Boiler water replenishing system capable of collecting waste heat and condensed water

A water replenishment system and condensate water technology, which is applied in the field of boiler water replenishment systems for collecting waste heat and condensate water, can solve problems such as complexity, environmental pollution, and poor absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

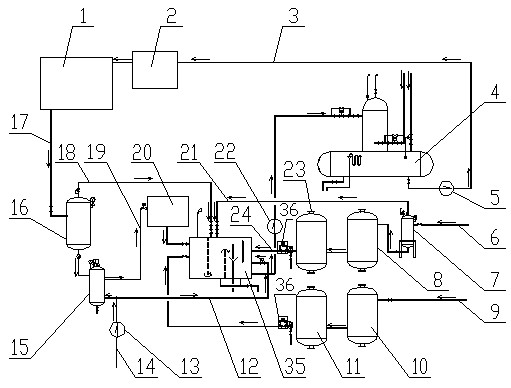

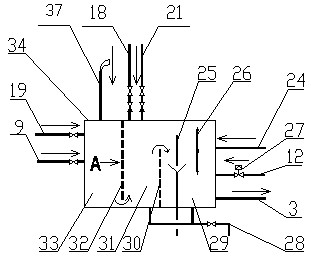

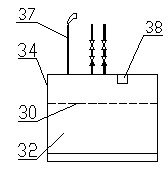

[0018] Depend on Figure 1-Figure 3 A boiler water replenishment system for collecting waste heat and condensed water is shown, including a fire-tube saturated steam boiler 1, a fire-tube saturated steam boiler 1 with a first-level boiler economizer 2, and a boiler sewage pipe 17 of the fire-tube saturated steam boiler 1 Connect the sewage expansion tank 16, the exhaust port of the sewage expansion tank 16 is connected to a hot water tank 35 through the sewage flash steam pipe 18, the sewage pipe of the sewage expansion tank 16 is connected to the continuous discharge heat exchanger 15, and the continuous discharge heat exchanger 15 It is a water-to-water heat exchanger, and the continuous row heat exchanger 15 is also connected with a softened water inlet pipe 14, and the softened water inlet pipe 14 is connected to the soft water station through the water supply pump 13, and the sewage of the boiler 1 is heated by the continuous row heat exchanger 15. After the softened wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com