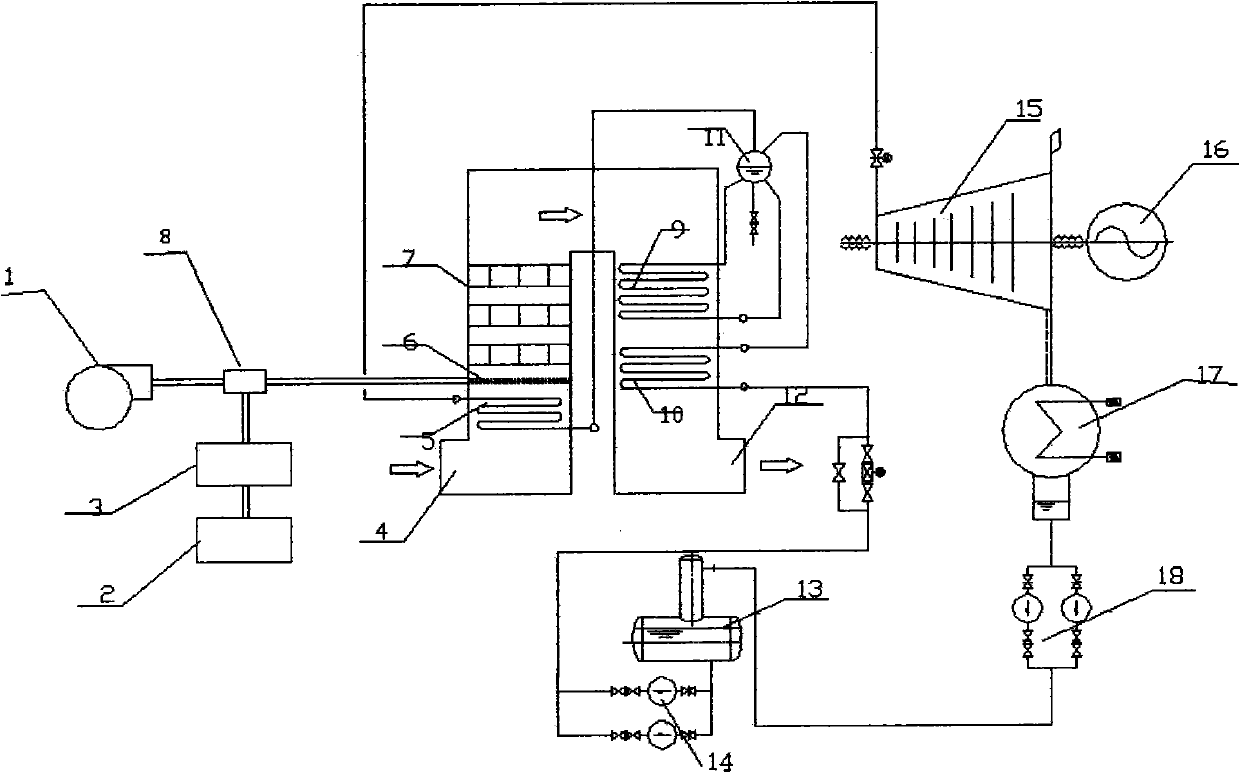

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0015] Such as figure 1 As shown, the liquid ammonia stored in the ammonia storage tank 2 flows out from the cylinder through the pressure reducing valve and enters the liquid ammonia water heater 3 . After the liquid ammonia absorbs heat, it is vaporized into gas ammonia, and flows into the ammonia spraying fence 6 through the regulating valve 8 . The flue gas (about 500°C) discharged from the glass kiln enters the waste heat boiler through the flue gas inlet 4 installed in the denitrification waste heat boiler, and is cooled to 350°C after passing through the superheater 5 (this temperature is a sensitive temperature for chemical reactions) Enter the denitrification section of the boiler. The flue gas passes through the heater 5 and mixes with the ammonia gas flowing into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com