A kind of operation method adopting heating surface section return water boiler

An operation method and heating surface technology, applied in the field of boilers, can solve the problems of high initial emission concentration of sulfur-containing compounds and NOx, the safety of materials cannot be guaranteed, and the boiler load is not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

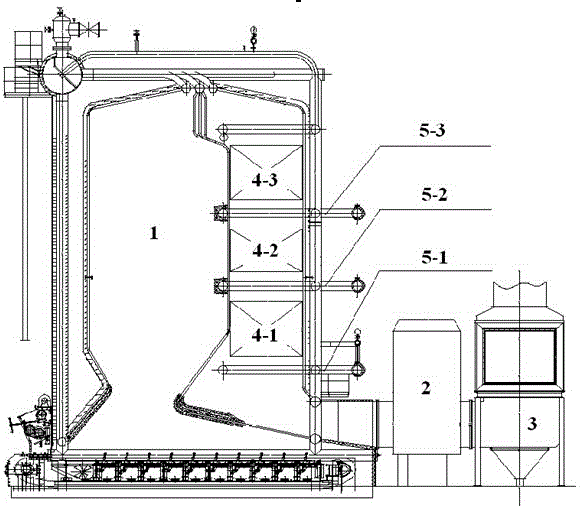

[0053] Such as figure 1 As shown, a 50MW heating boiler with segmented air supply includes a furnace 1, a dust collector 2, an air preheater 3, a first-stage convection tube 4-1, a second-stage convection tube 4-2, and a third-stage convection tube 4-3, and the first-level return water header 5-1, the second-level return water header 5-2, and the third-level return water header 5-3, and each level of convection pipe independently has a water supply temperature sensor and a return water temperature sensor and a water pump controller, the boiler is also equipped with an exhaust gas temperature sensor, the water supply temperature sensor, the return water temperature sensor and the water pump controller (to control the circulating water volume), and the exhaust gas temperature sensor is connected with the micro-host, and the water supply temperature Information, return water temperature information, circulating water volume information, and exhaust gas temperature information are...

Embodiment 2

[0055] A method for operating the boiler described in Embodiment 1 is provided, the method includes adopting a segmented backwater load changing mode.

[0056] When the boiler is running, according to the change of the boiler load, the segmented return water method is adopted, so that the exhaust gas temperature of the boiler body can be controlled, that is, the adjustment of each segment of the return water is aimed at controlling the exhaust gas temperature of the boiler body.

[0057] The boiler return water can be connected in parallel with three-stage convection pipes, and according to the change of boiler load and especially the change of exhaust gas temperature at the tail, the respective return water distribution of the three-stage convection pipes (that is, the circulating water volume) is adjusted respectively. This makes it possible to control the exhaust gas temperature of the boiler body to about 130°C, preferably about 120°C.

[0058] Further or preferably, each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com