Method for preparing fracturing propping agent by utilizing waste residues generated by laterite-nickel ore smelting

A fracturing proppant, laterite nickel ore technology, applied in earthwork drilling, chemical instruments and methods, drilling composition, etc. Sexual development, easy availability of resources, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

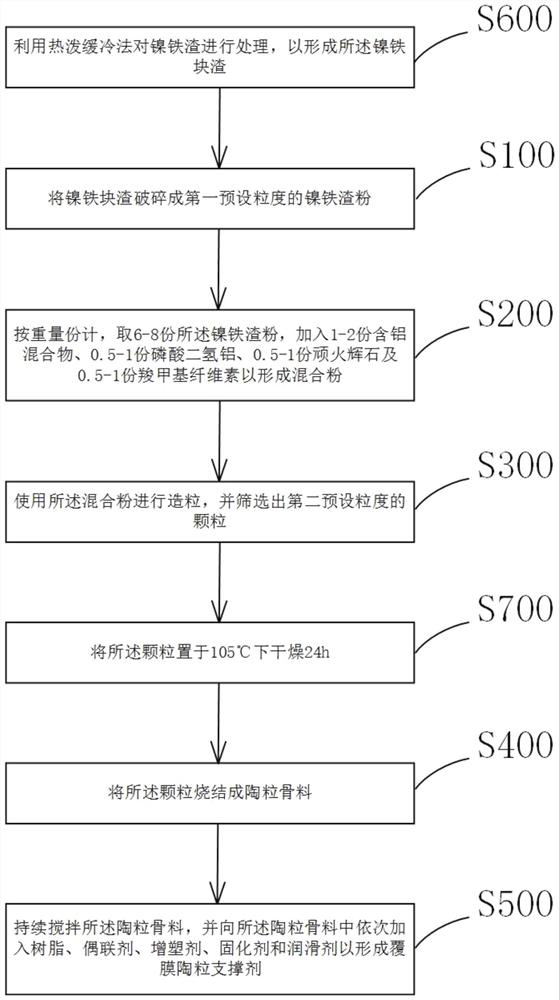

Method used

Image

Examples

Embodiment 1

[0064] (1) Ferronickel block slag is broken into ferronickel slag powder with particle size less than 325 mesh;

[0065] (2) In parts by weight, take 6 parts of ferronickel slag powder, add 1 part of low-grade bauxite, 1 part of aluminum dihydrogen phosphate, 1 part of enstatite and 1 part of hydroxymethyl cellulose to form a mixed pink. Then, use the mixed powder to granulate through a pan granulator or a round pan granulator, and screen out particles with a particle size of 20-40 mesh;

[0066] (3) The sieved particles were sintered at 1100° C., and the holding time was 60 minutes to obtain ceramsite aggregate;

[0067] (4) Weigh 1000g of ceramsite aggregate and heat it to 250°C, keep it for 2min, then lower the temperature to 190°C, stir rapidly, add 20g of epoxy resin, 0.02g of coupling agent, and 0.2g of plasticizer in turn while stirring After 5 minutes of stirring evenly, add 0.2g of curing agent to solidify the epoxy resin, add 0.2g of lubricant before the particles ...

Embodiment 2

[0069] (1) Ferronickel block slag is broken into ferronickel slag powder with particle size less than 325 mesh;

[0070] (2) In parts by weight, take 8 parts of ferronickel slag powder, add 2 parts of low-grade bauxite, 0.5 part of aluminum dihydrogen phosphate, 0.5 part of enstatite and 0.5 part of hydroxymethyl cellulose to form a mixed pink. Then, use the mixed powder to granulate through a pan granulator or a round pan granulator, and screen out particles with a particle size of 50-70 mesh;

[0071] (3) The sieved particles were sintered at 1300°C, and the holding time was 120min to obtain ceramsite aggregate;

[0072] (4) Weigh 1000g of ceramsite aggregate and heat it to 260°C, keep it for 3 minutes, then lower the temperature to 210°C, stir rapidly, add 100g of epoxy resin, 1.2g of coupling agent, and 10g of plasticizer in turn while stirring, After 10 minutes of stirring evenly, add 8g of curing agent to solidify the epoxy resin, add 6g of lubricant before the particl...

Embodiment 3

[0074] (1) Ferronickel block slag is broken into ferronickel slag powder with particle size less than 325 mesh;

[0075] (2) In parts by weight, take 7 parts of ferronickel slag powder, add 1.5 parts of low-grade bauxite, 0.75 parts of aluminum dihydrogen phosphate, 0.75 parts of enstatite and 0.75 parts of hydroxymethyl cellulose to form a mixed pink. Then, use the mixed powder to granulate through a pan granulator or a round pan granulator, and screen out particles with a particle size of 20-40 mesh;

[0076] (3) The sieved particles were sintered at 1200° C., and the holding time was 90 minutes to obtain ceramsite aggregate;

[0077] (4) Weigh 1000g of ceramsite aggregate and heat it to 255°C, keep it for 2.5min, then lower the temperature to 200°C, stir quickly, add 50g of epoxy resin, 1.2g of coupling agent, and 10g of plasticizer in turn while stirring After 8 minutes of stirring evenly, add 8g of curing agent to solidify the epoxy resin, add 6g of lubricant before the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com