Auxiliary cementing material as well as preparation method and application thereof

A gelling material and an auxiliary technology, applied in the field of preparation of the auxiliary gelling material, can solve the problems of unstable expansion in the later stage, difficult to control expansion rate and the like, and achieve simple processing and manufacturing process, easy control of expansion rate, and raw material resources easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

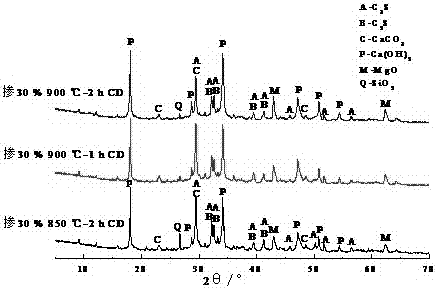

Image

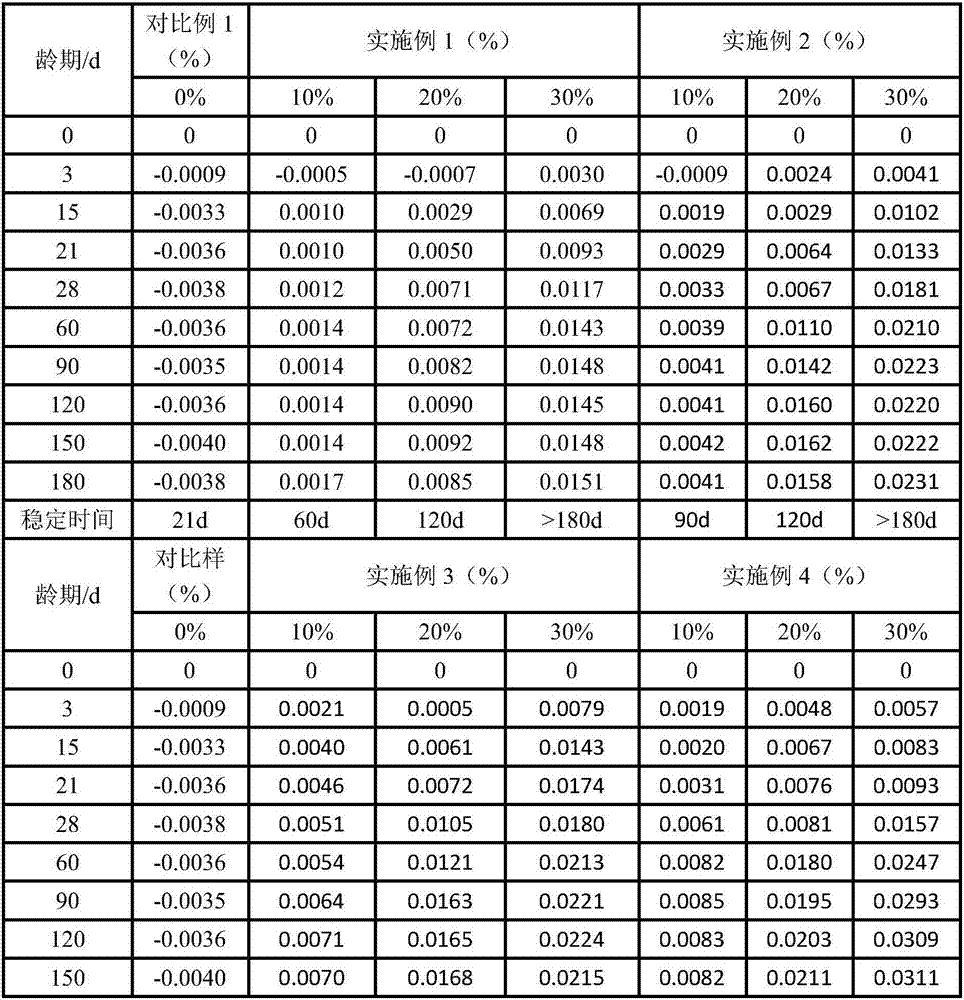

Examples

Embodiment 1

[0026] The dolomite used in the test was taken from Hexian County, Anhui Province, with a very low impurity content of 1.22%. The main components are shown in Table 1. The cement is P·II 52.5 Portland cement produced by Jiangnan Onoda Cement Co., Ltd., and its physical properties are shown in Table 2. The sand is river sand with a fineness modulus of 2.1.

[0027] Table 1

[0028] raw material

w(MgO)

w(CaO)

w(SiO 2 )

w(Al 2 o 3 )

w(Fe 2 o 3 )

sum

dolomites

21.01

30.39

0.21

0.61

0.39

46.17

98.78

[0029] Table 2

[0030]

[0031] Prepare the auxiliary cementitious material, that is, dolomite powder according to the following method: a) Mining dolomite, washing, drying and crushing; the crushed dolomite is screened through a 5mm sieve, and the remainder of the screen is continued to be crushed until all pass through 5mm sieve;

[0032] b) The crushed dolomite pellets are natur...

Embodiment 2

[0035] The calcination temperature is 800° C., the holding time is 2 hours, and the rest of the methods are the same as in Example 1.

Embodiment 3

[0037] The calcination temperature is 850° C., the holding time is 1 h, and the rest of the methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com