Temperature Control Method of Indirect Flue Gas Heat Exchanger for 600mw Coal-fired Boiler

A temperature control method and flue gas heat exchanger technology, applied in the control system, feed water heater, preheating and other directions, can solve the problems of different parameter control strategies, difficult parameter control operation control, and difficulty in accurately distinguishing critical points, etc. Ensuring safe operation and well-controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

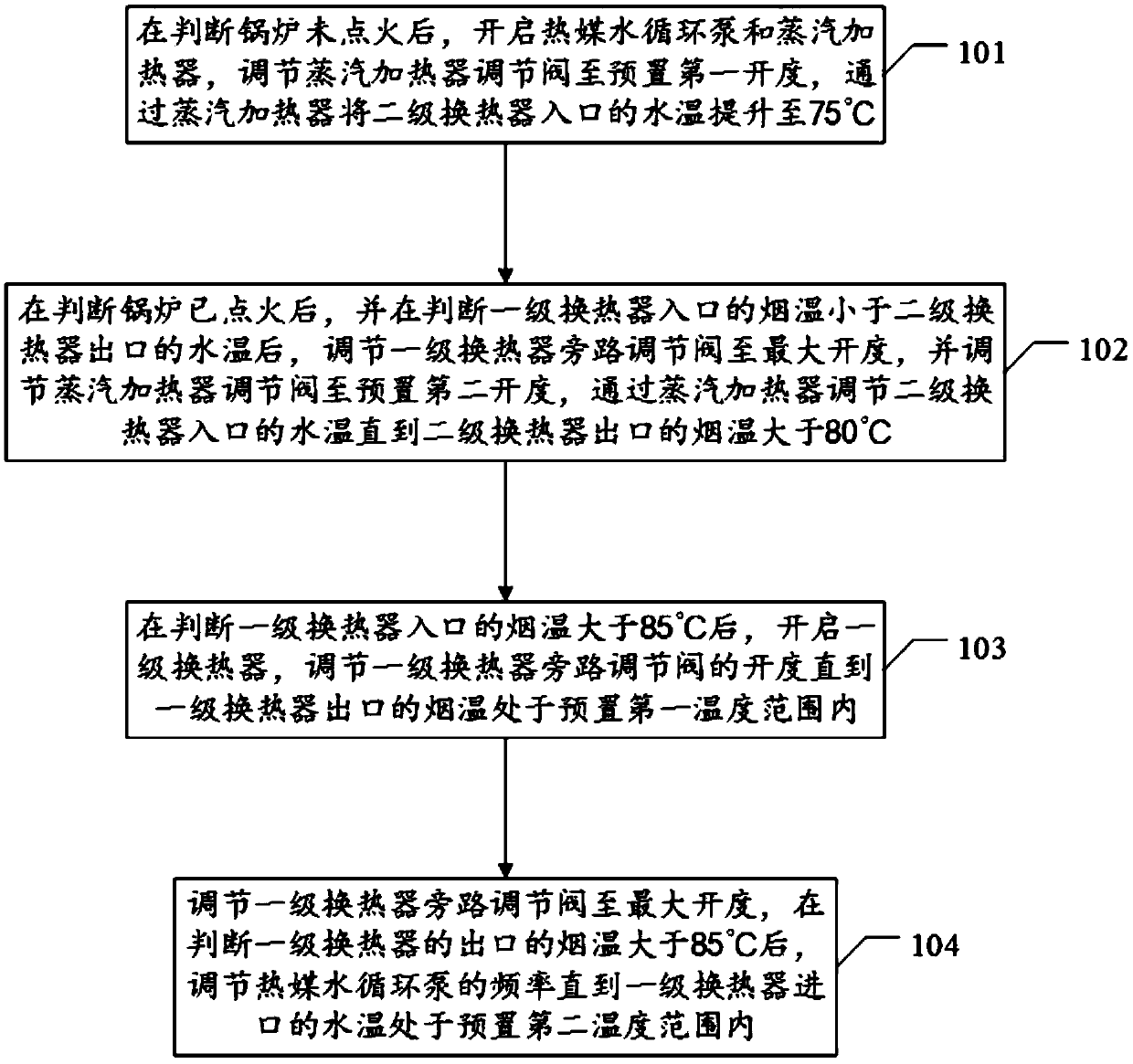

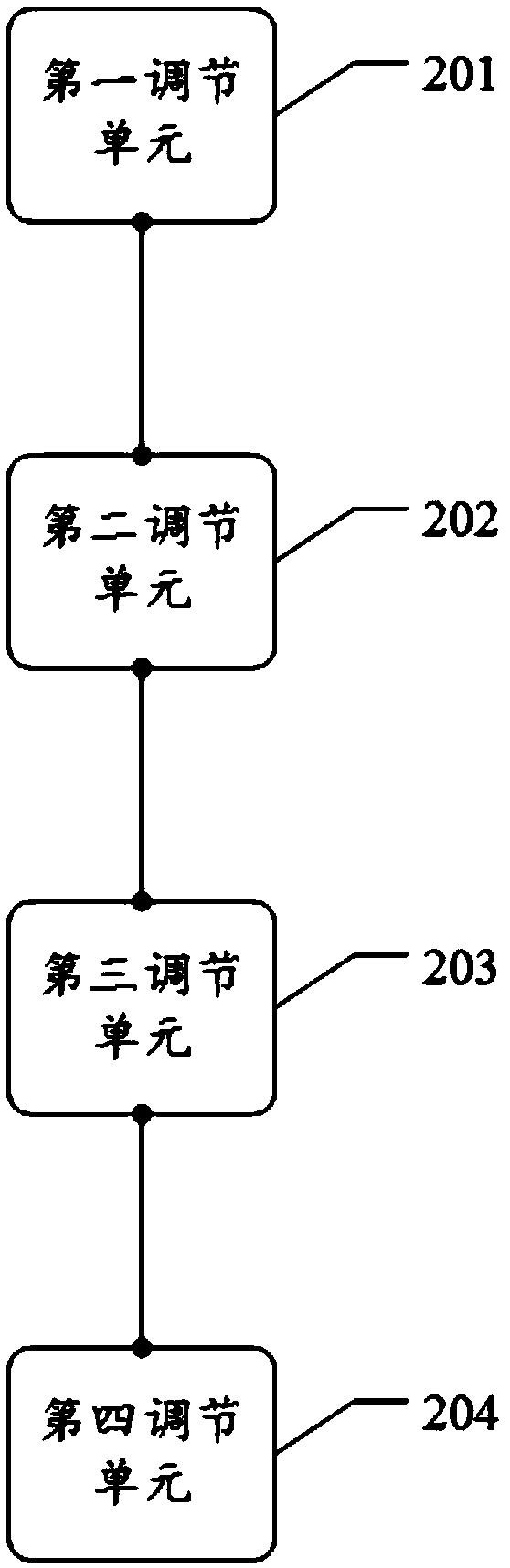

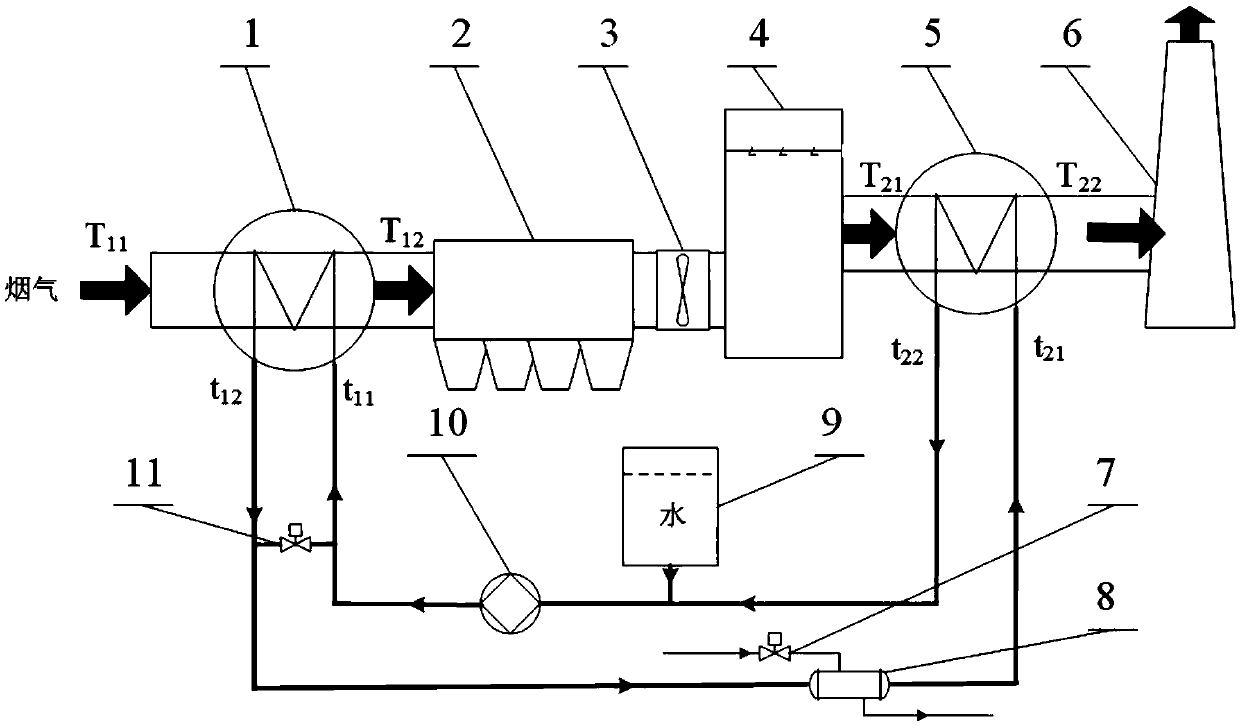

[0029] The embodiment of the present invention provides a temperature control method and device for an indirect flue gas heat exchanger of a 600MW coal-fired boiler, which is suitable for the indirect flue gas heat exchanger in each stage of low, medium and high load after the unit boiler is ignited. The control of temperature / circulating water temperature ensures good control of the exhaust gas temperature of the chimney during the full load process of the unit, and realizes the emission of smoke and dust up to the standard.

[0030] In order to make the purpose, features and advantages of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the following The described embodiments are only some, not all, embodiments of the present invention. Based on the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com