ACC automatic combustion control method for waste incineration plant

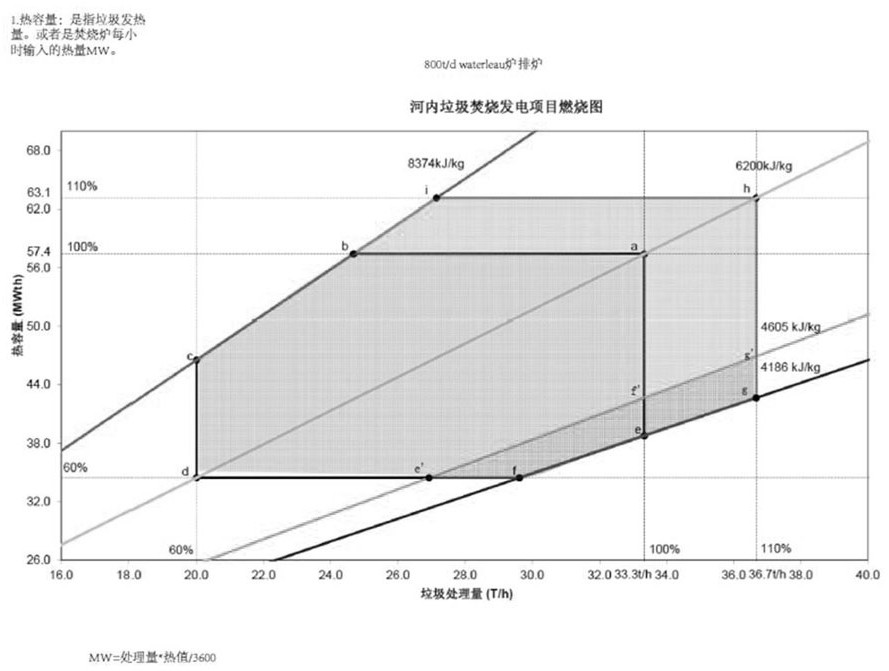

A technology of waste incineration and automatic combustion, applied in the combustion method, combustion chamber, combustion type, etc., can solve the problems of increased waste residue, long lag time, partial material in the incinerator, etc., to achieve automatic input rate increase, accurate smoke exhaust temperature, the effect of reducing the processing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

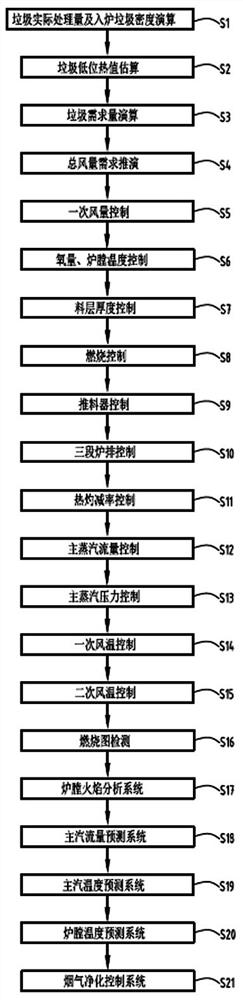

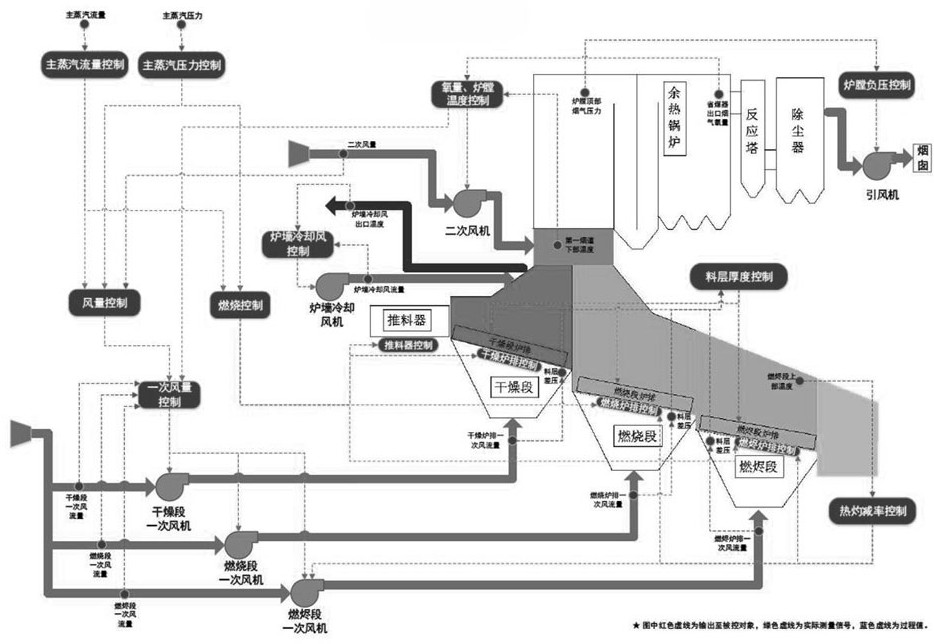

Method used

Image

Examples

specific Embodiment approach

[0248] Specific implementation: through the parameters in the prediction parameter table in the DCS system, the NO is predicted by XGboost and denitrification BP neural network algorithm X value, the ammonia water regulating valve passes through the cascade control loop, and the measured NO X Value and forecast NO X The deviation value of the value is input into the main tune PID controller as feedforward, and the output value of the main tune PID is automatically set as the auxiliary tune set value and the actual measured ammonia water flow for PID adjustment through the setting formula, and the opening degree of the ammonia water regulating valve is output. The dilution water regulating valve converts the ammonia water concentration setting value through the solvent formula and the measured flow rate of the dilution water for PID adjustment, and outputs the opening degree of the dilution water regulating valve. Achieve stable NO X value target.

[0249] 3) Dry deacidifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com